Major Capability Acquisition (MCA) Pathway

1/21

There's no tags or description

Looks like no tags are added yet.

Name | Mastery | Learn | Test | Matching | Spaced |

|---|

No study sessions yet.

22 Terms

Milestone Decision Authority (MDA)

The approval authority responsible for a program as it progresses through the MCA pathway

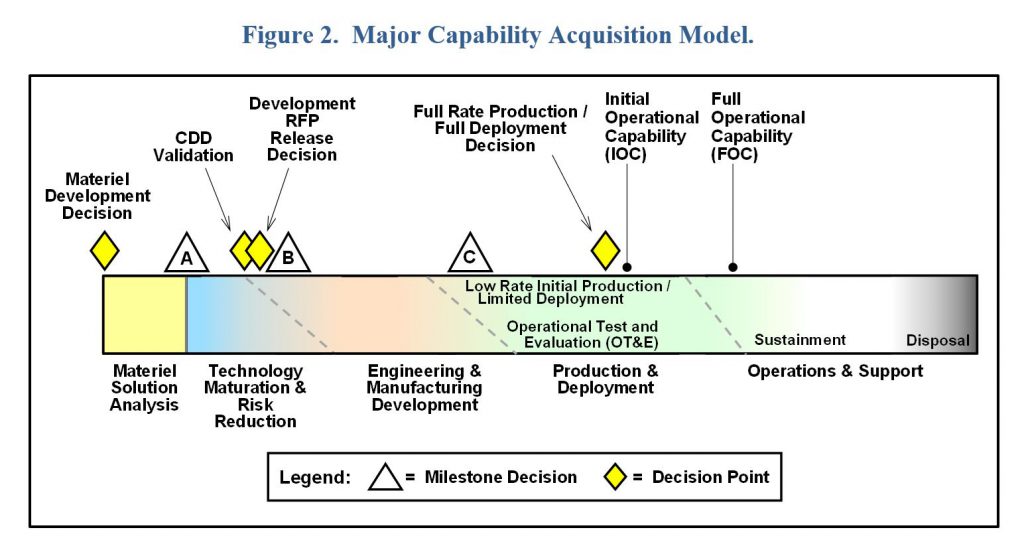

Describe the Materiel Development Decision (MDD)

Purpose: The starting point for all programs where the entry phase is determined

Inputs:

ICD that identifies gap

Analysis of Alternatives (AoA) Study

Affordability Analysis to determine if budget can support effort

Outputs:

Acquisition Decision Memorandum (ADM) that decides the program’s next phase

Describe the purpose of the Materiel Solution Analysis (MSA) Phase

Purpose: Assess all solutions to determine what system will meet the capability gap

Inputs:

ICD

AoA Study

Outputs:

Completed AoA with materiel solution recommendation

Draft CDD that translates gap to system requirements

Milestone A

Purpose: Select the materiel solution

Inputs:

ICD

AoA recommendation

Outputs:

ADM for chosen materiel solution

Acquisition Strategy (AS)

Describe the purpose of the Technology Maturation and Risk Reduction (TMRR) Phase

Purpose: Reduce risks enough to feel confident about successful program execution

Inputs:

AS

Outputs:

Fully developed and validated CDD

Preliminary Design Review (PDR) to identify the high-level system architecture

Request for Proposal (RFP) to solicit contractor design bids

Identify the purpose of Milestone B

Purpose: Officially initiate program

Inputs:

TMRR results (risk acceptability, program affordability, technology maturation)

Outputs:

Acquisition Program Baseline (APB) to create and commit to program

Engineering Manufacturing Development (EMD) contract awarded to company

Engineering Manufacturing Development (EMD) Phase

Purpose: Produce a requirements-meeting system and prepare for full production

Inputs:

CDD

Outputs:

Critical Design Review (CDR) to determine maturity, documentation, and risk

Production Readiness Review (PRR) to determine if the design and production are capable

Identify the four main work efforts of the EMD phase

1.) Design the System

2.) Build the Prototype

3.) Test Prototype

4.) Prepare for Production, Deployment, and Sustainment Decisions

Design the System

Define the system, complete hardware/software design, and reduce system level risk

CDR is performed after this step to initiate prototyping

Build the Prototype

System prototype is built from CDR specifications

Test Prototype

Perform Development Test and Evaluation (DT&E) on the prototype to prove the system meets requirements

Prepare for Production, Deployment, and Sustainment Decisions

PRR is completed to ensure the design is stable and meets requirements, manufacturing/processes risks are controlled, and supplier qualifications are complete

Milestone C

Purpose: Authorize the system to enter the Production and Development (P&D) phase

Inputs:

CDR, DT&E, and PRR results

Program affordability

Outputs:

Updated APB

P&D contract to production company

Identify the purpose of the Production and Deployment phase

Purpose: Produce and delivery capability-closing system to receiving organizations

Inputs: N/A

Outputs:

Low-Rate Initial Production (LRIP)

Operational Test and Evaluation (OT&E)

Full Rate Production (FRP) Decision

Reach Initial Operational Capability (IOC)

Low-Rate Initial Production (LRIP)

Manufacturing of a small quantity of assets to determine large-scale production risks and inefficiencies

Operational Test and Evaluation (OT&E)

Operational testing of the system are conducted in threat environments to assess effectiveness, suitability, and survivability

Full Rate Production (FRP) Decision

OT&E results and manufacturing/development activities are assessed before moving to full production

Initial Operational Capability (IOC)

The minimum number of systems necessary to conduct operations are delivered

Operations and Support (O&S) Phase

Purpose: Ensure the product is fully supported and sustained throughout the system’s lifecycle

Outputs:

Reach Full Operational Capability (FOC)

System turnover of operation and maintenance

Disposal plan

Full Operational Capability (FOC)

All units scheduled to receive the system have obtained it and can employ and maintain it

Describe the [5] unique characteristics of space programs

1.) One Shot at Launch

2.) Operate in Harsh Environment

3.) Requires Sufficient Fuel and Redundancies to Last

4.) Limited Maintenance Options

5.) More Expensive Per Program (inverse cost curves)

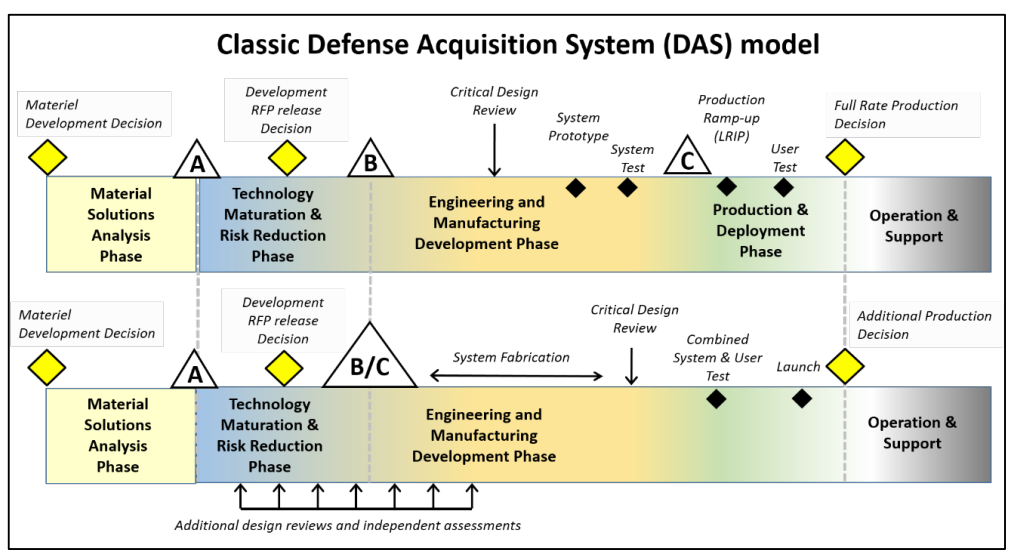

Identify how MCA is tailored to support space programs

1.) More design reviews and independent assessments

2.) Milestones B and C are combined

3.) No prototyping is done; a single system is created and tested

4.) System and User Test are combined