Polymers & Polymer Processing (L7&8)

1/45

There's no tags or description

Looks like no tags are added yet.

Name | Mastery | Learn | Test | Matching | Spaced |

|---|

No study sessions yet.

46 Terms

Advantages of polymer processing

Unlimited part geometries

net shape process

less energy than metals

doesn’t require finishing

General properties of polymers (relative to metals)

Low Density

Low strength & stiffness

Low electrical & thermal conductivity

Good chemical resistance

High coefficient of thermal expansion

Low useful temperature range

Tend to creep

IR radiation sensitive

creep

Permanent deformation that occurs in material over time that is subjected to a constant load

Polymer

Compound consisting of long-chain molecules

A polymer can contain millions of small units (monomers)

Derived from the Greek words

Poly = “many”

Meros = “part”

3 classifications of polymers

thermoplastic, thermosets, elastomers

thermoplastic

Chemical structure remains unchanged during heating and shaping

Comprises ~ 70% of total plastics tonnage

Thermosets

Undergo a curing process during heating and shaping, causing a permanent change in molecular structure, called cross‑linking

Once cured, they cannot be remelted

Elastomers

Exhibit extreme elastic extensibility when subjected to relatively low mechanical stress

Polymer melt

heating polymer so that it softens to the consistency of a liquid

Viscosity

is a fluids resistance to flow

Viscoelasticity

Material property that determines the strain that the material experiences when subjected to combinations of stress and temperature over time

combines both viscous and elastic behaviors

When stress is removed, material does not immediately return to its original shape; instead, the strain decays gradually

How does viscosity of a polymer melt change with increasing shear rate?

Viscosity decreases

Meaning it is Pseudoplastic (shear-thinning fluid)

Die Swell

the extrusion process experiences this issue with polymer melts and shape memory

Name the 6 processes by which products can be made from polymers

Injection Molding

Extrusion

Film Production

Fiber Production

Blowmolding

Thermoforming

Injection Molding

Most widely used process for making plastic parts. Capable of simple or complex 3-D parts in a wide variety of sizes and a wide variety of polymers

Needs:

Injection Molding Machine

Injection Mold Tool (aka the “mold”)

Polymer feedstock in form of pellets

Extrusion

Continuous length constant cross-section (“profile”) parts in a wide variety of sizes and a wide variety of polymers

Needs:

Extruder (machine)

Extrusion Die

Polymer feedstock in form of pellets

Film Production

Forms uniform thickness continuous sheet & film

Needs:

Film blowing/Extrusion Machine

Cooling, Slitting, Winding equipment

Typically starts with polymer pellets as feedstock

No mold/die required

Blow molding

Forms Pre-formed polymer part into more complex thin-walled parts (e.g., bottles/jugs)

Needs:

Blow molding Machine

Mold

Extruded Parison or Preform

Thermoforming

Forms flat sheet into 3-D parts with mostly uniform wall thickness

Needs:

Thermoforming Machine

Mold

Plastic Sheet Feedstock

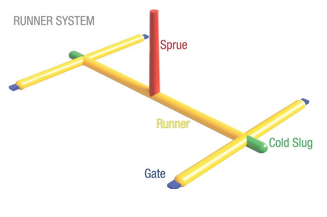

Runner System

The network of channels within a mold that guides molten plastic from the injection molding machine's sprue to the mold cavity gates, where the plastic enters to form the final part

Name the parts of the runner system

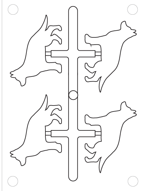

Family Mold

A single mold base with multiple cavities designed to produce several different, but related, parts from the same material in a single molding cycle.

Multi Cavity Mold

A single mold base with multiple cavities designed to produce several of the same part in a single molding cycle

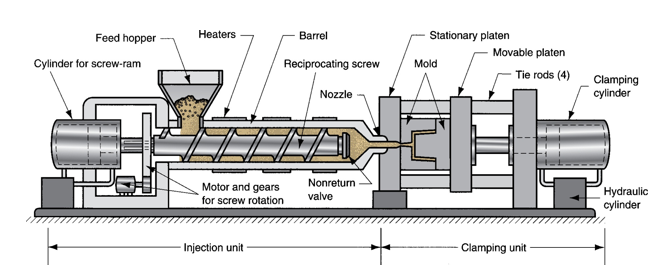

Principal components of an injection molding maching

injection unit, clamping unit

injection Unit function

Melts and delivers polymer melt

Operates much like an extruder

Clamping Unit function

Opens and closes mold each injection cycle

Injection unit components

Consists of barrel fed from one end by hopper containing supply of plastic pellets

Inside the barrel is a reciprocating screw with two functions:

Rotates for mixing and heating polymer

Acts as a ram (i.e., plunger) to inject molten plastic into mold

Clamping Unit Types

Mechanical (“Toggle”) clamp

Hydraulic clamp

Used on higher tonnage machines (150-1000 tons)

Can set tonnage at given positions during the stroke

Hydromechanical clamp

Capable of even larger tonnage (>1000 tons)

Rapidly move mold toward closing position (hydraulic cylinders)

Lock position (mechanical)

High-pressure hydraulic cylinders used to close the mold and build tonnage

Injection Molding — Mold Components

Cavity that imparts the part shape

Polymer supply “piping” (sprue/runner/gate)

Means for ejecting the part

Due to polymers high thermal expansion coefficients, what happens when molding?

Shrinkage occurs during solidification, so dimension of mold cavity must be made larger than specified part dimension

Cold Runner Mold Components

Sprue: main channel through which the plastic enters the mold

Runner: Connects all of the parts and spreads the plastic along the face where the halves of the mold meet

Gate: Controls the flow of the plastic into the cavity

Two Plate Cold Runner Mold

Cavity/core, distribution channel, ejection system, cooling system, and air vents

Three Plate Cold Runner Mold

Also includes a third plate which is used to separate parts from sprue and runner when mold opens

Allows automatic operation of molding machine!

Hot Runner Mold

eliminates the solidification of sprue and runner by locating heaters around the corresponding runner channels

Parting Line

where two halves of the mold meet

Taper

drafted walls ensure parts aren’t parallel to the pull direction

Ejector Pins

applies force to push the molded part out when the mold opens

Name the 8 common injection mold defects

Warping

Sink marks

Knit lines/weld lines

Burn marks

Short shot

Flash

Voids

Flow marks

Warping

feature of the part (or the whole part) bends as the material cools

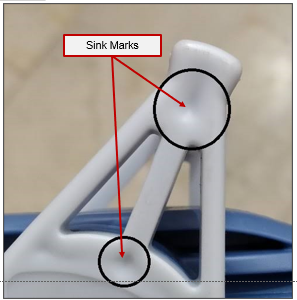

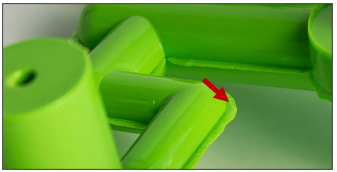

Sink Marks

type of warp that happens in the middle of a face when the material is too thick

Knit lines/Weld Lines

region where separate flows meet (as a result of flowing around holes and other features) may lead to deformations and discolourations

Burn marks

result from trapped air being compressed and heated to ignition temperature

Short Shot

dead-end areas can also lead to incompletely filled mold cavity

Flash

thin, excess plastic that escapes the mold cavity at the parting lines

Voids

hollow cavities that form within injection-molded plastic parts, caused by plastic shrinkage during cooling and improper packing

Flow marks

surface defect in injection-molded parts that appear as wavy lines or color variations, caused by uneven material flow and differing cooling rates, which can impact aesthetics.