03 Material Characterization and Mechanical Properties

1/40

There's no tags or description

Looks like no tags are added yet.

Name | Mastery | Learn | Test | Matching | Spaced |

|---|

No study sessions yet.

41 Terms

Which kind of testing methods are there?

Destructive testing: characterization of material properties and validation of component parameters in test & design phases, control

Non-destructive testing: quality assurance, inspection

Examples of destructive testing (6)

Tension test

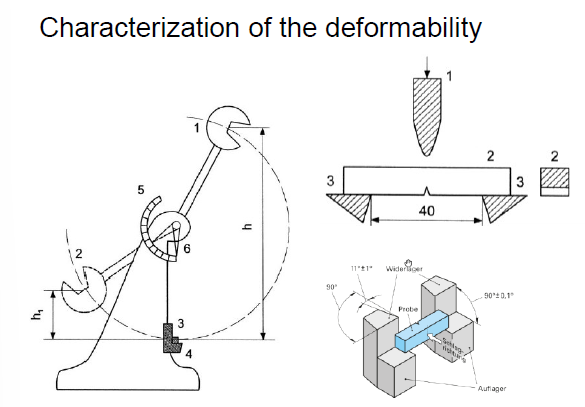

Compression test

Bending test

Hardness test

Creep test

Fatigue test

Examples of non-destructive testing (3)

Ultrasonic inspection

X-ray

Acoustic emission

Usual loads for material characterization (5)

Tensile

Compressive

Shear

Torsional

Bending

Are testing methods standarized?

Yes, normally by DIN or ISO

What are isotropic materials?

Materials with the same properties in every direction

Whar are orthotropic properties?

Properties that vary as a function of the direction

What is the setup for a tensile test? (6)

Electro-mechanical test frame with moveable traverse and gauge to determine position s

Material specimen

Gripper

Mechanical extensomenter/strain gauge/optical extensometer to measure ΔL

Load cell to determine F

Data acquisition device over time t

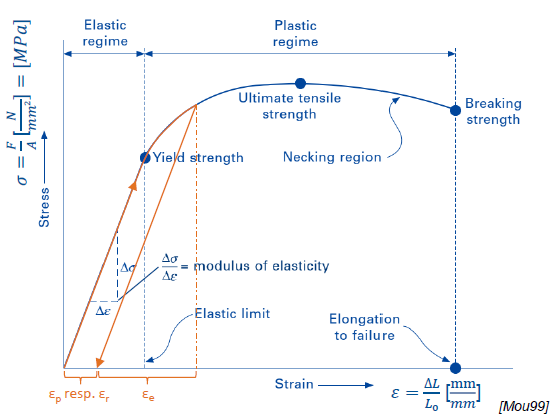

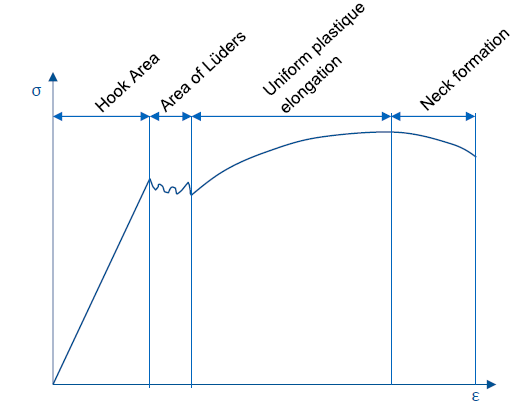

Which parameters can be read from the Stress-Strain-Diagram? (7)

Modulus of elasticity (E)

Proportional limt

Yield strength

Ultimate tensile strength

Elastic strain (strain in elastic (linear) region)

Plastic strain

Elongation to failure

What is the elastic region?

Region in which deformation is reversible (no permanent deformation after loading)

What is the plastic region?

Region in which deformation is permanent

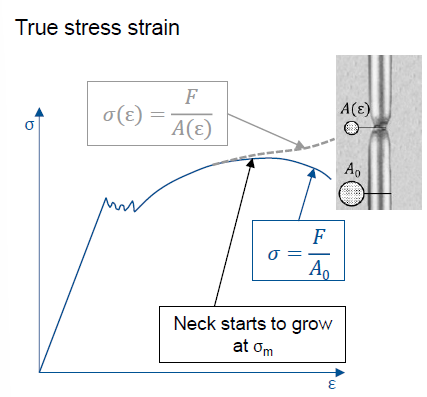

What is the ultimate tensile strength?

Point in which σ is max.

What is the breaking strength?

σ close to failure of specimen

What is the elongation to failure?

ε at breaking strength

What is the yield strength?

σ at the elastic limit (σ withstand by the material without undergoing plastic deformation)

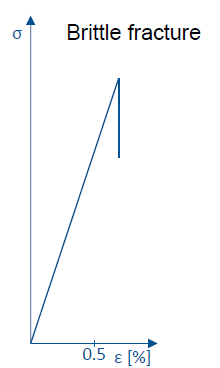

How does brittle fracture look like?

High E and abrupt break at (yield point, elastic limit)

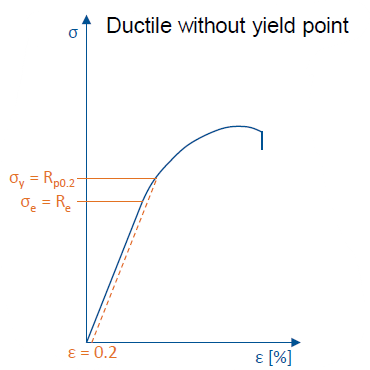

How does a ductile fracture without yield point look like?

Continuous graph without oscillations and eventual break in plastic region

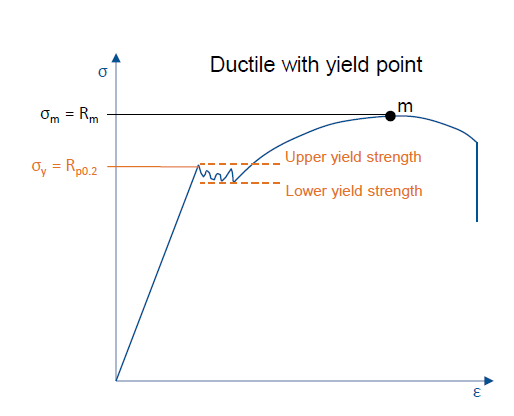

How does a ductile fracture without yield point look like?

Continuous graph with oscillations aroud yield point (between lower and upper yield strength) and eventual break in plastic region

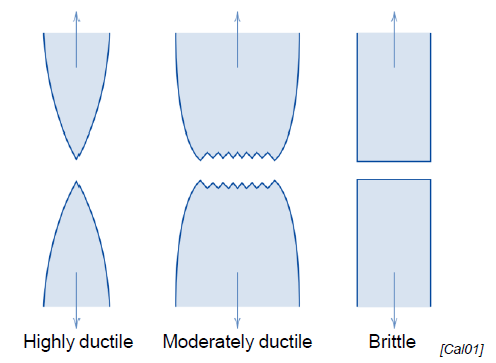

Ductile vs. Brittle fracture

Where does the neck appear in the σ-ε-Diagram?

After the ultimate strength

What are the regions of the σ-ε-Diagram?

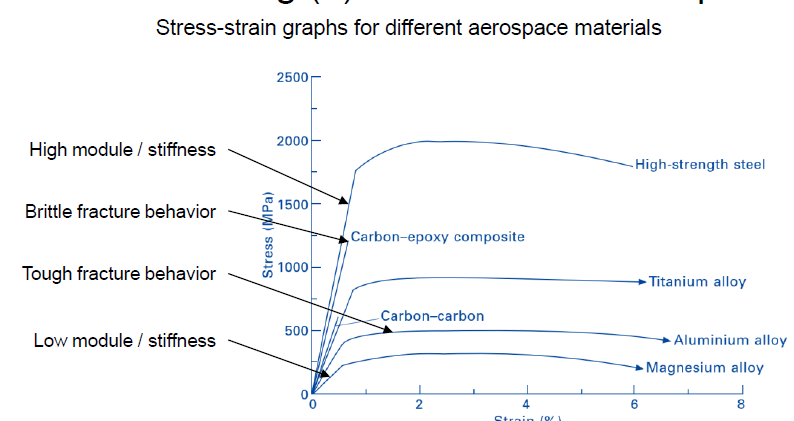

How are aerospace materials ordered in a σ-ε-Diagram? (4 by E)

Magnesium Alloy < Aluminium Alloy < Titanium Alloy < Carbon-Carbon (brittle) < Carbon-epoxy composite (brittle) < High-strength Steel

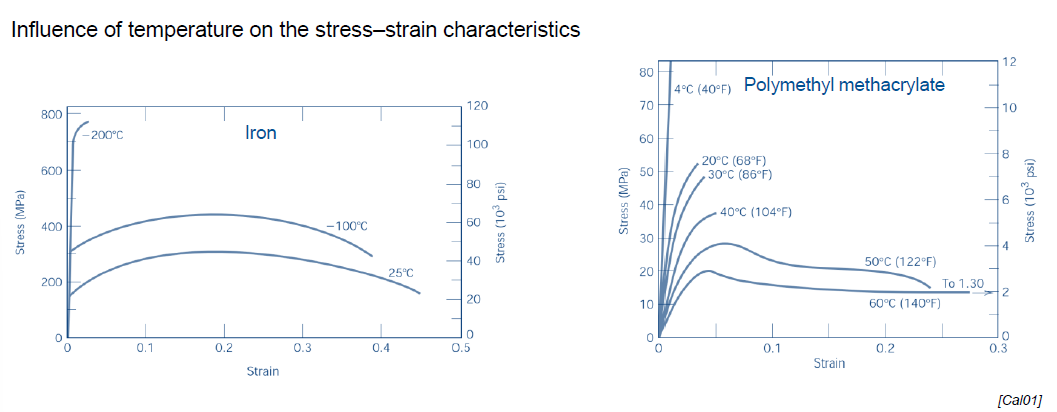

What is the relation between temperature and σ-ε-Diagram?

The higher the temperature, the more ductile the material

The lower the temperature, the more brittle the material

How is hardness defined?

Resistance of a material to penetration by another materials

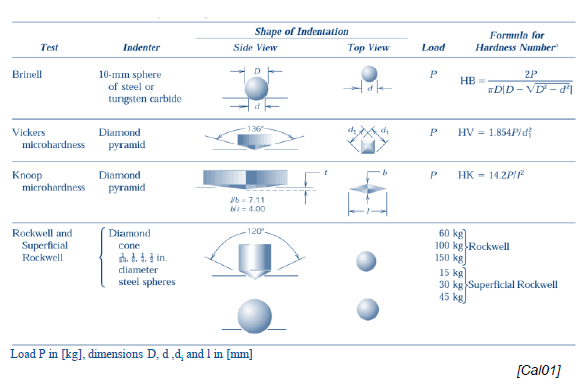

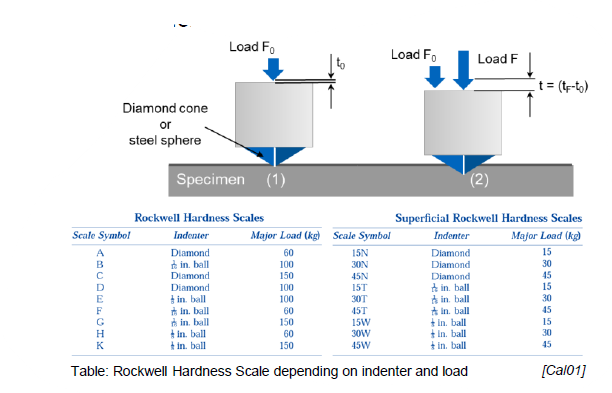

Which methods are used to test hardness? (5)

Brinell (HB)

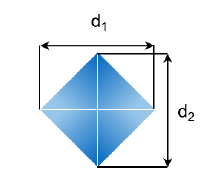

Vickers (HV)

Rockwell

Knoop (HK)

Shore

What are general characteristics of hardness tests?

Only slightly destructive (small indentation)

Inexpensive

Used for quality assurance in production lines (deviations in composition/production is detectable in the grade of hardness)

What is the indenter of every main hardness test?

Brinell: sphere

Vickers: pyramid

Knoop: pyramid

Rockwell: cone (double sphere)

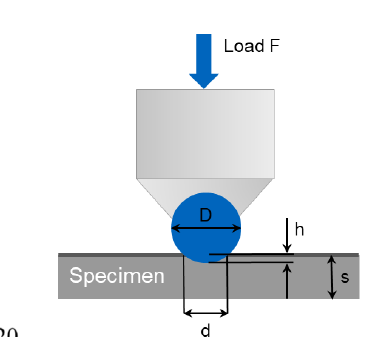

Pros and cons of Brinell:

Pros:

Measure medium hardness for heterogenous materials

Cons:

Not for thin layer materials

For hard materials the load is too large

Pros and cons of Vickers:

Pros:

Wide range of materials

Thin plates

More precise than Brinell

Pros and cons of Rockwell:

Pros:

Quick and automatable

Cons:

Small indenter, sensitive local effects

Reduced accuracy at high hardness

Various scales

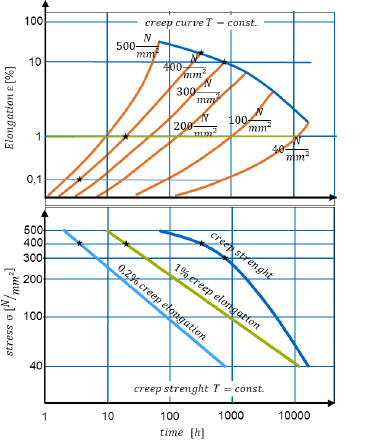

What is creep?

Tendency of a solid material to slowly and permanently deform under the influence of constant mechanical stresses over extended periods, often at elevated temperatures.

How is creep displayed normally?

With a creep curve (elongation as a function of time (logarithmic) for a given temperature)

With the creep strength (withstood stress as a function of time (log) for a given temperature)

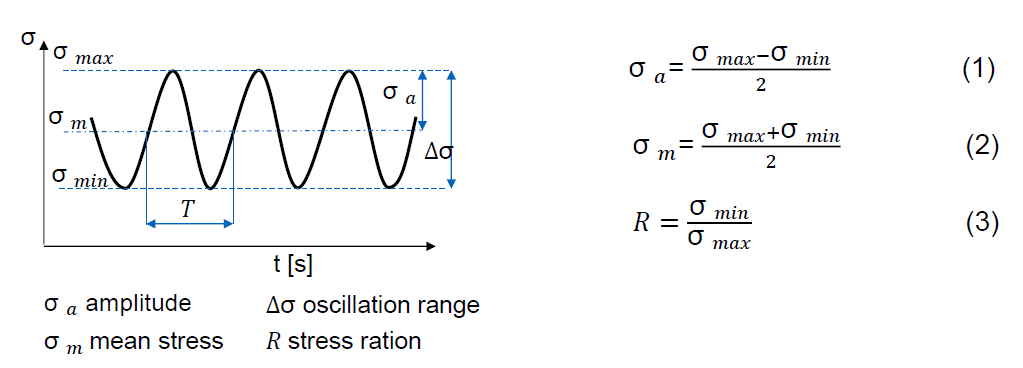

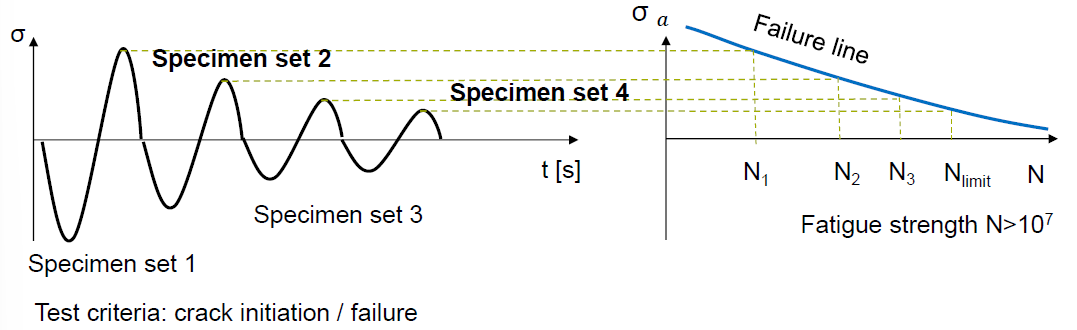

What is fatigue?

Progressive and localized structural damage that occurs when a material is subjected to cyclic or fluctuating stresses or strains

Like creep but due to cyclic loads and not to constant loads

Ex: bending repeatedly a plastic fork until it breaks

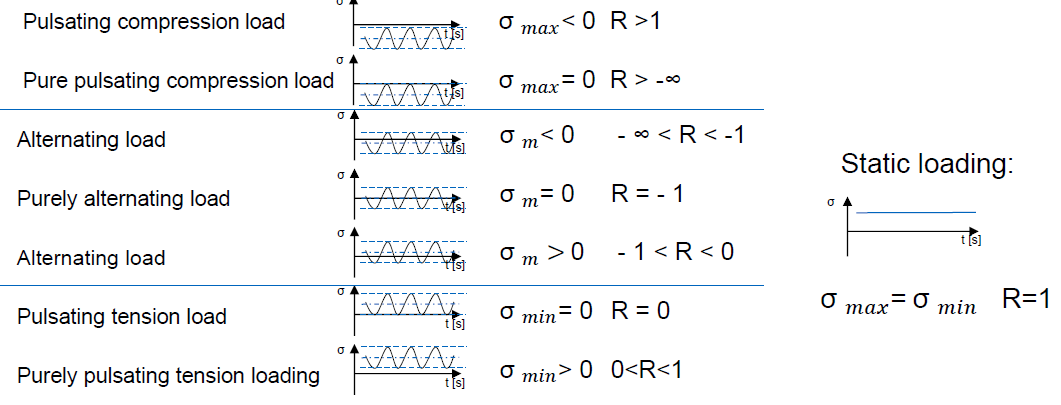

Through which load cases is fatigue tested? (7)

Pulsating compression load (σmax < 0; R > 1)

Pure pulsating compression load (σmax = 0; R > -infinite)

Alternating load (σm < 0; -infinite < R < -1)

Pure alternating load (σm = 0; R = -1)

Alternating load (σm > 0; -1 < R < 0)

Pulsating tension load (σmin = 0; R = 0)

Pure pulsating tension load (σmin > 0; 0 < R < 1)

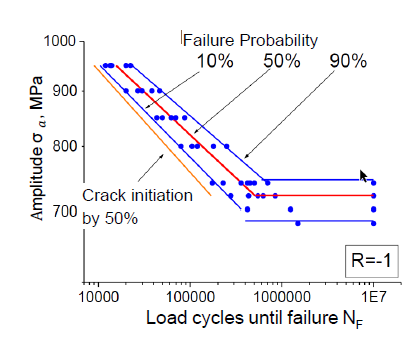

What is described by the Wöhler Curve?

How the stress withstood by an specimen decreases as a function of the number of cycles of the applied load for a given load case

How does an impact bending test works?

A standarized specimen is stricken with a pendulum hammer

Suitable for comparative assessment only

High impact → ductile fracture

Low impact energy → brittle fracture

SQ: What information do you get out of the uniform plastic elongation zone which you get out of a tension test?

Yield point (initial point)

Ultimate strength (final point)

SQ: Is it possible to use the Brinell hardness with thin sheet metals? If yes, under which circumstances?

In general, no. Only if s >= 8h (thickness of sheet bigger or equal to 8 times the indentation depth)

SQ: How does a yield strength behave with temperature?

Is lower for higher temperatures

SQ: Which types of test methods are available?

Destructive

Non-destructive

SQ: How does a typical test method work?

Setup

Initial, standarized, known conditions

Physical relations

Measurements

Calculations

Output