properties of metals

1/38

Earn XP

Description and Tags

Name | Mastery | Learn | Test | Matching | Spaced | Call with Kai |

|---|

No analytics yet

Send a link to your students to track their progress

39 Terms

Names of the ores for…

copper

tin

aluminium

zinc

copper - chalcopyrite

tin - cassiterite

aluminium - bauxite

zinc - zinc blende

Stock forms for metals

Sheet - Thin, flat metal that can be easily cut and shaped, used in roofing, car bodies, and cladding.

Plate - Similar to sheet but much thicker, used in shipbuilding, heavy-duty machinery, and bridges.

Structural

H beam - Large cross-section shaped like an 'H', used in construction for strong load-bearing structures.

I beam - Similar to H beam but with thinner web and flanges, widely used in bridges and buildings.

Tee - T-shaped cross-section, used for reinforcement and structural support.

Channel - U-shaped cross-section, used for framing, bridges, and enclosures.

Angle - L-shaped cross-section, used in frameworks, supports, and reinforcements.

Tube

Round tube - Hollow cylindrical shape, used in piping, handrails, and structural frameworks.

Square tube - Hollow square cross-section, used in construction, frames, and supports.

Rectangular tube - Similar to square tube but with different width-to-height ratios, used in furniture, framework, and structural applications.

Hexagonal tube - Six-sided hollow shape, less common but used in specialist engineering applications.

Bar

Flat bar - Rectangular cross-section, used for framework, gates, and general fabrication.

Round bar - Circular cross-section, used for axles, shafts, and reinforcement.

Square bar - Square cross-section, used for ornamental work, frames, and supports.

Hexagonal bar - Six-sided bar, commonly used for fasteners, bolts, and engineering components.

What is hardness?

The ability of a metal to resist indentation, wear, and abrasion (e.g. hard metals such as tool steel are used in cutting tools and machinery)

What is toughness?

The ability to absorb energy and resist fracture under impact (e.g. high-toughness metals like stainless steel are used in structural applications)

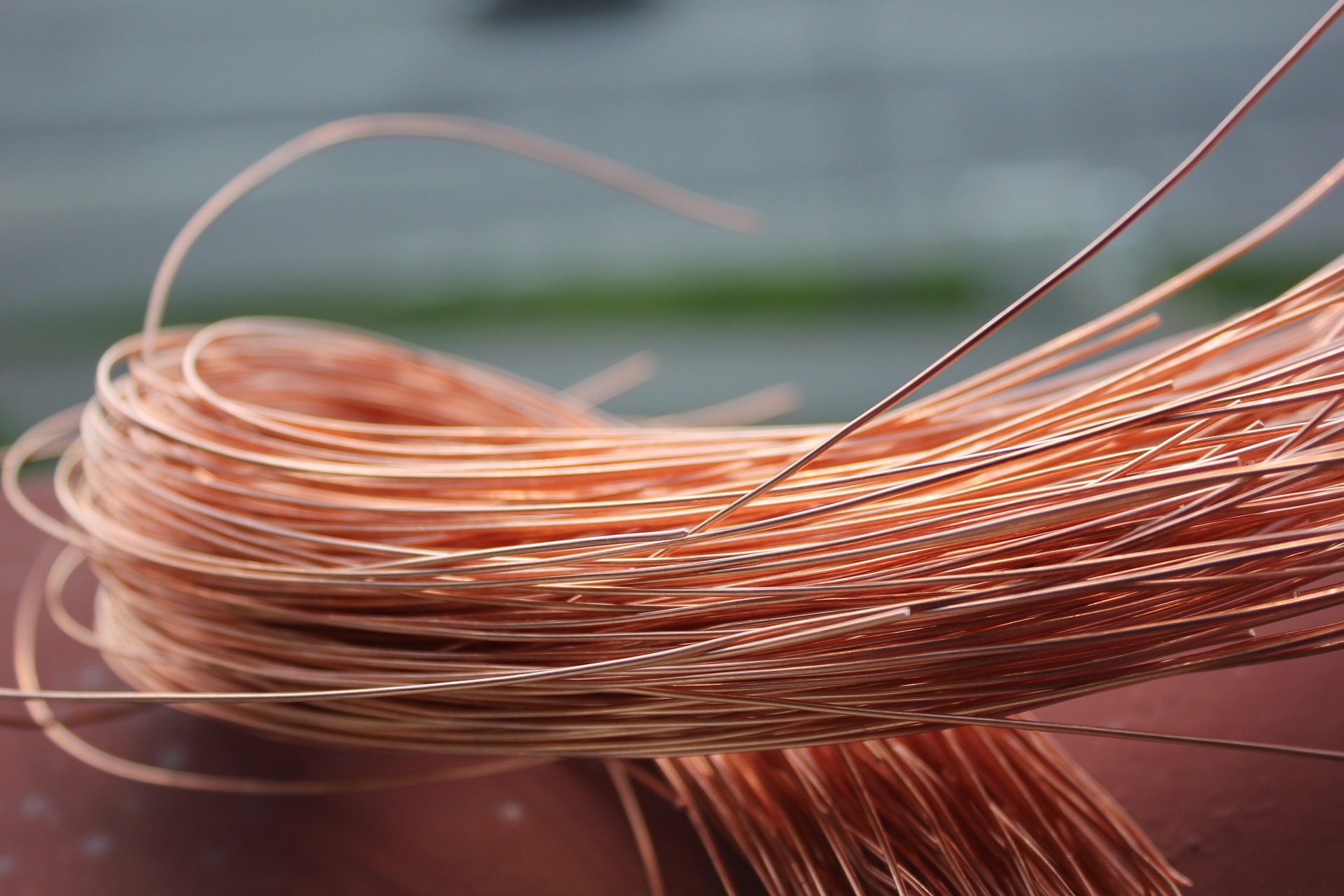

Malleability

The ability to be shaped or deformed under compressive forces without cracking. Copper and aluminium are highly malleable and used in wiring and sheet metal.

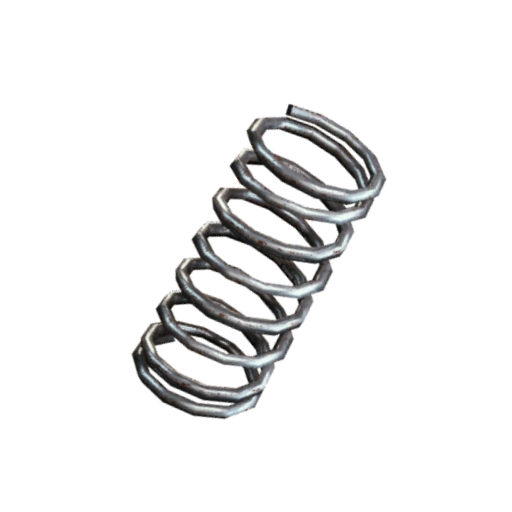

Elasticity

The ability to return to its original shape after being deformed. Spring steel is highly elastic and used in suspension systems

Tensile Strength

The ability to resist stretching forces without breaking. High-tensile steels are used in bridges, cables, and aircraft structures

Density

The mass of the metal per unit volume. Dense metals like lead are used in radiation shielding, while lighter metals like aluminium are used in aerospace

Resistance to Corrosion

The ability to withstand oxidation and environmental damage. Stainless steel and aluminium have good corrosion resistance and are used in marine and outdoor applications.

Thermal Conductivity

The ability to transfer heat efficiently. Copper and aluminium are excellent thermal conductors used in heat exchangers and cookware

Resistance to Corrosion

The ability to withstand oxidation and environmental damage. Stainless steel and aluminium have good corrosion resistance and are used in marine and outdoor applications

Electrical Conductivity

The ability to carry an electrical current. Copper and silver are highly conductive and used in electrical wiring and circuit boards

Melting Points

The temperature at which a metal changes from solid to liquid. High-melting-point metals like tungsten are used in filaments and aerospace applications

Ability to be Alloyed

The ability to mix with other metals to enhance properties

Ability to be Joined with Heat Processes

The ability to be welded, brazed, or soldered. Metals like mild steel are highly weldable and used in fabrication.

Ability to Take Applied Coatings and Finishes

The ability to be painted, anodised, or plated for improved aesthetics and protection. Galvanised steel is coated with zinc to prevent rust.

non-ferrous

CAT GSTZ

Non-ferrous metals are more corrosion resistant than ferrous metals

Non-ferrous metals tend to be more expensive than ferrous metals due to their rarity

Non-ferrous metals tend to be lighter than ferrous metals

Copper

Non-ferrous - melting point 1080c, used for plumbing, electrical components, cookware, roof coverings

Advantages

Good heat and electrical conductor

Ductile

Malleable

Soft

Disadvantages

Needs annealing when worked

Danger of electrolysis when in contact with water

Corrodes easily

Expensive

Aluminium

Non-ferrous - melting point 660c, used for window frames, cooking foil, ladders, expensive bike frames

Advantages

Lightweight

Corrosion resistant

Good conductor of electricity

Malleable

Though

Disadvantages

Cracks under stress

Needs annealing when worked

Does not withstand great loads

Tin

Non-ferrous - melting point 230c, used for food cans, beer cans, whistles, tin foil and solder (rarely used pure)

Advantages

Malleable

Ductile

Corrosion resistant

Disadvantages

Hard to recycle

Not very strong

Gold

Non-ferrous - melting point 1340c, used for jewellery and in computers

Advantages

Highly corrosion-resistant

Excellent electrical conductivity

Soft and easily shaped

Non-reactive and biocompatible

Attractive appearance

Disadvantages

Extremely expensive

Soft and wears easily unless alloyed

Heavy

Silver

Non-ferrous - melting point 960c, used for jewellery, high quality cutlery, coins, trophies and mirror

Advantages

Excellent electrical and thermal conductivity

Highly corrosion-resistant

Soft and easily worked

Antimicrobial properties

Attractive appearance

Disadvantages

Expensive

Soft and prone to scratching

Tarnishes over time

Titanium

Non-ferrous - melting point 1670c, used for aircraft, ship hulls and joint replacement

Advantages

High strength-to-weight ratio

Excellent corrosion resistance

Biocompatible (non-toxic and non-reactive in the body)

Resistant to extreme temperatures

Good fatigue resistance

Disadvantages

Expensive to produce

Difficult to machine

Poor thermal and electrical conductivity

Zinc

Non-ferrous - melting point 420c, used to galvanise / coat screws, steel buckets, batteries

Advantages

Corrosion resistant

Self-healing

Recyclable

Durable

Disadvantages

Low toughness

Brittle when worked

May corrode when in contact with water/moisture for a long time

non ferrous alloy

BBDP

Brass

Non ferrous alloy - alloy of copper and zinc melting point 1670c, used for instruments, firearms cartridges, taps (casts well)

Advantages

Casts well

Easy to machine

Good conductor of heat and electricity

Low friction coefficent

Strong (not as strong as steel, but stronger than copper)

Disadvantages

Susceptible to cracking when cold worked

Needs to be constantly annealed

Not very corrosion resistant

Bronze

Non ferrous alloy - alloy of mainly copper with tin melting point 1670c, used for ship propellers, underwater fittings, statues and medals

Advantages

Corrosion-resistant, especially in marine environments

Strong and durable

Good wear resistance

Low friction properties

Good electrical conductivity

Disadvantages

More expensive than brass and steel

Can be brittle

Heavier than aluminium and some other non-ferrous metals

Duralumin

Non ferrous alloy - alloy of mainly aluminium, copper, manganese melting point 600c, used for aircraft and vehicle parts

Advantages

Lightweight

Strong (similar to LCS)

Casts well

Tough/hard

Disadvantages

Not corrosion resistant

Brittle

Pewter

Non ferrous alloy - melting point 200c, used for flasks, photo frames, decorative objects and candlesticks

Advantages

Low melting point, easy to cast

Does not tarnish easily

Soft and easy to shape

Attractive silvery appearance

Disadvantages

Very soft, can be easily scratched or dented

Limited structural strength

Some older pewter alloys contain lead, which is toxic

Ferrous metals

LMC SH

As carbon content is increased, ferrous metals become more brittle and harder

Ferrous metals contain iron which makes them magnetic

Ferrous metals are prone to rust and corrosion due to the iron within the metals

Ferrous metals tend to be used in construction and as tools due to their good mechanical properties

Steel properties

The higher the carbon content, the harder, tougher and less ductile

Low carbon steel (LCS)

Ferrous - uses up to 0.25% carbon melting point 1430c, used for nuts, bolts and car bodies

Advantages

Easy to machine and weld

Good ductility and toughness

Low cost and widely available

Can be case-hardened for improved wear resistance

Disadvantages

Low tensile strength

Prone to rusting if not protected

Not suitable for high-stress applications

Medium Carbon Steel

Ferrous - melting point 1490c, used for springs and gardening tools

Advantages

Harder than mild steel

Ductile

Strong material

Wear resistant

Disadvantages

Due to increased carbon content it is less ductile/malleable than mild steel

Hard to shape/cut

Cast Iron

Ferrous - melting point 1150c, used for machinery, cooking pots, and pipes

Advantages

Good casting properties

High machinability

Good wear resistance

Corrosion resistant

Disadvantages

Very heavy

Brittle

Low tensile strength

Stainless Steel (11%+ Chromium content)

Ferrous - melting point 1510c, used for cutlery, chemical processing equipment and surgical

Advantages

Excellent corrosion resistance

Strong and durable

Good aesthetic appearance

Heat and chemical resistant

Disadvantages

More expensive than carbon steels

Lower thermal conductivity

Difficult to machine and weld

High Speed Steel (HSS)

Ferrous - melting point 1430c , used for drill bits, lathe tools, cutting tools

Advantages

Can withstand high temperatures

Retains hardness when heated

Highly wear-resistant

Excellent cutting performance

Disadvantages

Brittle compared to other steels

More expensive than carbon steels

Difficult to machine

ferrous alloy

SD

Die Steel

Ferrous alloy - melting point 1460c, used for blanking punches and dies

Advantages

Extremely hard and durable

High wear resistance

Can withstand high temperatures

Good impact resistance

Can be hardened and tempered

Disadvantages

Expensive compared to standard steels

Difficult to machine

Can be brittle if not properly heat-treated

Stainless Steel (Chromium, Nickel, Steel)

Ferrous alloy - melting point 1510c, used for kitchen utensils, medical tools and construction

Advantages

Corrosion resistant

Heat resistant

Can be recycled

Good strength to weight ratio

Hygenic/non-toxic

Disadvantages

Expensive

Hard to machine