turbines AGB

1/48

There's no tags or description

Looks like no tags are added yet.

Name | Mastery | Learn | Test | Matching | Spaced |

|---|

No study sessions yet.

49 Terms

AGB purpose

transfers rotational power from the engine to various accessories/components

houses accessory drive and reduction gears

used during starting process to transfer starter rotation to rotate the engine

why should AGB be reliable

loss of AGB causes loss of every component attached to AGB

how much horsepower does the AGB take from the engine on high bypass engines

500

location of AGB depends on

engine design and aerodynamic needs

what drives AGB

HP rotor

what provides power to AGB

rotary power from engine

AGB location on turbojet

above or below compressor casing

AGB location on turbofan

below and/or side of fan case

AGB location on turboprop

back, front, bottom

prop reduction gearbox and governor at front

AGB location on turboshaft

front and/or back of engine

what does AGB power

Fuel pump

Hydraulic pump

Oil pump

Fuel control unit

Electrical generators

Starters (electric of pneumatic)

what component drives the AGB

starter (drives AGB therefore drives HP rotor)

hand crank mechanism

typical engine-to-AGB mechanical drive sequence

High pressure rotor > inlet gearbox > transfer gearbox > AGB

PT6 AGB

AGB at the rear - rotational energy powers gas generator section

prop reduction gears and prop governor at front - rotational energy comes from power section

what do gears do

AGB transmits power to drive accessories through gears

types of gears

spur

helical

bevel

spiral bevel

straight spur gear

Consists of a cylinder or disk with teeth protruding radially

Edge of each tooth is straight and aligned parallel to axis of rotation

Can only be meshed correctly when both shafts are parallel in direction

bevel gear

Used when direction of the shaft’s rotational output needs to be changed through an angle

types of bevel gears

straight, spiral, helical

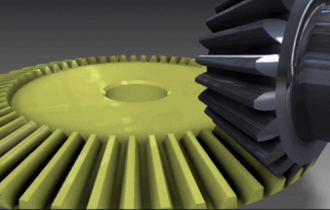

straight bevel gear

straight and tapered teeth

simplest

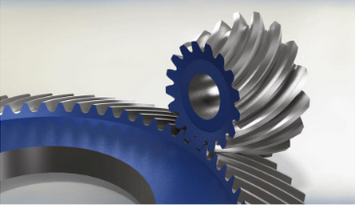

spiral bevel gear

curved, oblique teeth

Transmit higher loads than straight bevel due to greater tooth area contact

helical bevel gear

Gradually engage at one end of the tooth maintaining contact until gears fully engage for smooth transfer of rotation and torque from the driving gear to the driven gear

what displacement do gears experience

axial displacement directly proportional to torque transmitted

how do we figure out propeller torque

measure engine power output (torque at turboprop propeller) to indicate propeller torque

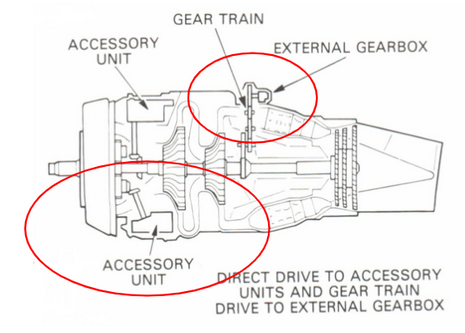

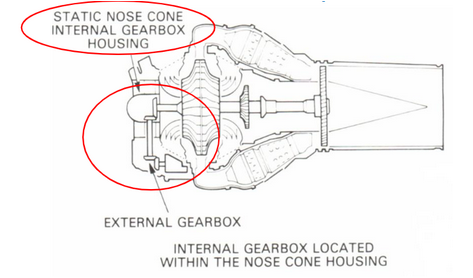

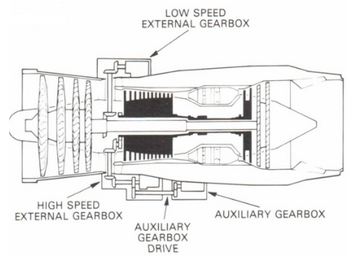

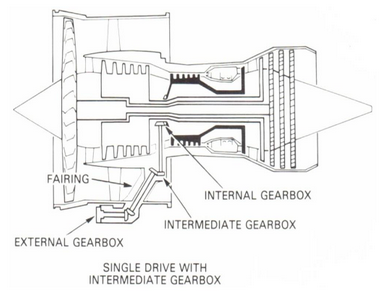

HP rotor drives the AGB through a driveshaft system through 3 different gear drive designs

direct (bevel gear)

stub shaft

idler gear shaft

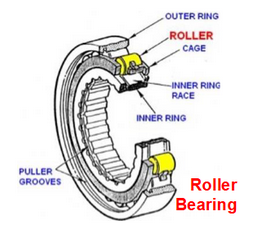

roller bearing

radial loads

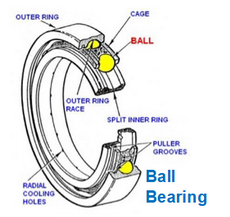

ball bearing

thrust (axial) and radial (centrifugal) loads

what do bearings do

support length of engine shaft

number of bearings is determined by

length and weight of rotor shaft

how are bearings numbered

front to back

AGB lubrication

provide lubrication and cooling for all gears, bearings and splines

Oil protects corrosion-prone materials from oxidation

Must carry foreign matter away from bearings and gearbox that can cause wear and damage

ATA AGB

83

ATA PT6 AGB

72

maintenance

servicing AGB oil, inspect magnetic chip detector or leaking oil

shear shaft

Shear shaft is subjected to a torque force exceeding maximum rating

Will snap if under force exceeding maximum rating and prevent damage to AGB and components

drive pad

Where each component is installed on the AGB

If AGB pad seal leaks, each pad has a dedicated drain line to safely drain away oil

magnetic chip detector

captures ferrous metal particles

magnetic chip detector types

electric - warning light cockpit

passive - maintenance must inspect AGB oil

engine hand-turn access

for maintenance only

roller bearing

ball bearing

helical bevel gear

spiral bevel gear

straight bevel gear

straight spur gear

internal/external AGB

internal/external AGB

auxiliary AGB

intermediate AGB