POLYMERS

1/30

There's no tags or description

Looks like no tags are added yet.

Name | Mastery | Learn | Test | Matching | Spaced | Call with Kai |

|---|

No analytics yet

Send a link to your students to track their progress

31 Terms

Thermoplastics

can be repeatedly softened by heating and hardened by cooling

acrylic

LDPE

HDPE

PET

PVC

uPVC

PP

ABS

Acrylic

tough

lightweight

good chemcial resistance

used for car lights, cnc laser cut items, lighting units, lighting covers and baths

LDPE

very tough

good chemical resistance

weather proof

low level of rigidity

used for squeezy detergent bottles, toys, carrier bags, bin lines, general packaging, food wrap film, food trays

HDPE

weatherproof

tough

good chemical resistance

used for chemical drums, toys, household and kitchenware, long life carrier bags, buckets, bowls

PET

tough

flexible

hard

lightweight

used for packaging, clothes,drink bottles, food packaging, detergent bottles and shampoo bottles

PVC

tough

rigid

good weather and chemical resistance

flexible

used for pipes, electrical insulation

uPVC

rigid

opaque

tough

hard

good weather, chemical resistance

used for window frames, external doors, guttering and downpipes, water service pipes, bank cards

PP

tough

flexible

good fatigure resistance

resistant to chemicals

used for food packaging, medical equipment, rope, folders

ABS

tough

hard

good impact strength

used for saftey helments, suitcases, computer housing, handles

Thermosetting

can only be heated and shaped once

Epoxy resin

UF

Polyester resin

Epoxy resin

tough

rigid

hard

good chemical resistance

encapsulating electrical components, adhesives, surface coating, pacemakers, aerospace applications

UF

good electrical insulation

hard

heat resistance

resistant to deformation

used for electrical casings, sockets, switches

Polyester resin

resistant to water, heat, and chemicals

ridid

brittle

used for bath tubs, boat hulls, chair seats, boat hulls

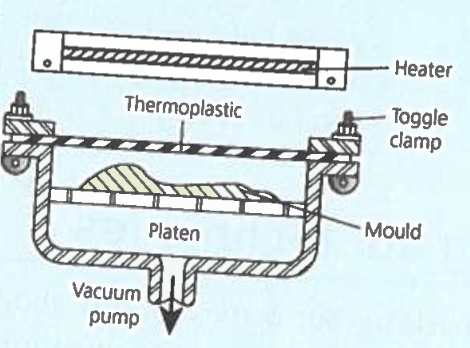

Vaccum Forming Method

materials used: HIPS, Polyester, ABS, Acrylic

used for plastic yogurt, pots, bath tubs

the mould is created from mdf/plywood

The mould is placed into vacuum former

plastic sheet placed into vacuum former and heated until pliable

mould is raised up into the sheet and air is removed to seal it

plastic takes shape of mould and allowed to cool

remove mould once cooled

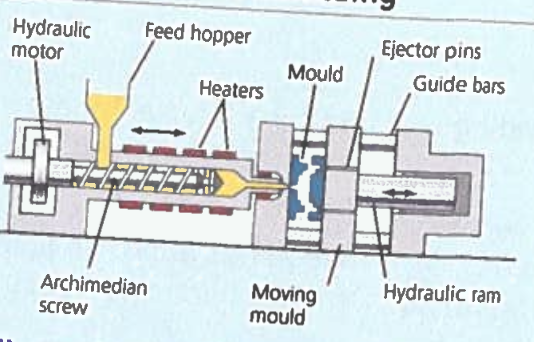

Injection Moulding Method

Materials - ABS, Acrylic, PVC

Beads, pellets, granites are placed into hopper

they are fed through and archimedes screw drag granules through melting it

once pass through heater and become liquid, hydraulic piston forces it into mould

plastic cools and takes shape of mould

removes mould using ejector pins

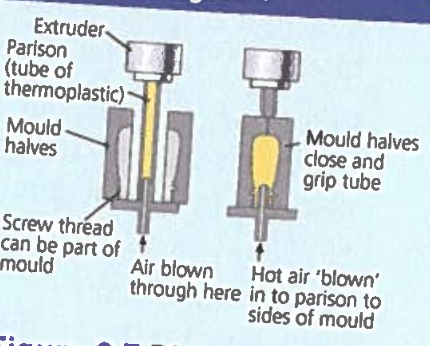

Blow Moulding method

Materials - HDPE, PP, LDPE, PET

water bottles, toys, bins

plastic is heated and extruded to create a piston

piston is placed in the mould, which closes on it and pinches the end of plastic

heated compressed air is blown into piston

plastic fills in the mould with hollow interior

plastic is cooled using water

once cooled, remove mould and trim excess plastic

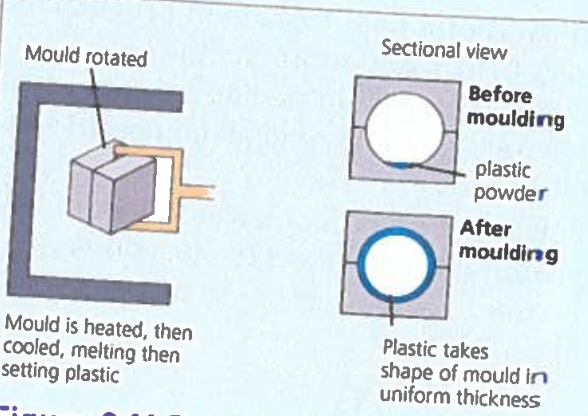

Rotational moulding method

Materials - HDPE, PP

plastic is weighed depending on desired thickness and put into mould

mould is placed on rig in huge oven and heated

as its heated it is rotated on 2 axes to allow polymer coat evenly

once desired thickness reached mould is cooled

remove from mould

Line Bending method

materials - Acrylic

mark out line that requires bending

preheat the strip heater to right temperature

add the plastics in heater on marked out line

once heated bend plastic to desired angle

Elastomer

materials which at room temp can be deformed under pressure and then upon release of the pressure return to their original shape

Natural rubber

high tensile strength

low elongation

good hardness

tough

electrical insulator

good cold resistance

used for automotive industry, tires, tubes, hoses, gaskets, belts, balloons, toys, footwear

Neoprene

good thermal resistance

toughness

good oil and chemical resistance

excellent weather resistance

good abrasion resistance

electrical insulator

used wet suits, laptop cases, industiral wire insulation, automotive applications

Polymers

made via fractional distillation of crude oil

takes hundreds of years to degrade

polymers are self finishing.

Resin casting method

Pour the polymer resin into a pre-made mould and then allow the resin to set into shape

The mould is then gently vibrated to expel any air bubbles from the casting

this is done at room temperature, where the moulds are made using mdg

materials - acrylic, polyester, epoxy

products - toys, jewellery, prototype models, dentistry

Blow moulding process

used for drink bottles, shampoo, detergent

heated plastic is extruded into parison tube

mould closes, parison is gripped in place

compressed air blown into parison tube which inflates

parison fills

screw threat in the neck of the bottle is formed during the process

mould cools

product trimmed

Injection moulding

used for electrical casings

thermoplastic granules are fed into a hopper

hopper feeds an archimedes screw that drags the granules past a heater where they are plasticized

when the soft, pliable plastic reaches the end of the screw a hydraulic piston forces it into the mould

Vacuum forming

used for lightweight trays, box inserts and liners, takeaway coffee cups, yogurt pots

mould created out of mdf

mould Is placed into a vacuum former

plastic sheet placed into vacuum former and heated until bendable

mould is raised up to the sheet and air is removed to seal it

plastic takes shape of mould and allowed to cool

remove mould once cooled

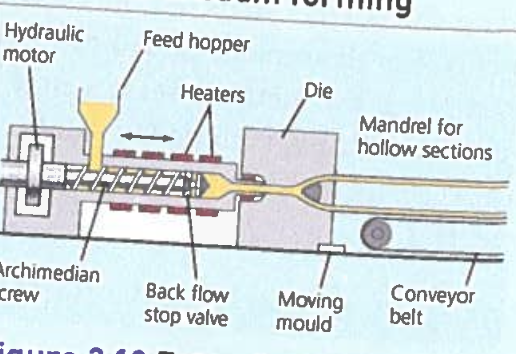

Extrusion

similar to injection moulding but the polymer is forced through a die at the end

used for solid rods, angle section, curtain track

Rotational moulding method

used for traffic cones, kayaks, water tankes, childrens play equiprment

polymer granules or powder weighed depending on wall thinking and put into mould

mould placed on rig in a huge oven and heated

as it heats its rotated slowly in two axes allowing the polymer to coat the inside of the mould evenly

once desired thickness reached mould is cooled

Blow moulding features

for making hollow thin walled components

high inital tooling cost

used for continous production

Injection moulding features

complex 3D shapes made quickly, easily

fast industrial production method

high inital tooling cost

used for large scale mass or continous

Rotational moulding features

produces seamless hollow components with large wall thickness

used in large-scale batch or mass production