Design and Manufacturing Lab Exam (copy)

1/147

There's no tags or description

Looks like no tags are added yet.

Name | Mastery | Learn | Test | Matching | Spaced | Call with Kai |

|---|

No analytics yet

Send a link to your students to track their progress

148 Terms

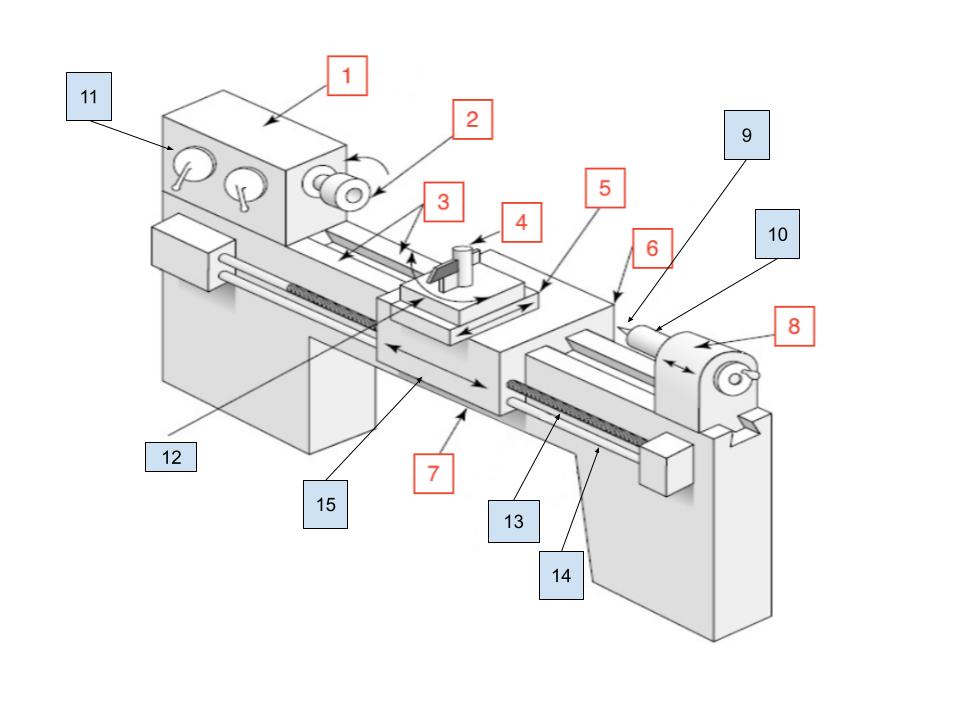

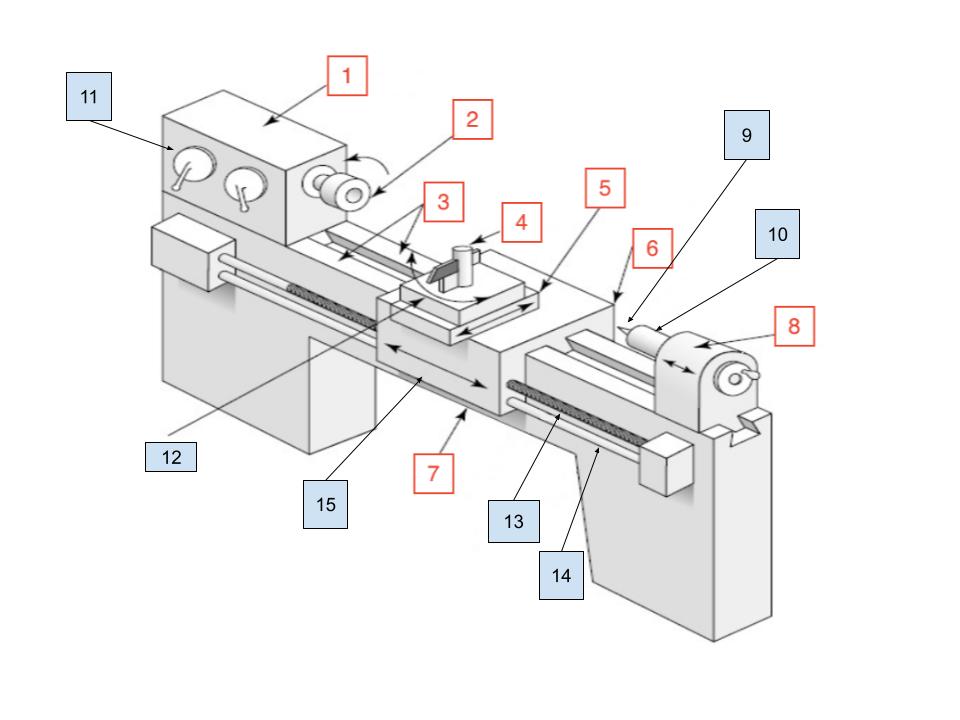

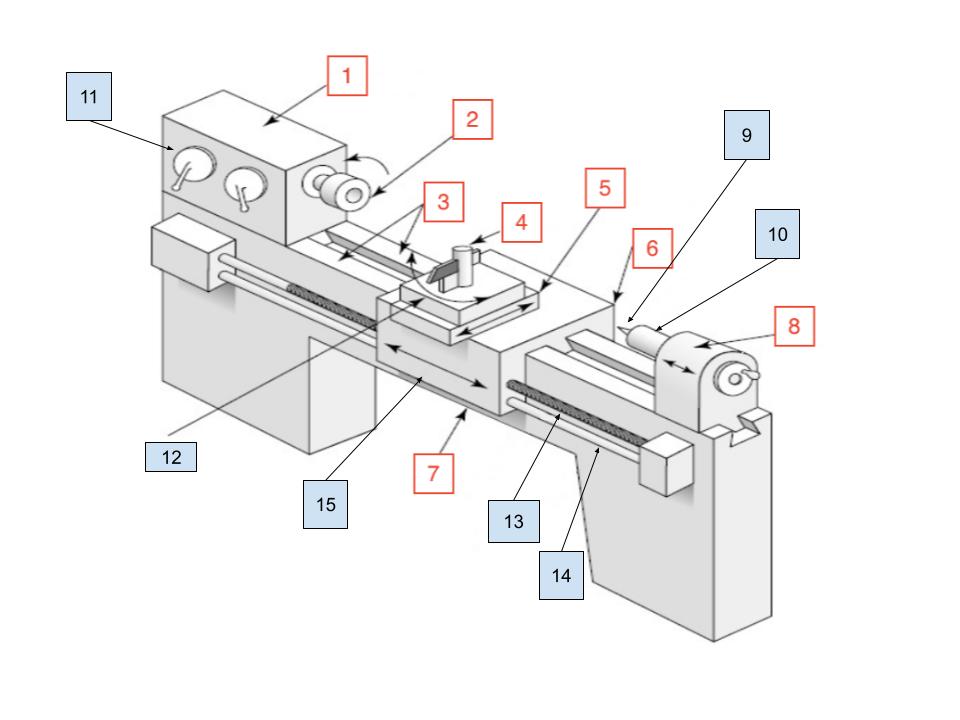

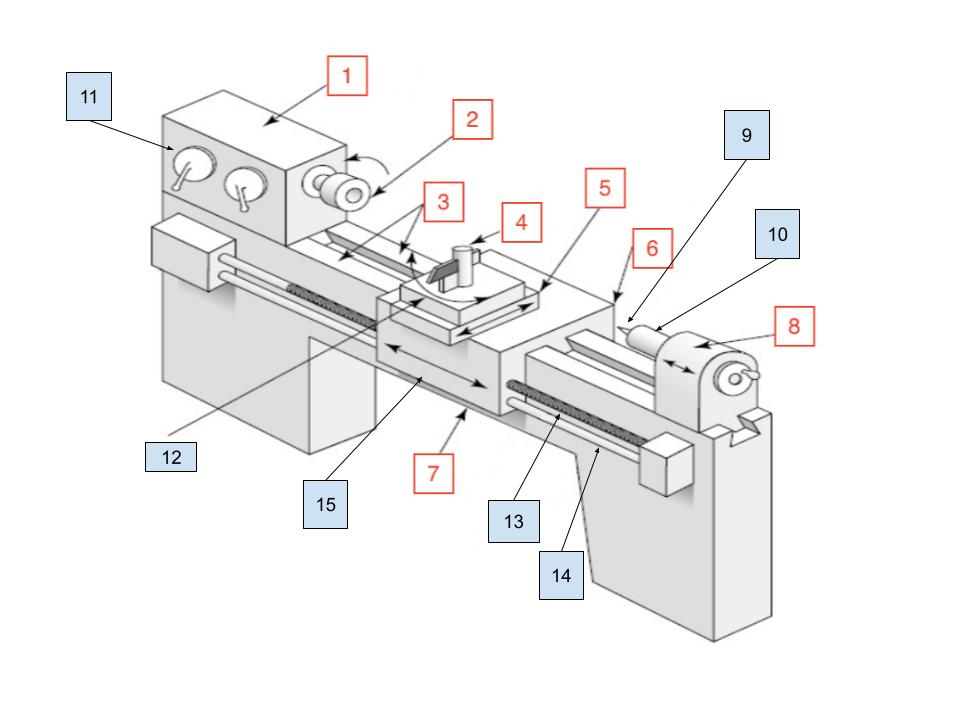

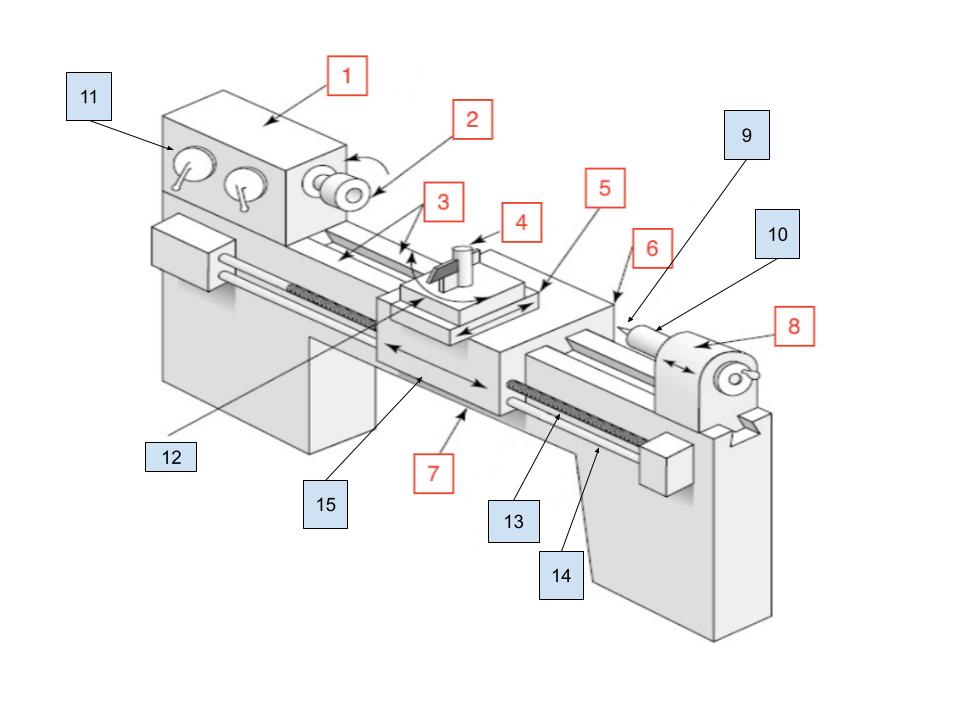

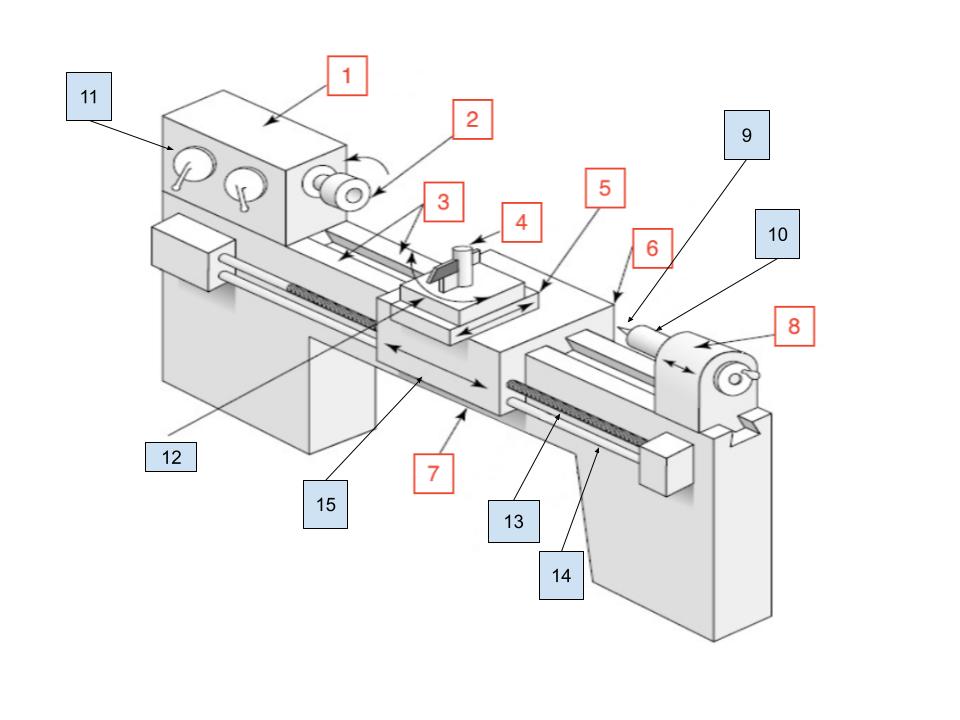

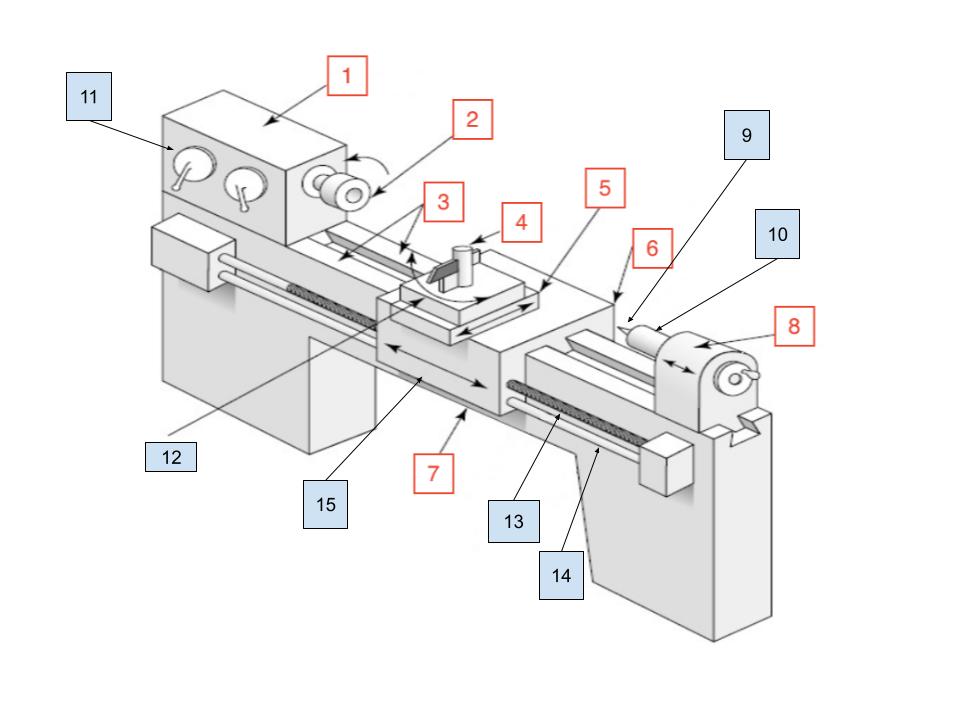

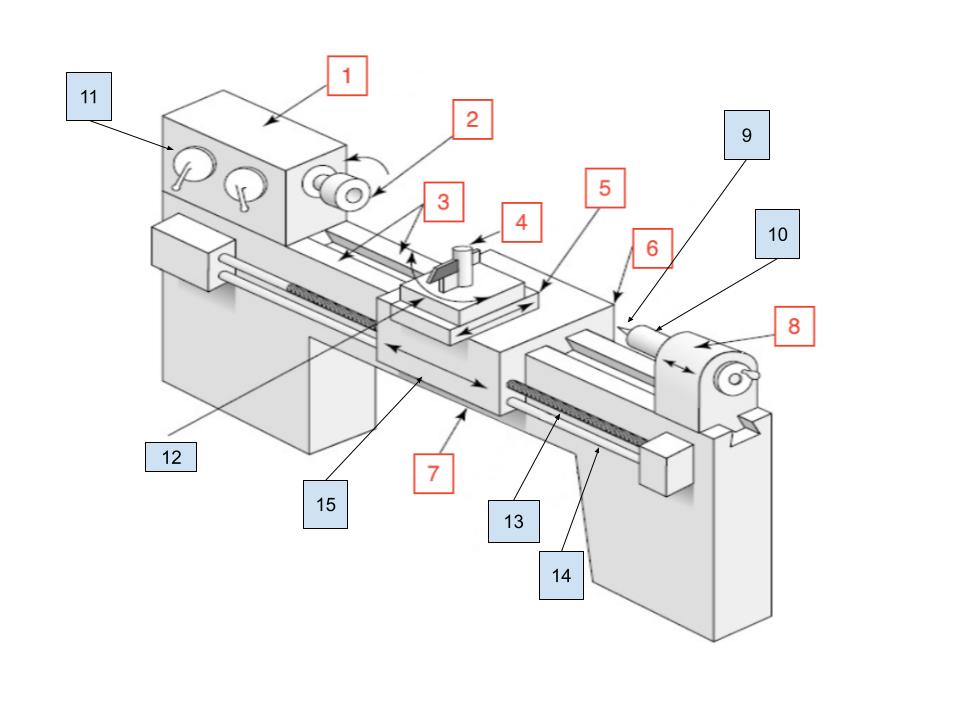

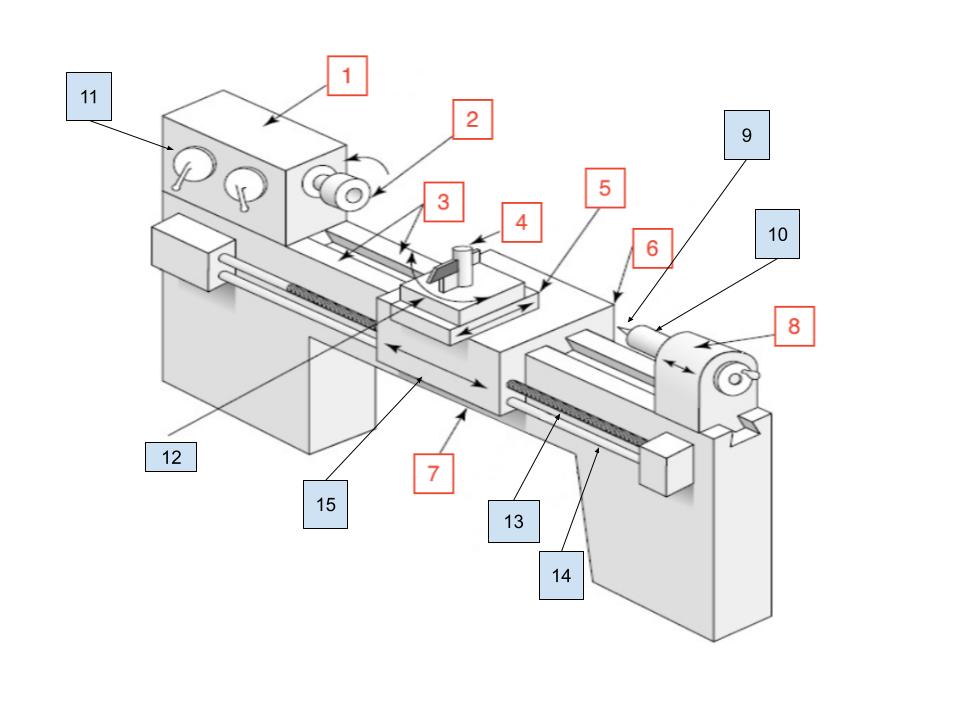

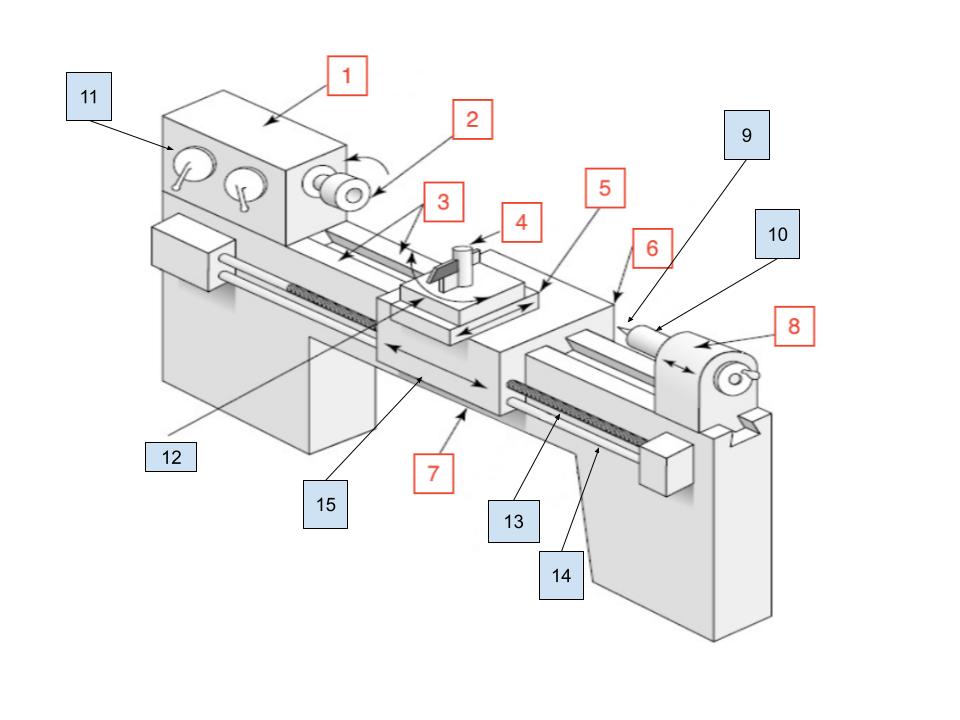

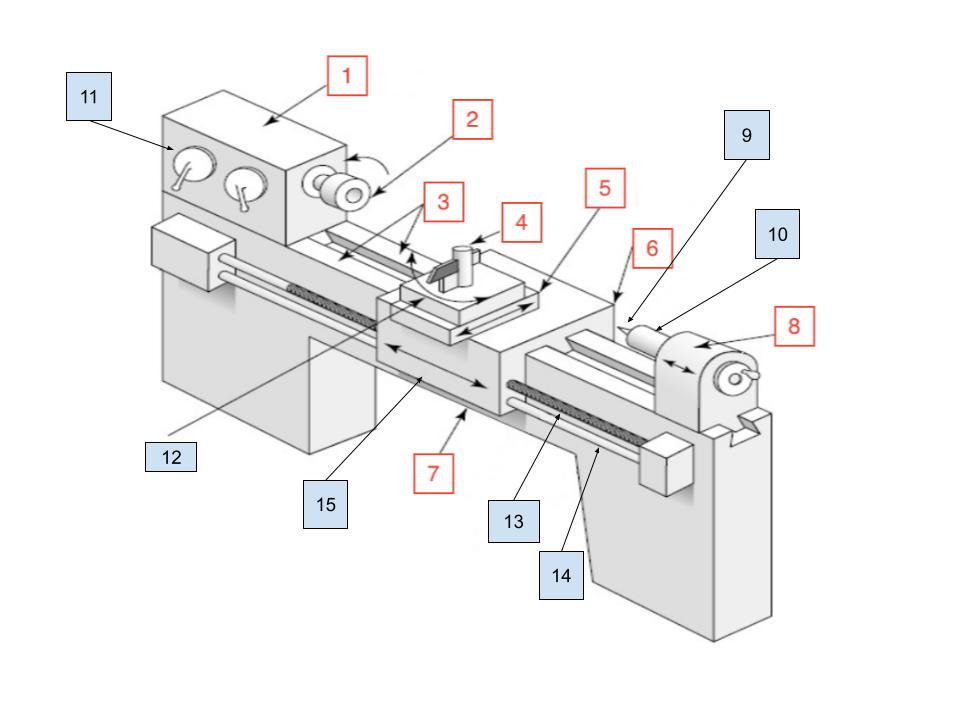

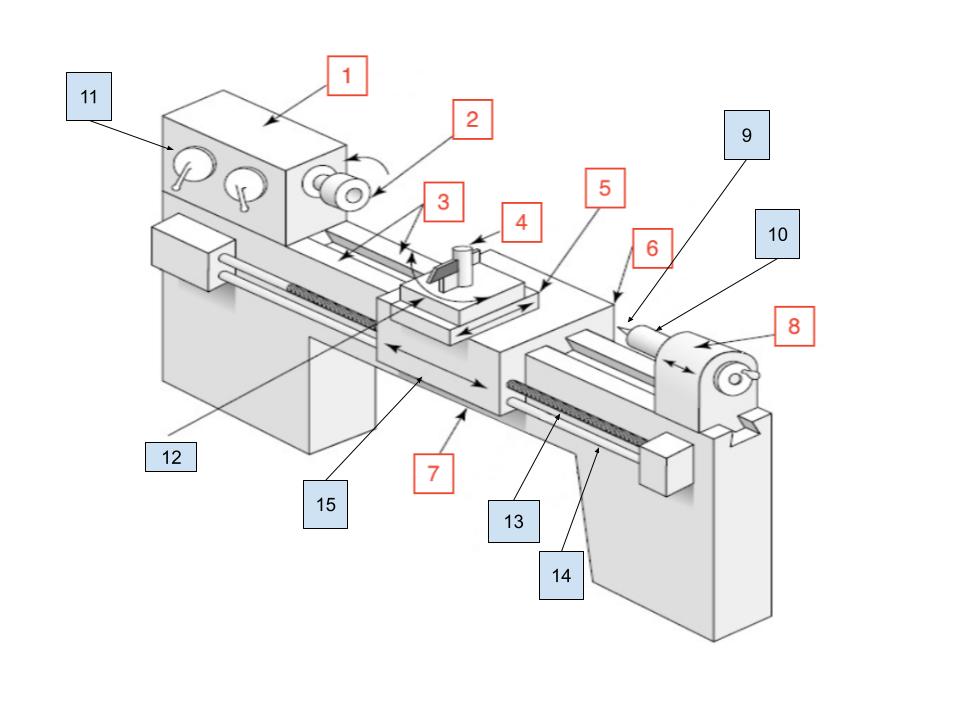

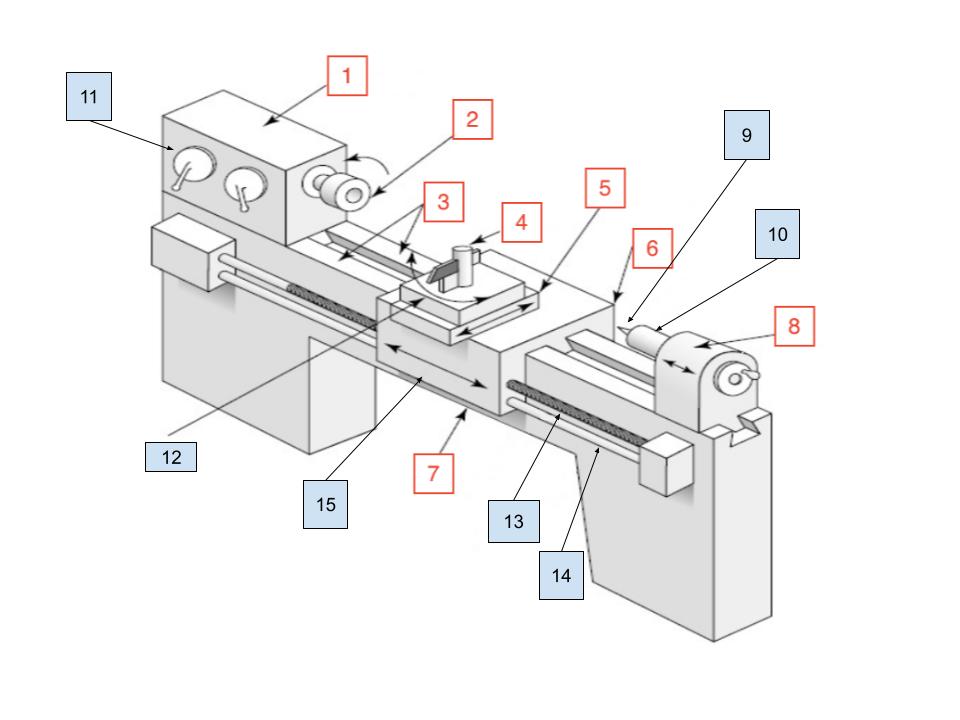

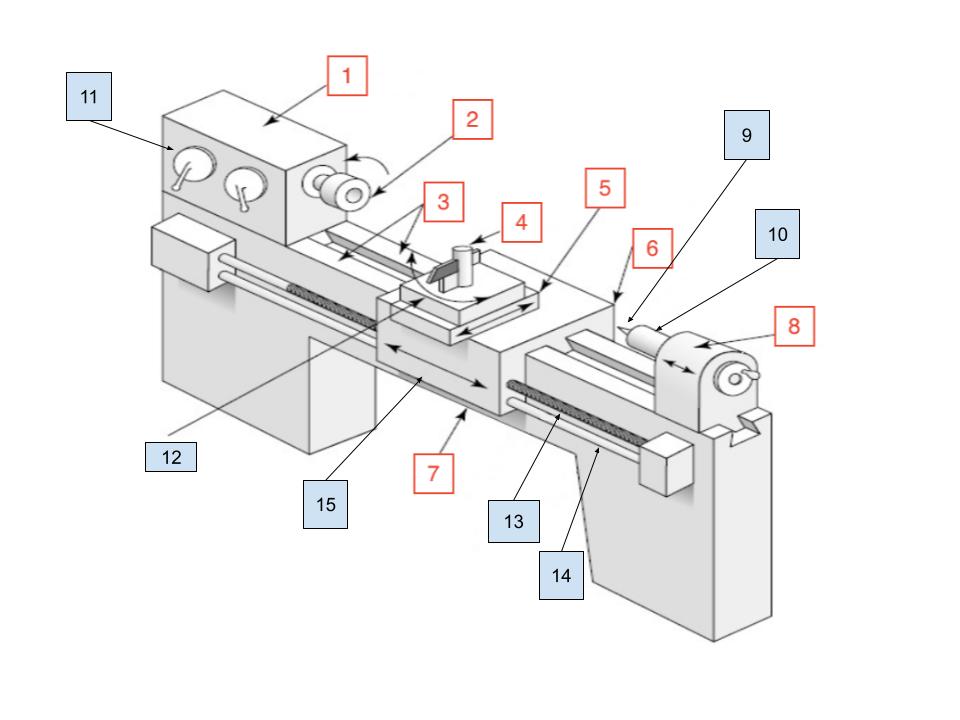

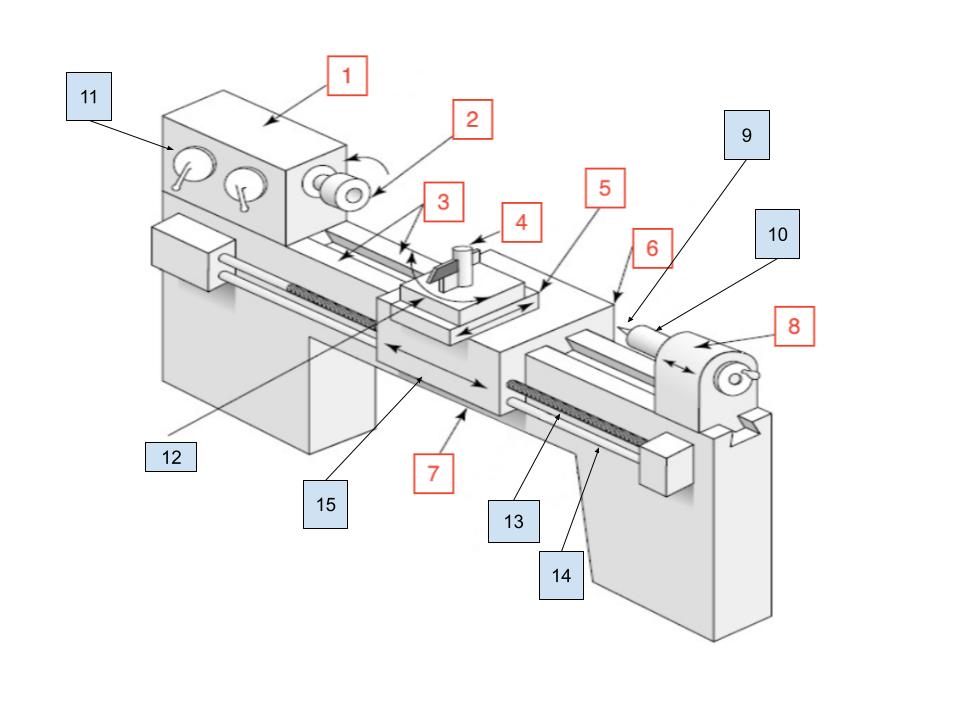

Headstock

1

Spindle

2

Ways

3

Toolpost

4

Cross Slide

5

Carraige

6

Bed

7

Tailstock

8

Center

9

Tailstock Quill

10

Spindle Speed Selector

11

Compound Rest

12

Lead Screw

13

Feed Rod

14

Apron

15

X Axis

Lathe axis that moves “in and out”, parallel to face of part

Z Axis

Lathe axis that moves “left and right”, parallel to axis of part

Recognize the problem/need

Design Process Step 1

Define your problem, and quantify it if possible

Design Process Step 2

Gather information

Design Process Step 3

Generate concepts based on constraints such as deadlines, strength, cost, etc.

Design Process Step 4

Out of the proposed concepts, select the best one using a decision matrix

Design Process Step 5

Communicate the design

Design Process Step 6

Detailed Design and Analysis using CAD

Design Process Step 7

Prototype Development and Testing

Design Process Step 8

Manufacturing

Design Process Step 9

Life Cycle Maintenance

Design Process Step 10

Bilateral Tolerance

A nominal measurement with a tolerance in both directions

Unilateral tolerance

A nominal measurement with a tolerance in one direction

Limit tolerance

A dimension with no nominal measurement, just an upper and lower bound

End Mill

Used for milling the sides of a workpiece. Used for profiling, contouring

Face Mill

Used for milling, creating a smooth, flat surface.

Collet

Used to hold tools in a mill or lathe

Clockwise

Direction mill should rotate

Counter-Clockwise

Direction lathe should rotate

Tap

A tool used to cut threads into a workpiece

Tap guide

A tool used to align the tap to ensure it’s going straight into the workpiece

Tap handle

The tool that rotates the tap when creating threads

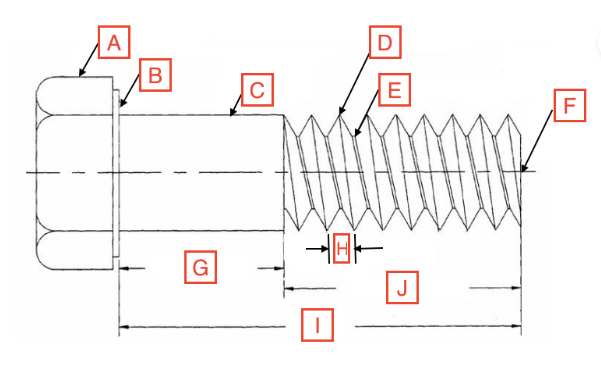

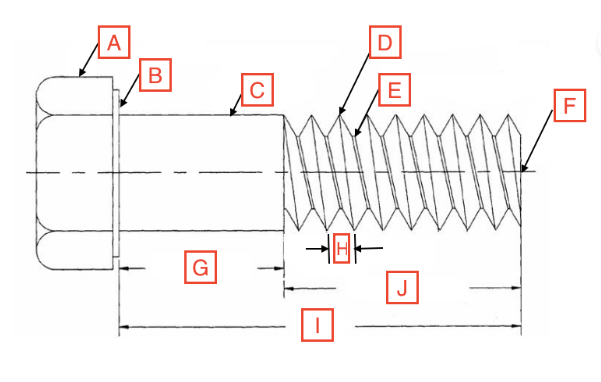

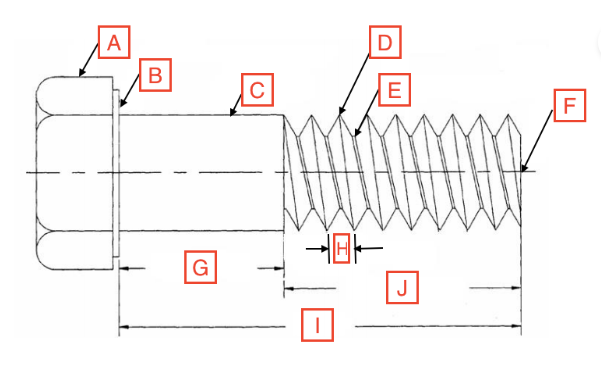

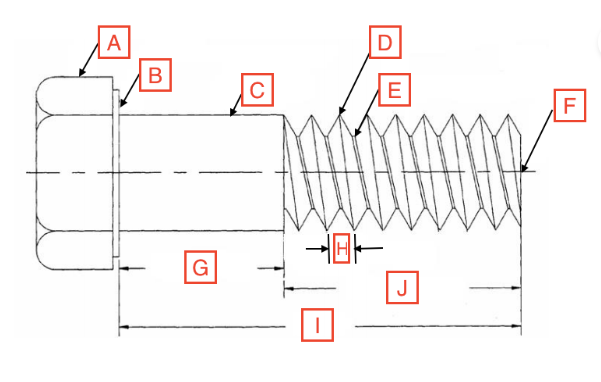

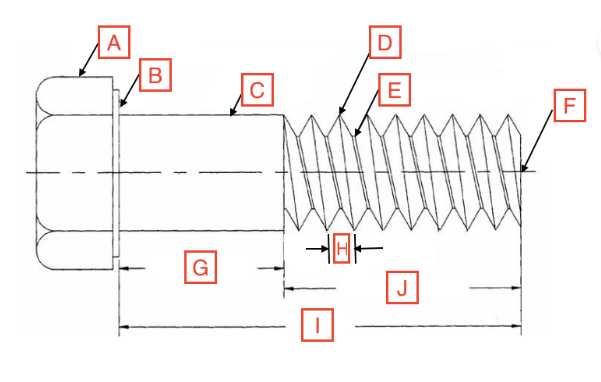

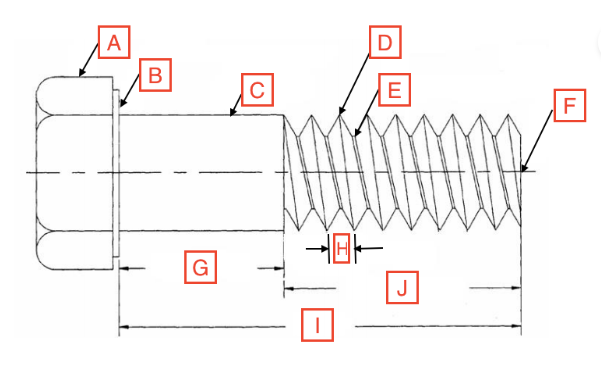

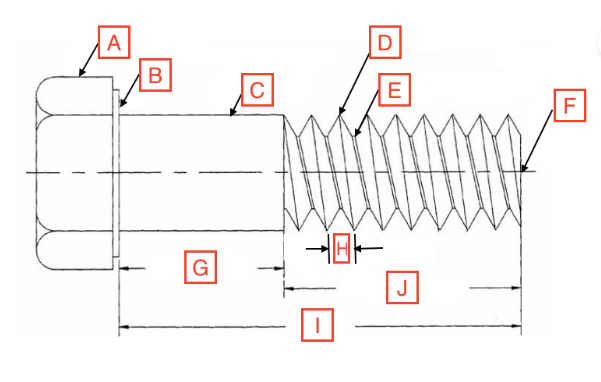

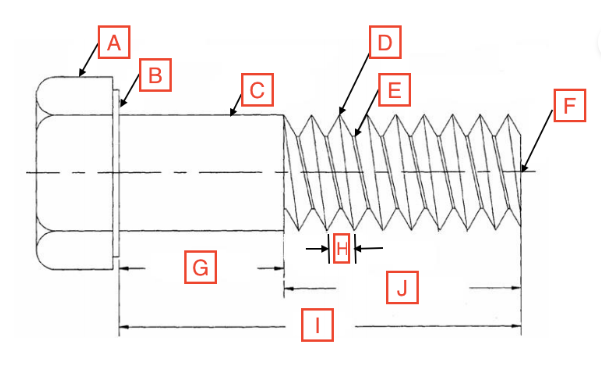

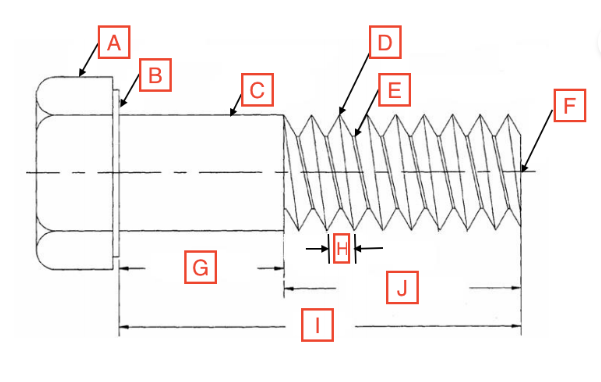

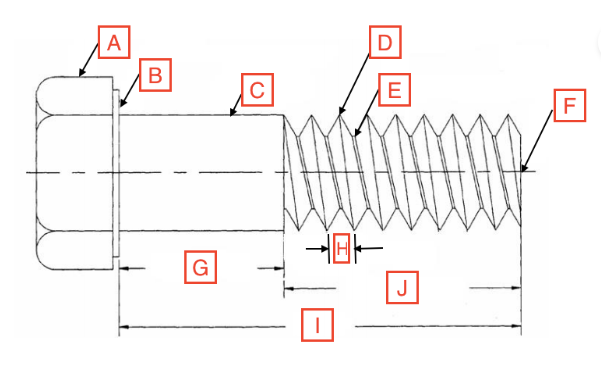

Grip Length/Shoulder

G

Thread Root

E

Head

A

Drive

The spot on the fastener where the screwdriver goes

Point

F

Length

I

Thread Length

J

Shank

C

Bearing Surface

B

Pitch

H

Thread Crest

D

Coarse threads - female threads are most likely to fail via shear at the major diameter, so more area in contact is better.

The larger size thread, better for stronger screws into weak materials. Why is it better?

Fine threads - male threads are more likely to fail from tensile loading at the thread root, so a larger minor diameter is better.

The smaller size thread, better for weaker screw, stronger material

Rolled —> Threads are made by being pushed in so the grains are compressed, rather than removed.

The threads on all quality fasteners are made by being _______. What does this mean?

Shear - the threaded portion has a slightly smaller diameter, the threaded portion has less surface area, and the thread will move and act as a file, removing material.

What force should threaded regions not be put under (use dowel pins or shoulders instead here). Why?

Tensile stress, torque

What two things keep a fastener secure

The point of the smallest diameter

Where do fasteners most commonly fail?

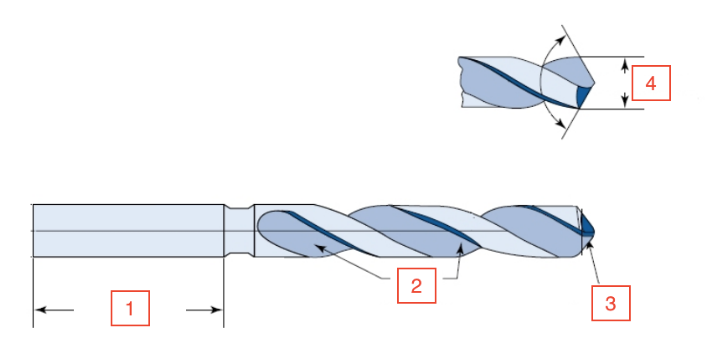

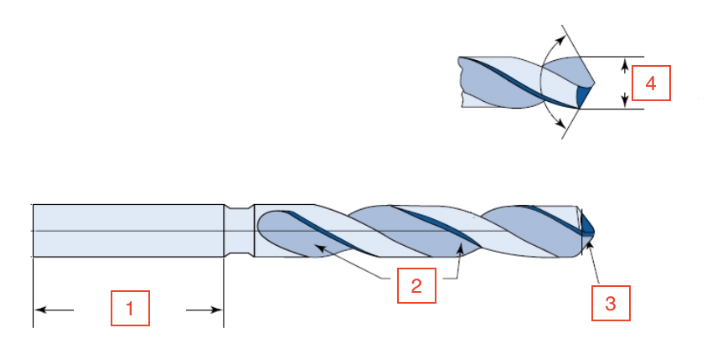

Shank Length

1

Flutes

2

Lip

3

Drill diameter

4

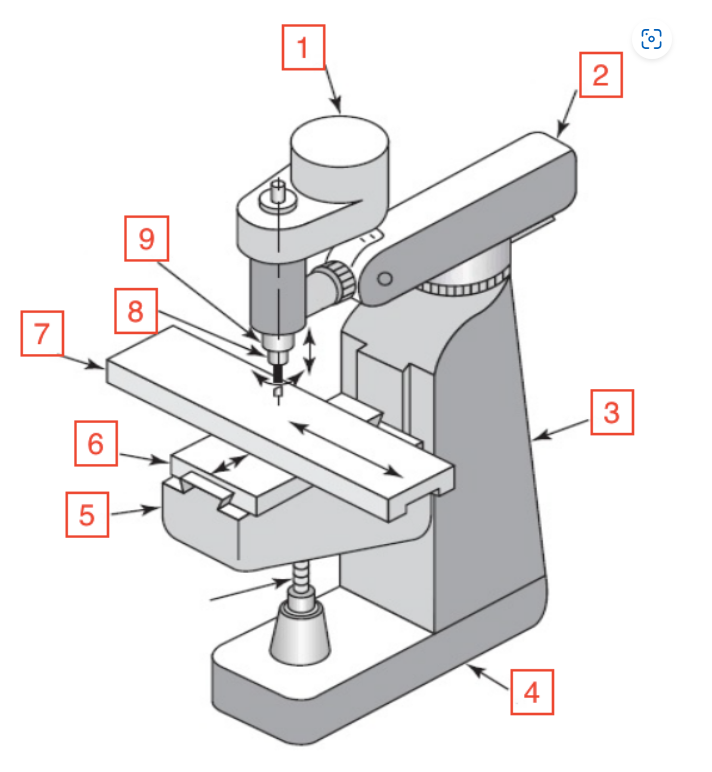

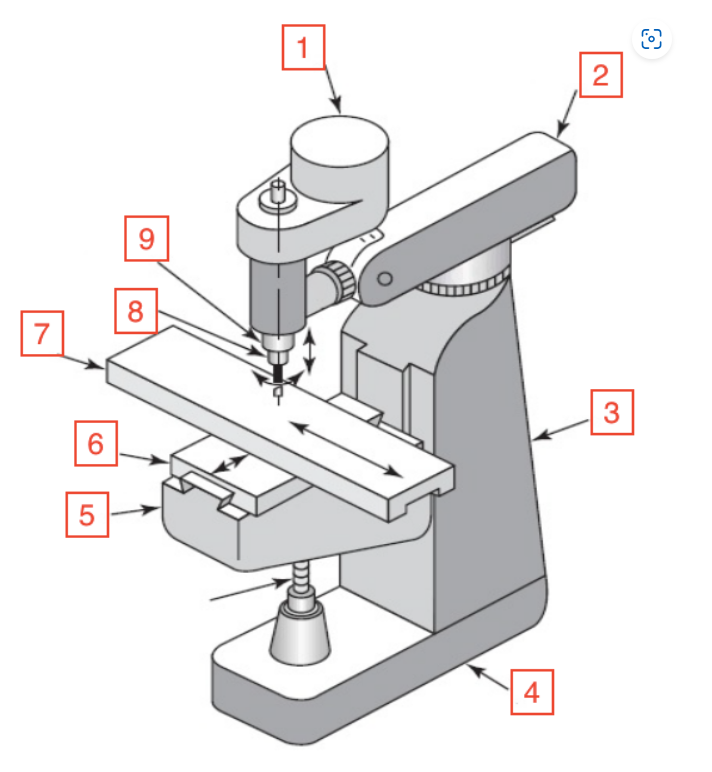

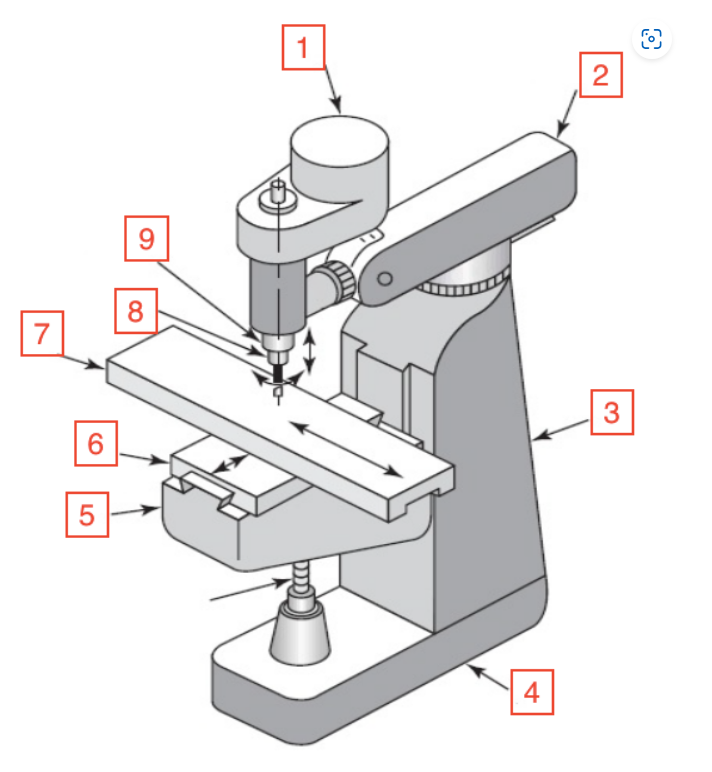

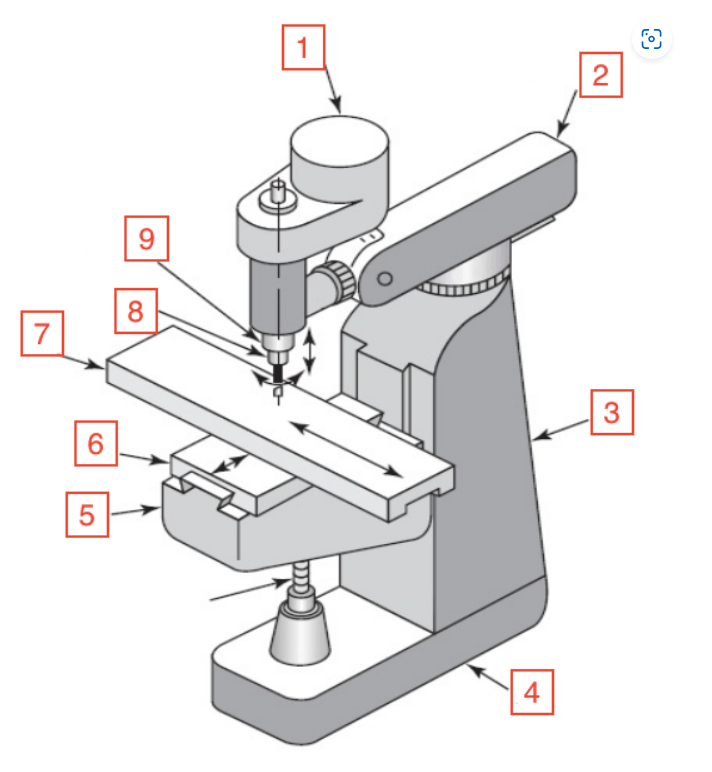

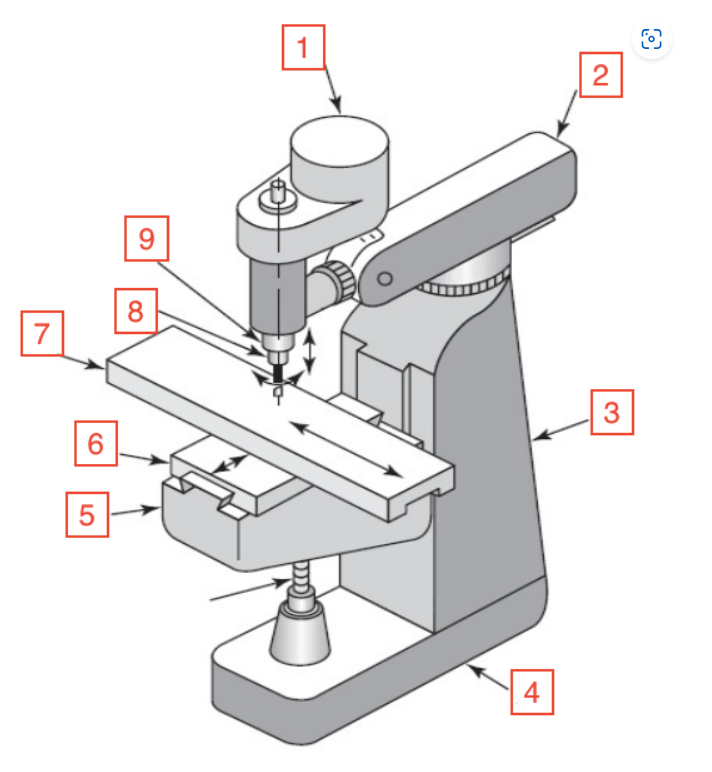

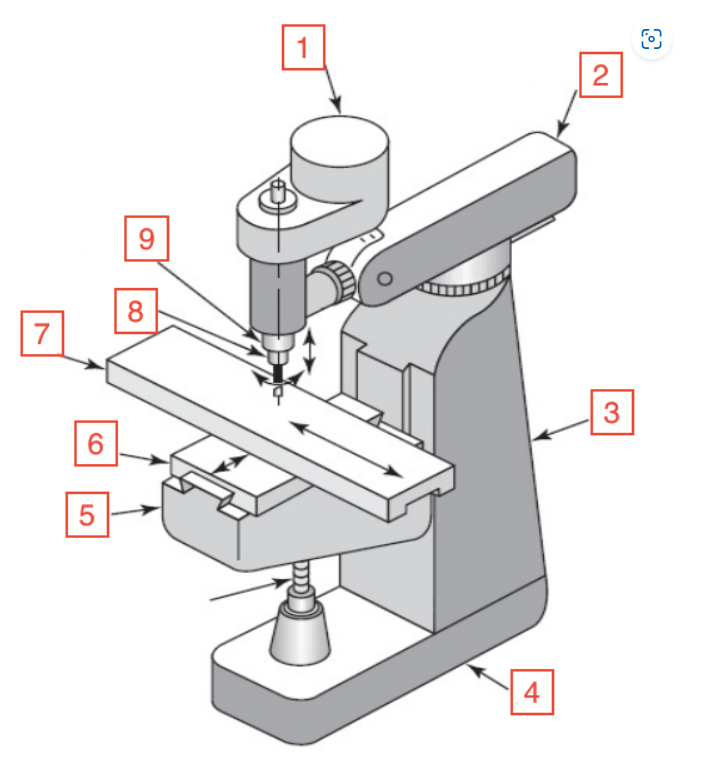

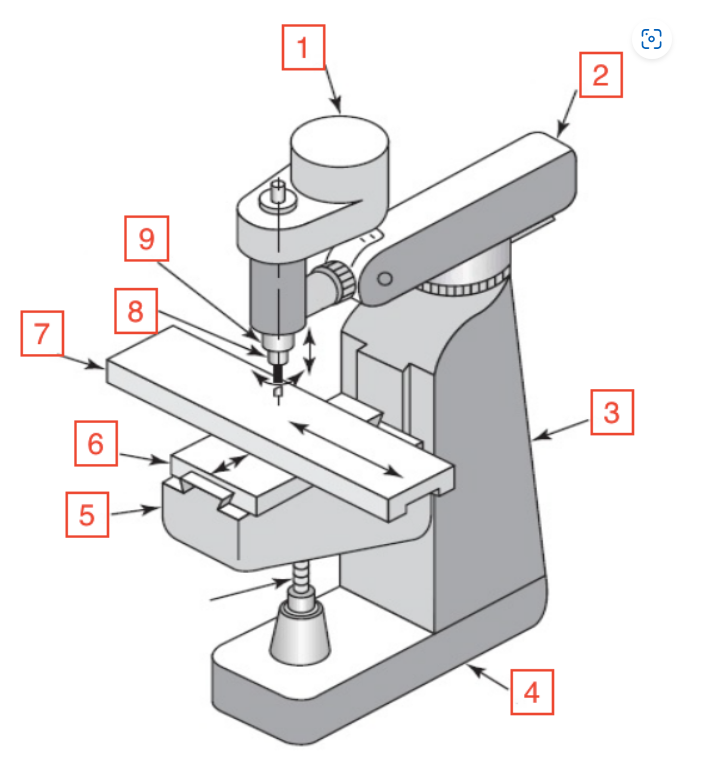

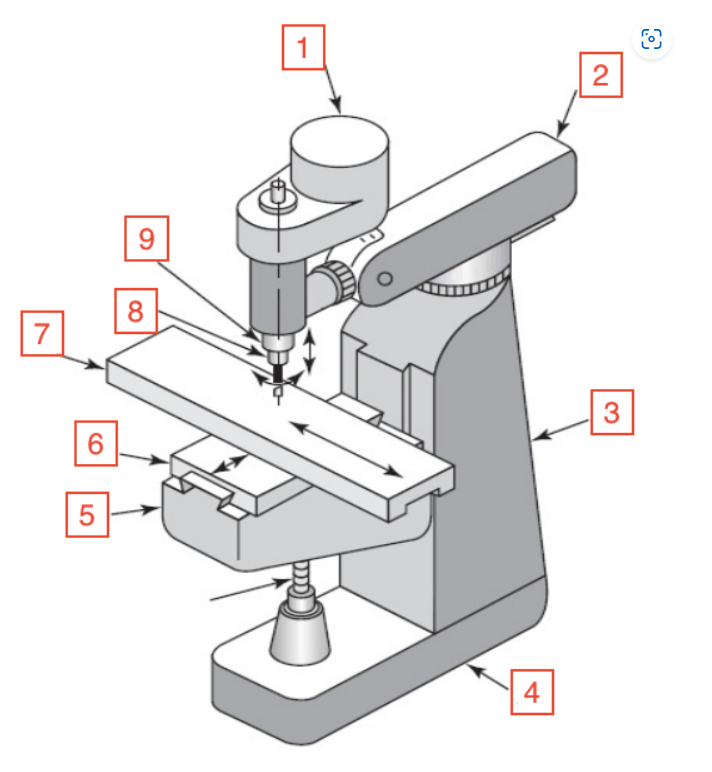

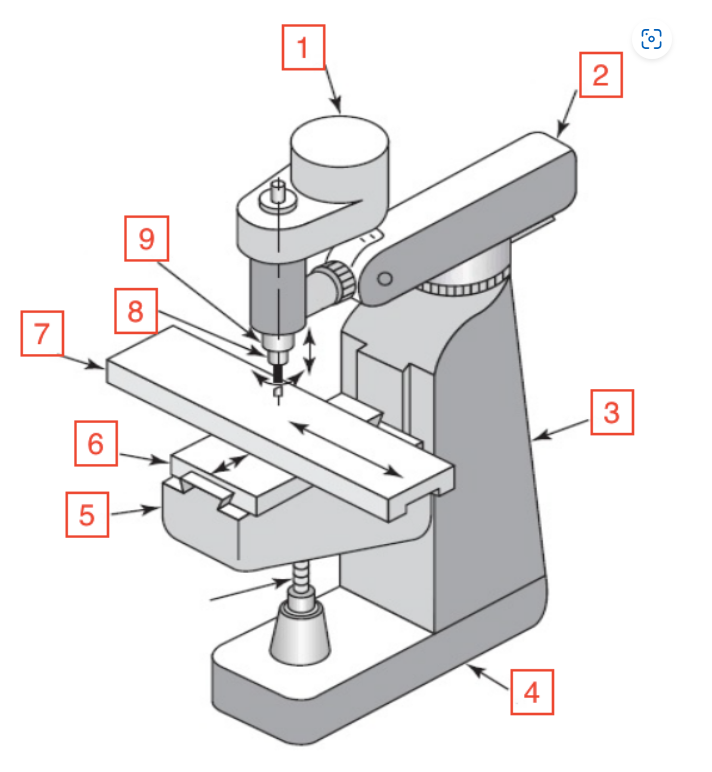

Motor

1

Overarm

2

Column

3

Base

4

Knee

5

Saddle

6

Table

7

Spindle

8

Quill

9

Quill handle

Bar used to move quill up and down on mill

Tap handle, used to twist the tap into the hole

What is this tool and what is its use?

Tap, creates threads in material

What is this tool and what is its use?

End mill, used to cut off larger amounts of material than face mills

What is this tool and what is its use?

Face mill, used to smooth surfaces and make surface level cuts

What is this tool and what is its use?

Reamer, used to make the diameter of holes very precise after they’ve been drilled

What is this tool and what is its use?

Collet, used to hold tools in the mill or lathe

What is this tool and what is its use?

Tool holder, used to hold lathe tools in place

What is this tool and what is its use?

Insert - used to cut material on the lathe

What is this tool and what is its use?

Drill bit - used to drill holes into material

What is this tool and what is its use?

Center drill - used to drill a leading hole into a material to ensure the drill bit is fully aligned when it goes through

What is this tool and what is its use?

Edge finder, used to take a non-destructive zero on the milling machine

What is this tool and what is its use

Drilling

In the "_______" process, a hole is produced by feeding a drill into a rotating workpiece along its axis.

Threading

During a "______" operation, external or internal threads are achieved by feeding a pointed tool linearly across the outside or inside surface of a rotating part.

Knurling

In an operation known as "________," a regular cross-hatched pattern is produced in work surfaces through metal forming.

Boring

A single point tool is fed linearly and parallel to the axis of a workpiece to enlarge a hole made by a previous process in the operation known as "_______."

Facing

Surfaces are typically positioned perpendicular to the axis of the workpiece in the "______" operation. This operation is dominated by radial feed.

Parting

For a "______" operation, the end of a part is cut off by feeding a tool radially into a rotating workpiece at a particular location along its length.

Profiling

In a "______" operation, both modes of tool feed are simultaneously desired to create tapered and contoured surfaces.

Chamfering

For a "_____" operation, a tool cuts the corner of a cylinder at an angle.

Turning

The generation of any cylindrical surface with a single point tool is referred to as "______." In this operation, the direction of the feeding motion is predominantly axial with respect to the machine spindle.

Steel

What material always needs to be oiled when cutting it? (Steel/aluminum)

Drilling

What operation always needs oil regardless of the material or size?

Roughing

Does a roughing or facing pass always need oil with aluminum?

0.02 (20 Thou)

What is the maximum depth of cut to be considered a “facing pass”?

Y Axis

On the mill, which axis is “front to back”?

X Axis

On the mill, which axis is “left and right”?

To clamp things together

What is the ONLY purpose of fasteners?

Endmills have more flutes, drills are usually longer per diameter, and endmills have cutting edges on the side.

What are differences in geometry between endmills and drills?

Cylindrical and conical

What are the two kinds of edge finders?

Stabilizing long parts in the lathe to avoid the moment generated

What is a center finder used for?

A reamer has straight instead of helical flutes.

What is a difference in geometry between a reamer and a drill?