IMOS Module 4 - Copper/Bronze

1/22

Earn XP

Description and Tags

UF IDS2935: Impacts of Material Science Quest Fall 2023

Name | Mastery | Learn | Test | Matching | Spaced | Call with Kai |

|---|

No study sessions yet.

23 Terms

Properties of Copper and Bronze

metals

malleable

opaque

electrical conductor

thermall conductor

shiny, hard appearance

Copper v. Bronze

pure element v. alloy of copper and impurity (arsenic or tin)

melting point at 1084C v. 950C

hardness of 80 MPa v. 700 MPa

yield strength of 70 MPa v. 220 MPa

methods to strengthen bronze

plastic deformation (permanent)

elastic deformation (temporary) (dislocations → plastic deformation)

work hardening (add dislocations)

cold-rolling (increase tensile strength)

impurtities (block disolations)

Copper reaction

CuCO3 + heat = 2Cu + CO2

2CuCo2 + O2 = 2CO

CuO + CO = Cu + CO2

Smelting process

calls for mixing of ore with charchoal

resource intensive

140 lbs of wood = 20 lbs of charchol

2 lbs of CuCo2 (malachite) = 1lb copper

crucible and furnace

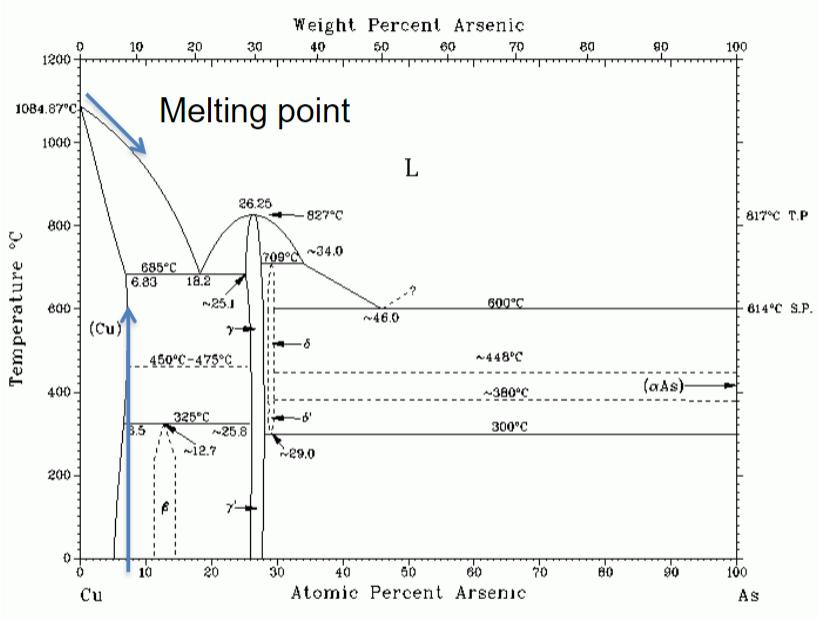

Phase diagram of Arsenic

x-axis = composition (As)

y-axis = temp.

6.8% at 685C is max solubility in copper

Arsenic alloy

produces altered color

increases the hardness of copper

lower melting point

oxidizes during smelting

produces AsO3 bi-product (toxic)

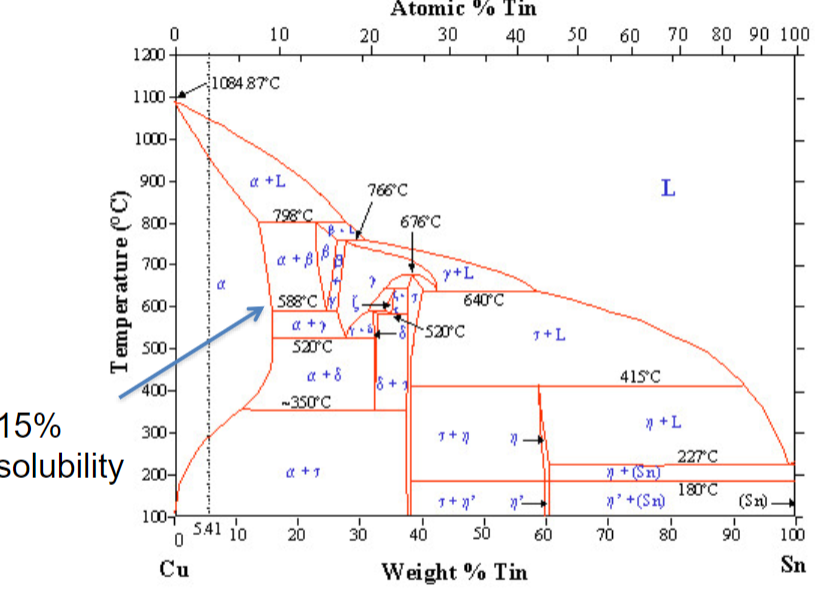

Tin alloy

increases strength

heat treat ment changes strength

adding too much tin can cause copper to be weaker

Tin v. Arsenic alloy

dissolve more tin than arsenic (<15%)

less toxic

harder to find than arsenic

Copper Age

5500-3000 BC

coppersmiths drew correlations between sources, conditions, and properties of copper

deposits’ purity depends on the region

used arsenic and tin as impurities

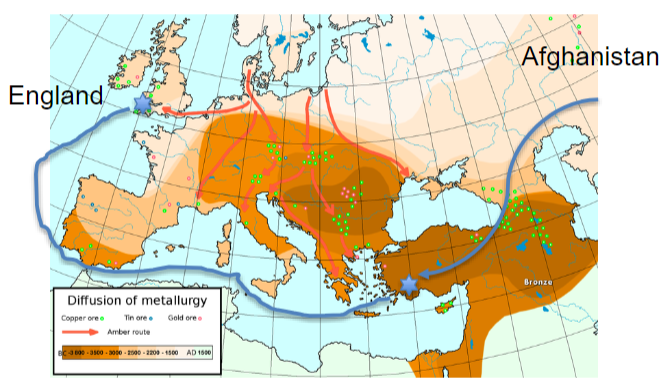

Bronze Age

3300-1200 BC

process of smelting

Otzi mummy is proof of copper smelting

King Solomon’s temple

parallel discoveries of copper around the world

social impacts (health, mining, exploration, and experimentation)

Trade developed around copper

England was the source of tin for Europe

Afghanistan also developed

casting technology created productino of art, tools, and weapons

Trade of Bronze Age

Egypt had gold

Afghanistan had tin (tin was precious metal)

Turkey had good metallurgists

very entangled society

End of Bronze Age

200 yrs. of drought, mass starvation, and earthquakes

ports shut down, centers are not used, and the tin supply chain stops

sea people attack Egypt and Hittites

society breaks down

iron and Phencians rise

Annealing

cold treatment (less brittle, more efficient)

Copper ingots

circular shaped (England); ox-hide shaped (Mediterranean)

Copper ores

mMalachite (oxidized), Fahlerz (sulphides)

Pure Copper v. 10% Tin Copper Alloy

melting point 1083C v. 1000C

cast hardness: 50 HB v. 100 HB

cold-worked hardness: 100 HB v. 230 HB

Metallurgy importance

technological: new skills became necessary and common

economic: raw and finished materials became abundant

social: introduces new scales of value and social divisions

Coppersmiths

Germany

Spain

mythological smiths (Dwarfs)

Solar cells/Photovoltaic material

something that converts light into electricity; needs to beable to break bonds and create electrons and holes

Impacts of photovoltaics and solar cells

50% of CO2 comes from electricity generation

50-70% of the world relies of fossil fuels

solar energy produces 50x less CO2 than fossil fuels

solar energy is 300x cheaper than 40 years ago

industry growth is making solar energy cheaper

some regions need >9% of land area to produce enough energy

hard to recycle Si at the end of life

Grid parity

new energy cost = grid cost

Semiconductor materials

Si

CdTe

CIGS

Pervoskites