Materials of Construction

1/319

There's no tags or description

Looks like no tags are added yet.

Name | Mastery | Learn | Test | Matching | Spaced |

|---|

No study sessions yet.

320 Terms

High temperature strength

Ability to resist corrosion

What are the two (2) overriding considerations that must be prioritized when selecting engineering materials for chemical process plants?

READ.

Under introduction,

The process engineer will be responsible for recommending materials that will be suitable for the process conditions.

The process engineer must also consider the requirements of the mechanical design engineer; the material selected must have sufficient strength and be easily worked.

Other factors, such as product contamination and process safety, must also be considered.

READ.

Under introduction,

The process engineer will be responsible for recommending materials that will be suitable for the process conditions.

The process engineer must also consider the requirements of the mechanical design engineer; the material selected must have sufficient strength and be easily worked.

Other factors, such as product contamination and process safety, must also be considered.

True

(ADDITIONAL: This material will have the lowest cost over the working life of the plant, allowing for maintenance and replacement.)

TRUE OR FALSE. The most economical material that satisfies both process and mechanical requirements should be selected.

Mechanical properties

Effect of temperature on mechanical properties

Corrosion resistance

Any special properties required

Ease of fabrication

Availability in standard sizes

Cost

MATERIAL PROPERTIES. Determine what is being asked below.

Enumerate the seven (7) most important characteristics to be considered when selecting a material of construction.

Mechanical properties

MATERIAL PROPERTIES. Determine what is being asked below.

Examples of this characteristic include strength, stiffness, toughness, hardness, fatigue resistance, and creep resistance.

Availability in standard sizes

MATERIAL PROPERTIES. Determine what is being asked below.

Examples of this characteristic include plates, sections, and tubes.

Special properties required

MATERIAL PROPERTIES. Determine what is being asked below.

Examples of this characteristic include thermal conductivity, electrical resistance, magnetic properties, etc.

Effect of temperature on mechanical properties

MATERIAL PROPERTIES. Determine what is being asked below.

Examples of this characteristic include the effects of high temperature, low temperature, and thermal cycling.

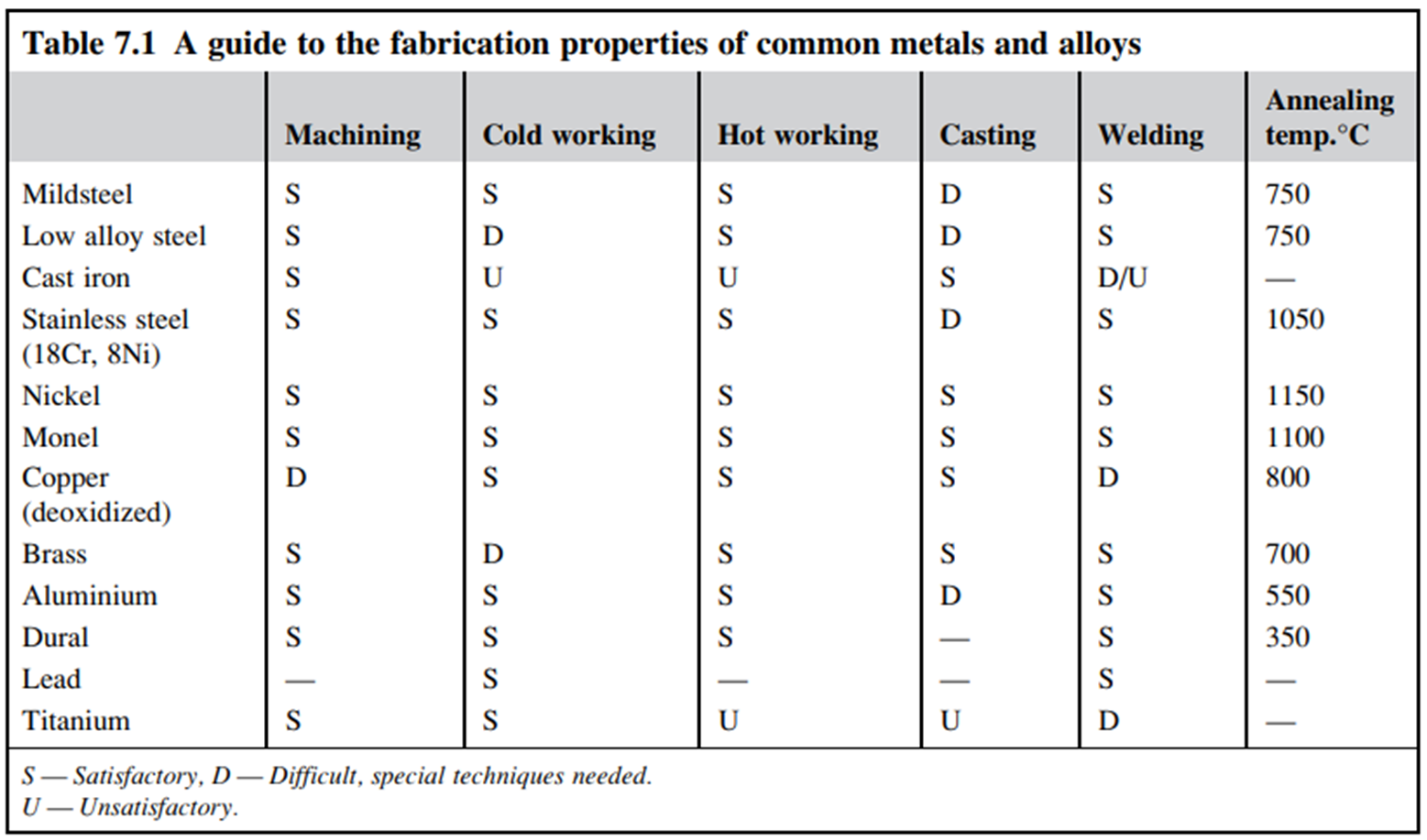

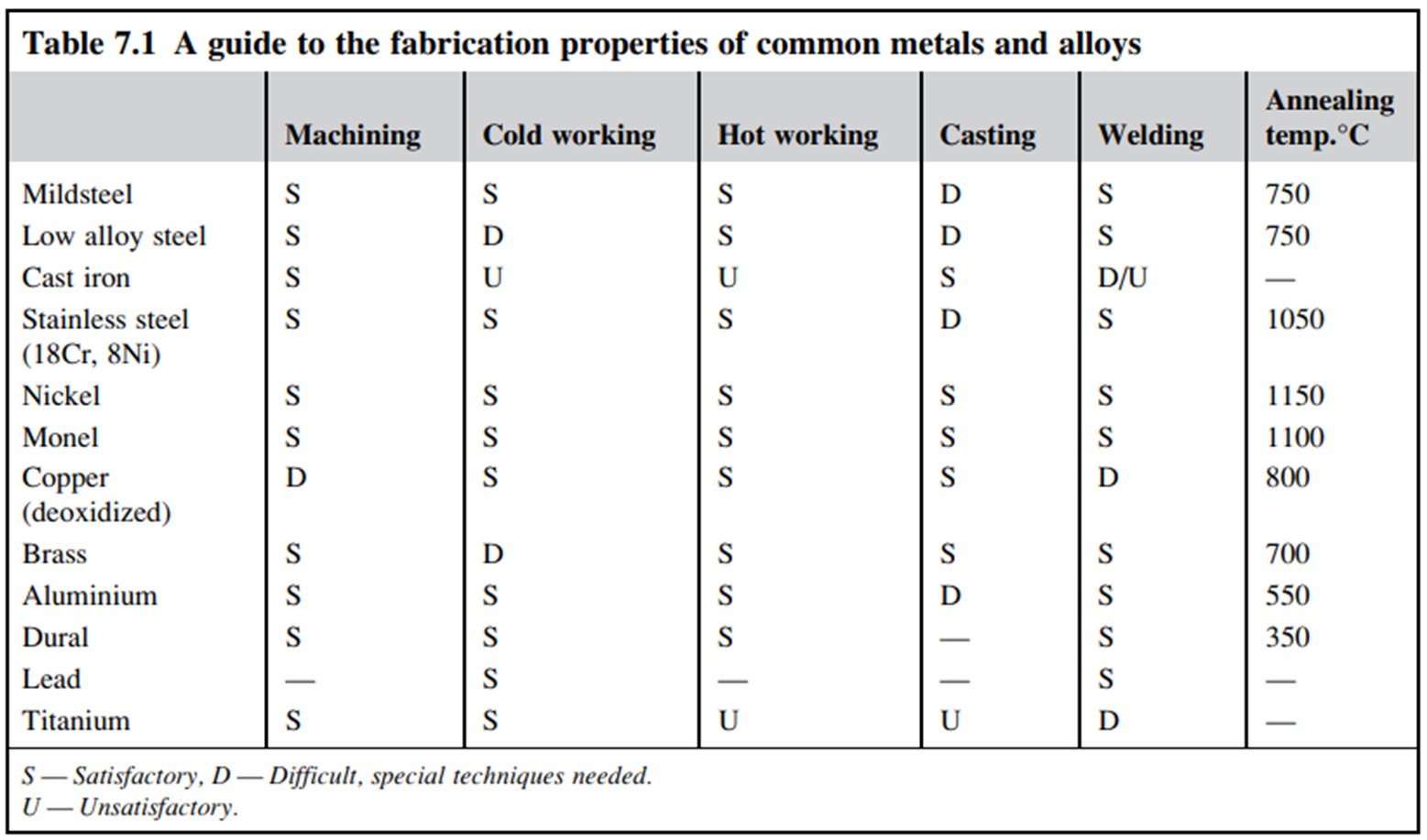

Ease of fabrication

MATERIAL PROPERTIES. Determine what is being asked below.

Examples of this characteristic include forming, welding, casting, and more.

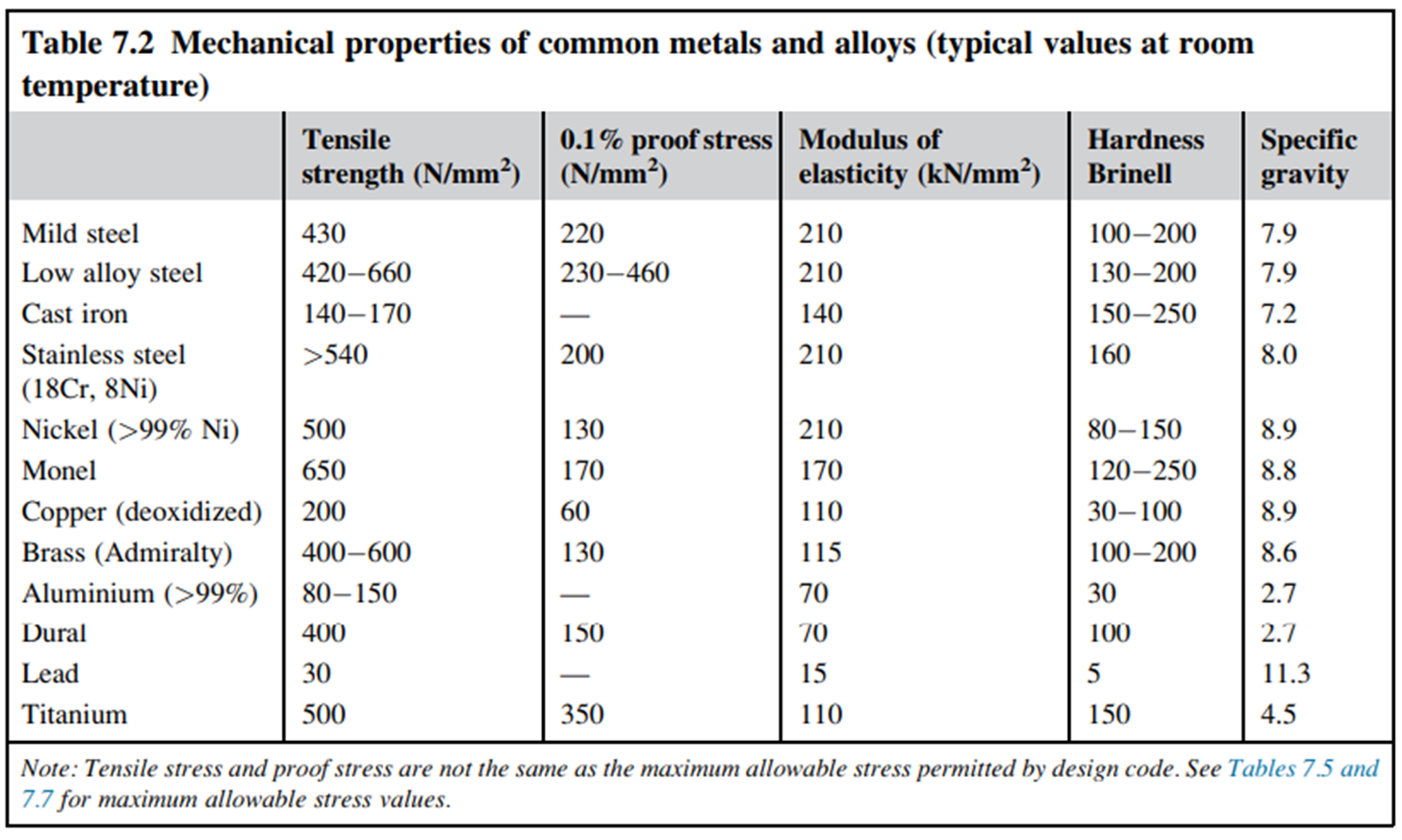

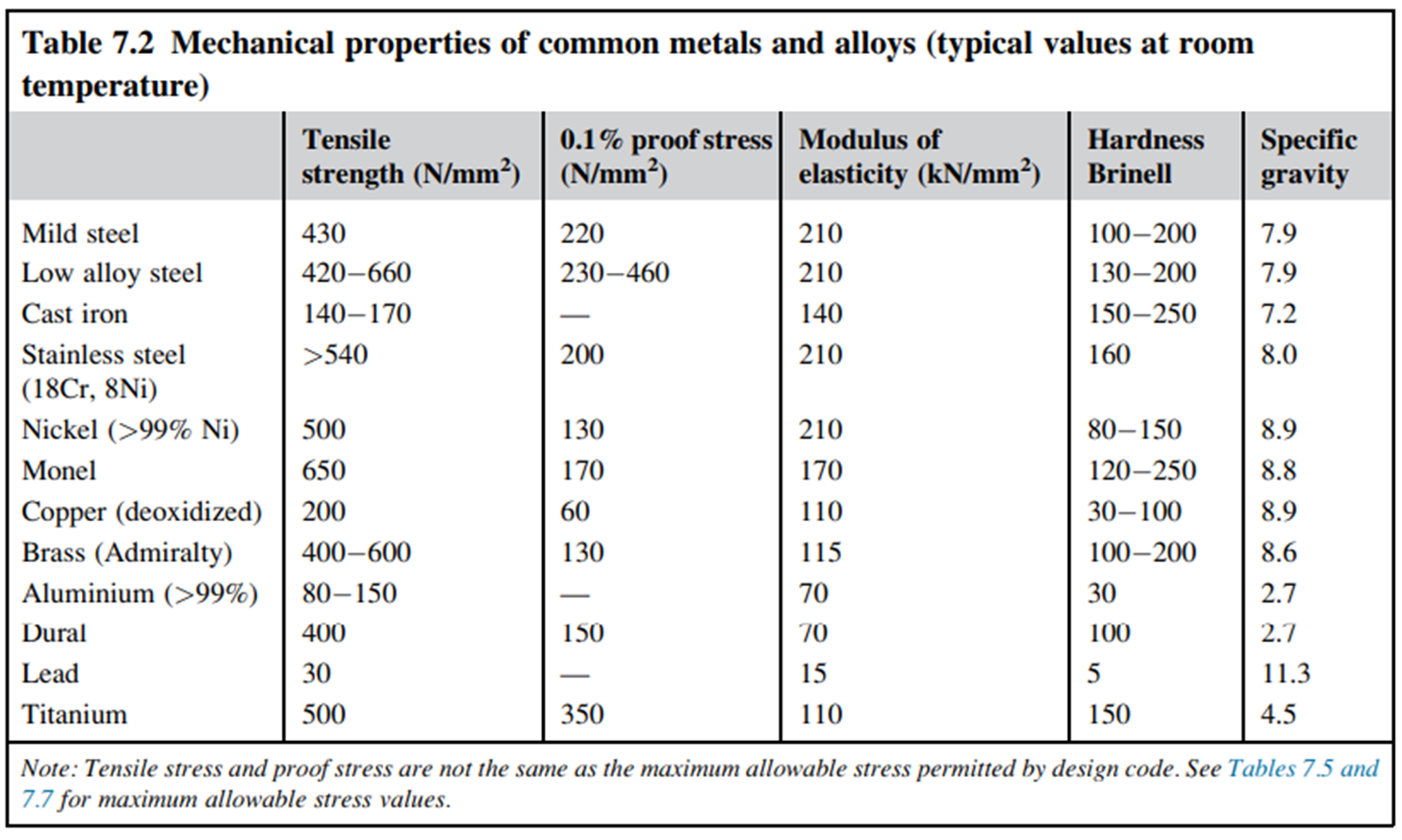

Strength (tensile strength)

Stiffness

Toughness

Hardness

Fatigue resistance

Creep resistance

MECHANICAL PROPERTIES. Determine what is being asked below.

Enumerate the six (6) mechanical properties of materials mentioned in the module.

Tensile strength or stress

MECHANICAL PROPERTIES. Determine what is being asked below.

It is a measure of the basic strength of a material.

Ultimate tensile strength (UTS)

MECHANICAL PROPERTIES. Determine what is being asked below.

It is the older name for tensile strength or stress.

Proof stress

MECHANICAL PROPERTIES. Determine what is being asked below.

It is the stress to cause a specified permanent extension (~0.1 %).

Tensile strength/stress

MECHANICAL PROPERTIES. Determine what is being asked below.

It is the maximum stress that the material will withstand, measured by a standard tensile test.

READ.

Under tensile strength/stress,

The maximum allowable stresses specified by the ASME Boiler and Pressure Vessel (BPV) Code and the European EN 13445 pressure vessel code are calculated from these and other material properties at the design temperature.

READ.

Under tensile strength/stress,

The maximum allowable stresses specified by the ASME Boiler and Pressure Vessel (BPV) Code and the European EN 13445 pressure vessel code are calculated from these and other material properties at the design temperature.

Stiffness

MECHANICAL PROPERTIES. Determine what is being asked below.

It is the ability to resist bending and buckling.

Stiffness

MECHANICAL PROPERTIES. Determine what is being asked below.

It is an indicator of the tendency for an element to return to its original form after being subjected to a force.

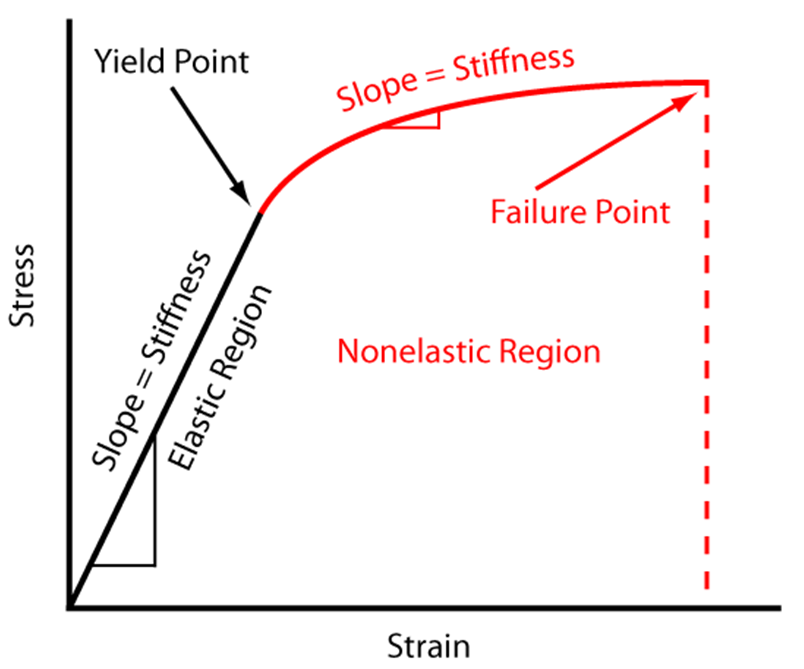

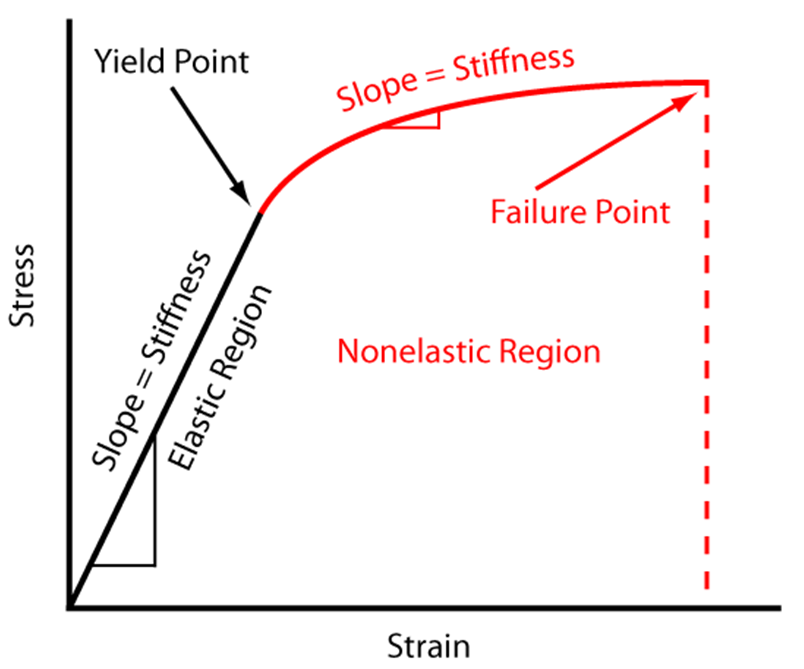

A stress-strain curve shows how a material deforms under stress, illustrating its elastic and plastic behavior until failure.

A stress-strain curve shows how a material deforms under stress, illustrating its elastic and plastic behavior until failure.

Stiffness

MECHANICAL PROPERTIES. Determine what is being asked below.

It is a function of the elastic modulus of the material and the shape of the cross-section of the member (the second moment of area).

Strength

MECHANICAL PROPERTIES. Determine what is being asked below.

It measures how much stress can be applied to an element before it deforms permanently or fractures.

Toughness

MECHANICAL PROPERTIES. Determine what is being asked below.

It is a measure of the material’s resistance to crack propagation.

True

MECHANICAL PROPERTIES. Determine what is being asked below.

TRUE OR FALSE. Toughness is associated with tensile strength.

False

(EXPLANATION: Brittle materials are weak in tension but strong in compression.)

MECHANICAL PROPERTIES. Determine what is being asked below.

TRUE OR FALSE. Brittle materials are strong in tension but weak in compression.

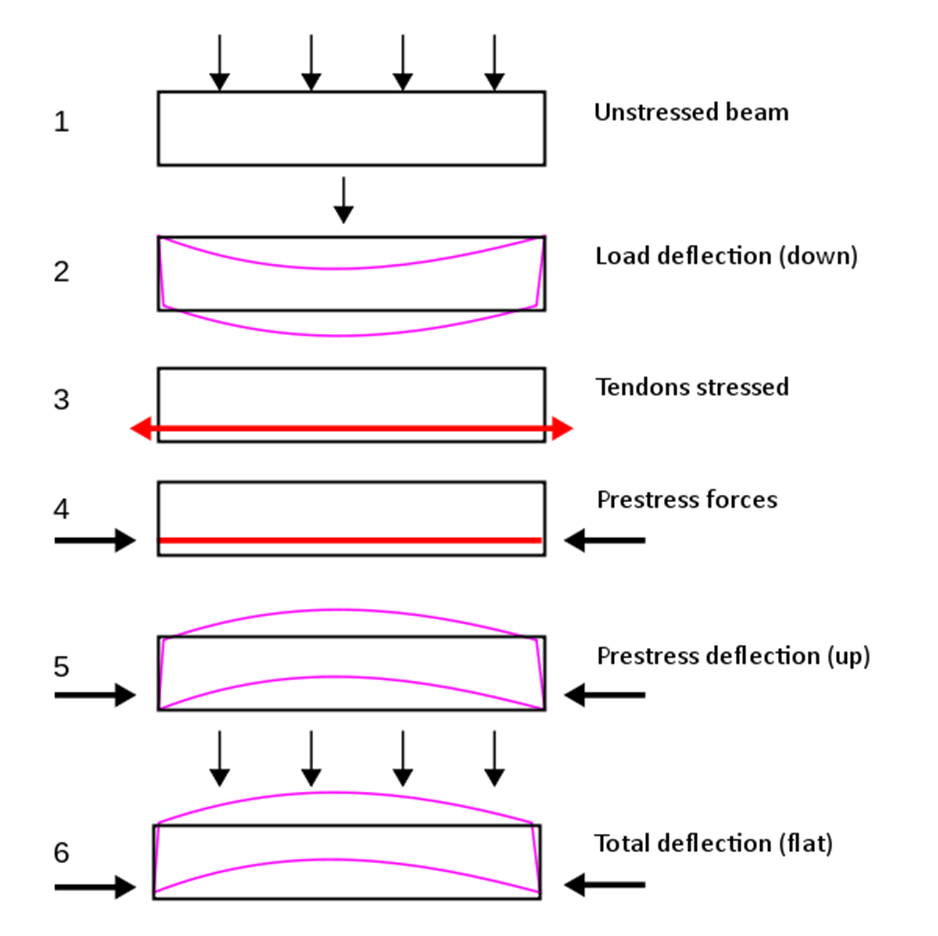

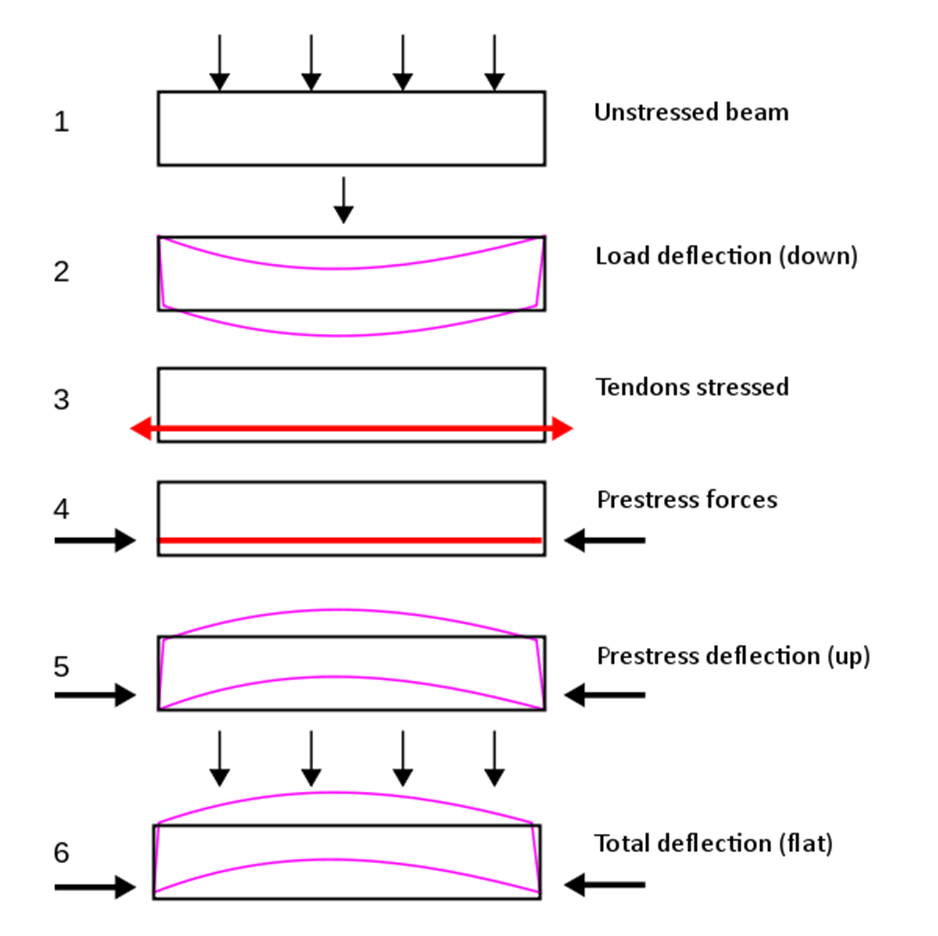

READ.

Under toughness,

The crystal structure of ductile materials, such as steel, aluminum, and copper, is such that they stop the propagation of a crack by local yielding at the crack tip.

In other materials, such as cast irons and glass, the structure is such that local yielding does not occur, and the materials are brittle.

Under compression, any incipient cracks present are closed up.

Various techniques have been developed to allow the use of brittle materials in situations where tensile stress would normally occur. (Ex.: The use of pre-stressed concrete, and glass-fibre-reinforced plastics in pressure vessel construction.)

READ.

Under toughness,

The crystal structure of ductile materials, such as steel, aluminum, and copper, is such that they stop the propagation of a crack by local yielding at the crack tip.

In other materials, such as cast irons and glass, the structure is such that local yielding does not occur, and the materials are brittle.

Under compression, any incipient cracks present are closed up.

Various techniques have been developed to allow the use of brittle materials in situations where tensile stress would normally occur. (Ex.: The use of pre-stressed concrete, and glass-fibre-reinforced plastics in pressure vessel construction.)

READ.

Under pre-stressing of concrete,

Internal stresses are induced to counteract external stresses.

READ.

Under pre-stressing of concrete,

Internal stresses are induced to counteract external stresses.

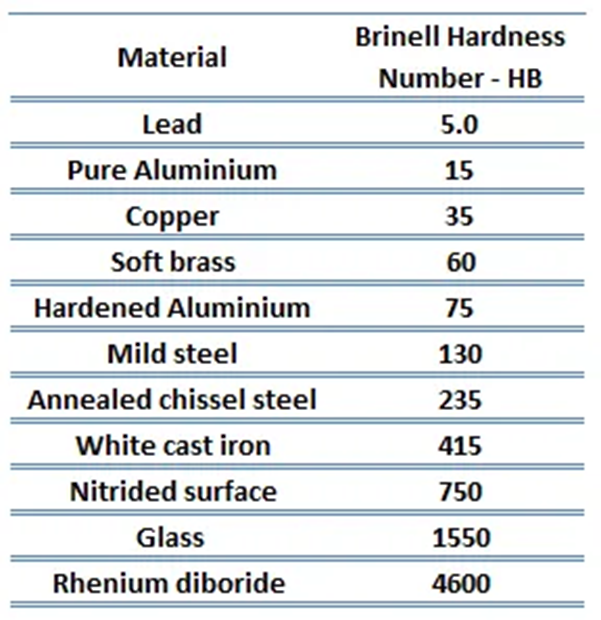

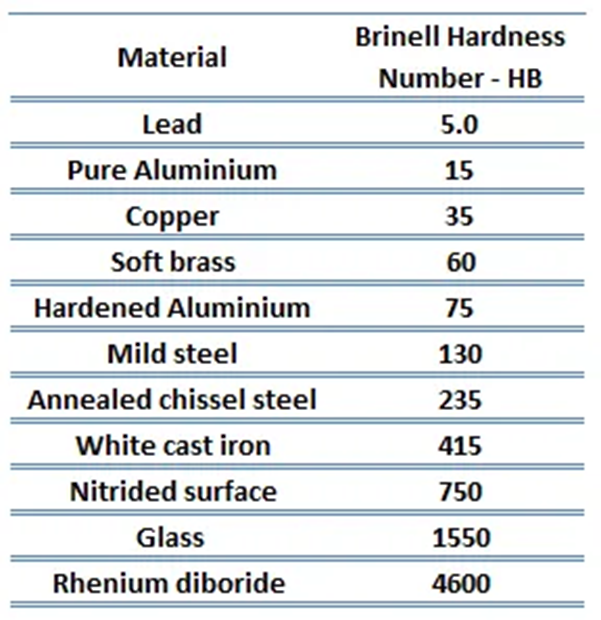

Hardness

MECHANICAL PROPERTIES. Determine what is being asked below.

It is an indication of a material’s ability to resist wear.

Hardness

MECHANICAL PROPERTIES. Determine what is being asked below.

It measures a material’s resistance to surface deformation.

Hardness

MECHANICAL PROPERTIES. Determine what is being asked below.

It is an important property to be considered if the equipment is being designed to handle abrasive solids, or liquids containing suspended solids that are likely to cause erosion.

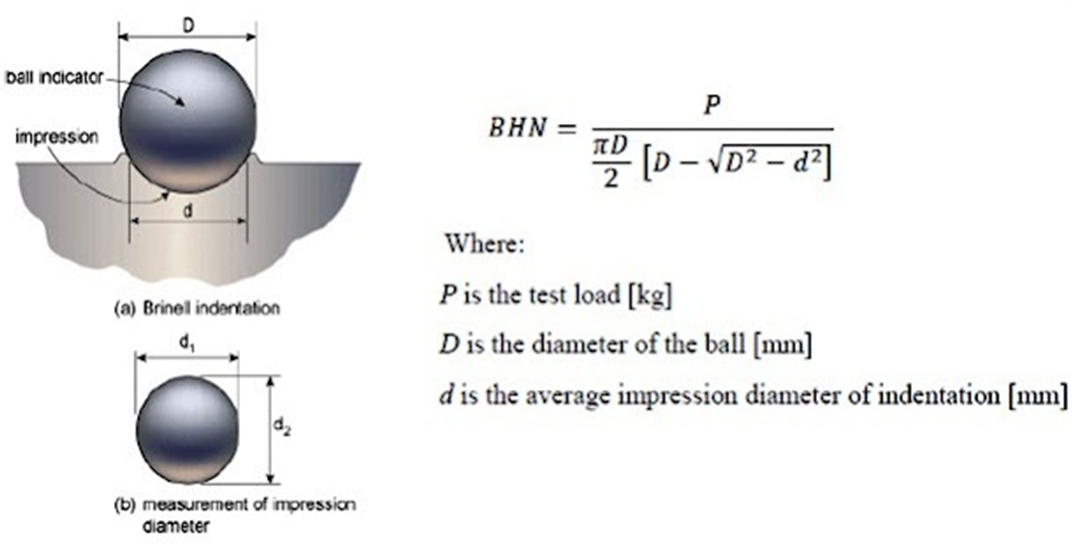

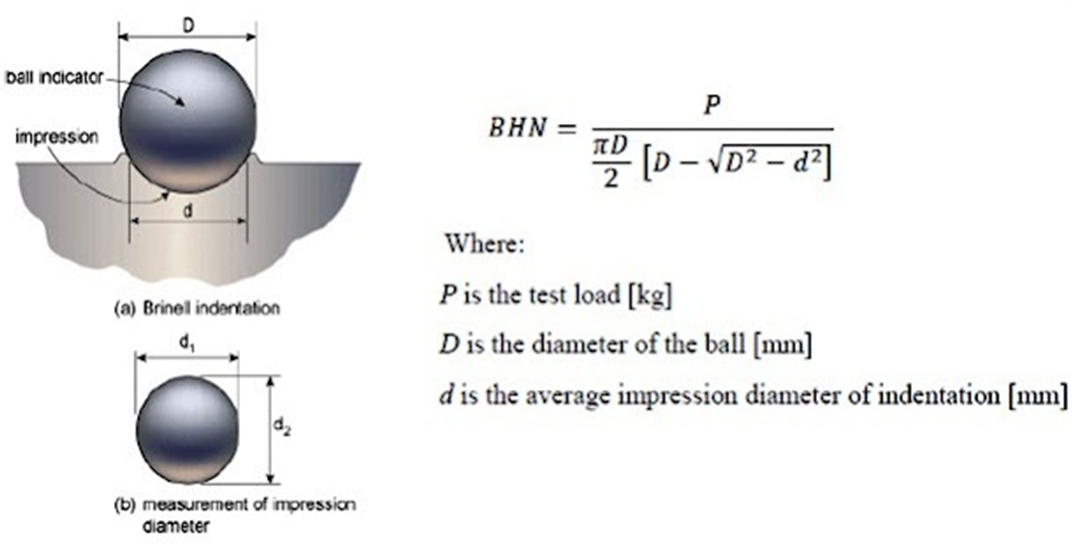

ADDITIONAL: A higher Brinell Hardness Number means the material is harder and more resistant to deformation, while a lower number indicates it is softer and more easily indented.

ADDITIONAL: A higher Brinell Hardness Number means the material is harder and more resistant to deformation, while a lower number indicates it is softer and more easily indented.

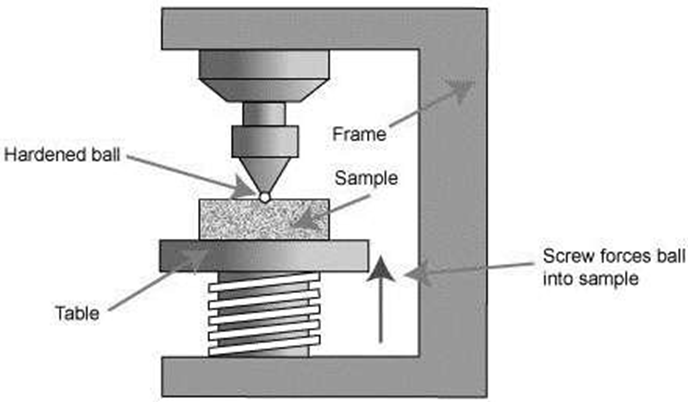

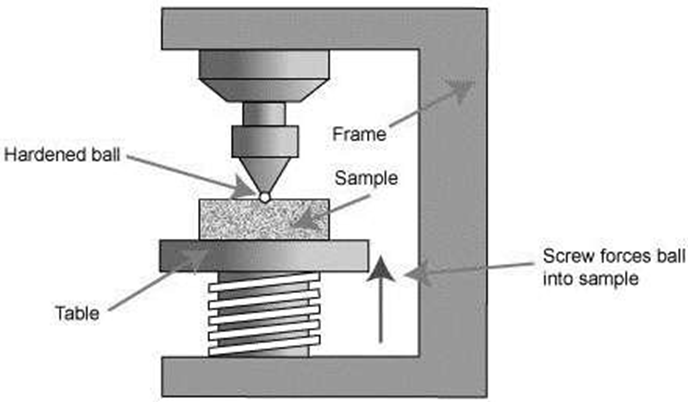

Brinell hardness test

MECHANICAL PROPERTIES. Determine what is being asked below.

Hardness of a material is measured in a standard test such as ___.

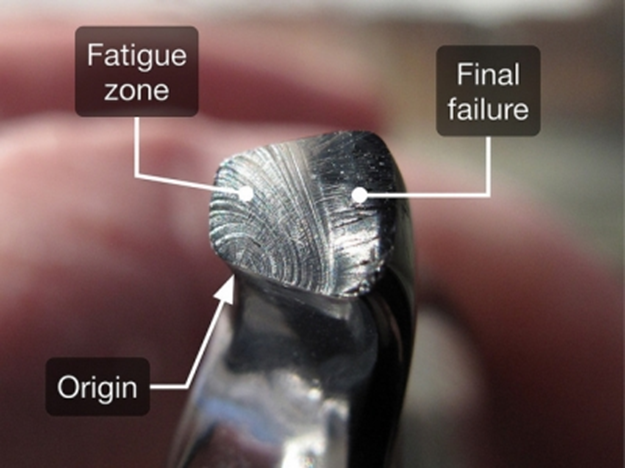

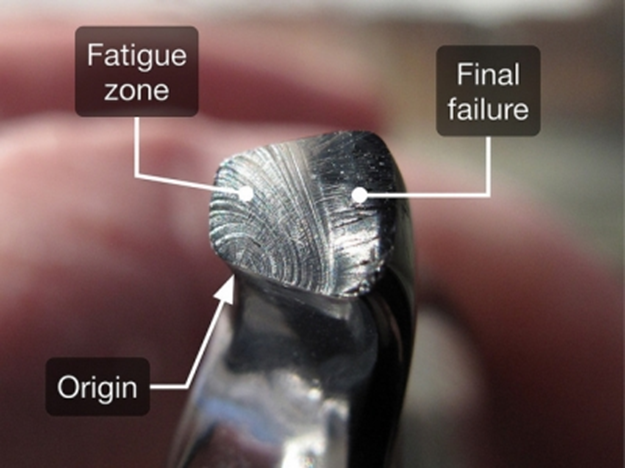

Fatigue

(ADDITIONAL: Rotating equipment (pumps, compressors, etc.) and equipment subjected to temperature or pressure cycling are often subjected to fatigue failure.)

MECHANICAL PROPERTIES. Determine what is being asked below.

It is likely to occur in equipment subject to cyclic loading.

Creep

MECHANICAL PROPERTIES. Determine what is being asked below.

It is the gradual extension of a material under a steady tensile stress, over a prolonged period of time.

Creep strength

MECHANICAL PROPERTIES. Determine what is being asked below.

It is usually reported as the stress to cause rupture in 100,000 hours at the test temperature.

READ.

Under creep,

It is usually only important at high temperatures, ex. with steam and gas turbine blades.

For a few materials (ex. lead), the rate of creep is significant at moderate temperatures.

Lead will creep under its own weight at room temperature and lead linings must be supported at frequent intervals.

READ.

Under creep,

It is usually only important at high temperatures, ex. with steam and gas turbine blades.

For a few materials (ex. lead), the rate of creep is significant at moderate temperatures.

Lead will creep under its own weight at room temperature and lead linings must be supported at frequent intervals.

True

MECHANICAL PROPERTIES. Determine what is being asked below.

TRUE OR FALSE. The tensile strength and elastic modulus of metals decrease with increasing temperature.

READ.

Under effect of temperature on the mechanical properties,

The tensile strength of mild steel (low carbon steel, C < 0.25%) is 450 N/mm² at 25°C falling to 210 at 500°C, and the value of Young’s modulus 200,000 N/mm² at 25°C falling to 150,000 N/mm² at 500°C.

The ASME BPV Code Section II Part D specifies maximum temperatures for each material.

READ.

Under effect of temperature on the mechanical properties,

The tensile strength of mild steel (low carbon steel, C < 0.25%) is 450 N/mm² at 25°C falling to 210 at 500°C, and the value of Young’s modulus 200,000 N/mm² at 25°C falling to 150,000 N/mm² at 500°C.

The ASME BPV Code Section II Part D specifies maximum temperatures for each material.

True

MECHANICAL PROPERTIES. Determine what is being asked below.

TRUE OR FALSE. The maximum allowable stress used in design is always based on the design temperature.

False

(EXPLANATION: Creep resistance will be important if the material is subjected to high stresses at elevated temperatures.)

MECHANICAL PROPERTIES. Determine what is being asked below.

TRUE OR FALSE. Creep resistance will be important if the material is subjected to high stresses at lower temperatures.

READ.

Under effect of temperature on the mechanical properties,

Materials must be chosen that have sufficient strength at the design temperature to give an economic and mechanically feasibly wall thickness.

Special alloys, such as Inconel 600 (UNS N06600) or Incoloy 800 (UNS N08800) (both trademarks of International Nickel Co.) are used for high temperature equipment such as furnace tubes in environments that do not contain sulfur.

READ.

Under effect of temperature on the mechanical properties,

Materials must be chosen that have sufficient strength at the design temperature to give an economic and mechanically feasibly wall thickness.

Special alloys, such as Inconel 600 (UNS N06600) or Incoloy 800 (UNS N08800) (both trademarks of International Nickel Co.) are used for high temperature equipment such as furnace tubes in environments that do not contain sulfur.

True

MECHANICAL PROPERTIES. Determine what is being asked below.

TRUE OR FALSE. Stainless steels are superior in having sufficient strength at the design temperature to plain carbon steels.

READ.

Under effect of temperature on the mechanical properties,

At low temperatures (less than 10°C), metals that are normally ductile can fail in a brittle manner.

For low temperature equipment, such as cryogenic plant and liquefied-gas storage, austenitic stainless steel (FCC) or aluminum alloys (Hex) should be specified.

Serious disasters have occurred through the failure of welded carbon steel vessels at low temperatures.

The phenomenon of brittle failure is associated with the crystalline structure of metals.

READ.

Under effect of temperature on the mechanical properties,

At low temperatures (less than 10°C), metals that are normally ductile can fail in a brittle manner.

For low temperature equipment, such as cryogenic plant and liquefied-gas storage, austenitic stainless steel (FCC) or aluminum alloys (Hex) should be specified.

Serious disasters have occurred through the failure of welded carbon steel vessels at low temperatures.

The phenomenon of brittle failure is associated with the crystalline structure of metals.

False

(EXPLANATION: Metals with a body-centered cubic (BCC) lattice are more liable to brittle failure.)

MECHANICAL PROPERTIES. Determine what is being asked below.

TRUE OR FALSE. Metals with a body-centered cubic (BCC) lattice are less liable to brittle failure than those with a face-centered cubic (FCC) or hexagonal lattice.

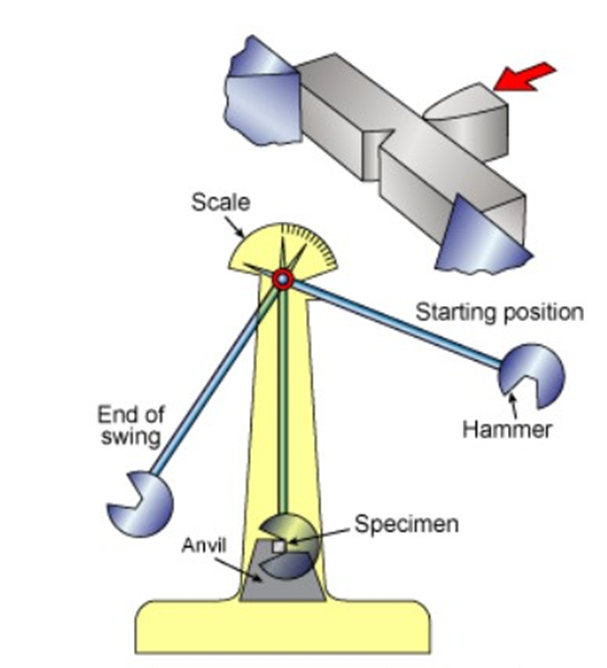

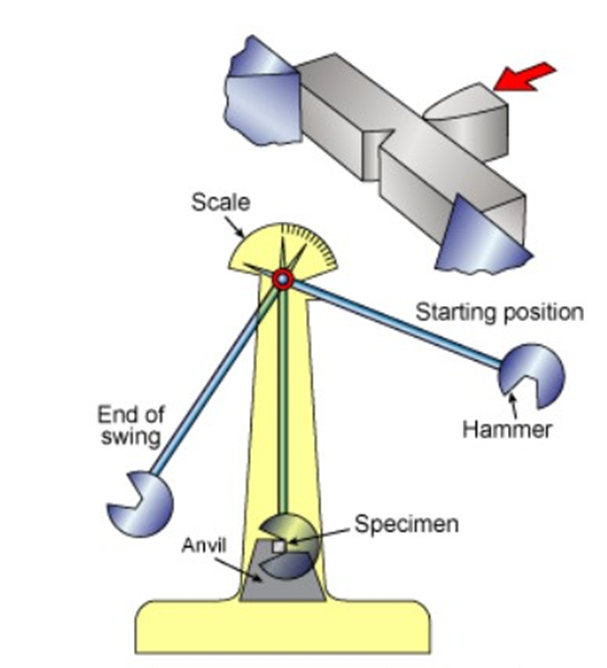

Charpy test

MECHANICAL PROPERTIES. Determine what is being asked below.

V-notch impact tests, such as the ___, are used to test the susceptibility of materials to brittle failure.

ADDITIONAL: The Charpy impact test measures the amount of energy a material absorbs before fracturing to determine its toughness and impact resistance

ADDITIONAL: The Charpy impact test measures the amount of energy a material absorbs before fracturing to determine its toughness and impact resistance

READ.

Under effect of temperature on the mechanical properties,

The brittle fracture of welded structures is a complex phenomenon and is dependent on plate thickness and the residual stresses present after fabrication, as well as the operating temperature.

READ.

Under effect of temperature on the mechanical properties,

The brittle fracture of welded structures is a complex phenomenon and is dependent on plate thickness and the residual stresses present after fabrication, as well as the operating temperature.

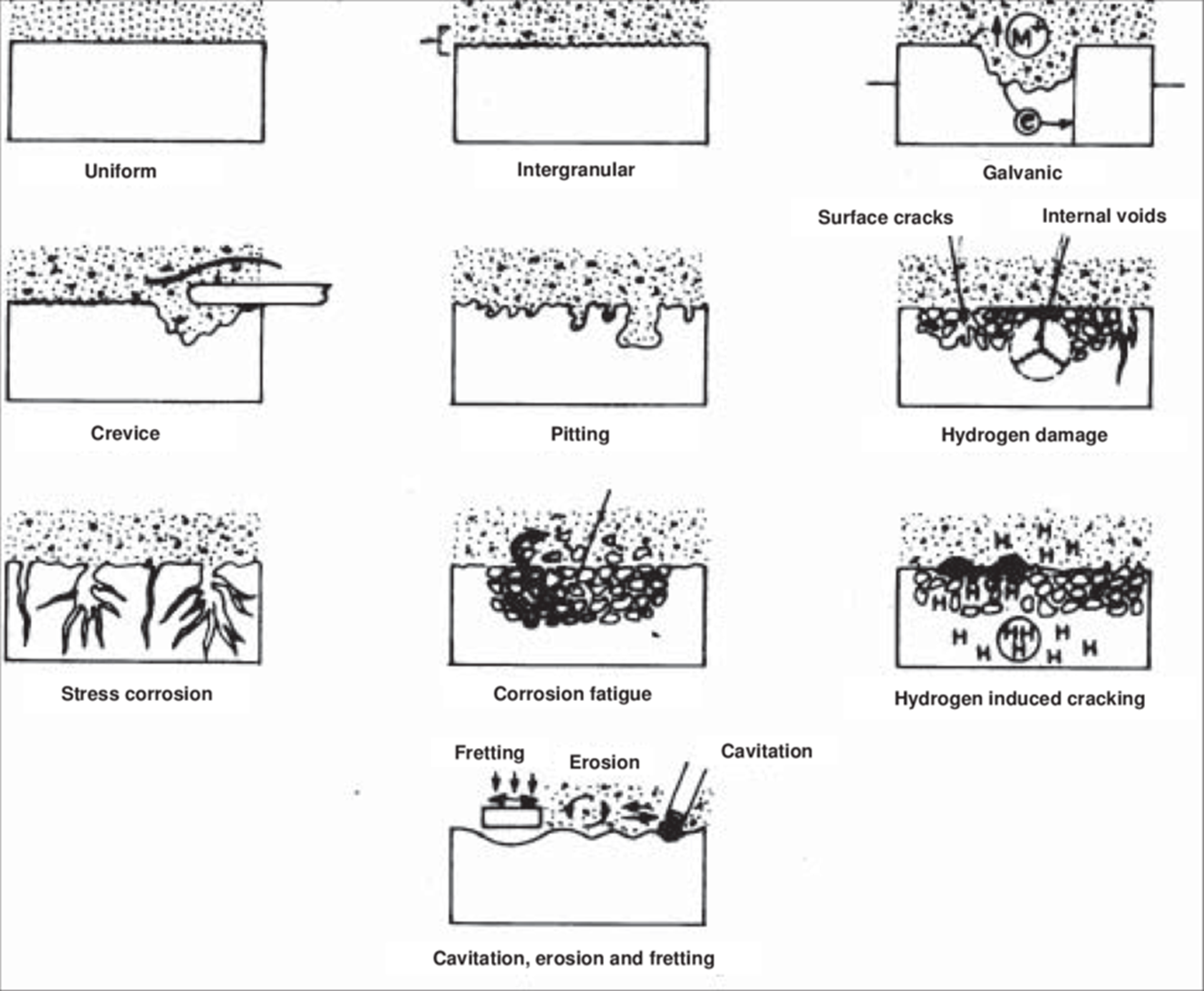

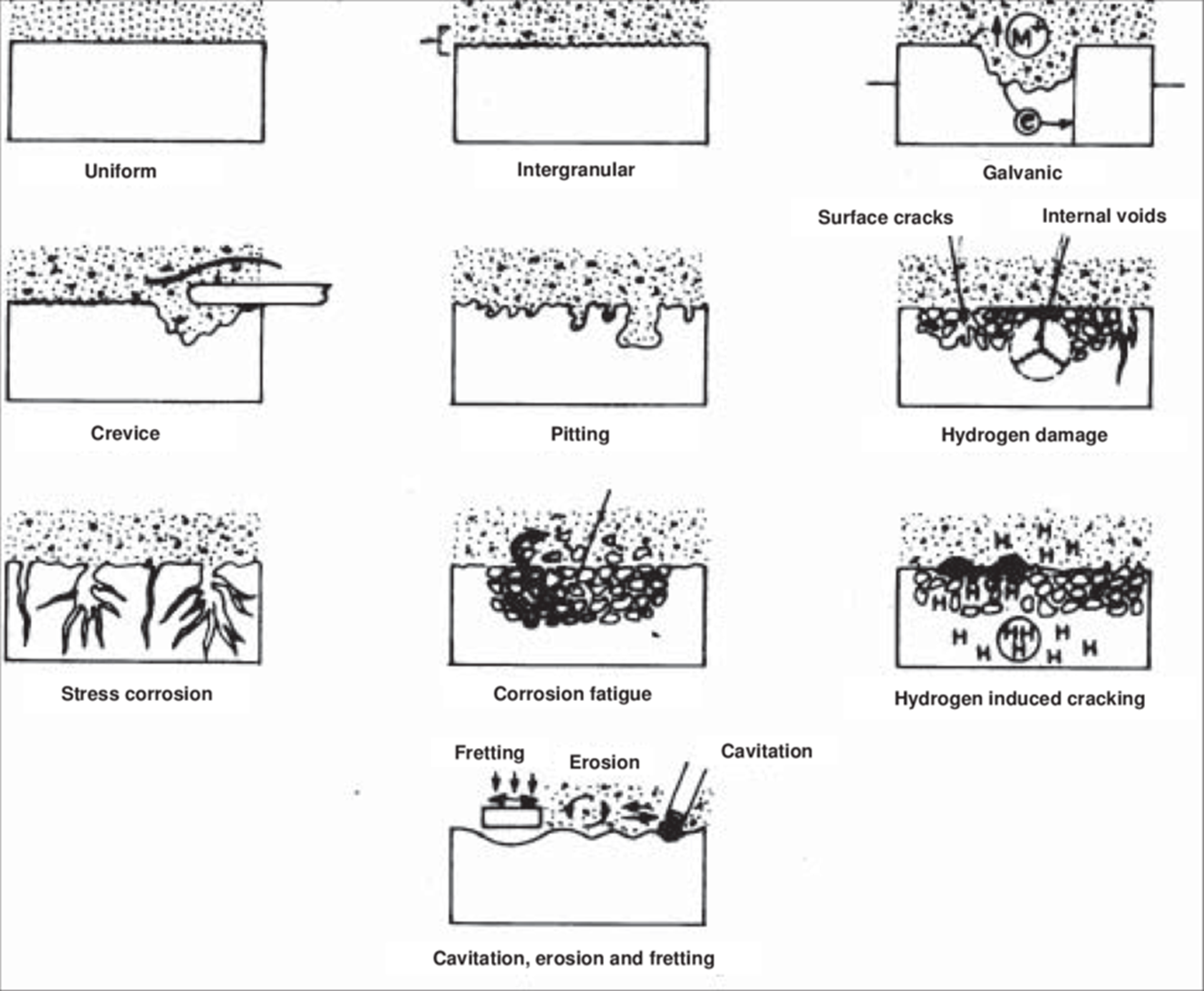

Uniform corrosion

Galvanic corrosion

Pitting

Intergranular corrosion

Stress corrosion

Erosion corrosion

Corrosion fatigue

High temperature oxidation and sulphidation

Hydrogen embrittlement

CORROSION RESISTANCE. Determine what is being asked below.

Enumerate the nine (9) classifications or categories of corrosion mentioned in the module.

Metallic corrosion

CORROSION RESISTANCE. Determine what is being asked below.

It is considered an electrochemical process.

Anode

Cathode

Electrolyte

Completion of the electrical circuit

CORROSION RESISTANCE. Determine what is being asked below.

Enumerate the four (4) components necessary to set up an electrochemical cell.

Anode

CORROSION RESISTANCE. Determine what is being asked below.

It is the corroding electrode.

Electrolyte

CORROSION RESISTANCE. Determine what is being asked below.

It is the conducting medium or the corroding fluid.

Cathode

CORROSION RESISTANCE. Determine what is being asked below.

It is the passive, non-corroding electrode.

Dissimilar metals

Corrosion products

Inclusions in the metal, such as slag

Less well-aerated areas

Areas of differential concentration

Differentially strained areas

CORROSION RESISTANCE. Determine what is being asked below.

Cathodic areas can arise in many ways (6):

Uniform corrosion

CORROSION RESISTANCE. Determine what is being asked below.

It is the uniform wastage of material by corrosion, with no pitting or other forms of local attack.

True

CORROSION RESISTANCE. Determine what is being asked below.

TRUE OR FALSE. If the corrosion of a material can be considered to be uniform, the life of the material in service can be predicted from experimentally determined corrosion rates.

Corrosion rates

(ADDITIONAL: These can also be expressed as a weight loss in milligrams per square decimeter per day (mdd)).

CORROSION RESISTANCE. Determine what is being asked below.

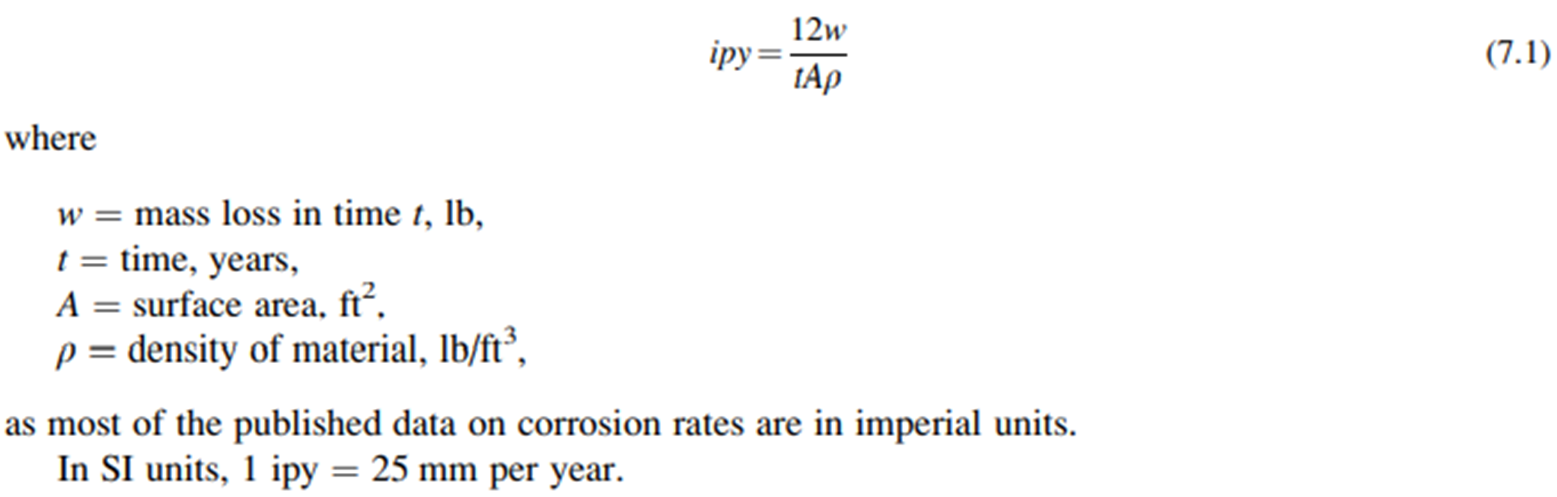

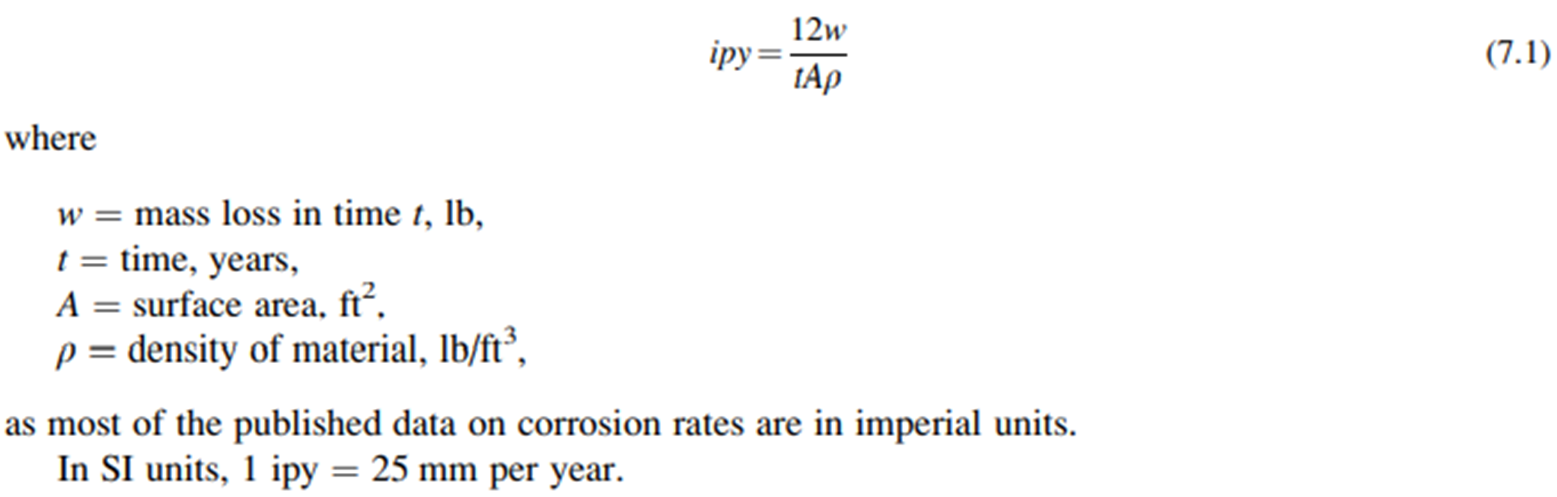

These are usually expressed as a penetration rate in inches per year (ipy), or mills per year (mpy) (1 mill = 10^-3 inches).

Corrosion rate

CORROSION RESISTANCE. Determine what is being asked below.

In corrosion testing, it is measured by the reduction in weight of a specimen of known area over a fixed period of time.

READ.

Under uniform corrosion,

When judging corrosion rates expressed in mdd, it must be remembered that the penetration rate depends on the density of the material.

For ferrous metals, 100 mdd = 0.02 ipy.

READ.

Under uniform corrosion,

When judging corrosion rates expressed in mdd, it must be remembered that the penetration rate depends on the density of the material.

For ferrous metals, 100 mdd = 0.02 ipy.

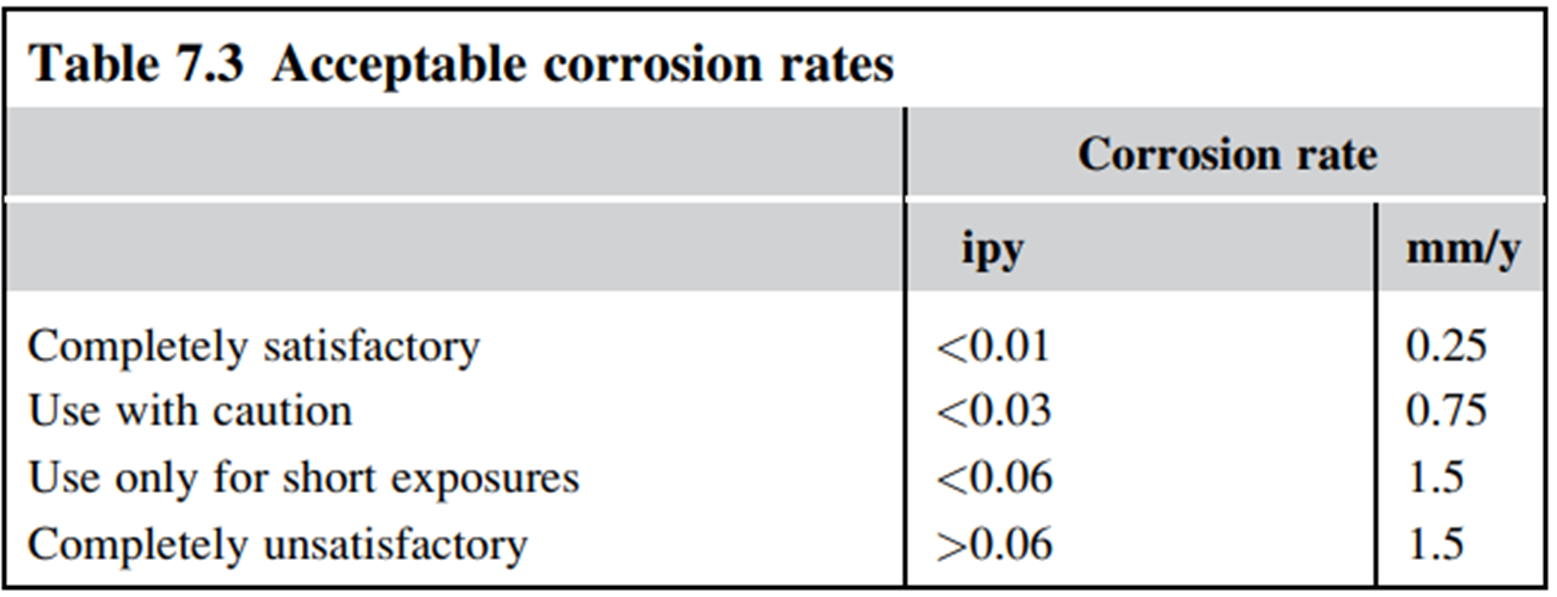

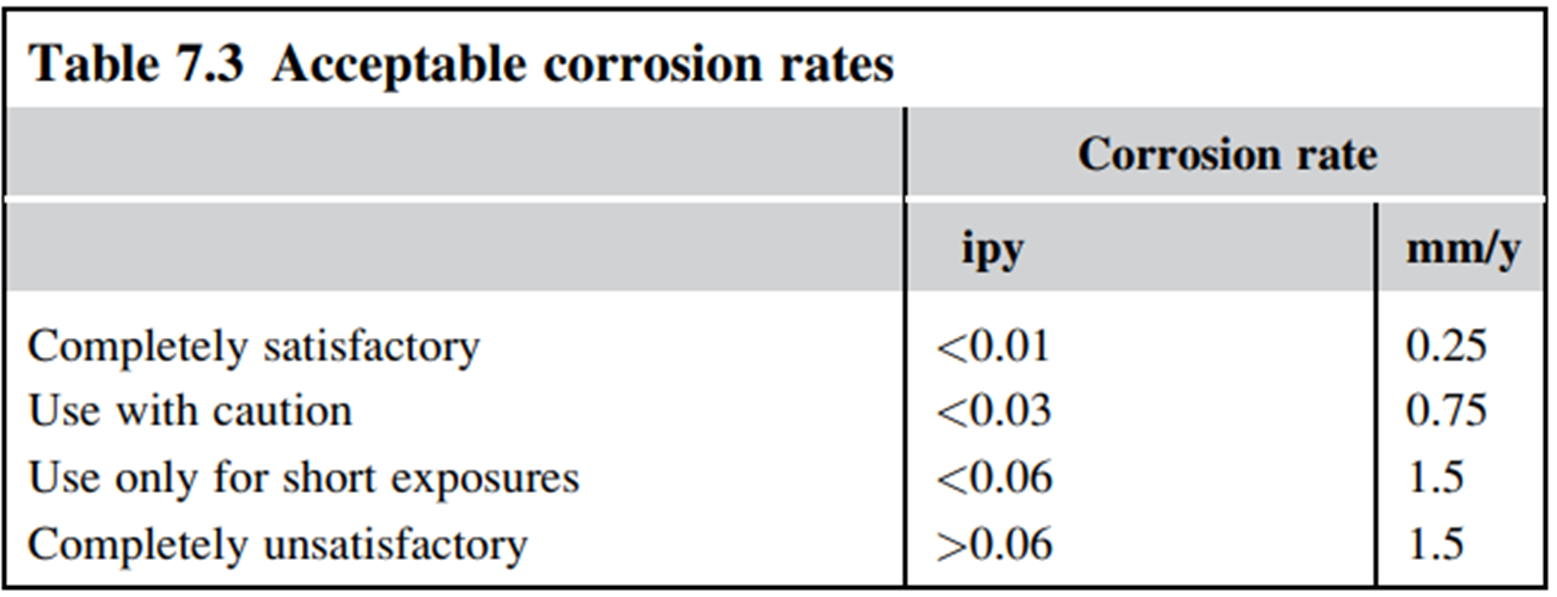

Cost of material

Duty, particularly as regards to safety

Economic life of the plant

CORROSION RESISTANCE. Determine what is being asked below.

What can be considered as an acceptable rate of attack will depend on three (3) factors:

READ.

Under uniform corrosion,

For the more commonly used inexpensive materials, such as carbon and low alloy steels, Table 7.3 serves as a guide.

For the more expensive alloys, such as the high alloy steels, the brasses and aluminum, the figures given in Table 7.3 should be divided by 2.

READ.

Under uniform corrosion,

For the more commonly used inexpensive materials, such as carbon and low alloy steels, Table 7.3 serves as a guide.

For the more expensive alloys, such as the high alloy steels, the brasses and aluminum, the figures given in Table 7.3 should be divided by 2.

READ.

Under uniform corrosion,

If the predicted corrosion rate indicates only short exposures, then the design engineer should allow for frequent inspection of the plant and periodic replacement of the affected equipment.

This affects process economics in two ways: (1) Reduces the on-stream factor, and (2) Increases the maintenance costs.

Usually, the economic impact of frequent shutdown and replacement is so negative that the use of a more expensive alloy with better corrosion resistance can be justified.

READ.

Under uniform corrosion,

If the predicted corrosion rate indicates only short exposures, then the design engineer should allow for frequent inspection of the plant and periodic replacement of the affected equipment.

This affects process economics in two ways: (1) Reduces the on-stream factor, and (2) Increases the maintenance costs.

Usually, the economic impact of frequent shutdown and replacement is so negative that the use of a more expensive alloy with better corrosion resistance can be justified.

On-stream factor

CORROSION RESISTANCE. Determine what is being asked below.

It refers to the number of days of production per year.

READ.

Under uniform corrosion,

Allowances for expected corrosion over the plant life or time between replacements must be added to the minimum vessel wall thicknesses calculated to comply with the pressure vessel codes.

These corrosion allowances can be economically or mechanically prohibitive if the corrosion rate is high.

Guidance on corrosion allowances is given in the ASME BPV Code Section VIII Div.1 Nonmandatory Appendix E.

READ.

Under uniform corrosion,

Allowances for expected corrosion over the plant life or time between replacements must be added to the minimum vessel wall thicknesses calculated to comply with the pressure vessel codes.

These corrosion allowances can be economically or mechanically prohibitive if the corrosion rate is high.

Guidance on corrosion allowances is given in the ASME BPV Code Section VIII Div.1 Nonmandatory Appendix E.

True

CORROSION RESISTANCE. Determine what is being asked below.

TRUE OR FALSE. The corrosion allowance should at least equal the expected corrosion loss during the desired life of the vessel.

Temperature

Concentration of the corrosive fluid

CORROSION RESISTANCE. Determine what is being asked below.

Corrosion rate depends mainly on two (2) factors which are:

True

(ADDITIONAL: This is not always the case. The rate will depend on other factors that are affected by temperature, such as oxygen solubility.)

CORROSION RESISTANCE. Determine what is being asked below.

TRUE OR FALSE. Increase in temperature usually increases rate of corrosion.

Galvanic corrosion

(ADDITIONAL: If dissimilar metals are placed in contact in an electrolyte, the corrosion rate of the anodic metal will be increased, as the metal lower in the electrochemical series will readily act as a cathode.)

CORROSION RESISTANCE. Determine what is being asked below.

This happens if dissimilar metals are placed in contact in an electrolyte.

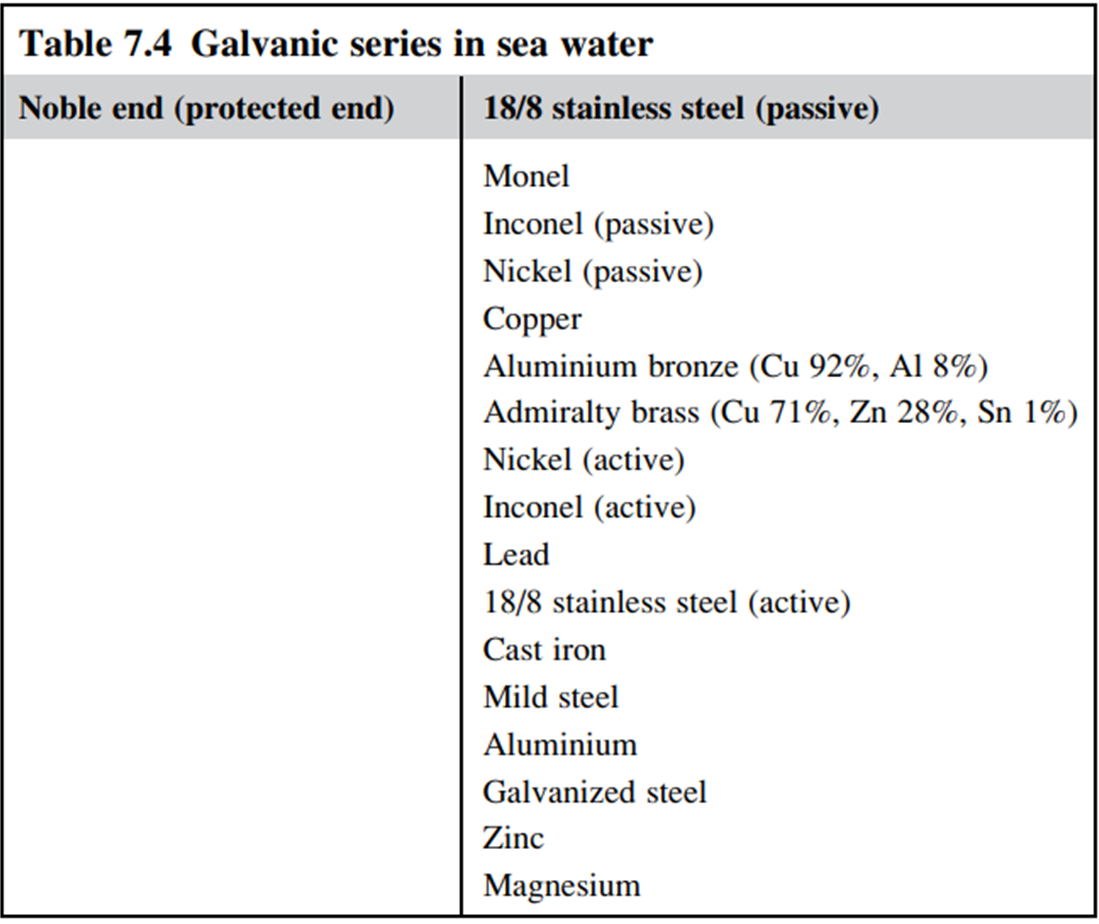

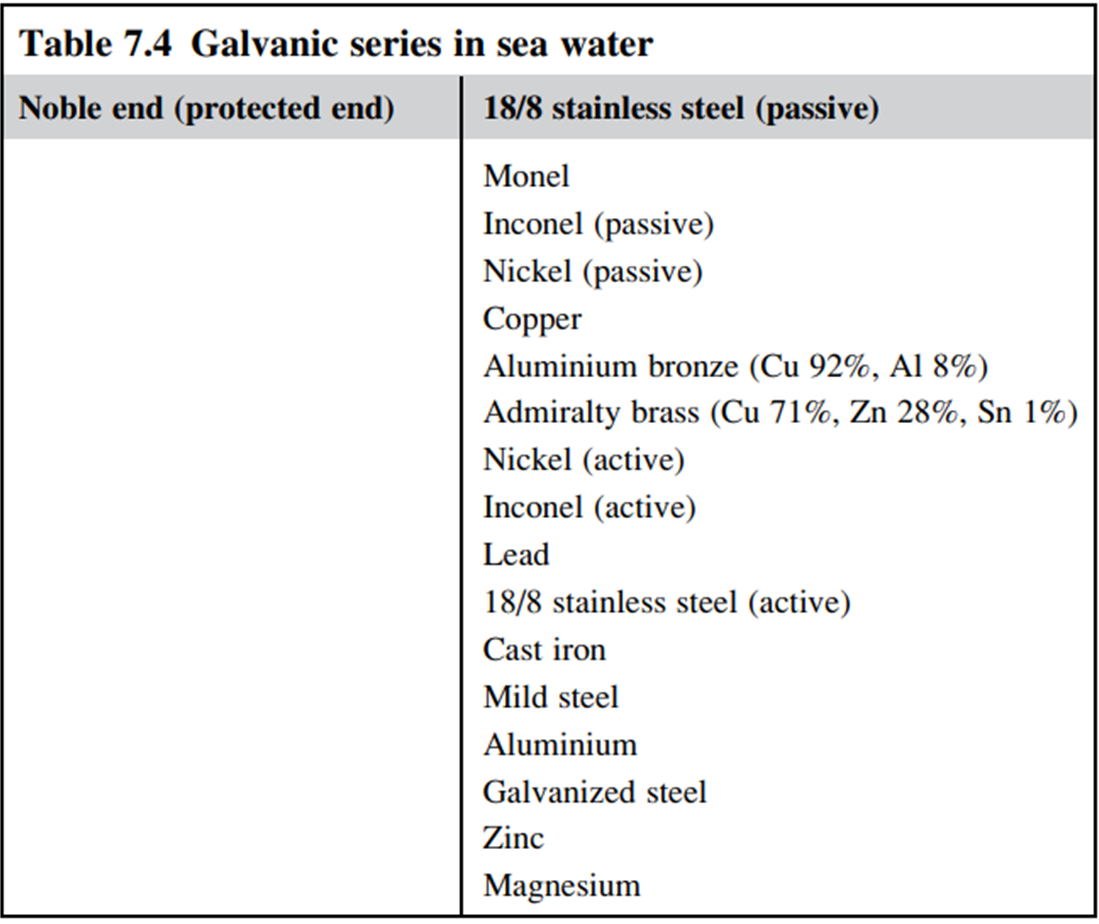

READ.

Under galvanic corrosion,

The galvanic series in seawater for some of the more commonly used metals is shown in Table 7.4.

Some metals under certain conditions form a natural protective film, for example, stainless steel in oxidizing environments. This state is denoted by “passive”.

“Active” indicates the absence of the protective film, for example, where the surface of the metal is subject to wear due to moving parts or abrasion by fluid.

Minor shifts in position in the series can be expected in other electrolytes, but the series for seawater is a good indication of the combinations of metals to be avoided.

READ.

Under galvanic corrosion,

The galvanic series in seawater for some of the more commonly used metals is shown in Table 7.4.

Some metals under certain conditions form a natural protective film, for example, stainless steel in oxidizing environments. This state is denoted by “passive”.

“Active” indicates the absence of the protective film, for example, where the surface of the metal is subject to wear due to moving parts or abrasion by fluid.

Minor shifts in position in the series can be expected in other electrolytes, but the series for seawater is a good indication of the combinations of metals to be avoided.

Electrically insulated

CORROSION RESISTANCE. Determine what is being asked below.

If metals that are widely separated in the galvanic series have to be used together, they should be ___ from each other, breaking the conducting circuit.

Thickness

CORROSION RESISTANCE. Determine what is being asked below.

Alternatively, if sacrificial loss of the anodic material can be accepted, the ___ of this material can be increased to allow for the increased rate of corrosion.

Relative areas of the anodic and cathodic metals

CORROSION RESISTANCE. Determine what is being asked below.

In galvanic corrosion, the corrosion rate will depend on ___.

True

CORROSION RESISTANCE. Determine what is being asked below.

TRUE OR FALSE. A high cathode to anode area should be avoided to prevent galvanic corrosion.

Sacrificial anodes

CORROSION RESISTANCE. Determine what is being asked below.

These are used to protect underground steel pipes.

Pitting

CORROSION RESISTANCE. Determine what is being asked below.

It is a highly localized corrosion that forms pits in the metal surface.

True

CORROSION RESISTANCE. Determine what is being asked below.

TRUE OR FALSE. If a material is liable to pitting, penetration can occur prematurely and corrosion rate data are not a reliable guide to the equipment life.

Pitting

CORROSION RESISTANCE. Determine what is being asked below.

It is caused by any situation that causes localized increase in corrosion rate.

Not uniform composition of metals

Impingement of bubbles

Aerated medium

CORROSION RESISTANCE. Determine what is being asked below.

Enumerate the three (3) causes of pitting mentioned in the module.

Impingement of bubbles

CORROSION RESISTANCE. Determine what is being asked below.

This occurs during cavitation in pumps, which can also be an example of erosion-corrosion.

READ.

Under pitting,

The presence of slag in welds is an example of a non-uniform composition of metals.

In aerated medium, the oxygen concentration will be lower at the bottom of a pit, and the bottom will be anodic to the surrounding metal, causing increased corrosion and deepening of the pit (attack is reduced with a good surface finish.)

READ.

Under pitting,

The presence of slag in welds is an example of a non-uniform composition of metals.

In aerated medium, the oxygen concentration will be lower at the bottom of a pit, and the bottom will be anodic to the surrounding metal, causing increased corrosion and deepening of the pit (attack is reduced with a good surface finish.)

Intergranular corrosion

CORROSION RESISTANCE. Determine what is being asked below.

It is the preferential corrosion of material at the grain (crystal) boundaries.

False

(EXPLANATION: Intergranular corrosion can cause the catastrophic failure of equipment even though the loss of material is small.)

CORROSION RESISTANCE. Determine what is being asked below.

TRUE OR FALSE. Intergranular corrosion can cause the catastrophic failure of equipment because the loss of material is large.

Intergranular corrosion

CORROSION RESISTANCE. Determine what is being asked below.

It is a common form of attack on alloys but occurs rarely with pure metals.

READ.

Under intergranular corrosion,

The attack is usually caused by a differential couple being set up between impurities existing at the grain boundary.

Impurities will tend to accumulate at the grain boundaries after heat treatment.

READ.

Under intergranular corrosion,

The attack is usually caused by a differential couple being set up between impurities existing at the grain boundary.

Impurities will tend to accumulate at the grain boundaries after heat treatment.

Weld decay of unstabilized stainless steel

CORROSION RESISTANCE. Determine what is being asked below.

What is a classic example of intergranular corrosion in chemical plant?

Weld decay (of unstablized stainless steel)

CORROSION RESISTANCE. Determine what is being asked below.

It is caused by the precipitation of chromium carbides at the grain boundaries in a zone adjacent to the weld, where the temperature has been between 500 to 800°C during welding.

Annealing after welding, if practical (post-weld heat treatment)

Using low carbon grades (<0.3% C) or grades stabilized by the addition of titanium or niobium

CORROSION RESISTANCE. Determine what is being asked below.

Weld decay can be avoided by (2):

True

CORROSION RESISTANCE. Determine what is being asked below.

TRUE OR FALSE. Corrosion rate and the form of attack can be changed if the material is under stress.

READ.

Under effect of stress,

The rate of attack will not change significantly within normal design stress values.

But for some combinations of metal, corrosive media, and temperature, stress corrosion cracking can occur.

READ.

Under effect of stress,

The rate of attack will not change significantly within normal design stress values.

But for some combinations of metal, corrosive media, and temperature, stress corrosion cracking can occur.

Stress corrosion cracking

CORROSION RESISTANCE. Determine what is being asked below.

It is the general name given to a form of attack in which cracks are produced that grow rapidly, and can cause premature, brittle failure of the metal.

Simultaneous stress and corrosion

A specific corrosive substance; in particular the presence of Cl-, OH-, NO3-,or NH4+ ions

CORROSION RESISTANCE. Determine what is being asked below.

Enumerate the two (2) conditions necessary for stress corrosion cracking to occur.

The season cracking of brass cartridge cases

Caustic embrittlement of steel boilers

Stress corrosion cracking of stainless steels in the presence of chloride ions

CORROSION RESISTANCE. Determine what is being asked below.

Enumerate three (3) examples of stress corrosion cracking.

READ.

Under effects of stress,

Mild stress can cause cracking; the residual stresses from fabrication and welding are sufficient.

Stress corrosion cracking can be avoided by selecting materials that are not susceptible in the specific corrosion environment; or, less certainly, by stress relieving by post-weld heat treatment.

READ.

Under effects of stress,

Mild stress can cause cracking; the residual stresses from fabrication and welding are sufficient.

Stress corrosion cracking can be avoided by selecting materials that are not susceptible in the specific corrosion environment; or, less certainly, by stress relieving by post-weld heat treatment.

Corrosion fatigue

CORROSION RESISTANCE. Determine what is being asked below.

It is the premature failure of materials in corrosive environments caused by cyclic stresses.

True

CORROSION RESISTANCE. Determine what is being asked below.

TRUE OR FALSE. Corrosion fatigue can occur in any corrosive environment and does not depend on a specific combination of corrosive substance and metal.

READ.

Under corrosion fatigue,

Even mildly corrosive conditions can markedly reduce the fatigue life of a component.

Materials with a high resistance to corrosion must be specified for critical components subjected to cyclic stresses.

READ.

Under corrosion fatigue,

Even mildly corrosive conditions can markedly reduce the fatigue life of a component.

Materials with a high resistance to corrosion must be specified for critical components subjected to cyclic stresses.