Design of Goods and Services

1/26

There's no tags or description

Looks like no tags are added yet.

Name | Mastery | Learn | Test | Matching | Spaced |

|---|

No study sessions yet.

27 Terms

Goods and Services Selection

Organizations exist to provide goods or services to society

Great products are the key to success

Top organizations typically focus on core products

Customers buy satisfaction, not just a physical good or particular service

Fundamental to an organization's strategy with implications throughout the operations function

Goods or services are the basis for an organization's existence

Limited and predicable life cycles requires constantly looking for, designing, and developing new products

New products generate substantial revenue

Product Decision

The objective of the product decision is to develop and implement a product strategy that meets the demands of the marketplace with a competitive advantage

Product Strategy Options

Differentiation

Shouldice Hospital

Low cost

Taco Bell

Rapid response

Toyota

Product Life Cycles

May be any length from a few days to decades

The operations function must be able to introduce new products successfully

Product Life Cycle and Strategy - Introductory Phase

Fine tuning may warrant unusual expenses for

Research

Product development

Process modification and enhancement

Supplier development

Product Life Cycle and Strategy - Growth Phase

Product design begins to stabilize

Effective forecasting of capacity becomes necessary

Adding or enhancing capacity may be necessary

Product Life Cycle and Strategy - Maturity Phase

Competitors now established

High volume, innovative production may be needed

Improved cost control, reduction in options, paring down of product line

Product Life Cycle and Strategy - Decline Phase

Unless product makes a special contribution to the organization, must plan to terminate offering

Generating New Products

Understanding the customer

Economic change

Sociological and demographic change

Technological change

Political and legal change

Market practice, professional standards, suppliers, distributors

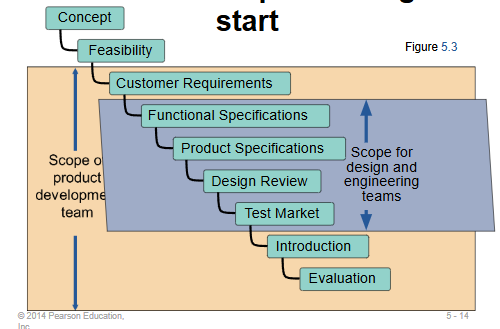

Product Development Stages

Quality Function Deployment

Identify customer wants

Identify how the good/service will satisfy customer wants

Relate customer wants to product hows

Identify relationships between the firm’s hows

Develop customer importance ratings

Evaluate competing products

Compare performance to desirable technical attributes

Organizing for Product Development - Traditionally

distinct departments

Duties and responsibilities are defined

Difficult to foster forward thinking

Organizing for Product Development - Champion

Product manager drives the product through the product development system and related organizations

Organizing for Product Development - Team Approach

Cross functional – representatives from all disciplines or functions

Product development teams, design for manufacturability teams, value engineering teams

Organizing for Product Development - Japanese “whole organization” approach

No organizational divisions

Manufacturability and Value Engineering

Benefits:

Reduced complexity of the product

Reduction of environmental impact

Additional standardization of components

Improvement of functional aspects of the product

Improved job design and job safety

Improved maintainability (serviceability) of the product

Robust design

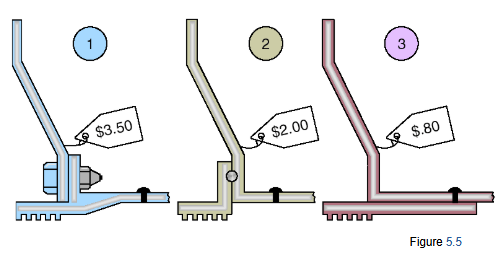

Cost Reduction of a Bracket via Value Engineering

Issues for Product Design

Robust design

Modular design

Computer-aided design (CAD)

Computer-aided manufacturing (CAM)

Virtual reality technology

Value analysis

Sustainability and Life Cycle Assessment (LCA)

Robust Design

Product is designed so that small variations in production or assembly do not adversely affect the product

Typically results in lower cost and higher quality

Modular Design

Products designed in easily segmented components

Adds flexibility to both production and marketing

Improved ability to satisfy customer requirements

Computer Aided Design (CAD)

Using computers to design products and prepare engineering documentation

Shorter development cycles, improved accuracy, lower cost

Information and designs can be deployed worldwide

Extensions of CAD

Design for Manufacturing and Assembly (DFMA)

Solve manufacturing problems during the design stage

3-D Object Modeling

Small prototype development

CAD through the internet

International data exchange through STEP

Computer-Aided Manufacturing (CAM)

Utilizing specialized computers and program to control manufacturing equipment

Often driven by the CAD system (CAD/CAM)

Benefits of CAD/CAM

Product quality

Shorter design time

Production cost reductions

Database availability

New range of capabilities

Virtual Reality Technology

Computer technology used to develop an interactive, 3-D model of a product from the basic CAD data

Allows people to ‘see’ the finished design before a physical model is built

Very effective in large-scale designs such as plant layout

Value Analysis

Focuses on design improvement during production

Seeks improvements leading either to a better product or a product which can be produced more economically with less environmental impact

Sustainability and Life Cycle Assessment (LCA)

Sustainability means meeting the needs of the present without compromising the ability of future generations to meet their needs

LCA is a formal evaluation of the environmental impact of a product