ENGINEERING TOPIC 2

1/38

Earn XP

Description and Tags

DONGKINATURE

Name | Mastery | Learn | Test | Matching | Spaced |

|---|

No study sessions yet.

39 Terms

History of the bicycle

Early Development - Velocipede and was an the amalgamation of wheels and a rocking horse

2) Pedal Power - pedals, attached to long arms, that connected to cranks on the rear wheel (locomotive drive)

3) Penny-Farthing - Consists of one Gear and was the size of the driven wheel - extremely tall and heavy bicycles

4) Safety Bicycle - front wheel smaller + reliable bicycle chain and geared chained drive - Safety bicycles were much smaller and easier to mount and ride - Pneumatic tyres

5) Modern Bicycles - Most changes were in materials, gearing systems and braking systems

History of the Train

1) Horse Powered - From the 14 th to the 18 th century, trains were in used but powered by horses on rails made originally made of timber but later replaced by iron rails - The gauge of the tracks (still used today) was determined by the width of a horse

2) Steam Trains - Could do more work than a horse at 8km/h and began to do regular work - Speeds increased while carrying large loads and passenger railway lines became widespread

3) Electric Trains - First to challenge the dominance of the steam train as they were less polluting in the area they were used in but could not travel in areas without infrastructure - Now an essential part of public transport systems beginning from the early 20th century - Older electric trains used DC electricity as AC motors were hard to control (NSW trains)

4) Diesel-Electric Trains - The true successor to the steam train as they can service areas without power infrastructure - Initially, diesel engines powered generators which supplied DC electricity to DC motors - Afterwards, alternators began to replace generators (more efficient) and was rectified to power DC motors (AC motors were hard to control) - Most recent trains use an alternator and AC induction motors which are controlled through PWM

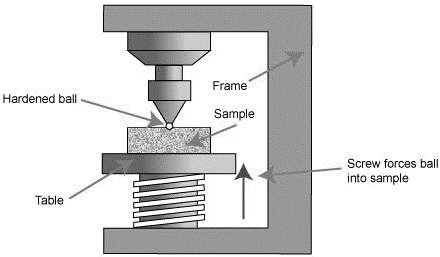

Brinell - Hardness test

A hardened steel ball is forced into an object under specified loads and hardness number is determined with a formula with depth and surface area of the impression

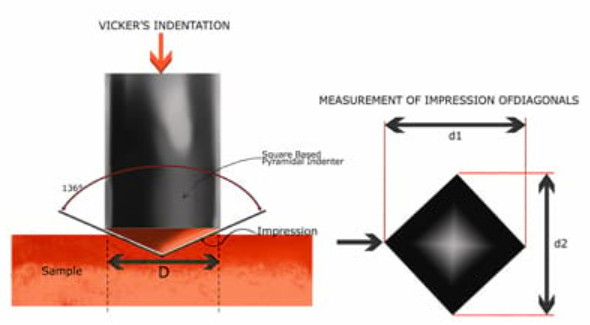

Vickers - Hardness test

A small square pyramid is forced into a test piece, and hardness number is determined with a formula that contains load and area of indentation

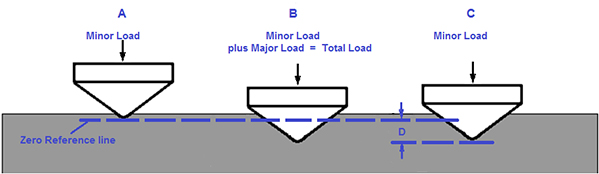

Rockwell - Hardness test

A diamond cone or sphere is forced into a test piece under specified loads and a reading is displayed on a scale (different scales for different loads and materials)(diameter of indentation)

Shore Scleroscope - Hardness test

Involves a small striker in a a tube, which is dropped (the height that the striker bounces is a measure of hardness)

What impact tests are these and explain how they work

Izod and Charpy respectively and these tests involve a pendulum that is raised and released to impact a specimen with a notch to concentrate stress and provide a place to prompt crack propagation

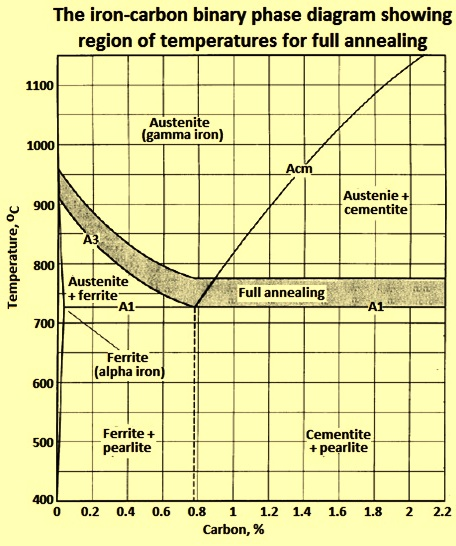

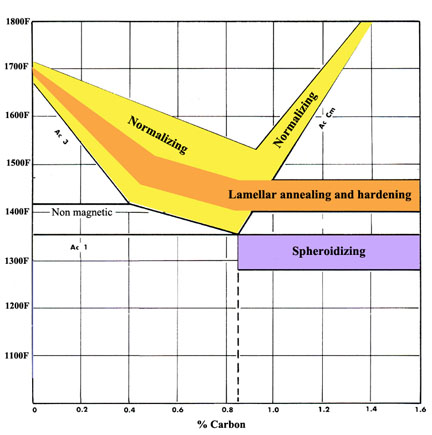

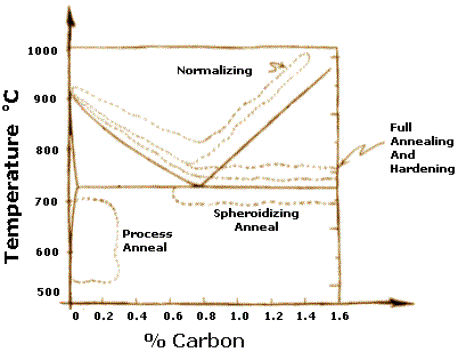

Annealing? - Heat treatment

Heating of a steel with less than 0.3% C to a temperature usually between 550-650°C

Full annealing involve eutectoid or hypo-eutectoid (less than or equal to 0.8% C) into the austenite region (40°C above UCT) then slow cooled in a furnace

Full annealing produces a softer and coarser (larger) grained steel with both ferrite and pearlite both unstressed

Normalising? - Heat treatment

Similar to full annealing but cooled in air rather than slow cooled in a furnace (faster process)

Produces a finer equiaxed grain structure and hence a stronger steel compared to annealing

Hardening? - Heat treatment

Steel (above 0.4% C) is heated well above the UCT then cooled rapidly (quenching in oil or water)

From FCC austenite to BCC ferrite, the carbon is not given enough time to move and cause the formation of a distorted BCT structure (martensite)

- Martensite has an acicular (needle-like) microstructure and is a very hard and brittle material

Tempering? - Heat treatment

A fully hardened steel has limited usefulness and can only be used where hardness is required but not toughness

- If both are needed, the steel must be tempered, which involves heating the hardened steel between 200-600°C (higher temperatures leads to more tempering)

- This breaks down martensite into ferrite and cementite, trading off a degree of hardness for increased toughness

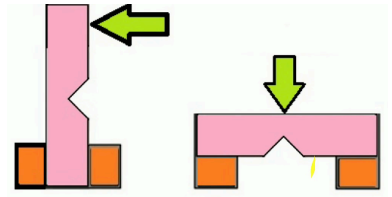

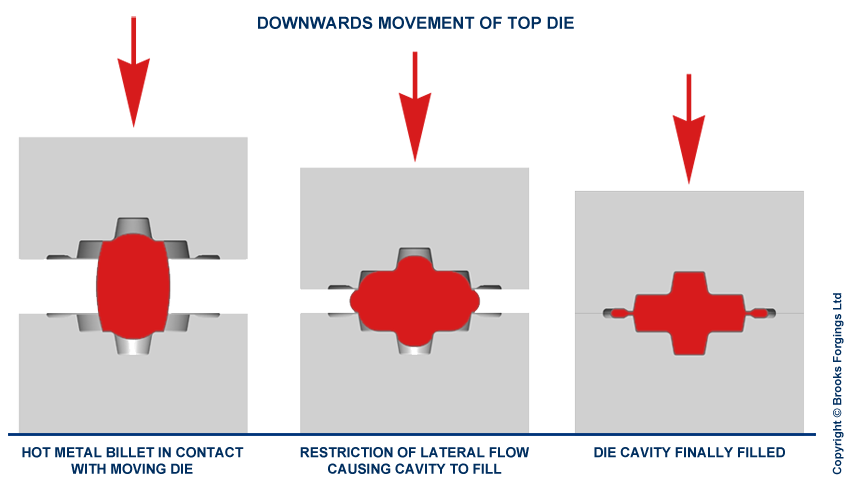

Forging? - Manufacturing process

The shaping of metal through use of force

Forging produces grain flow in the metal that follows the shape of the object, increasing strength as it eliminates planes of weakness

Cold forging - stress - much harder

Hot forging - more grains

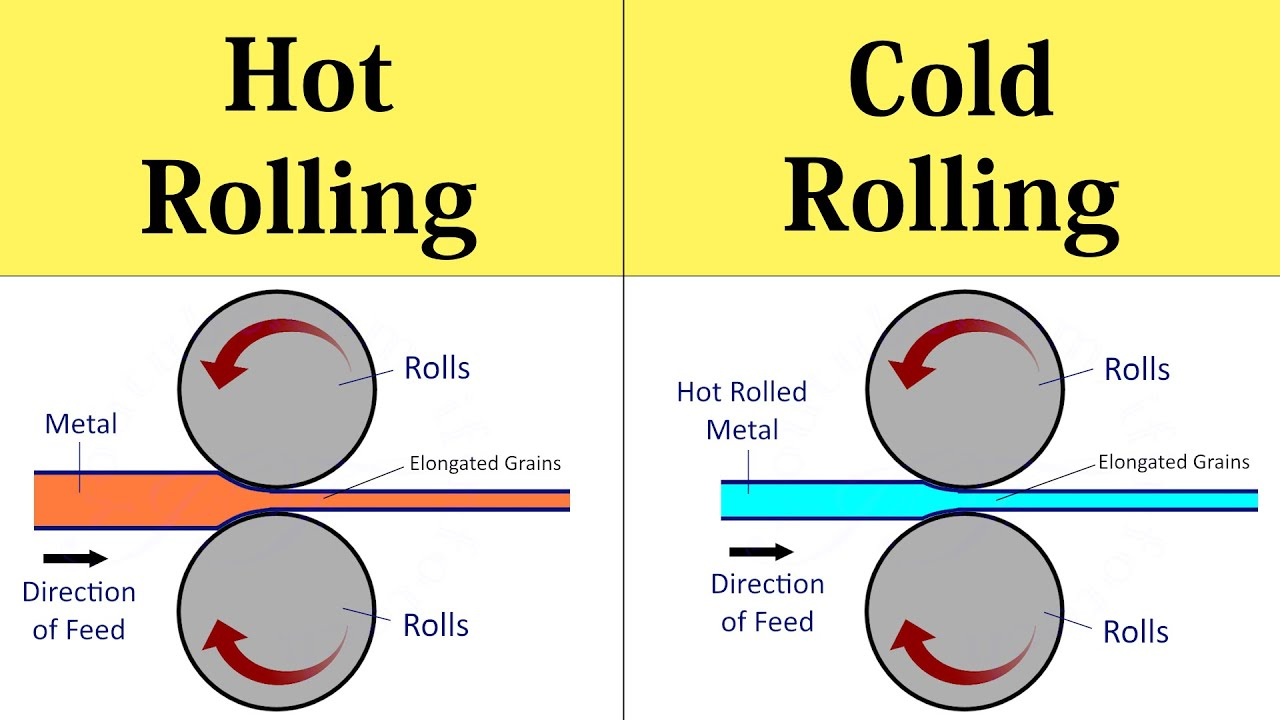

Rolling? - Manufacturing process

Ingots of required metal are passed through successive rollers to produce required thickness and cross section

- Hot rolling results in an unstressed grain (fine and equiaxed) but causes the final product to have less dimensional accuracy

- Cold rolling is a harder process on machinery but allows for a stronger and harder final product (work hardening and coarse, elongated grains) which is more dimensionally accurate

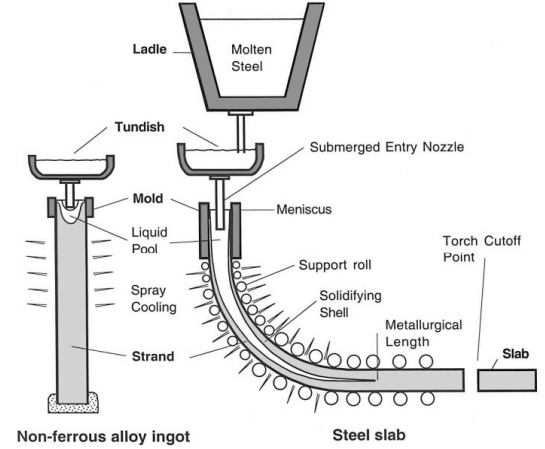

Ingot Casting?

Done by pouring a molten metal into a large tapered metal mould

Continuous Casting?

Molten metal is poured into a water-cooled ingot with a sliding bottom (faster and more cost effective than ingot casting)

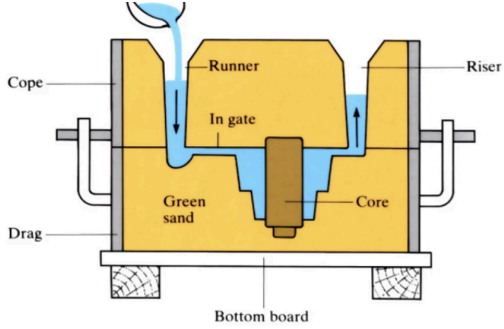

Sand Casting?

Green sand, composed of sand and a binder, is packed around a pattern and runner and riser pins are placed in the mould to allow metal to flow into the cast

The mould is created in two halves allowing the pattern to be removed (halves creates a seam in the cast object and forms rough surface but cheap and easy)

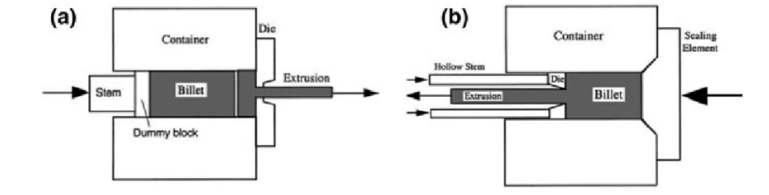

Extrusion?

Heated metal is forced through a die and takes the shape of die as it passes (analogous to squeezing toothpaste from a tube)

- Can be in the form of direct extrusion (ram pushes metal into the die) or indirect extrusion (ram and die are one part)

- Direct extrusion requires more effort so it is usually used with ductile materials and indirect extrusion is used with lower ductility materials, but avoided preferentially to direct extension due to equipment cost

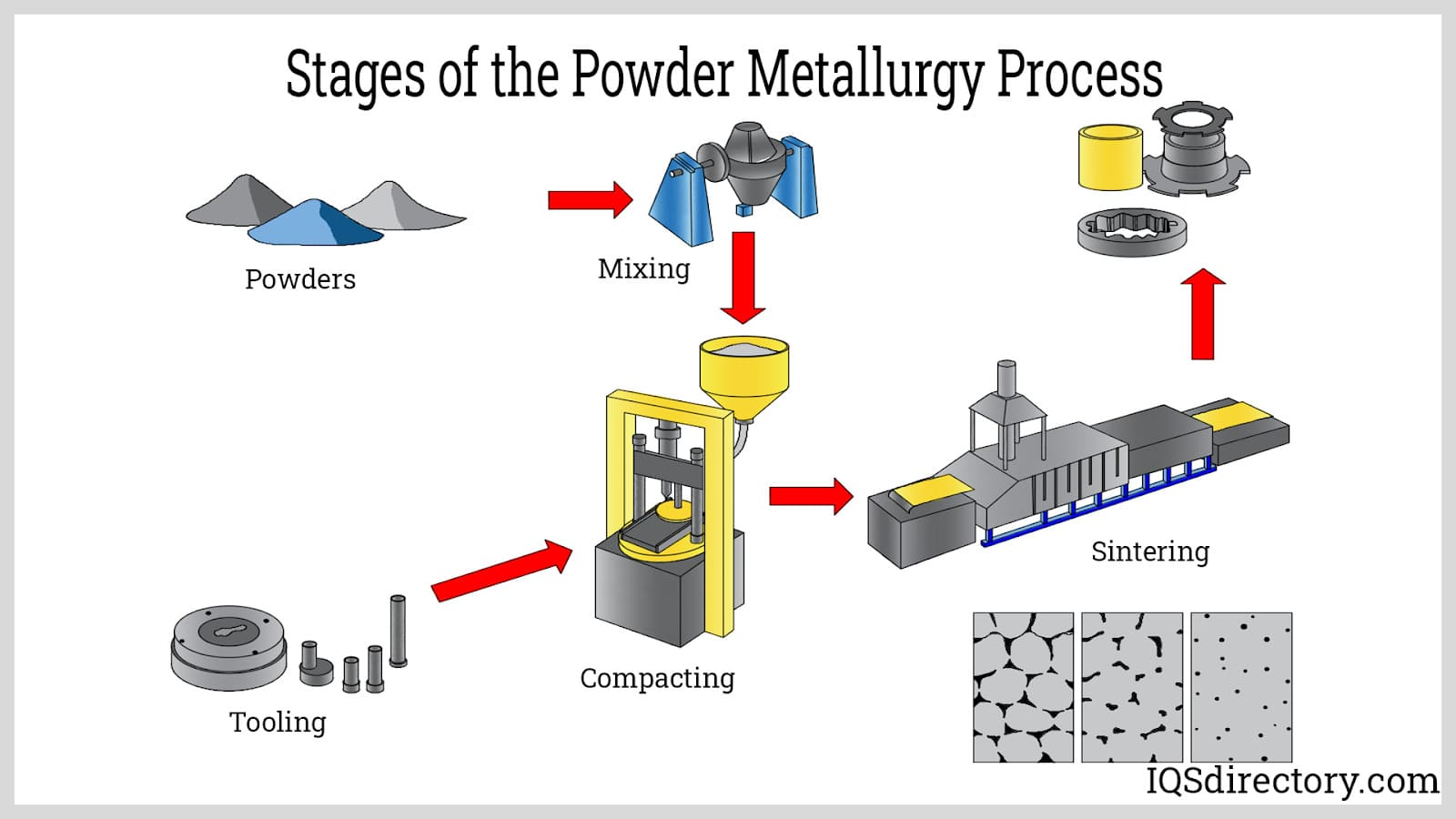

Powder Forming?

Metal is powdered via mechanical disintegration, atomizing the metal from liquid form by chemical means or by electrolytic methods

Powders are blended with a dry lubricant and pressed into a mould to from the required shape (gains enough strength to be handled)

The pressed item is sintered to allow atoms to diffuse between grains and produce a homogeneous grain structure

- Powder forming can be used to make porous metals (self lubricating), complex articles, composites or products with difficult materials to machine

Case Hardening - Surface hardening

Case hardening involves heating and soaking the steel in a carbon rich atmosphere or medium

- The carbon diffuses into the structure at the surface, increasing carbon content and hardness

- Useful for low carbon steels that cannot be hardened by quenching

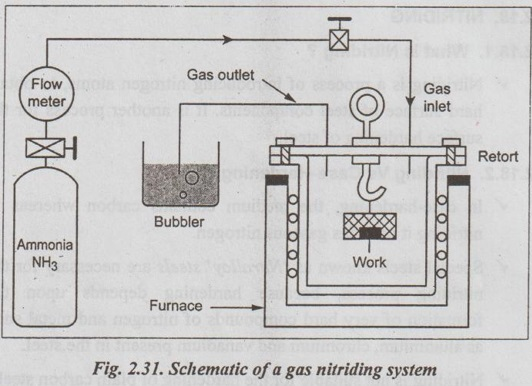

Nitriding - Surface hardening

Special alloy steel is heated in a furnace with gaseous nitrogen (not atmospheric nitrogen) at around 500°C between 40 and 100 hours

- If alloy is heated above 500°C again, the nitriding is permanently lost

- The nitrogen reacts with aluminium, chromium or vanadium in the steel and produces a hard and corrosion resistant surface

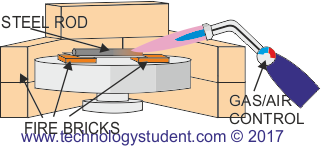

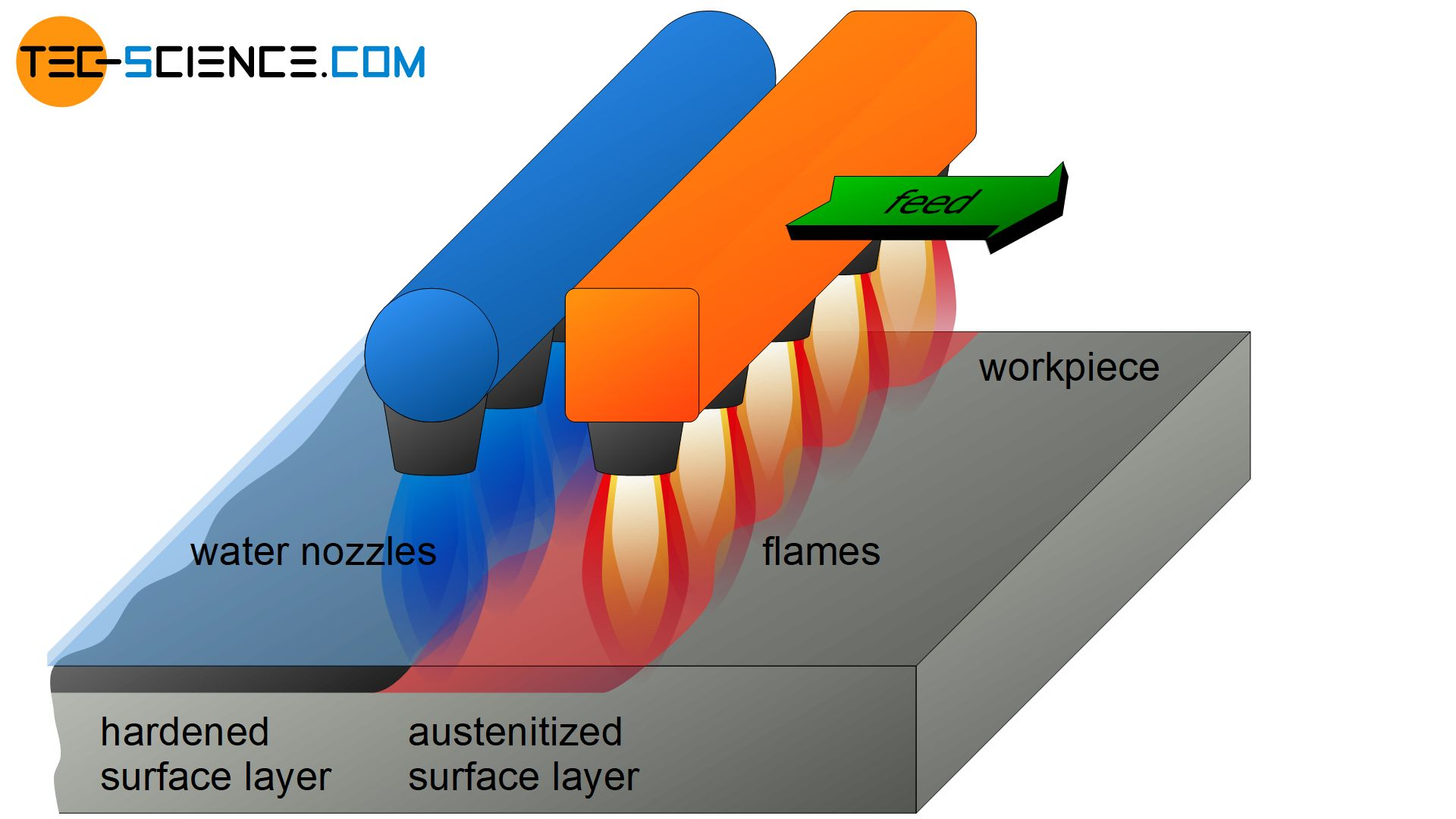

Flame Hardening - Surface hardening

Takes a steel above 0.4% C and applies a flame to a localised area then quenches it

- Process can be mechanised with a flame holder and water jet in one assembly, with the water jet trailing the flame

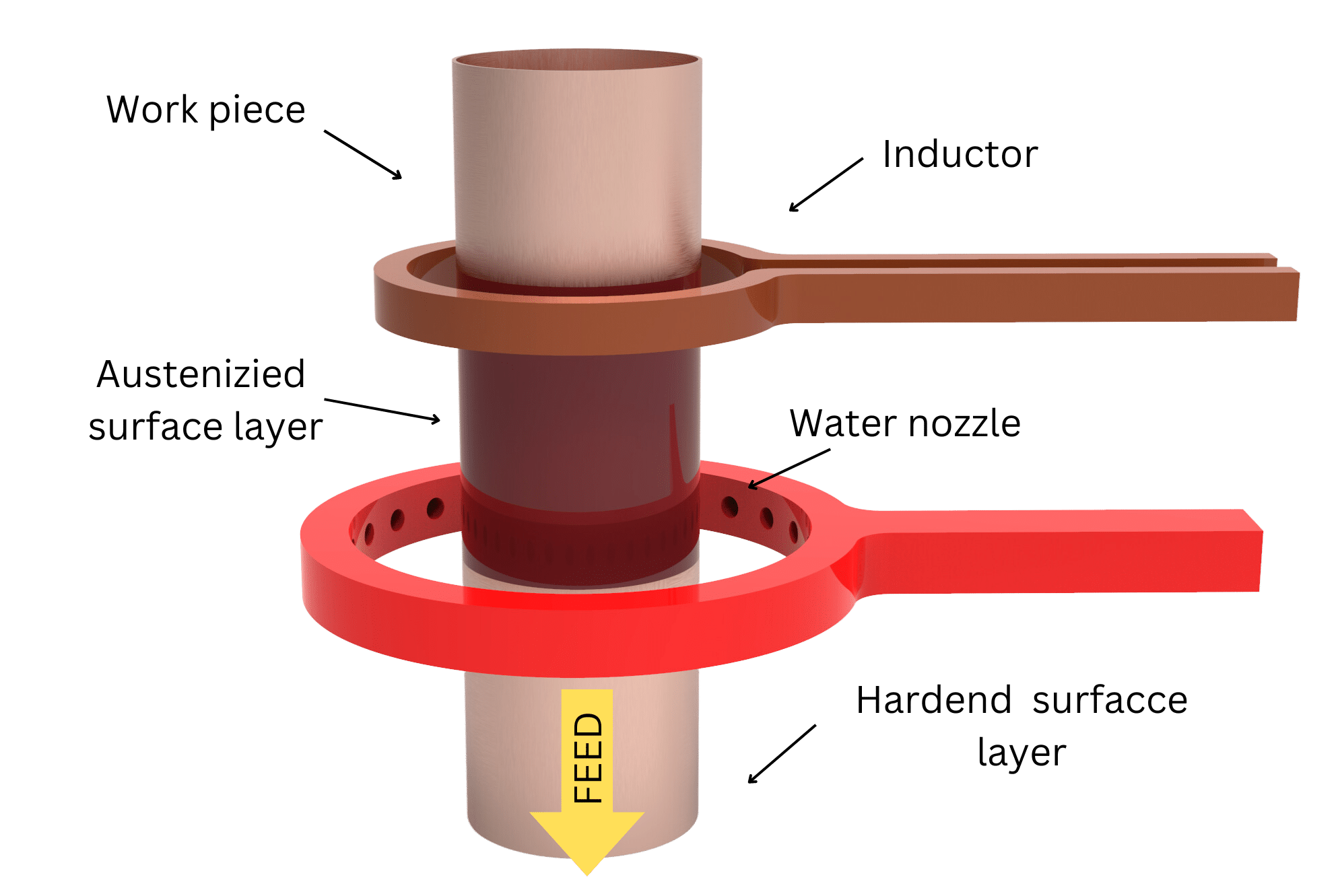

Induction hardening - Surface hardening

Same concept as flame hardening but the steel is heated via an induction coil

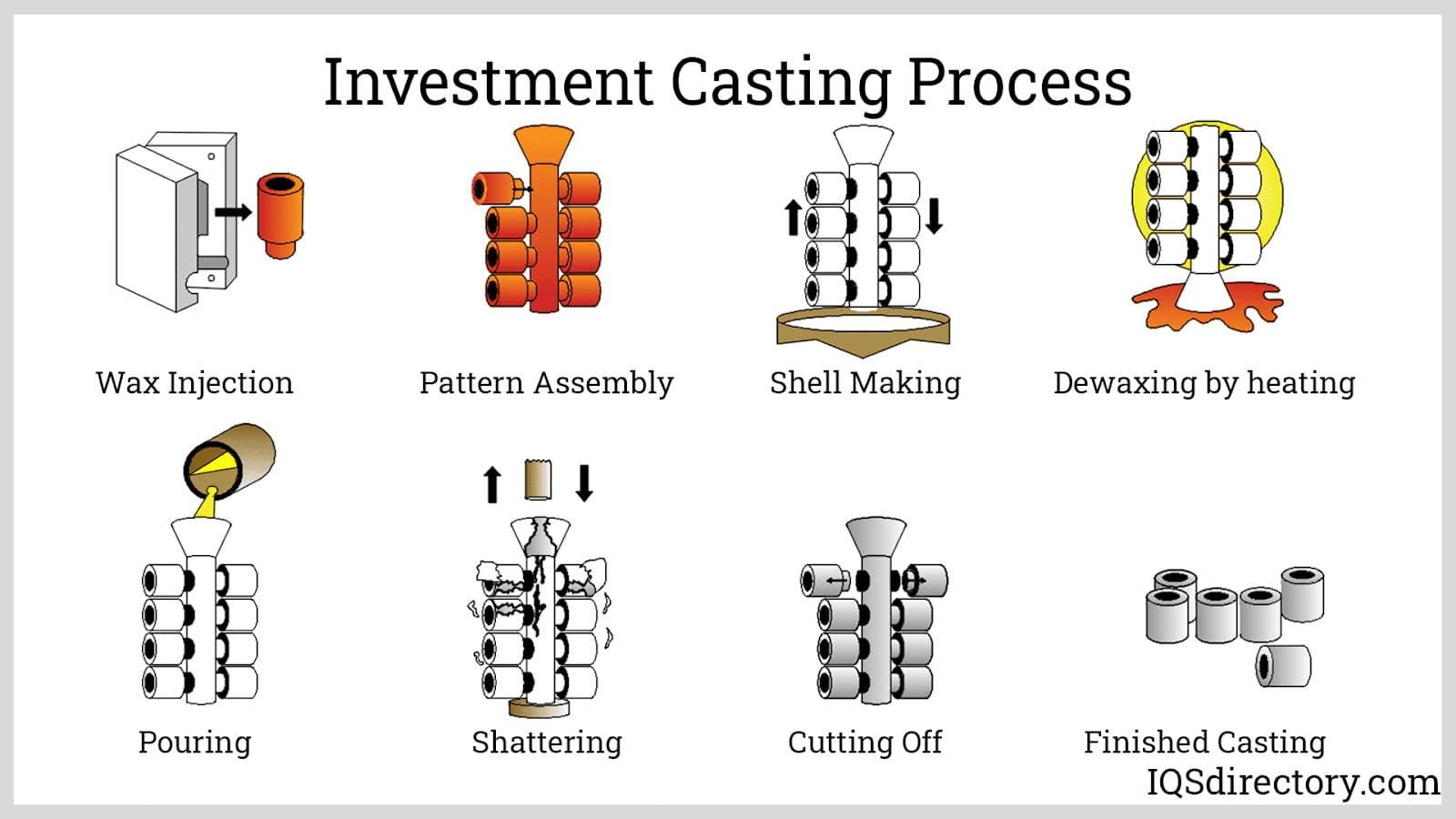

Investment Casting

A pattern made of wax is encased in ceramic and is heated such that wax is drained out (leaves no seams and smoother finish, also known as lost wax casting)

Centrifugal Casting - rare

Relies on centrifugal force to spin the metal to the outsides of a mould to create a hollow cylinder (useful for casting pipes)

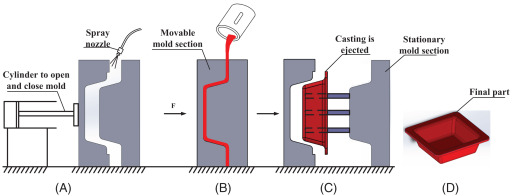

Permanent Mould (Die) Casting

Gravity die-casting involves the use a permanent metal mould where molten metal is poured in by gravity (mould cannot be broken so must be made in halves)

Pressure die-casting involves molten metal (non-ferrous) forced in under pressure

High initial cost but cost-effective in high production runs and results in smoother finish compared to sand casting but still has a seam

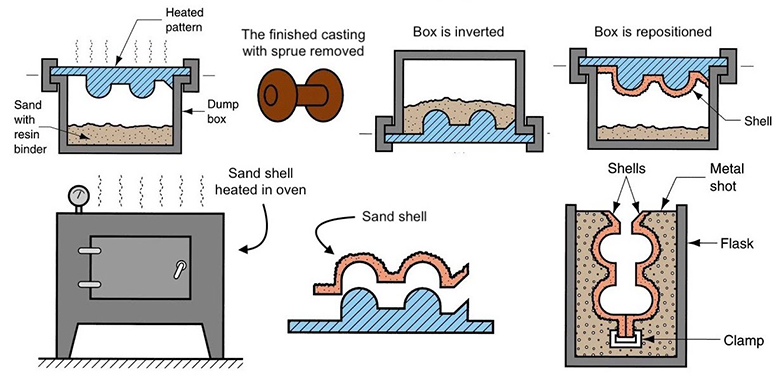

Shell Moulding - casting

Closely related to sand casting but uses sand and a thermosetting resin to create a mould over a heated metal pattern plate

The sand is placed over the plate and cured in an oven, then two half moulds are placed (or bolted) together in a box ready to receive the molten charge

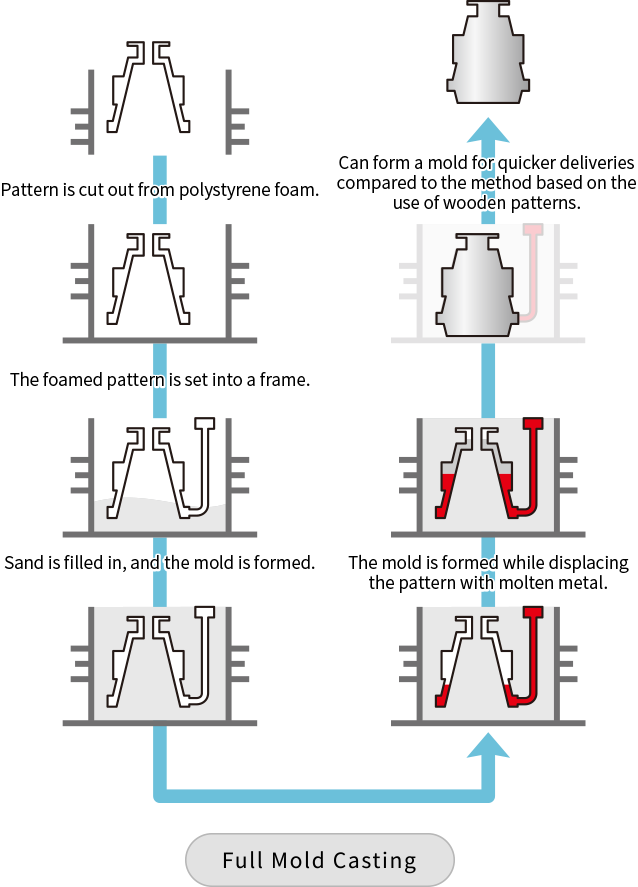

Full Mould process - casting

Closely related to investment casting but used for one-off items or prototypes

A styrofoam pattern is placed in a box surrounded with sand, then molten metal is poured into the foam runner and melting the foam

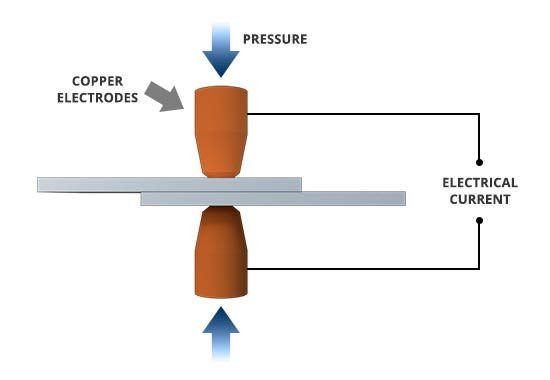

Spot Welding

Electric current melts metal sheets under pressure, joining it in spots

- Extensively used in manufacturing (car body panels)

Butt Welding

Metal is butted together at ends and current melts the metal together

- Used for joining tubes end to end

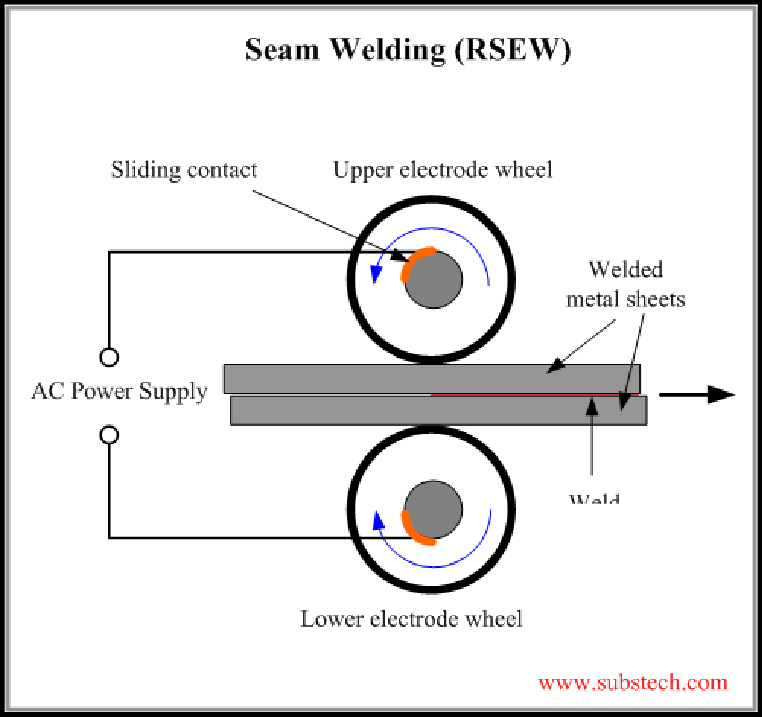

Seam Welding

Metal is moved through rotating wheels that pass electric current into the metal, melting it in a seam

- Used in the manufacture for tubes for cheap bicycles

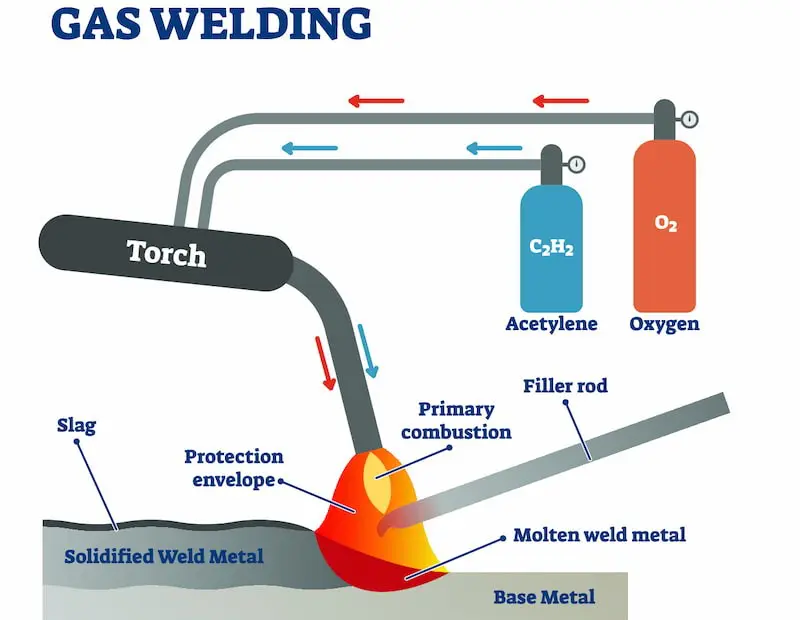

Oxy-acetylene Welding

Metal is melted by an oxy-acetylene flame and a filler metal is added

- Finds greater use in home style DIY projects rather than manufacturing

Bronze Welding

A flame (usually oxy-acetylene) heats the parent metal and a bronze filler is added to the joint (little melting of the parent metal)

- Resembles brazing and used in lower temperature projects where the parent metal cannot be melted

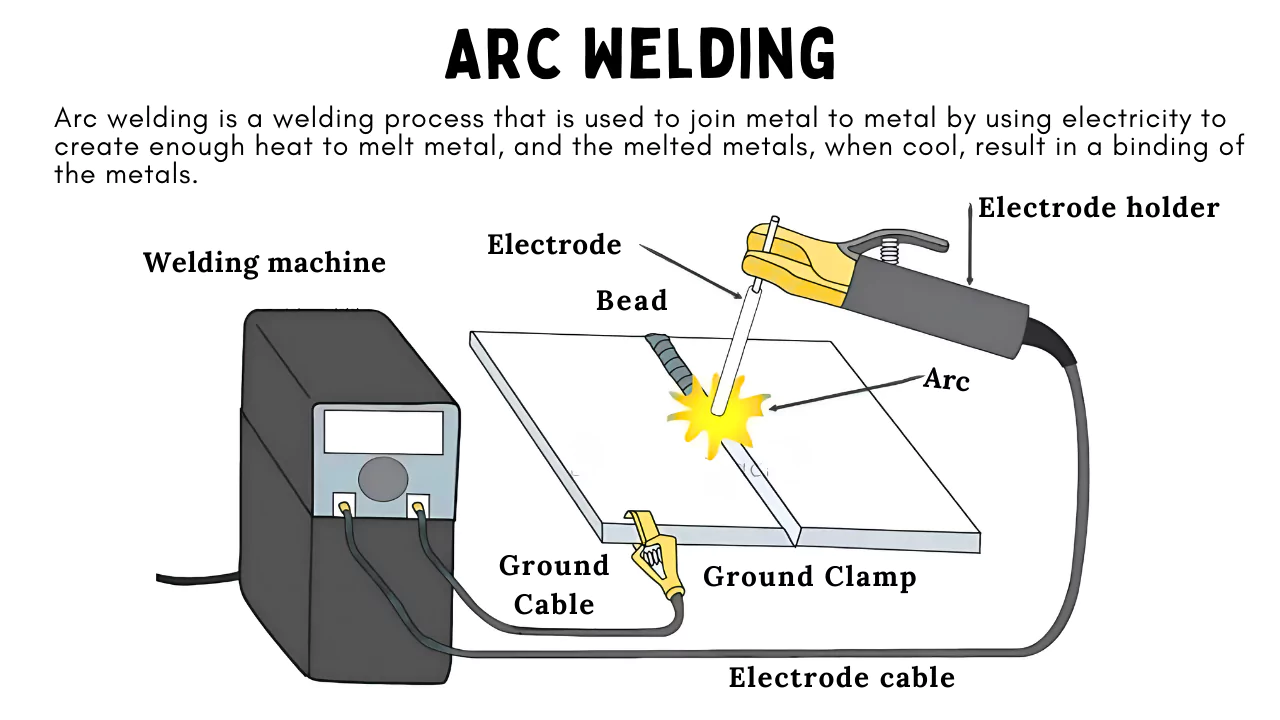

Electric Arc Welding

Metal is melted by an arc from a consumable electrode, which is also the filler metal and contains a shielding flux to prevent oxidation of the joint

- Manual process where the welder must move the electrode to maintain the arc and electrode must be replaced periodically

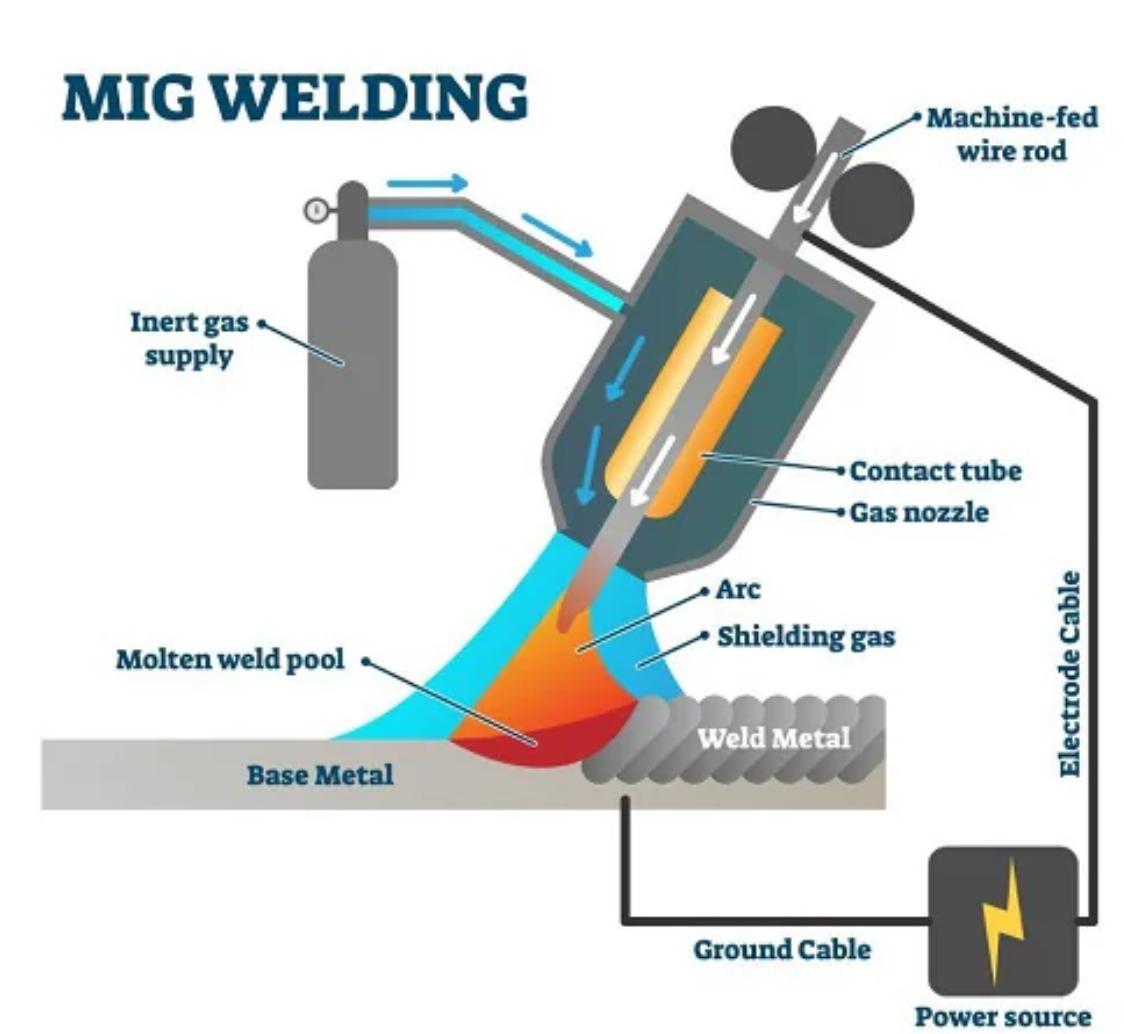

Metal Inert Gas (MIG) Welding

Replaces the electrode with a continuous feed of wire (more automated) and flux is replaced by an inert gas (usually argon)

- Well suited for automation and finds use in manufacturing industries, such as bicycles and cars

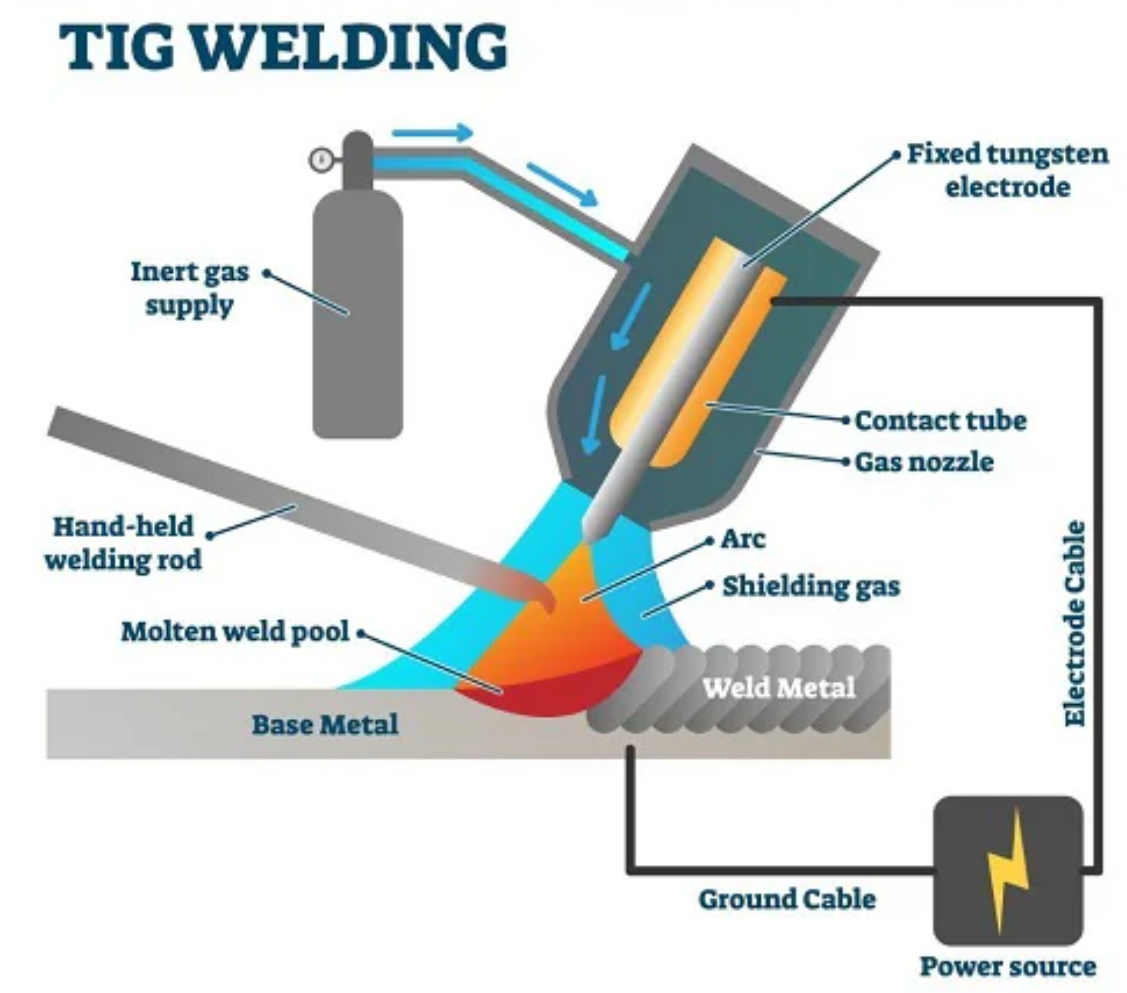

Tungsten Inert Gas (TIG) Welding

Uses a tungsten electrode and a filler rod fed by the welder with an inert gas-shield (usually argon)

- Find uses in welding alloys such as stainless steels and aluminium and titanium alloys

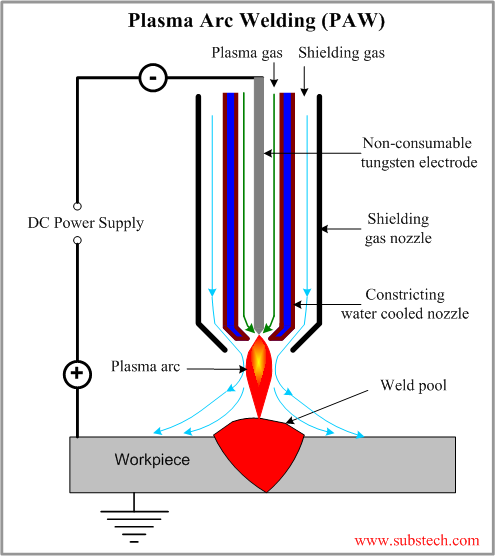

Plasma Arc Welding

A gas (argon) is passed through an electric arc and the gas ionises to form plasma and a hot flame

- Used with refractory metals such as tungsten and molybdenum

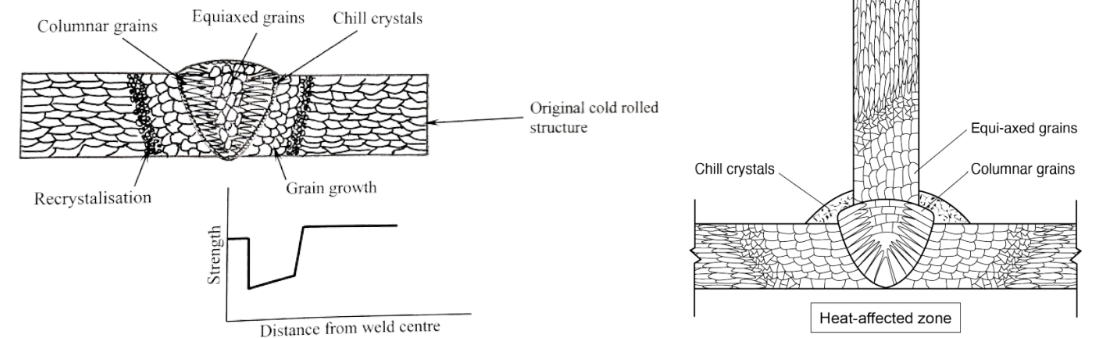

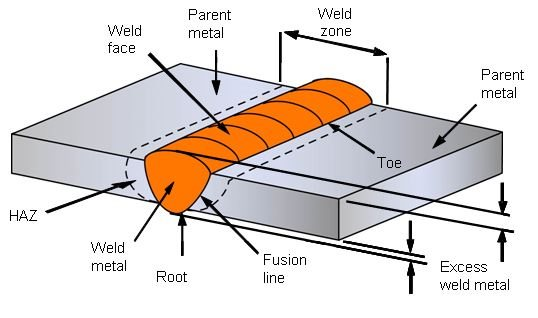

WELDING EFFECTS

OFFERS A WEAKER BARRIER AROUND WELDED AREA - RELIEVED STRESS UPON THE COLD FORGED ALLOY