MOD&D - Ceramics and Pottery

1/242

There's no tags or description

Looks like no tags are added yet.

Name | Mastery | Learn | Test | Matching | Spaced |

|---|

No study sessions yet.

243 Terms

Pottery

Said to be one of the most ancient arts an in all ages reflect the condition of every art

Ceramics or pottery

Refers to artifacts made of heated earth or earthenware but the usual modern distinction is to apply it to ware that is opaque when it comes from the kiln or oven

Ceramics (Keramos)

Comes from a Greek word meaning specifically potter's clay, which is used to describe a whole body of ware made of clay, mixed with water, shaped by the potter and hardened by fire

12,000 years ago

When was the first dated fired earth vessels invented? By Jomon culture in Japan

Vitrification

the progressive partial fusion of a clay, or of a body, as a result of a firing process. As it proceeds, the proportion of glassy bond increases and the apparent porosity of the fired product becomes progressively lower

Pottery

Ceramics that does not undergo vitrification

Greenware

the clay state; the ware is formed but hasn't undergone under firing; they are very brittle but they can be handled with care; often sanded with fine grade sandpaper to ensure a smooth finish in the completed item

Bisque

term literally meaning half-baked; when the ware has undergone preliminary low range firing through an oven or a kiln; all underglaze colors and printing are applied to the biicuit; this ware is normally a plain red, white or brown color depending on which type of clay is used

Glazed State

State after the ware has been covered with glaze and has undergone a second firing; basically done to make wares sanitary

Glaze

A mixture of chemicals, mostly silica, the major component of glass, clay, a melting agent, water, colorants and a suspension agent allowing the chemicals to stick together and not separate like oil and water; mainly composed of feldspar or another produced by fusing silica of quartz or sand by means of flux, generally of lead oxide; common kinds include alkaline, lead and tin glazes

Lead-glazed

Transparent glazed ceramics using sulphides or lead oxide; coat the ceramic body and render it impervious to liquids; shiny and transparent after firing

Tin-glazed

Opaque and white glazed ceramics used by medieval, Islamic potters, for Spanish lustreware, Italian maiolica, European faience and Delftware; usually this provides a background for brightly painted decoration; decoration is usually applied to the unfired glaze surface by brush with metallic oxides, commonly cobalt oxide, copper oxide, iron oxide, manganese dioxide and antimony oxide; for realistic polychrome finish

Alkaline-glazed

Shiny, frequently transparent glaze ceramics; uses silica (sand) and soda (nitre); also salt-glazed; usually stoneware, with a glaze of glossy, translucent and slightly orange-peel-like texture which was formed by throwing common salt into the kiln during the higher temperature part of the firing process; sodium from the salt reacts with silica in the clay body to form a glassy coating of sodium silicate

Ferric Iron Oxide

Glaze Coloring

Pale yellow to black, also iron red, celadon green

manganese oxide

Glaze Coloring

Bright red purple to dark purplish brown

Antimony Oxide

Glaze Coloring

Yellow

Earthenware

A soft pottery; probably the oldest and also most universal pottery; natural clays fired at temperatures from 900-1200 deg C or 1652-2192 deg F and are usually porous and opaque; pale tan to red and brown; tendency to chip and break; examples include Southwest Indian Work, French cooking utensils, Mexican ware and Pennsylvania Dutch tableware

900-1200 C or 1652-2192 F

Firing temperature of earthenware in deg C and deg F

Biscuit

Type or state of earthenware after the first firing; can only be used for ornamental purposes; can be readily recognized since it is either tan or terracotta in color and dull in finish; can have a scratched or painted design which can be glazed by additional firing

Stoneware

Clays containing a higher percentage of sand when fired from 1200-1280 deg C or 2191-2336 def F; extremely hard, usually vitrified and impermeable to water; dull and glazed forms may be white or colored; made by Chinese in antiquity and became known in Northern Europe after Renaissance; usually for pickle and preserve jars

1200-1280 C or 2192-2336 F

Firing temperature of stoneware in C and F

Porcelain

Common name: China.

Look: Clear white color, extremely hard, translucent.

History: Chinese invention feldspathic material in a fusible state incorporated in a stoneware composition. End of the Han period; first mastered in a German factory in Meissen. The aristrocrat of the potter's wheel.

Composition: Kaolin base plus decayed granite. Firing Temperature: 1280-1400C or 2336-2552F.

Use: Electrical insulators and laboratory equipment. Figurines, tableware and other decorative objects.

Sound: bell-like ring when struck.

Pentutse

China stone; a less decayed, more fusible feldspathic material, was also used in Chinese porcelain, it forms white cement that binds together the particles of less fusible kaolin

Protoporcelain

Early vitreous wares produced by the Chinese before they developed their white vitreous ware (true porcelain) that was later admired by the Europeans

Hard Porcelain

Considered the best kind of porcelain fired between 1310-1410C or 2390-2570°F; usually called "true porcelain; it is made of kaolin with feldspathic glaze and fired in one with the body

1310-1410C or 2390-2570°F

Hard porcelain firing temperature

Soft porcelain

Porcelain fired below 1260C or 2300F which is really imitation porcelain; more translucent, but not as white in color nor does it have the clear ringing tone of true porcelain; glaze is added at second firing which was lower in temperature than the first; suffers more damage through time; made of soft paste

1260C or 2300F

Soft porcelain firing temperature

Soft paste

A mixture of white clay and a ground glassy substance

Bone China

Invented by English potters in mid-18th C.;

A white hard translucent ceramic ware, usually glazed; Gained whiteness, translucency and stability through the inclusion of calcium phosphate in the form of calcined (fired, chemically altered) ox bones;

2 or more firings at different temperatures (1515C,1357 OR 2760F, 2475F); broader in scope that earthenware or porcelain; opaque, but not as hard as porcelain; between soft paste and hard paste in whiteness and tone

2760F and 2475F

1st and 2nd firing temperature of bone china

Engobe/Slip

Thick semi-solid fluid composed of clay and water into which the ware was dipped when it was dry enough to be fired; can be brushed, trailed or dropped from the spout of a vessel on the ware in the desired design; ancient in origin having been used by Romans and by various countries during medieval times

Terra Sigillata

(from Italian meaning "sealed earth") A very fine particle slip (clay and water). It typically comes in red / terra cotta, white, and black. It can be burnished to give the surface of the clay a sheen.

Decalcomania

The art of transferring designs from specially prepared paper to a wood or glass or metal surface

Lithography

the process of printing from a flat surface treated so as to repel the ink except where it is required for printing; image and non-image areas are treated

Sgraffito

Designs that are drawn with a pointed tool that scratches through slip to reveil the body

Overglaze

Glaze decoration applied on the surface of an already glazed piece and then re-fired

Underglaze

A colored decoration applied on raw or bisque ware before the glaze is applied; patterns are painted before glazing and firing

Primitive Ceramics

Ceramics used by primitive man for utilitarian purposes; these are vessels fashioned and made of hardened earth to serve as storage for grain and water; usually plain but later on have included patterns like the zigzag and chevron

Egyptian Ceramics

Pottery in Ancient Egypt which served different purposes other than as containers for practical or domestic items; used in ritualistic rites that area geared towards the burial ceremony

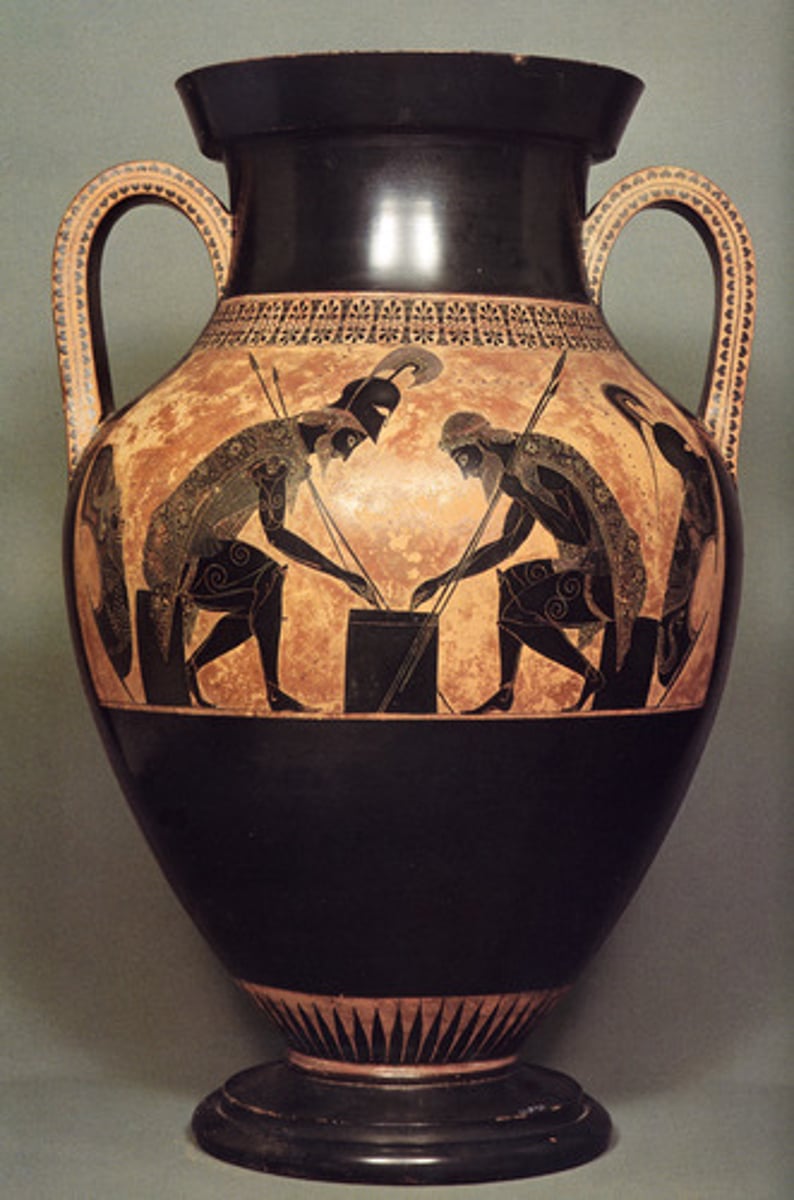

Black Figure Ware

Greek ceramics wherein figures are painted black on a red background

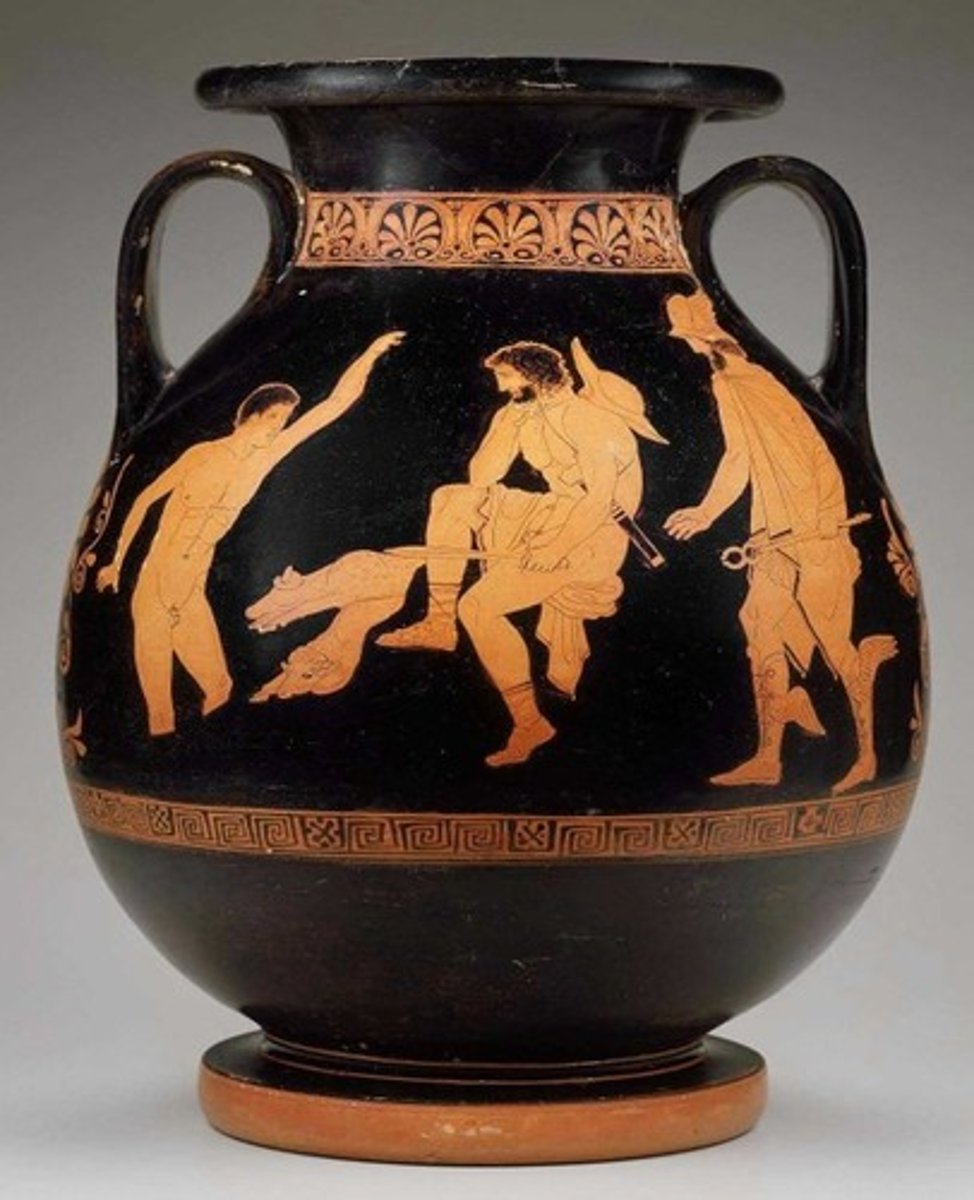

Red Figure Ware

Greek ceramics wherein figures are painted red on a black background

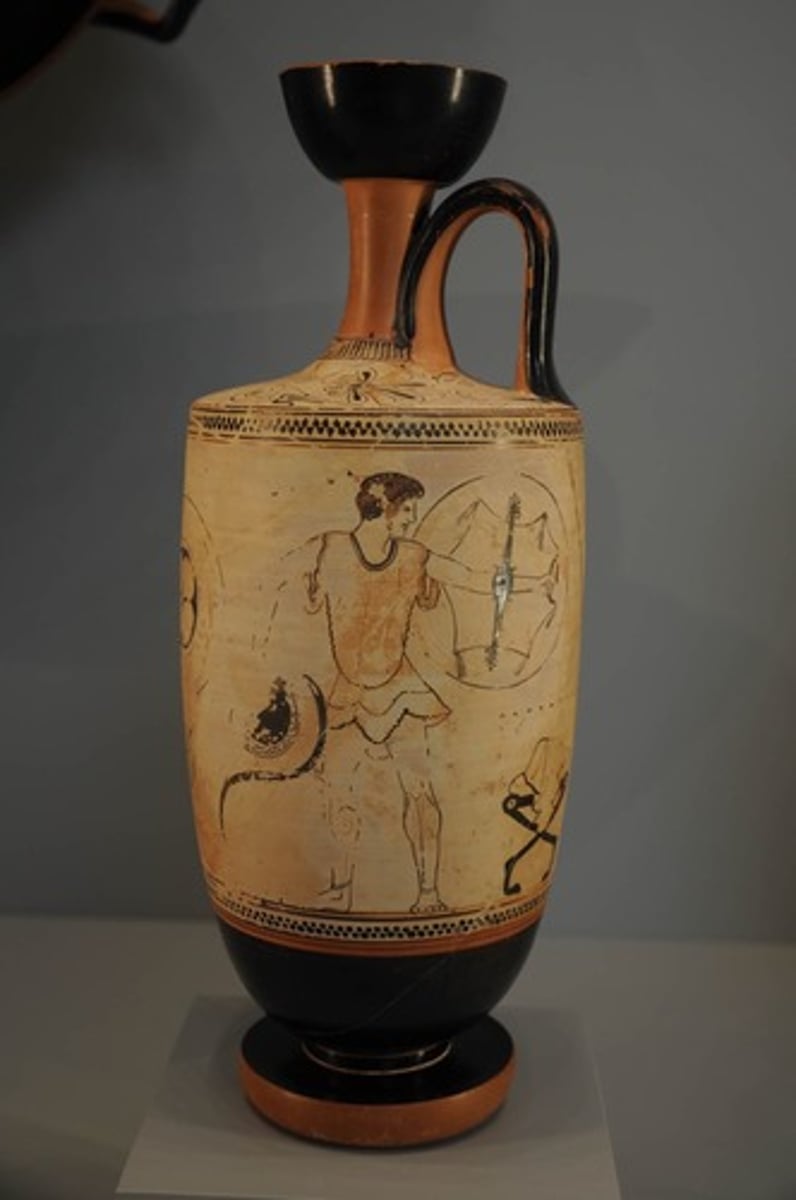

White Ground Ware

Greek ceramics wherein figures are painted either red or black on a white background

Skyphos

Greek drinking cup

Kylix

Greek drinking cup; shallower

Column krater

Greek bowl for mixing wine and water

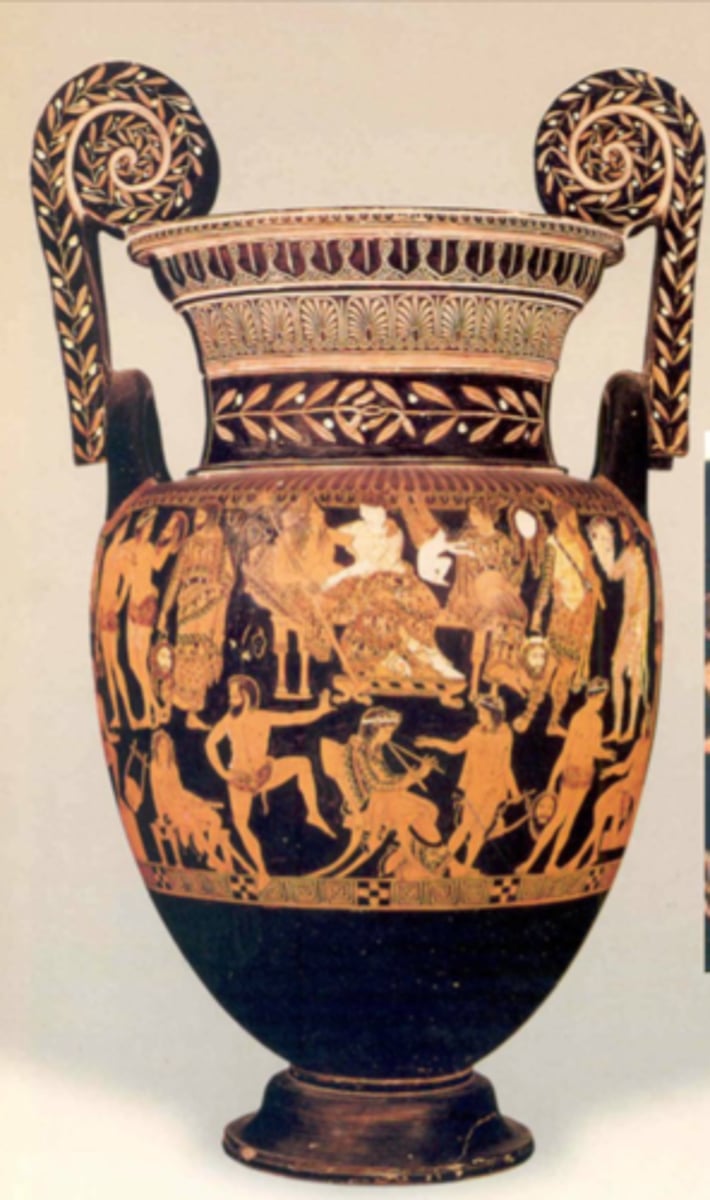

Volute Krater

Greek bowl for mixing wine and water

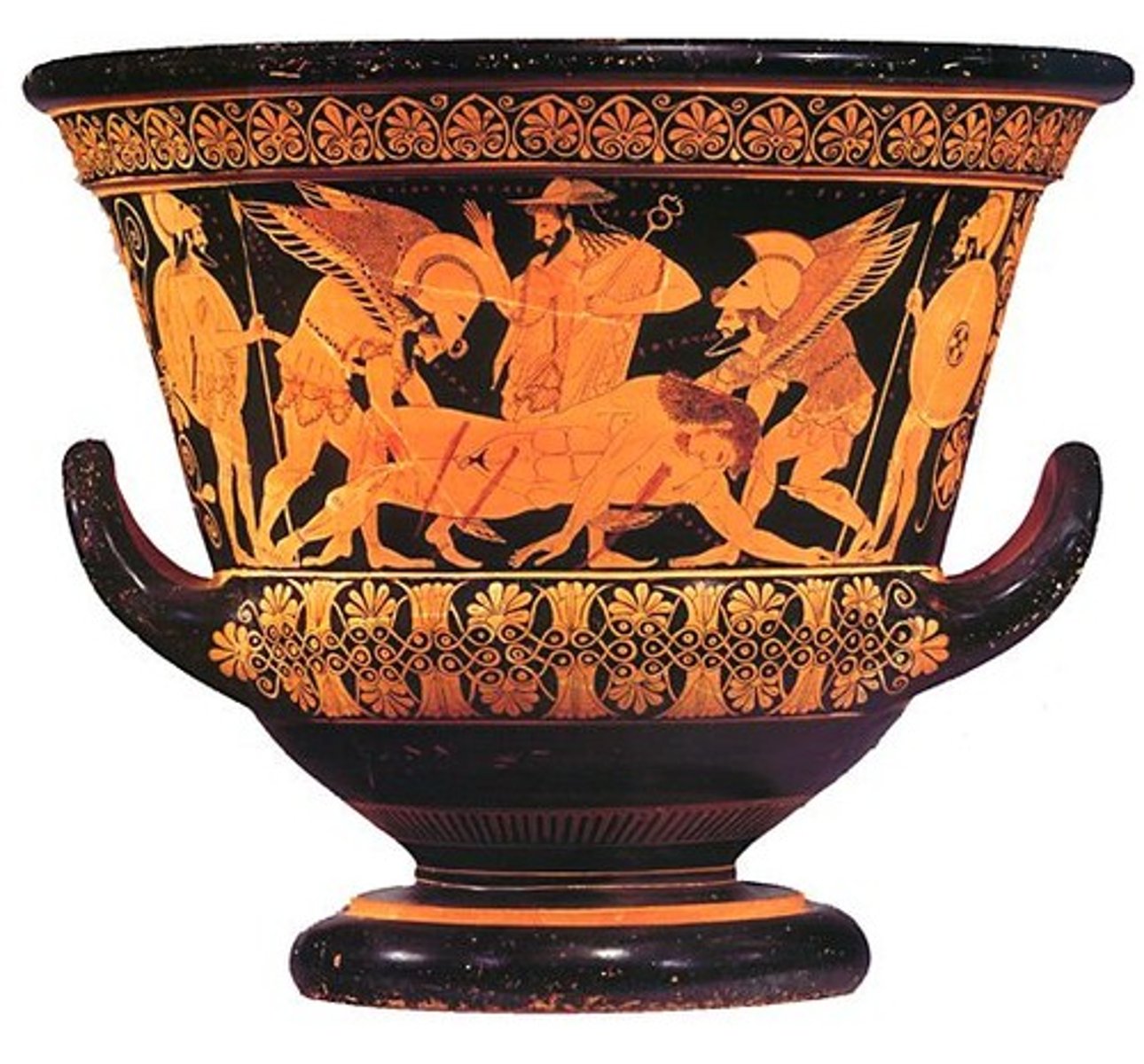

Calyx Krater

Greek bowl for mixing wine and water

Bell Krater

Greek bowl for mixing wine and water

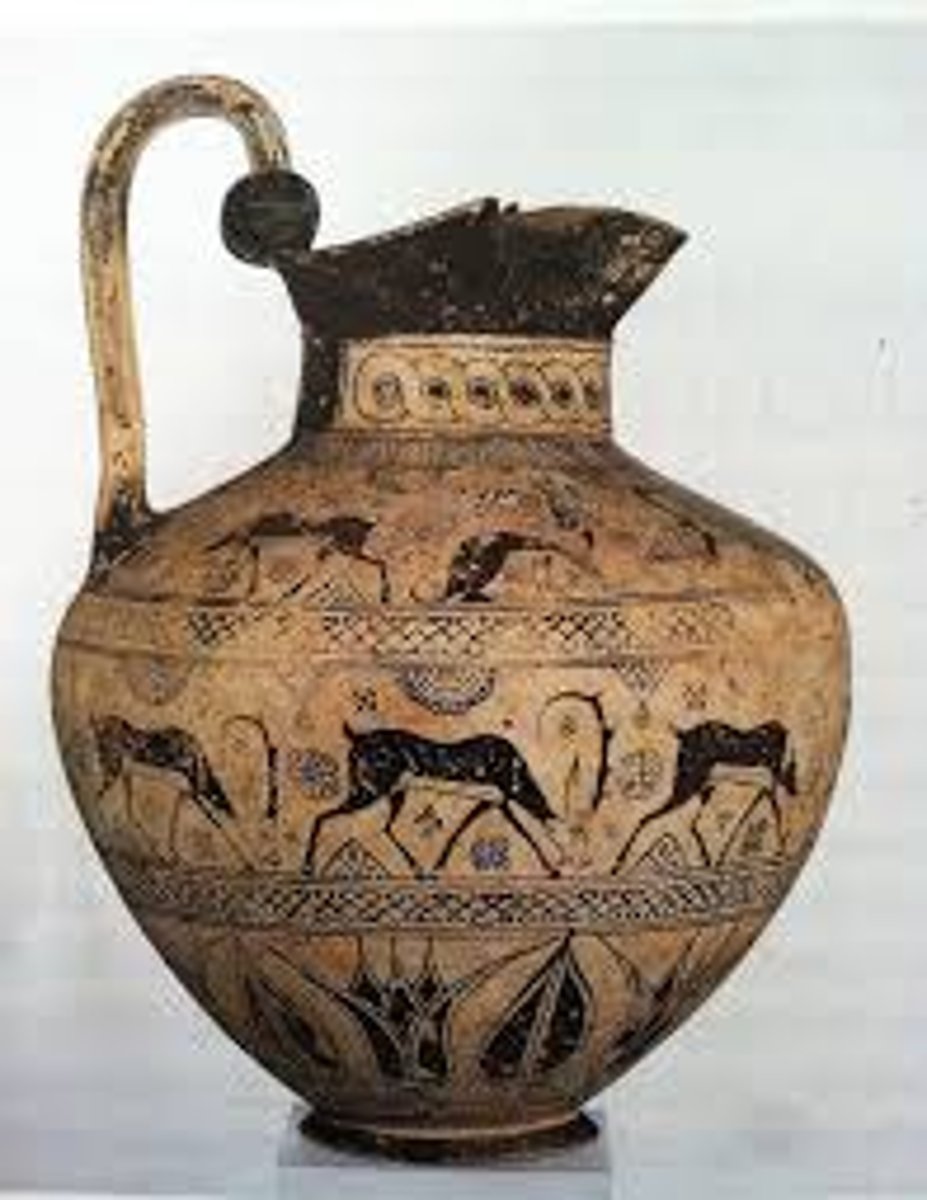

Oinochoe

a Greek wine jug with a round mouth and a curved handle

Hydria or Kalpis

Greek water jug

Lekythos

A Greek oil jug with an ellipsoidal body, a narrow neck, a flanged mouth, a curved handle extending from below the lip to the shoulder, and a narrow base terminating in a foot. It was used chiefly for ointments and funerary offerings.

Aryballos

A small Greek globular or ovoid flask for holding oil or perfume

Amphora

Greek storage jar for honey, olive oil, wine and water

Pelike

A Greek storage jar with two handles; a

container for wine or other supplies.

Stamnos

Greek wine or water container

Italian

Pottery for this culture became a vehicle of artistic expression; it was given value not inferior to canvases and frescos of the same period; it improved more in merit and value

Early Renaissance

Period when ceramics were first utilized in Italy (utilitarian ceramics); these ceramics were influenced by the Moorish Majorca wares

Majorca

Origin of Italy's ceramics; Moorish wares which was tin-glazed earthenware from Majorca, Spain

Istoriato

A new, rich decorative style of ceramics which replaced the majolica towards the end of the 16th century

Bianchi di Faenza

Lightly decorated white wares made in Faenza, replacing majolica whose production had declined due to economic constraints; it continued the tradition of new designs and fine workmanship

Passeri

An Italian antiquary of distinction, he claims the discovery and introduction of the ware for Pesaro; he alone records the art of pottery-making in Italy as early as the 13th century; affixes the date 1492 to the introduction of Majolica ware

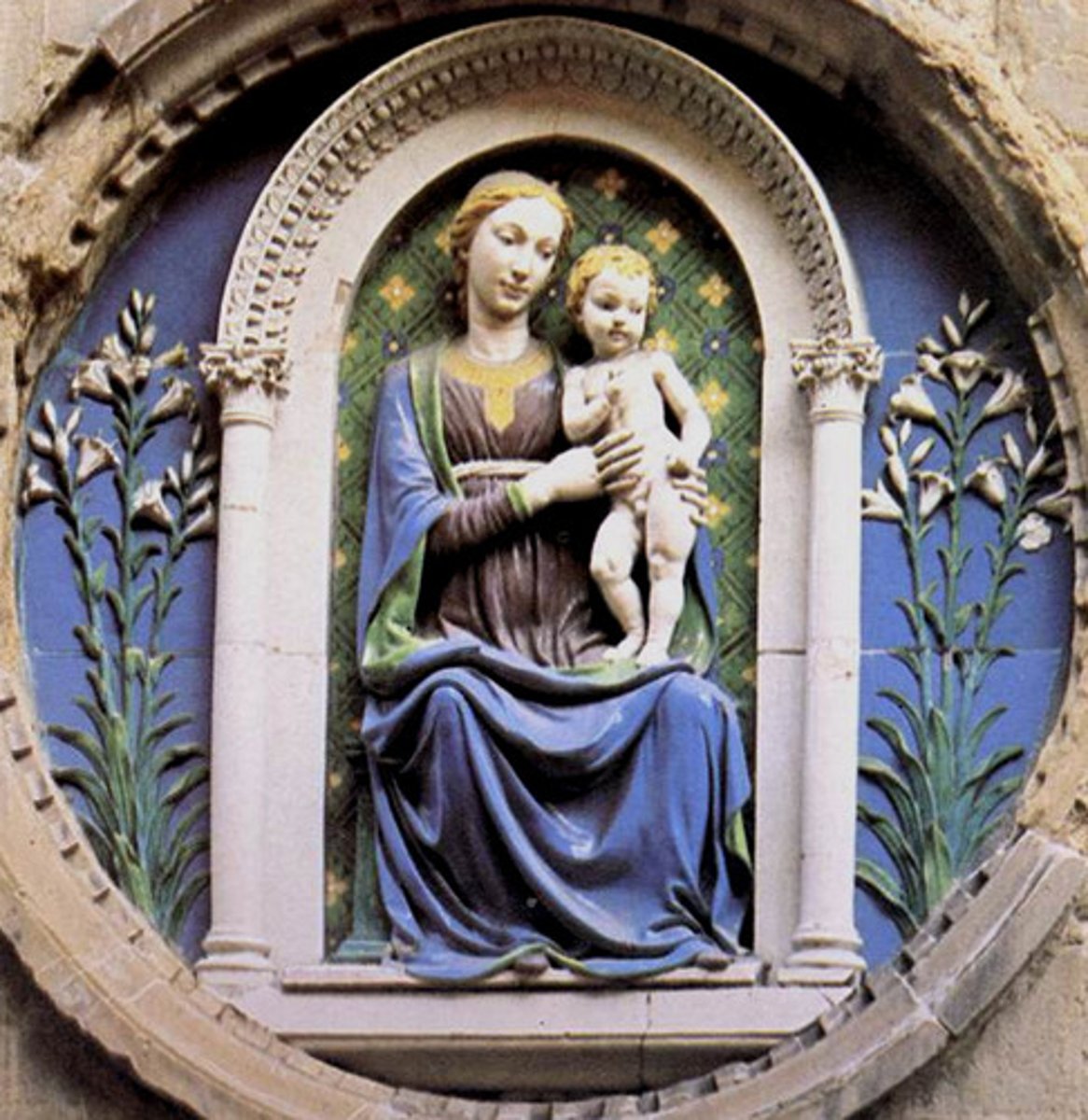

Luca Della Robbia

He was born in Florence (1400); successful goldsmith and sculptor; he proposed to himself the question of producing his works in baked clay, covered with a glazing, as a substance more flexible and quite as durable as the marble itself; first discovery is the stanniferous enamel, the hardest then in use; credited to be the one to raise the production of majolica from a craft to high art in Italy (applying majolica to sculpture)

Stanniferous enamel

Ceramic glaze invented by Lucca Della Robia, the hardest glaze in use then

Master Giorgio Andreoli

Known to have perfected the luster technique, to a point he was frequently hired to embellish the work of other workshops

Luster technique

Glazing technique perfected by Master Giorgio Andreoli, achieved after three firing and simulates the luster of gold and ruby (rubino)

Francesco de Medici

First European to create porcelain after the Chinese; he produced an inferior type of soft-paste porcelain in his Florence workshop during the 16th Century

Medici Porcelain

Also known as strange ware produced by Francesco de Medici; first porcelain produced in Europe with only nineteen pieces; has observable pittances or pits

Francesco Vezzi

He established the first porcelain factory in Venice which produced hard-paste porcelain and was in operation for 7 years; surviving pieces included teapots with chinoiserie decoration

Doccia Ware

ceramics produced in a factory founded in Doccia near Florence in 1737, where Marchese Carlo Ginori began experiments with the manufacture of hard-paste porcelain; admirable imitation of the majolica and successful reproduction of the bas-reliefs of Lucca Della Robia; tin glazed; principal mark is two triangles crossed, forming a sixpointed star

Tulipano

Painted stylized floral pattern which decorated Doccia Ware

Capo di Monte

porcelain factory by Charles III and created soft-paste porcelain characterized by a pronounced creamy color and unusually glossy clear glaze making it a particularly successful medium for undecorated porcelain sculpture; principal mark is an N surmounted by a crown, in blue (sometimes R. F. are substituted - created under Ferdinand's time)

Commedia dell'arte

A type of improvisational street theater - provided a seemingly limitless source of subjects for both porcelain modelers and painters in the 18th Century;

Pulcinella

one of commedia dell'arte's principal characters, immediately identifiable by his typical costume of a loose tunic, tall conical hat, and black mask with a prominent hooked nose

Delftware

Dutch tin-glazed ceramics heavily influenced by Islamic techniques and motifs steeped in the majolica tradition; Dutch Blue and White which emulated the Chinese wares using majolica techniques; soft-bodied earthenware fired at a relatively low temperature and covered with tin glaze; polychrome versions copy the Chinese Kang-hsi and Japanese Imari wares

Royal Porcelain Jar or Bottle (De Koninklijke Porceleyne Fles)

The only remaining original producer of Dutch delftware founded in 1653 with a stylized jar logo

Hague Porcelain

Hard-paste porcelain, similar as Amstel and identical with Dresden ware in body and glaze

Bleu de roi

Royal blue color with rich gilding used to decorate Hague porcelain table service

Delft Blue and Polychrome

Two colors used to decorate Delftware

Amstel Porcelain

Ceramics produced in Weesp near Amsterdam (first in Holland); varieties from Dresden has fine white body, best quality, closely resembling the body of Dresden china with landscape and figure decorations, which was later on discontinued

Peasant Delft

Dutch ceramics or delftware decorated with farm stables, summer seasons; are done in haste, less careful; mostly done by apprentices

Faenza

tin-enameled earthenwares of France originating form a town in Italy

Terre de pipe

A favorite earth in the construction of pottery in France; its pure whiteness and earth was applied in the Oiron or Henri II ware

Faience de Oiron or Henri Deux Ware

Also known as the Saint Porchaire ware; said to be the earliest high quality French pottery; bold and elegant designs and are extremely rare, made for nobility and religious institutions and royalty; uses terre de pipe

Bernard Palissy

he worked for 16 years in vain to imitate the white-glazed pottery after seeing a cup from Italy; produced Palissy ware which was admired for smooth glazes in richly colored enamels; royal potter of Catherine de Medici; noted for pieces reproducing scriptural and mythological subjects in low relief and for his rustic pieces (rustic ware) decorated with sharply modeled forms copied from nature i.e. insects and plants

Rouen Faience Factory

Factory owned by the Poterat family in France producing soft-paste porcelain characterized by their bluish glaze and distinctive underglaze blue decoration; no factory mark

Saint-Cloud Factory

Factory in France experimenting on soft-paste porcelain imitating Chinese blue-and-white porcelain but soon initiated French style of decoration derived from French prints; decorated with foliage, scrollwork, animals or human heads

Pierre Chicanon

Established the Saint-Cloud Factory

Chantilly Factory

Established factory in France by Louis Henry, duc de Bourbon; produced soft-paste porcelain heavily influenced by Japanese porcelain in particular, some were direct copies of Japanese pieces (Japanese interpretations and imitations)

Mennesy Factory

Factory established by Francois Barbin in the town of Villeroy, France; produced utilitarian ware of considerable originality and somewhat naïve charm; closed in 1773

Sevres

Soft-paste porcelain founded in Vincennes, France (1740) dominating European ceramics for the 2nd half of the 18th century; produced whiter and freer of imperfections; hired most talented French artists to design; attracted the attention of Louis XV who provided financial backing and purchased the first dinner service they produced; flourished because of its constant innovation

Pate Tendre

Soft-paste

Pate dure

Hard-paste

Limoges

First hard-paste porcelain in France due to discovery of kaolin in France; became a subsidiary of the royal factory in Sevres; was making the finest, purest white porcelain in the world

Salt-glazed stoneware

European stoneware developed in Germany at the eng of 14th century; common salt used as an alkali was thrown into the kiln, and the soda from the salt created a glassy layer on the pot's surface

Hafner Ware

A German lead-glazed stoneware popular in the 16th and 17th Century, with many vessels imitating metal jugs and tankards

Poterie deluxe

German ceramics which was exceedingly fine in color, form and ornament; the highest eminence which German pottery reached (1500-1620)

Fayence

German tin-enameled pottery

Johann Friedrich Bottger

German alchemist who discovered the materials required to produce a white, translucent, high-fired porcelain body (true hard-paste porcelain); also developed high-fired red stoneware

Bottger stoneware

high-fired red stoneware which was used both for wares and for figures