Process Safety Exam 1

1/101

There's no tags or description

Looks like no tags are added yet.

Name | Mastery | Learn | Test | Matching | Spaced |

|---|

No study sessions yet.

102 Terms

Myth or Truth: Process safety is a soft science with no more than hard hats and safety glasses - not engineering science

Myth

Myth or Truth: Industry should train graduates in process safety and it should not be part of the undergraduate curriculum.

Myth

Truth or Myth: Process safety only applies to the petrochemical industry

Myth

Myth or Truth: Process safety is the same as personal safety

Myth

What type of events does process safety cover?

high consequence, low frequency events

Myth or Truth: Process safety does not include product safety

Myth

Aluminum Company of America (ALCOA)

largest supplier of aluminum in the world

Hired Paul O’Niell as CEO to improve company

He focused on safety and increased profits from $264 million to $1.5 billion

Individual Risk

One person exposed to one or more hazards (Usually location dependent)

Societal Risk

A group of people exposed to one or more hazards

Voluntary Risk

A risk that is consciously tolerated by someone seeking to obtain the benefits of the activity that poses the risk

Examples: Riding a car, motorcycle, mountain climbing, skiing

Involuntary Risk

Risk that is imposed on someone who does not directly benefit from the activity that poses the risk

Example: Living near a chemical plant, riding a train, riding an airplane, visiting a mall

Process Incident

The sudden unintended release of or exposure to a hazardous substance, which results in or might reasonably have resulted in deaths, injuries, significant property or environmental damage, evacuation or sheltering in place

Hazards

Things that have the potential to cause damage to people, property or environment

Example: fire or explosion

Risk

A function of likelihood and consequence (magnitude)

Lagging metrics

Data that is collected after an incident has occured usually easier to define and tabulate

Examples: First aid incidents, loss of primary containment (LOPC) incidents, property damage, injuries, fatalities, accident statistics

Leading metrics

Data that is collected before an incident has occured

Examples: Response time for process safety suggestions, number of workers with overdue training, number of operating procedures updated each year, work order backlog, near misses

More serious incidents can be reduced by focusing on what type of data?

Leading indicators since you normally have more data

Fatality Rate (FR)

Accident statistic that is independent of exposure time, # of fatalities per year/total number of people in applicable population

Relative Risk Index

Used to compare the risk to an average job. Fatality rate for a group/fatality rate of all jobs

Risk Tolerance or Acceptance

The maximum level of risk of a particular technical process or activity that an individual or organization accepts to acquire the benefits of the process or activity (People accept risks based on their perceived risk, which might not be the actual risk)

Risk Matrix

A semi-quantitative method to represent risk and to help companies make risk acceptance decisions

Should be regularly reviewed and updated

Code

Set of rules developed by a team of knowledgeable people

Do not have legal authority but governments might adopt it into law

Standard

more elaborate

codes tell you what you need to do and a standard tells you how to do it

Do not have legal authority but governments might adopt it into law

Regulation

developed by a government and has legal authority

can be based on a code or standard

violations can result in fines or jail time

Safeguards

A design feature, equipment, procedure or even software that is in place to prevent or mitigate the consequences of an initiating event

Preventative Safeguards

Stop the incident from happening after an initiating event

Examples: alarm systems, maintenance, procedures, emergency shutoff valves

Mitigative Safeguards

Reduce the consequences after an incident has occured

Example: Active fire protection, sprinklers, emergency fire water system, blast resistant control rooms

Initiating Event

A device failure, system failure, external event or improper human inaction that begins a sequence of events leading to one or more undesirable outcomes

Examples: Operational problems, equipment failures, human error and design deficiencies, natural phenomena like lightning strikes, floods or tornadoes

Enabling Conditions

operating conditions necessary for initiating event to propagate into a hazardous event

Do not independently cause the incident, but must be present or active for it to proceed

Examples: the probability that a particular raw material or catalyst is in the process or the probability that the temperature or pressure is within the high or low values

Conditional modifiers

Conditions that occur after initiation and impact a step in the sequence either before or after the incident has occured

Example: weather conditions (wind direction and speed), presence of people, and probability of ignition

Inherently Safer Design

Eliminate hazards rather than to provide complex safeguard hierarchies around the hazards

Strategies:

Minimize amounts

Substitute less hazardous chemicals

Moderate conditions to reduce hazards

Simplify to limit operator error

Toxicology

Science of Poisons

Study interaction of humans with chemical or physical agents

What makes a substance harmful to humans?

Dose: Amount and time of exposure

Chirality

Objects that are not identical to their mirror image (in terms of toxicology, one molecule might be beneficial and its mirror image might be poison)

Toxicant

Chemical or physical agent with nature to cause harm to a biological system

Examples: chemicals, dusts, fibers, noise, radiation

Industrial hygiene

Study methods to prevent or reduce exposure and intrusion of toxicants into biological systems

Toxicity

An intrinsic property of an agent that causes a particular effect on a person

Cannot be controlled but the effect on a person can be reduced and controlled by hygiene methods

Acute Toxicity

Short period of exposure <24 hrs

Chronic Toxicity

Multiple exposures during long exposure period

Toxic Hazard

Likelihood of a damaging effect from exposure to agent

Routes of Infusion of Toxicants

Inhalation

Chemical Absorption though skin

Ingestion

Injection

Inhalation

most common route of infusion of toxicants in industrial facilities

particulates 2-5 um can reach and remain in the bronchial tubes and alveoli

Method of control: ventilation, respirators, hoods and other PPE

Ingestion

Through contamination of food

Modified and excreted in bile

Method for control: rules on eating, drinking and smoking

Chemical Absorption through skin

One of the most common routes of infucsion of toxicants in industrial facilities

rate varies widely with chemicals and skin conditions

Method for control: PPE, glove selection

Injection

through cuts into skin

Highest blood concentrations so you’ll see the consequences faster

Method for control: PPE, line of fire

Blood levels after infusion are affected by what parameters

exposure rate (conc. gradient)

extent of absorption (mass transfer)

all distributed amount entry routes

rate of biotransformation, metabolism

accumulation

excretion modes

Methods for eliminating toxins

excretion: kidneys, livers, lungs, sweat, hair and nails

detoxification: digestive tract converts chemicals to less harmful products

storage: fat cells, liver, kidney and bones

High infusion of toxins can damage kidneys, livers and lungs which reduces the efficiency of elimination

Probit

A mathematical transformation to change S-shape into a straight line

TLV-TWA

Time weighted average exposure without adverse effects (8 hr day during worker lifetime)

TLV-STEL

Short term maximum exposure limit up to 15 minutes countinously without suffering intolerable irritation, chronic or irreversible tissue change, narcosis of sufficient degree

TLV-C

Ceiling limit (concentration not to be exceeded at any time, not even instantaneously)

PEL

permissible exposure level determined by OSHA which is similar to the TLV-TWA (if different use the lower one to be more conservative)

IDLH

Immediately dangerous to life and health

Industrial Hygiene

Science of anticipating, recognizing, evaluating, and controlling workplace conditions that may cause workers’ injury or illness

Three important phases in any industrial hygiene project

Identification

Evaluation

Control of occupational conditions which cause sickness and injury

Safety Data Sheet (SDS)

lists physical properties of substance that may be required to determine potential hazards

One of the most important references used during an industrial hygiene study

Globally Harmonized System (GHS)

world-wide system that all countries can use to identify the hazardous properties of chemicals and to provide unified labelling to facilitate shipping chemicals between countries

Nine Major Hazard Groups

Health Hazard

Oxidizer

Other hazards

Environmental

Corrosive

Flammability

Explosive

Compressed Gas

Acute Toxicity

Health Hazard

Flammability

Compressed Gas

Corrosive

Explosive

Oxidizers

Environmental

Acute Toxicity

Other Hazards

What are the two signal words?

Danger (most severe) and Warning (less severe)

Odor Threshold

Concentration at which most people detect an odor

Relying on your nose for safety is unreliable so you need monitoring equipment

Potential Exposures of Hazards

Single volatile toxicant

Multiple toxicant

Dust

Noise

Toxic vapors in enclosure, with ventilation

Vaporization of liquid

For multiple volatile toxicants, the total exposure factor must be less than or equal to what number to avoid overexposure

1

To avoid overexposure with multiple volatile toxicants, the sum of the concentrations of the toxicants must be less than what?

The time weighted average exposure without adverse effects for the mix

What are the two important assumptions when applying this equation?

An average concentration

Steady state

1st Degree Burn

Least severe, red painful skin that swells slightly

2nd Degree burn

Blisters and are painful

3rd Degree Burn

Damages all layers of the skin and skin looks white or charred (can cause little to no pain if the nerves are damaged)

What are the two types of control of workplace exposure?

Environmental control: reducing exposure/concentration via enclosure, ventilation, wet methods & housekeeping

PPE: providing a protection barrier via earplugs, gloves, etc. (last line of defense)

What is the wet method?

Using liquid to reduce dust

Noise Reduction Ratio (NRR)

a unit of measurement used to determine the effectiveness of hearing protection devices to decrease sound exposure within a given working environment

Ventilation in Hoods

local ventilation, with positive or negative pressure to remove contaminants

preferred method of ventilation since it eliminates or greatly reduces worker exposure

Dilution Ventilation

used when local ventilation is not possible but not preferred since worker is exposed

Air is used as a diluent

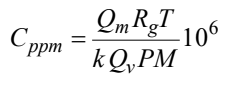

Source Models

Describe how material escapes from a process

What data do source models provide?

Release rate

total amount released

state of material: liquid, solid, gas, combination

Source Model: Liquid through a hole

pressure is the driving force

mechanical (pressure) energy is converted to kinetic energy

losses due to friction due to liquid flow

What does the discharge coefficient depend on?

Reynolds number and hole diameter

Liquid Flow Through Pipes Source Model

Driving Force is Pressure

Velocity is constant so long as the cross sectional area of the pipe is constant

Losses due to viscous drag

Gas Flow Through a Hole

Pressure is the driving force

Gas expands as pressure decreased through hole

Frictional losses occur in this process

Isentropic

Constant entropy throughout the system

Where can toxins be stored?

Fat Cells

Kidney

Liver

Bones

What are the major routes of excretion of toxins?

Kidneys

liver

lungs

What size of dust particles present the greatest hazard to lungs?

2 to 5 micrometer

Does density change for incompressible fluids?

No

What does the discharge coefficient account for?

Friction

What is the Fanning friction factor a function of?

Reynolds number and relative roughness e/d

Gas expands as pressure does what?

Decreases

Choked Flow

Maximum flowrate of a vapor through a hole

Throttle Expansion

Little of the energy is converted into kinetic energy

Detailed physical structure information of the leak is needed for an accurate source model

Free Expansion

most of pressure energy is converted to kinetic energy

only the leak diameter is required for an acceptable source model

Choked Pressure

The maximum downstream pressure resulting in the maximum flow through a hole or pipe

Gas Flow through pipes Source Model

Pressure is the driving force

as pressure decreases the gas expands and the velocity must increase

Temperature can either increase or decrease depending on the relative effects of gas expansion and friction