Polymers

1/17

There's no tags or description

Looks like no tags are added yet.

Name | Mastery | Learn | Test | Matching | Spaced |

|---|

No study sessions yet.

18 Terms

What is a polymer?

A very large organic molecule made up of small repeating units

How are polymers formed?

From reactions between small organic molecules called monomers in a process called polymerisation.

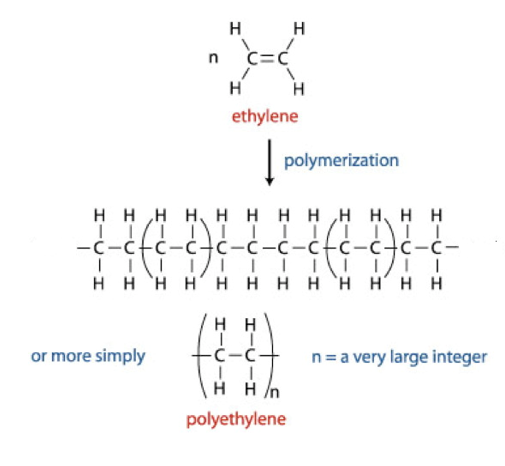

What are addition polymers and draw the polymerisation process of ethene?

They are formed from certain alkenes (containing a C=C bond)

Is addition polymerisation a spontaneous reaction?

No it is not spontaneous and requires high temperatures and high pressures.

What is the side affect of using high pressure and temperature for polymerisation?

A short chain of polyethene form and branch off the main polymer chain. These polymers have low densities and are loosely packed and are more flexible.

How can we reduce the number of side chains caused by high pressure and temperature polymerisation?

Use a catalyst and therefore lower temperature and pressure. This will have less branches, tightly packed and called high-density polymers.

How are condensation polymers formed?

From monomers containing two reactive functional groups.

a carboxylic acid and alcohol

a carboxylic acid and amine

What is produced in a condensation polymer reaction?

The polymer and water

What is a polypeptide?

A large number of amino acids joined together by peptide bonds

What is a peptide bond?

The bond formed between the two amino acids

What is nylon?

A condensation polymer that consists of polyamides

Properties of nylon

It is strong and elastic

It is easy to launder

It dries quickly

It retains its shape

It is resilient and responsive to heat setting

Polyester

Polyesters are long-chained polymers composed of ester groups in the main chain formed from a dicarboxylic acid and a diol.

What is the most common polyester?

Polyethylene terephthalate (PET) made from benzene-1,4-dicarboxylic acid and an alcohol, ethane-1,2-diol

PET fibres

The molecules are mainly arranged in one direction

PET film

They are in two directions and for packaging, they are in three directions

Uses of PET

capacitators, graphics, film base and recording tapes

fibres for a very wide range of textile fibres

bottles

food packaging

electrical components

magnetic tape

backing for adhesive tape

sail cloth

Properties of PET

Can be produced with varying degrees to crystallisation providing a range of rigidity absorbs very little water

Good gas barrier

Excellent moisture barrier

Chemically resistant to acids, oils, alcohol

Highly transparent and colourless

High mechanical strength

Low density

Impact resistant