turbines 4

1/33

There's no tags or description

Looks like no tags are added yet.

Name | Mastery | Learn | Test | Matching | Spaced | Call with Kai |

|---|

No analytics yet

Send a link to your students to track their progress

34 Terms

combustion chamber purpose

converts potential energy into kinetic energy

an effective combustion chamber must provide

Means for mixing fuel and air for efficient combustion

Burn the mixture efficiently

Provide sufficient cooling to a temperature tolerable by turbine blades under all operating conditions

Distribute hot gasses evenly to the turbine section

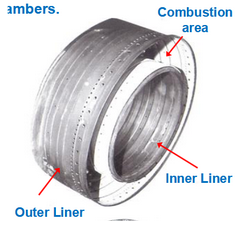

components of combustion chamber

casing

perforated inner liner

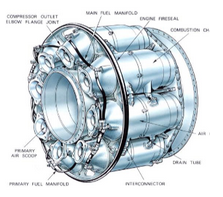

fuel drain system

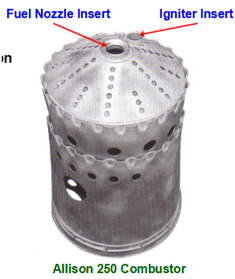

fuel nozzle fuel injection system

igniter plugs

casing

delivers high pressure air to inner liner

provides cooling

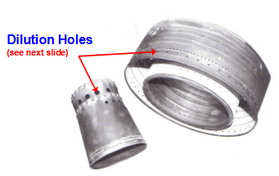

perforated inner liner

where fuel/air mixture burns

contains holes for air to enter for combustion and cooling

fuel drain system

located at lowest part of combustion chamber

draining fuel prevents tailpipe fires and hot starts during next engine start

fuel nozzle

inject atomized fuel into the inner liner for combustion

igniter plugs

provide initial ignition

primary air

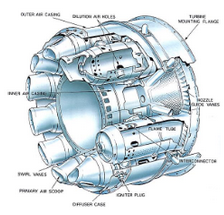

combustion air

directed into front of the inner liner to mix with fuel for combustion

secondary air

cooling air

passes through outer casing via holes in the liner to prevent combustion gasses from contacting inside wall of inner liner

louvers and cooling holes

directs cooling air along the inside wall of the liner and into combustion air

pre-swirl vanes

installed around fuel nozzles to swirl the incoming air to reduce velocity for combustion and swirl fuel spray

flameout causes

High or slow airflow rates

Turbulent weather

High altitude

Slow acceleration

High speed manoeuvers

types of flameout

lean die out

rich blowout

lean die out

occurs at high altitude, low engine speeds or low fuel pressure

rich blowout

Caused by rapid acceleration with overly rich mixture and insufficient airflow or low fuel temperature

types of combustion chambers

Single-can burner

Multiple-can

Annual combustor

Straight flow

Reverse flow

Can-annular combustor

single can burner

single fuel injection annular-type combustion can

multiple can burner

Consists of series of individual combustor cans that function as an individual unit (8-10 cans)

Cans are interconnected with flame propagation tubes > provide path to spread combustion

annular combustor

Consists of 360 degrees single circular combustor with a basket

straight flow annular combustor

air enters front (fuel nozzle area) and discharged at rear

reverse flow annular combustor

airflow reverses 180 degrees twice

helicopter and turboprop

can-annular combustor

Individual units are arranged radially around the axis of the engine

Cans are connected via interconnect tubes (flame propagation tubes) that move combustion to all cans

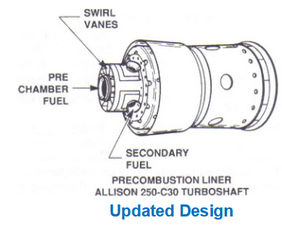

precombustor chamber

Portion of primary air enters precombustion chamber > air is mixed with fuel and ignited > gas enters main chamber and joins primary air and a 2nd fuel nozzle

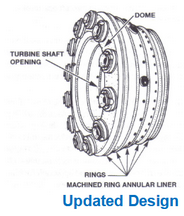

machined ring annular liner

Constructed by welding rings of heavy gauge metal together

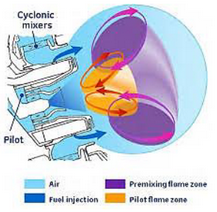

TAPS

Twin Annular Premixing Swirler Combustor Nozzle

Improves fuel efficiency and reduce nitrogen dioxide and nitric oxide emissions

contains 2 independently controlled annular flames for low power (pilot) and high power (cyclone)

TAPS

machined ring annular liner

precombustor chamber

can-annular

annular

multiple can

single can

louvers and cooling holes