L05 - Propellant management, injection & combustion chamber processes

1/95

There's no tags or description

Looks like no tags are added yet.

Name | Mastery | Learn | Test | Matching | Spaced |

|---|

No study sessions yet.

96 Terms

What are the two main types of propellant feed systems?

Short A: Pressure-fed and pump-fed.

Long A: In liquid rocket engines, propellants are delivered either using a pressure-fed system (using pressure differences) or a pump-fed system (using turbo-pumps).

What is the primary design goal for propellant tanks?

Short A: Minimize size and weight.

Long A: Propellant tanks should be designed to hold the necessary amount of propellant while keeping size and mass as low as possible for performance and efficiency.

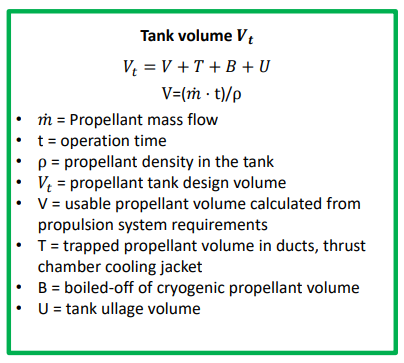

What is the formula for total tank volume Vt?

Short A: Vt=V+T+B+U

Long A: The total tank volume includes usable propellant V, trapped volume in ducts T, boil-off volume B, and ullage gas volume U.

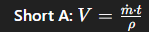

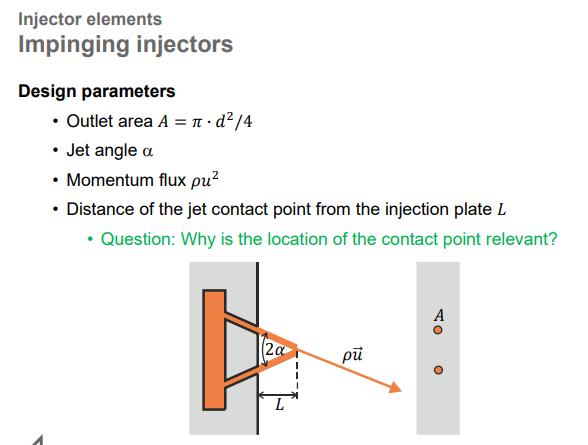

How is the usable volume of propellant calculated?

Long A: Usable volume is determined from the required mass flow rate m˙\dot{m}m˙, operation time ttt, and the density ρ\rhoρ of the propellant inside the tank.

What is the main design goal of interconnecting components in a propellant feed system?

Short A: Minimize pressure losses.

Long A: Interconnecting components must minimize pressure drops between the tank and engine inlets to ensure efficient fuel delivery.

Why are mounts critical in a rocket propulsion system?

Short A: For mechanical stability.

Long A: Mounts stabilize the system, protecting components from launch-induced vibrations and loads, and ensuring safe operation.

What design aspects should interconnecting components optimize besides pressure loss?

Short A: Size and weight.

Long A: Along with minimizing pressure loss, interconnecting ducts and pipes must also minimize mass and volume to enhance system performance.

The Vulcain 2 engine injector head is a key component of the thrust chamber, designed for

precise mixing and injection of propellants into the combustion chamber.

The injector head consists of several subcomponents

Distribution system:

Separates oxidizer and fuel flows into different domes.

Uses a distributor plate to guide flow.

Injection system:

Includes injector elements and the injector plate (or face plate).

Equipped with film cooling rings/slits to protect chamber walls.

Damping elements:

Cavities and baffles reduce acoustic instabilities.

Igniter:

Initiates combustion.

The injector head is responsible for several crucial tasks:

Feeding of oxidizer and fuel:

Controlled mass flow rate and mixing ratio.

Ensures optimal velocity and cross-section at inlet.

Propellant injection:

Atomizes the fuel and oxidizer.

Enables droplet evaporation and mixing.

Efficient & stable combustion:

Achieves complete combustion.

Resists acoustic vibrations (both low and high frequency).

What are the three main tasks of an injector head?

Short A: Feeding, injection, combustion.

Long A: The injector head feeds fuel and oxidizer, atomizes and mixes them, and ensures efficient and stable combustion.

Why is atomization important in propellant injection?

Short A: Better mixing and combustion.

Long A: Atomization increases the surface area of the fuel and oxidizer, enabling faster evaporation and more efficient combustion.

Injector design must satisfy several engineering requirements:

What are the three main performance aspects influenced by the injector head?

Short A: Efficiency, stability, wall loading.

Long A: The injector head affects combustion efficiency, flame stability, and thermal/chemical loads on the chamber wall.

What makes the injector head complex in production?

Short A: High integration.

Long A: The injector head combines multiple systems (injection, cooling, damping, ignition), making its design and manufacturing highly challenging and precise.

What determines the phase of a propellant during injection?

Short A: Pressure and temperature.

Long A: The thermophysical state depends on whether the injection conditions are above or below the propellant’s critical pressure and temperature.

What phase is hydrogen usually in during staged combustion?

Short A: Supercritical.

Long A: Hydrogen is typically injected in a supercritical state due to the high chamber pressures used in staged combustion cycles.

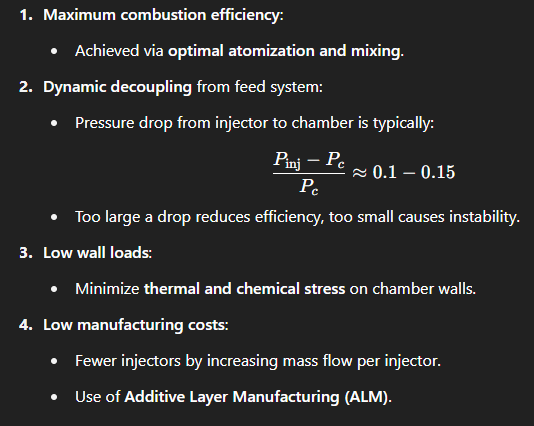

What is the function of an impinging injector?

Short A: To atomize via jet collision.

Long A: Impinging injectors atomize propellants by directing jets to collide at a point, enhancing mixing and evaporation before combustion.

What are impinging injectors sensitive to?

Short A: Instabilities and tolerances.

Long A: Impinging injectors can easily develop combustion instabilities and require very precise manufacturing to function correctly.

What determines the spray shape in impinging injectors?

Short A: Jet velocity and angle.

Long A: Spray shape and quality are influenced by the jet's speed, the angle of impact, and where the jets meet, all affecting sheet formation and droplet size.

There are several configurations of impinging injectors:

Unlike doublet: fuel and oxidizer jets intersect.

Unlike triplet/quadlet/pentad: more complex arrangements of intersecting streams.

Like doublet: same fluid streams intersect (rarely used alone).

What is the difference between unlike and like impinging injectors?

Short A: Unlike mixes different fluids, like mixes same fluid.

Long A: Unlike injectors intersect fuel and oxidizer jets, while like-on-like injectors collide identical fluid jets for better atomization within a single stream type.

How does changing ROF affect injector behavior?

Short A: Alters mixing patterns.

Long A: Changing the oxidizer-to-fuel ratio shifts the balance of jet velocities and angles in “unlike” injectors, affecting spray symmetry and combustion stability.

What are the main design parameters of impinging injectors?

Short A: Area, angle, momentum, distance.

Long A: Outlet area, jet angle, momentum flux, and the distance to the contact point all determine the atomization and spray pattern of impinging injectors.

Why is the location of the jet contact point relevant?

Short A: It affects spray and stability.

Long A: If the contact point is too close or too far from the plate, it can lead to incomplete atomization or impingement on chamber walls, reducing combustion efficiency.

What is decay phenomenology in impinging injectors?

When two liquid jets impinge, they form a liquid sheet that breaks into ligaments, and then into droplets. This is called decay phenomenology.

What does the disintegration frequency depend on in impinging injectors?

Short A: Jet angle, velocity, and cross-section.

Long A: It increases with higher jet velocity, smaller jet angle (cos(α)), and smaller beam cross-section, all influencing the breakup into ligaments and droplets.

Higher decay frequency in decay phenomenology

Higher decay frequency → smaller droplets → better combustion

What condition must be met for combustion to be stable, according to Hewitt criterion?

Short A: finj<fcc/1100

Long A: Combustion remains stable when the injection frequency is significantly lower than the natural frequency of the combustion chamber.

Showerhead injectors are

simple and cost-effective liquid/liquid injector designs

Rely purely on turbulent mixing, not jet impingement.

Because mixing is less effective, they require larger combustion chambers for complete combustion.

What is the main mixing mechanism in showerhead injectors?

Short A: Turbulent mixing.

Long A: Showerhead injectors rely solely on turbulent flow for fuel-oxidizer mixing, without any direct jet collision.

What is a key advantage of showerhead injectors?

Short A: Stable at many flow rates.

Long A: Showerhead injectors are very tolerant of changes in mass flow rate, making them robust for varying operating conditions.

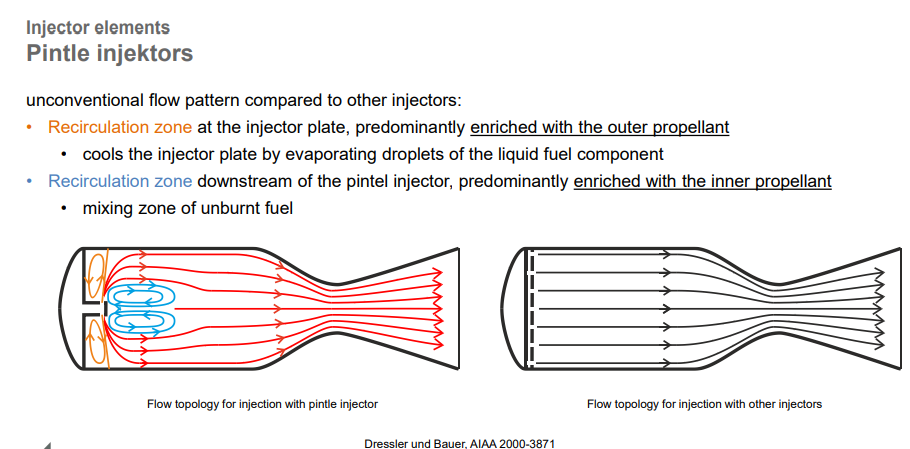

Pintle injectors

Pintle injectors spray fuel and oxidizer against each other, using a central pintle.

Simple and reliable design

Create unconventional flow patterns

Experience high thermal loads on the injector plate

Commonly used in throttleable engines (like landers, e.g. Apollo LEM)

What kind of engines often use pintle injectors?

Short A: Throttleable engines.

Long A: Pintle injectors are favored in engines that need variable thrust (like landers), due to their simple, reliable, and controllable flow design.

What is a key drawback of pintle injectors?

Short A: High thermal load.

Long A: Pintle injectors concentrate thermal loads on the injector face, requiring careful thermal management or cooling strategies.

What is the purpose of the upstream recirculation zone in pintle injectors?

Short A: Cools the injector face.

Long A: The recirculation zone at the injector plate helps cool it by using the outer propellant (usually fuel) to absorb heat through evaporation.

What happens in the downstream recirculation zone of a pintle injector?

Short A: Inner propellant mixes.

Long A: The downstream region facilitates mixing and combustion of the inner propellant (often oxidizer), improving overall combustion efficiency.

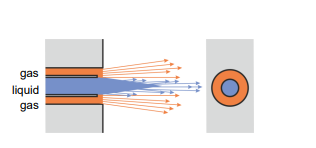

Coaxial injectors are commonly used for

Coaxial injectors are commonly used for gas/liquid propellant combinations such as LOX/GH₂.

What is the structure of coaxial injectors?

Liquid oxidizer flows through the central tube.

Gaseous fuel flows through the annular gap around the tube.

The gas velocity is significantly higher than the liquid:

ugas≫uliquid

What are the applications of coaxial injectors

Suitable for high-pressure combustion chambers, even supercritical injection regimes

What is the condition for supercritical injection in coaxial injectors?

Short A: Chamber pressure > critical pressure

Long A: When the combustion chamber pressure exceeds the critical pressure of the oxidizer, injection occurs in a supercritical state, affecting atomization and combustion behavior.

Coaxial Injectors – Operation and Characteristics

Mixing occurs through

Mixing occurs through high differential velocity and momentum transfer between gas and liquid.

What are the key benefits of coaxial injectors?

Effective for high density differences (e.g. LOX/GH₂)

Good combustion performance

Low thermal load on the injector face due to cooling by the fast gas

What are the drawbacks of coaxial injectors?

Sensitive to manufacturing tolerances

Sensitive to contaminants or impurities

What causes mixing in coaxial injectors?

Short A: Velocity and momentum difference

Long A: Coaxial injectors mix fluids by exploiting the large velocity and momentum difference between the fast-moving gas and slower liquid.

Why do coaxial injectors have low thermal loads on the faceplate?

Short A: Gas cooling effect

Long A: The high-speed gas flowing around the liquid jet provides a cooling effect that reduces the heat load on the injector faceplate.

What kind of fuel combinations are suitable for coaxial injectors?

Short A: Large density differences

Long A: Coaxial injectors are ideal when fuel and oxidizer have significantly different densities, such as liquid LOX and gaseous H₂.

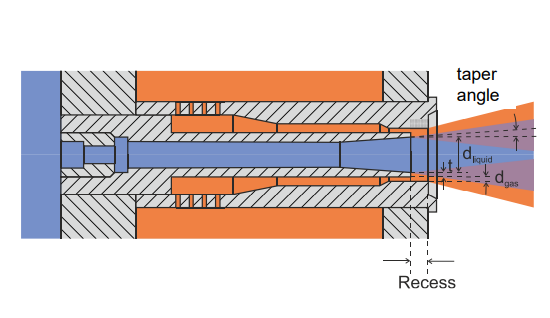

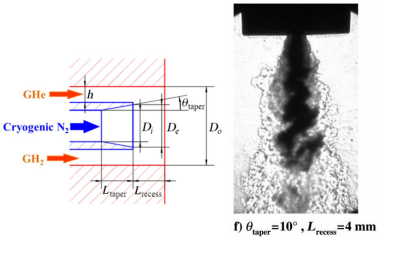

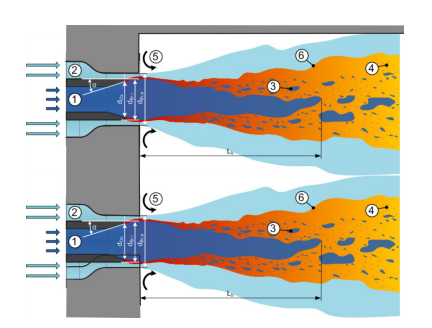

Coaxial Injectors – Design Parameters

dliquid: Diameter of the liquid oxidizer post (central tube)

dgas: Width of the annular gap for the gas

t: Tip thickness of the LOX post

Recess length: How deep the gas nozzle is set back

Taper angle: Controls the direction and expansion of the spray

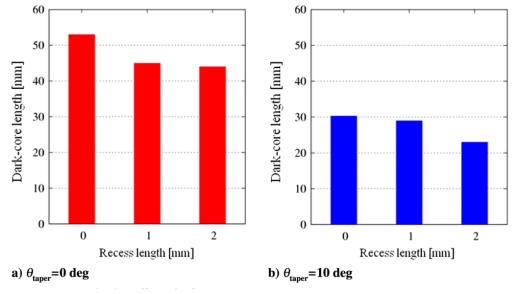

This experimental study shows how recess length and taper angle affect the dark-core length (length before jet fully atomizes).

What does dark-core length indicate in coaxial injectors?

Short A: Atomization delay

Long A: The dark-core length represents the portion of the liquid jet that remains unbroken. A shorter length means quicker atomization and better mixing.

How does taper angle affect atomization?

Short A: Enhances shear and breakup

Long A: A non-zero taper angle increases the shear between the gas and liquid jets, enhancing atomization and shortening the dark-core length.

What happens if you increase recess length at 0° taper?

Short A: Atomization worsens

Long A: Without a taper, increased recess can allow the liquid jet to stay coherent longer, leading to reduced atomization performance.

Swirl-coaxial injectors are an advanced variant of coaxial injectors where

Swirl-coaxial injectors are an advanced variant of coaxial injectors where one or both fluids are set into rotation before injection.

The swirling motion helps with: (Swirl-coaxial injectors)

Good atomization and fuel preparation

Better combustion at low flow rates (suitable for small thrusters)

Improved flame stability due to recirculation

Formation of a cooling film along the chamber wall due to the wide outlet spray angle

Swirl-Coaxial Injectors

However, the swirl also causes:

Stronger coupling between combustion and thermal load

High sensitivity to manufacturing tolerances and impurities

What is the main benefit of using swirl in a coaxial injector?

Short A: Enhanced atomization and flame stability.

Long A: Swirl improves fuel preparation, especially at low flow rates, and creates recirculation zones that enhance flame stability and cooling.

What is a drawback of swirl-coaxial injectors?

Short A: High sensitivity and thermal load interference.

Long A: The swirling motion increases the coupling between combustion efficiency and wall heating, making the injector sensitive to design imperfections.

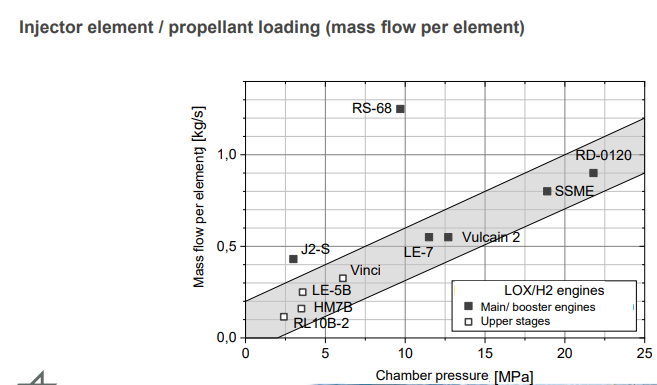

This plot compares various coaxial injectors based on:

Mass flow per element (kg/s)

Chamber pressure (MPa)

Observations:

Main/booster engines (filled symbols) operate at higher flow rates and pressures.

Upper-stage engines (empty symbols) use lower flow per element.

A trend shows that higher chamber pressure allows for more flow per injector (diagonal region).

How do main stage engines compare to upper stage engines in injector loading?

Short A: They have higher mass flow per injector.

Long A: Main and booster stage engines operate at higher chamber pressures and use larger injector mass flow rates compared to upper-stage engines.

What is the working principle of the API injector?

Short A: Uses many small channels and porous plates.

Long A: The API injects oxidizer (LOX) through micro-tubes and fuel (H₂ or CH₄) through a porous plate, enhancing evaporation and shear-driven atomization.

The API is a novel injector concept researched by DLR Lampoldshausen.

The setup provides:

And challenge:

Large LOX surface for evaporation

Shear forces at the interface for enhanced atomization

Disadvantage: Complex design can lead to pressure drop, clogging, or manufacturing difficulties

Which two injector types are most commonly used in liquid engines?

Short A: Coaxial and impinging.

Long A: Liquid rocket engines primarily use coaxial injectors (gas-liquid) and impinging injectors (liquid-liquid) due to their effective mixing capabilities.

What drives the development of new injector concepts like API?

Short A: Reducing manufacturing costs.

Long A: Innovations such as API and ALM aim to reduce costs and complexity while maintaining or improving performance.

What determines the choice of injector geometry?

Short A: Propellant properties.

Long A: The geometry of the injector is chosen based on the propellant’s phase (gas/liquid) and density, ensuring optimal mixing and combustion.

What forces dominate atomisation in coaxial injectors?

Short: Aerodynamic, surface tension, turbulence, swirl.

Long: Atomisation is driven by aerodynamic shearing from fast gas flows, opposed by surface tension. Turbulence enhances mixing, while swirl increases angular momentum aiding breakup.

What is the role of swirl in coaxial injectors?

Short: Enhances atomisation and flame stability.

Long: Swirl introduces angular momentum into the flow, leading to enhanced mixing, finer atomisation, and better flame anchoring/stability.

What happens to LOX at supercritical pressure?

Short: No surface tension.

Long: At pressures above its critical point (5.04 MPa), LOX no longer behaves like a conventional liquid and has no surface tension, significantly altering atomisation behavior.

Why is LOX’s equation of state important at supercritical conditions?

Short: It behaves like a real gas.

Long: Due to supercritical behavior, LOX must be modeled with a real gas equation of state to accurately capture thermodynamic properties for mixing and combustion.

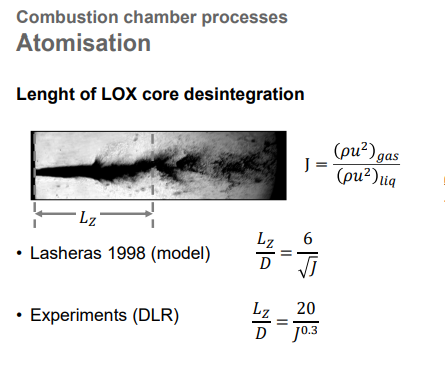

This slide discusses how far the LOX jet core travels before breaking up.

How does momentum flux ratio affect breakup length?

Short: Higher J = shorter Lz.

Long: As the gas-to-liquid momentum ratio increases, the LOX jet disintegrates sooner due to higher shear forces acting on the core.

How does LOX post thickness influence atomisation?

Short: Thinner post = faster breakup.

Long: Thinner LOX posts result in a shorter core length due to reduced structural resistance and altered flow characteristics, enhancing atomisation.

Why is spray modeling difficult?

Short: Complex, no universal model.

Long: Spray modeling is hard due to the chaotic nature of droplet formation, requiring heavy computation, empirical assumptions, and limited predictive capability.

What method is often used for supercritical spray modeling?

Short: LES.

Long: Large Eddy Simulation (LES) is used for supercritical conditions because it can resolve turbulence and mixing accurately, although it’s highly computationally expensive.

Droplet Transport

Liquid propellant is typically injected at a lower velocity than the gaseous propellant.

The combustion process partially accelerates the overall flow, increasing the velocity of both the gas and entrained droplets.

Droplets are dragged and accelerated by the faster-moving gas (like LOX in H₂ flow).

As droplets interact with turbulent high-speed gas, they may undergo secondary atomisation—breaking into smaller droplets.

What causes droplet acceleration in rocket combustion chambers?

A (Short): High-speed gas flow and partial combustion.

A (Long): The high-speed gaseous propellant and partial combustion increase the momentum of the flow, dragging and accelerating the slower-moving liquid droplets.

What is secondary atomisation?

A (Short): Further breakup of droplets in high-speed gas.

A (Long): Secondary atomisation refers to the process where already-formed liquid droplets break into smaller ones due to high shear and turbulence in the gas stream.

What two processes govern droplet evaporation?

Short: Mass diffusion and heat transport.

Long: Evaporation involves mass diffusion driven by partial pressure gradients and heat transfer from the hot gas to the cooler liquid droplet.

What happens above critical pressure to the droplets?

Short: Surface tension vanishes.

Long: At supercritical pressures, the droplet loses surface tension and traditional phase distinctions fade, requiring real-gas equations for modeling.

Spray Characterisation (Cold-Flow Tests & Hydraulic)

Why are cold-flow tests important?

Short: Detect defects and study atomization.

Long: These tests help identify manufacturing issues, evaluate spray patterns, and predict how injectors behave without combustion.

What happens to sprays at supercritical pressure?

Short: No surface tension, turbulent mixing.

Long: At supercritical conditions, surface tension vanishes, and the spray becomes a dense, diffusive jet with strong mixing due to loss of liquid-gas interface.

What is the purpose of injector hot run tests?

Short: To assess flame stability, interactions, and heat transfer.

Long: The purpose is to analyze flame stabilization, decay of jets in a reactive flow, interactions between jets and chamber walls or between injector elements, and heat transfer into the injector and chamber wall.

Why is flame stabilization important in hot-fire tests?

Short: To keep combustion steady and safe.

Long: Flame stabilization ensures continuous and safe combustion by preventing flame blow-off or flashback, which is crucial for reliable engine performance

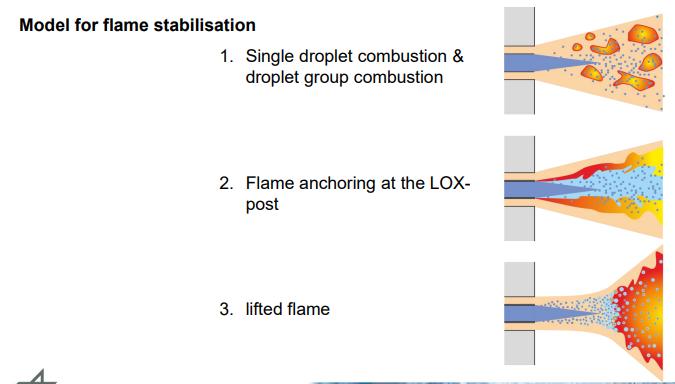

What are the three main flame stabilization modes in coaxial injectors?

Short: Single/group droplet combustion, anchoring at LOX post, and lifted flame.

Long: The modes include (1) single droplet combustion and droplet group combustion, (2) flame anchoring directly at the LOX post due to local mixing and heat, and (3) lifted flames where combustion stabilizes downstream of the injector.

What causes a flame to lift off from the LOX post?

Short: High velocity or low reactivity.

Long: A lifted flame occurs when the local conditions (like high relative velocity or low temperature) prevent flame anchoring, causing it to stabilize further downstream where combustion becomes sustainable.

Where does the flame anchor in a LOX/H₂ coaxial injector configuration?

Short: At the LOX post.

Long: The flame stabilizes directly at the LOX post, where liquid oxygen is injected and mixed with high-velocity hydrogen gas, enabling sustained and stable combustion

Why is flame anchoring important in a combustion chamber?

Short: To ensure stable combustion.

Long: Flame anchoring prevents oscillations, ensures consistent ignition near the injector, and enables better heat distribution, which is critical for performance and safety in rocket engines.

What is a lifted flame?

Short: A flame that stabilizes away from the injector.

Long: A lifted flame is one that is not anchored to the injector face or LOX post, instead stabilizing further downstream due to insufficient mixing or high velocity, which may increase instability

What might cause flame lifting in a LOX/CH₄ system?

Short: High velocities or poor mixing.

Long: Flame lifting in LOX/CH₄ combustion can occur when methane and oxygen fail to mix quickly enough near the injector, often due to high momentum or inadequate injector design.

Why is flame lifting undesirable in combustion chambers?

Short: It causes instability.

Long: A lifted flame can lead to combustion instabilities, uneven heat loads on chamber walls, and risk of flame blow-off, potentially endangering engine operation.

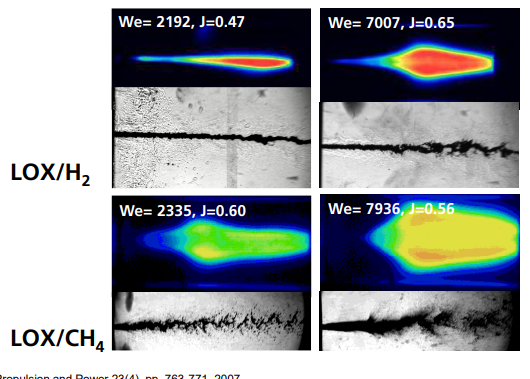

How does LOX/H₂ flame structure differ from LOX/CH₄?

Short: LOX/H₂ is compact; LOX/CH₄ is broader and lifted.

Long: LOX/H₂ flames anchor tightly at the injector face with a compact, stable structure due to fast reaction kinetics, while LOX/CH₄ flames tend to be wider and lift off due to slower methane combustion and flow behavior.

What physical properties cause differences between LOX/H₂ and LOX/CH₄ flame stabilization?

Short: Differences in reaction rate, momentum, and density.

Long: The contrast is due to hydrogen’s faster reaction kinetics, higher diffusion rate, and lower density compared to methane, which results in different mixing behavior, flame spread, and anchoring characteristics.

Which combination shows better flame anchoring behavior in coaxial injectors?

Short: LOX/H₂.

Long: LOX/H₂ injectors typically show superior flame anchoring near the LOX post due to rapid fuel oxidation and strong gas expansion, making the flame more stable and compact.

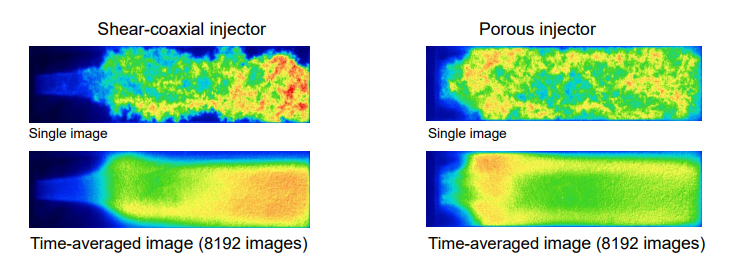

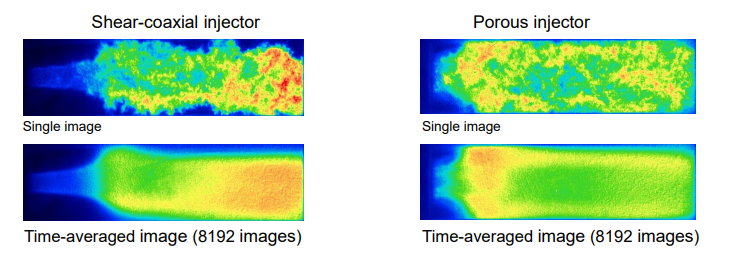

This slide presents Advanced Planar Imaging (API) results of a LOX/H₂ coaxial injector flame.

There are two injector types being compared:

Shear-coaxial injector

Porous-injector

What’s the difference between single-shot and time-averaged API images?

Short: Single shows instant flame; average shows stable pattern.

Long: A single-shot captures transient flame shape at a specific moment, while a time-averaged image shows the overall, stable structure of the flame over time, filtering out turbulence and fluctuation effects.

What advantages do porous injectors offer in flame behavior?

Short: Smoother flame and better cooling.

Long: Porous injectors can promote distributed combustion and reduce thermal loads on the injector face, contributing to smoother flame profiles and improved cooling performance.

What is the purpose of further thrust chamber testing after injector evaluation?

Short: To optimize combustion, heat transfer, and stability.

Long: These tests aim to refine injector geometry, evaluate combustion efficiency (

c*), analyze heat loads along the chamber, and test the chamber's response to pressure disturbances for stability.

What does the characteristic velocity c* indicate?

Short: Efficiency of combustion.

Long:

c*measures the speed at which combustion gases are generated per unit pressure. It’s a standard performance indicator showing how efficiently propellants are burned and energy is converted into thrust.

What is a “bomb test” in rocket engine development?

Short: A stability test with forced disturbance.

Long: A bomb test is an intentional disturbance (like a sudden pulse or small explosion) introduced into the combustion chamber to test how the system reacts, helping engineers assess combustion stability and dampening behavior.