Steel Test 2 - CVEN 659

1/178

There's no tags or description

Looks like no tags are added yet.

Name | Mastery | Learn | Test | Matching | Spaced |

|---|

No study sessions yet.

179 Terms

tension field action (TFA)

additional shear strength gained by considering post-buckling strength of web plate that occur from formation of tension field bw transverse stiffeners

not valid at end panels, so stiffeners closer together

max limit of a/h <= 3 to consider TFA

Transverse stiffeners

add stiffness to web plate of beam

transverse relative to longitudinal axis of beam (perpendicular to flange)

resist compressive force that will develop when web plate buckles in shear and TFA occurs

slenderness is limited to prevent local buckling

adding stiffeners cheaper than thickening web of main member

welded plates most common but can do bolted or welded angles

termination: welded, tight-fit, cut short

what properties important for steel

tension more important than compression

buckling limiting state for compression and controlled by geometrical conditions

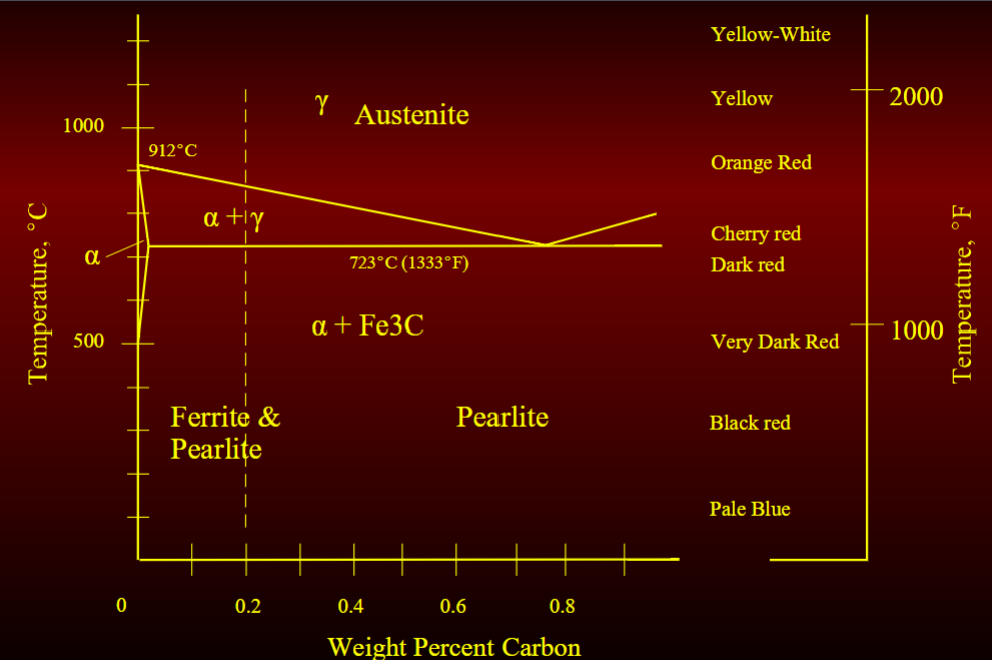

heated at low temps: blue color (600F) →dark red→ cherry red → orange-red-yellow→ white (2500F)

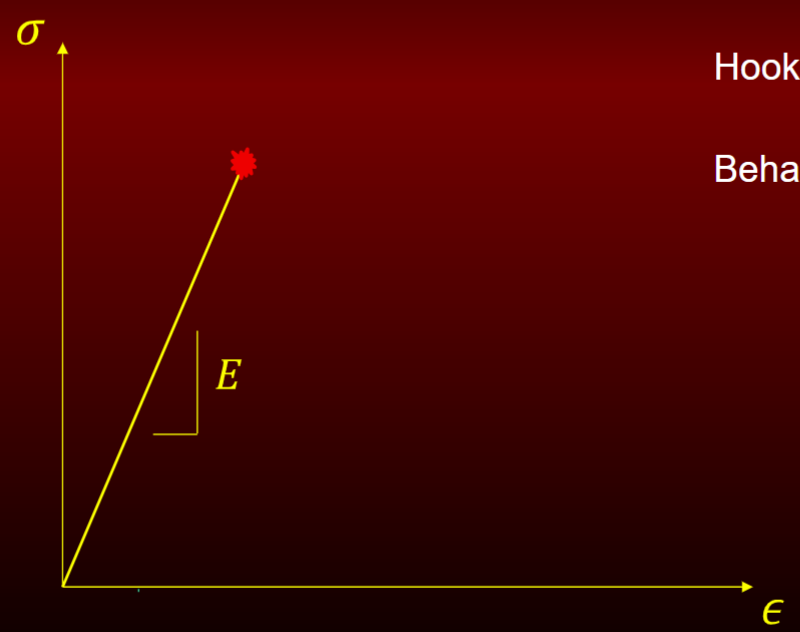

Elastic response

hooke’s law

behavior of glass

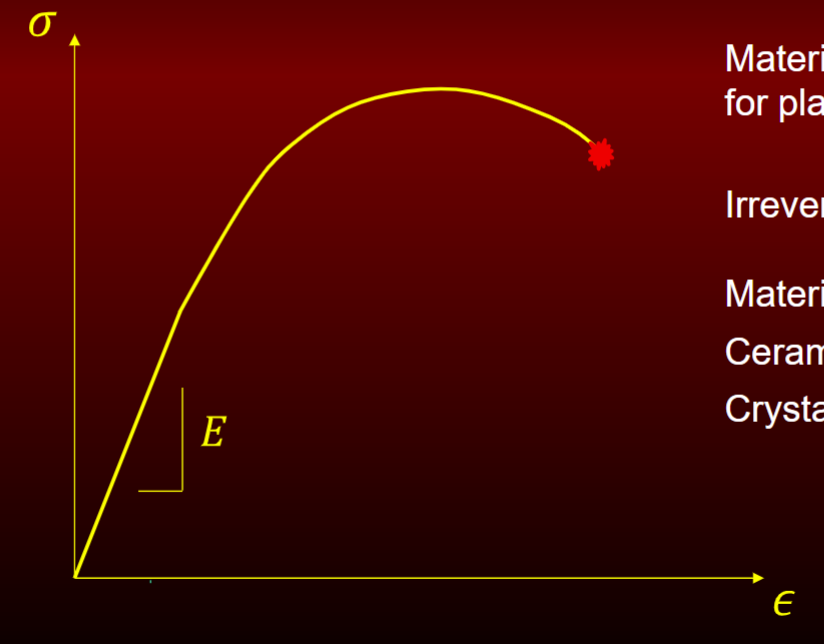

elastic-homogenous plastic response

has capacity for plastic deformation

irreversible plastic flow (can see in high strength steel)

materials: ceramics, crystalline polymers

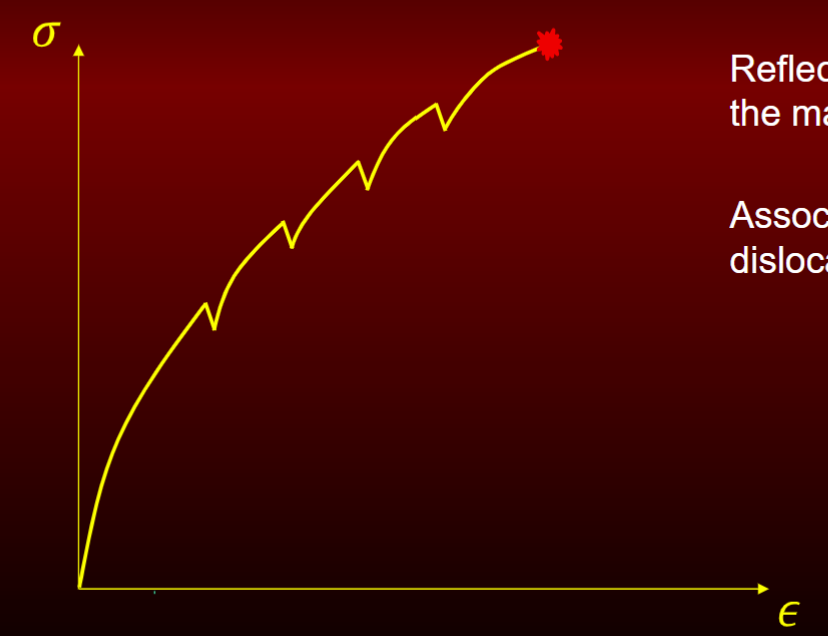

Elastic heterogenous plastic response

reflects non-uniformity of the material

associated w atomic dislocation interaction

very small portion

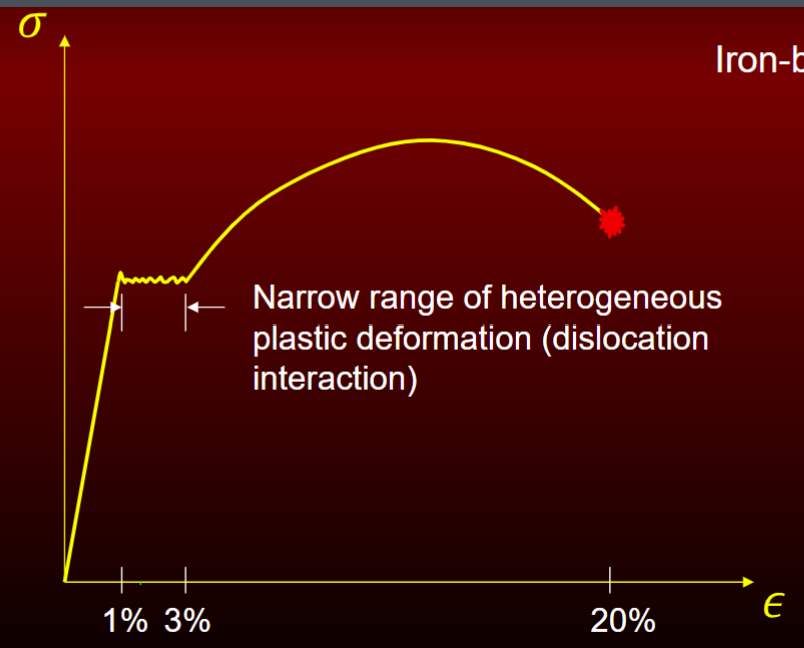

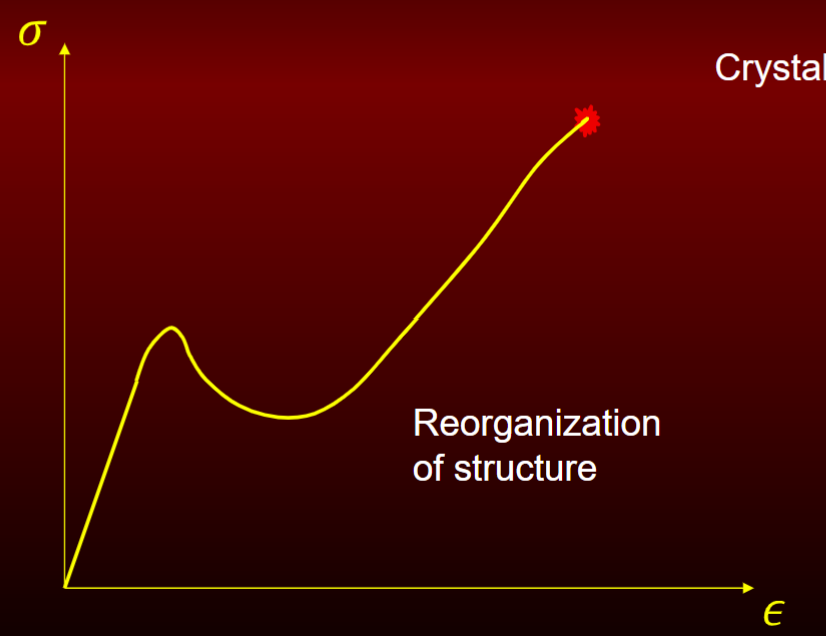

Elastic Heterogenous Plastic Homogenous Plastic

ex. iron based alloys (BCC)

include strain hardening and smaller squiggle = more alloyed

narrow range of heterogeneous plastic deformation (dislocation interaction)

Elastic plastic homogenous plastic response

ex. crystalline polymers (chains of mlc)

reorganization of structure = gain strength similar to post buckling

Theoretical strength of material

based on atomic bonding forces is always much higher than experimentally observed

bc presence of defects

point defect

atomic lattice is missing a single atom

have minimal effect on strength

vacancy may be occupied by alloy

line defect

defect is a line in the 3rd dimension and is a dislocation

under shear stress, atomic bonds around dislocation will break and reform consecutively allowing dislocation to move

dislocation stops at free surface or at grain boundary

if restrict dislocation movement, decrease ductility

alloy atoms bond with metal lattice if not alloy becomes impurity and strength is lowered

metallic bond

element have only 1/2/3 valence electrons and are bonded loosely to nucleus

as atoms come together, create electron gas

electrons try to repel each other but attraction to nucleus is greater

leads to good ductility and electrical conductivity

ductility

achieved as one plane of atoms slide over another plane without fracturing as atomic forces easily reach new equilibrium

Basic phases of steel that are 0.20% carbon

austensite

ferrite

cementite

austensite phaes (gamma iron)

iron w moderate solubility for carbon having a face centered cubic (FCC) structure

hot rolling structural shape and plate done at this temp range (1230-2250 F)

soft and has low modulus which reduces forces required to form and roll

Ferrite Phase (alpha iron)

iron w lower solubility for carbon with a body centered cubic (BCC) structure

low strength but high ductility

Cementite Phase (alpha + Carbide)

hard and brittle phase with high solubility for carbon

high strength but low ductility

Martensite

very brittle phase that can form if steel is heated above the austensite transformation temp and then it’s temp is quickly reduced (via quenced)

oxidation of steel

oxidation is an indicator of max temp

oxidation forms above 1200 F

Body Centered Cubic (BCC)

32% voids

Iron to 910 C and above 1400C to melting at 1538 C(2800F)

Carbon barely fits in the interstitial sites

carbon can be squeezed out if cool slowly

cool fast allow carbon get trapped = brittle bc strain from tensile

Face Centered Cubic (FCC)

26% voids

Iron (Fe) between 910 C to 1400 C

Cannonball stacking

most efficient, high ductility

more carbon allowed in structure

interstitial spacing is larger

100x more carbon can be dissolved here

Interstitials

small non-metallic atoms that located in vacant spaces bw metal atoms

larger than the free space but easily fit into interstitial sites

as metal cools, interstitials force iron atoms apart and creating strain

when FCC cools down to BCC, higher internal lattice strains

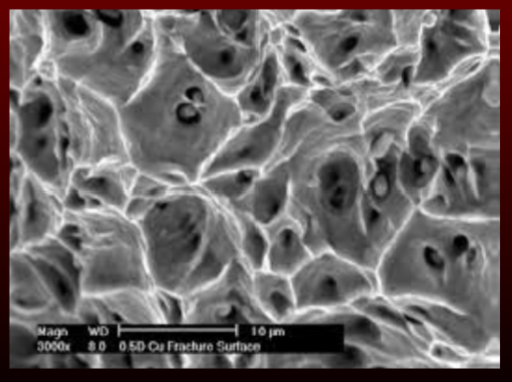

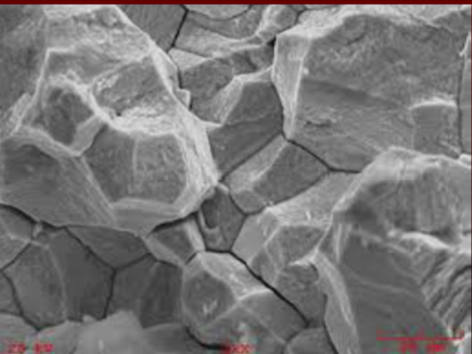

microscopic fracture/rupture mechanism

microvoid coalescence - give higher strength (want)

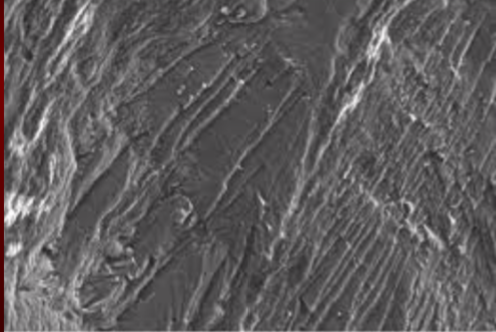

cleavage/transcrystalline - shear

intergranular fracture - don’t want bc rupture path bw grain

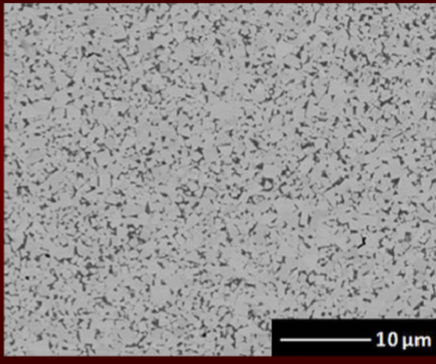

microvoid coalescence

initiated by nucleation of microvoid at inclusions or precipitate particles and surrounding lattice

as indv microvoids grow, begin to coalesce into larger cracks/seperation planes

high strength rupture

cleavage/transcrystalline

rupture along specific crystallographic planes

rupture path travels through grains

moderate strength

occur due to shear failure

Intergranular Fracture

brittle fracture where crack prefers to follow grain boundaries rather than through lattice structure or indv grains

characteristic of low fracture toughness

low strength fracture

Properties of steel and carbon content

Pure iron Fu = 4 ksi

w 0.2% carbon by wt Fu = 60 ksi

w 0.8% by wt Fu = 110 ksi

construction steel have carbon content bw 0.15 - 0.25% by wt

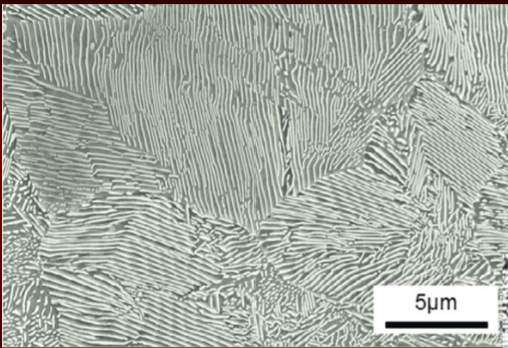

Pearlite

lamellar structure made of ferrite and carbide

Martensite Formation

if autensite cooled rapidly (quenching), diffusion of carbon prevented

trapped carbon in BCC cause lattice to distort into BCT (body centered tetrahedral)

non-symmetrical distortion causes internal strains that react strongly and lock dislocations reducing ductility

higher the carbon content, martensite formation occur at lower cooling rate → welding difficult

Tempered Martensite

brittleness of martensite can be minimized by reheating to some temp below 1350F (DO NOT RETURN TO AUSTENSITE PHASE)

carbon diffuses from solid solution into particles of cementite

tempering temp and a little time determine degree of martensite transformed into cementite

holding temp range from 800F-1200F

Annealing

Purpose: to soften

procedure: heated back up to above Austenite transformation line and cooling slowly

Steel strengthening mechanisms

chemistry - alloying

heat treating

fine-grain practice

alloying

solute atoms occupy dislocations restricting their movement, increasing strength, but reducing ductility

Aluminum alloying effect

deoxidizer, improves grain structure (removes O so Fe can bond w C)

Carbon alloying effect

improves strength and hardness at expense of ductility and toughess

low carbon: <0.3%

medium carbon: 0.3% - 0.5%

high carbon: 0.5% - 2%

cast iron: >2%

Chromium alloying effect

improves strength, hardness, corrosion resistance, and retention of strength at high temp

Copper alloying effect

improves corrosion resistance (A588) discover by accident

weather steel: corrosion product adhere to base metal and create protective layer

Niobium alloying effect

greatly improves strength

Manganese alloying effect

widely used to offset effects of sulfur

improves capability to be rolled

decreases ductility

improve capability to receive heat treatment

Molybdenum alloying effect

improves strength at high temps too

corrosion resistant

resistance to creep

Nickel alloying effect

w chromium, used to make stainless steel

improves toughness and impact strength

Phosphorus alloying effect

improves strength and machinability

reduces ductility

Silicon alloying effect

used in relatively large amount (25%) as an oxidizing agent

detrimental to steel if remains in small quantities

Vanadium alloying effect

improves grain structure

increases toughness and impact resistance

oxygen alloying effect

embrittles steel

upset atomic bonding

Sulfur alloying effect

reduces strength at elevated temperature

reduces toughness

improves machinability

comes from coal when burning for carbon

iron sulfide low melting/freezing points so it freezes after austenie phase of steel and will segregate grain boundaries

Hydrogen alloying effect

interferes with atomic bonding bw iron and carbon mlc

impurities

oxygen

sulfur

hydrogen

as steel solidifes, grain grow together and bond; impurities make it hard

Alloy Cleanliness

high quality steels achieved by melting in a vacuum bc reduces amount of inclusion and trapped gases

sulfur impurity major concern bc can form a film along grain boundaries

welding FeS is detrimental

can minimize FeS by adding Mn

Mn forms with FeS → MnS at higher temps so will have small spherical inclusions instead

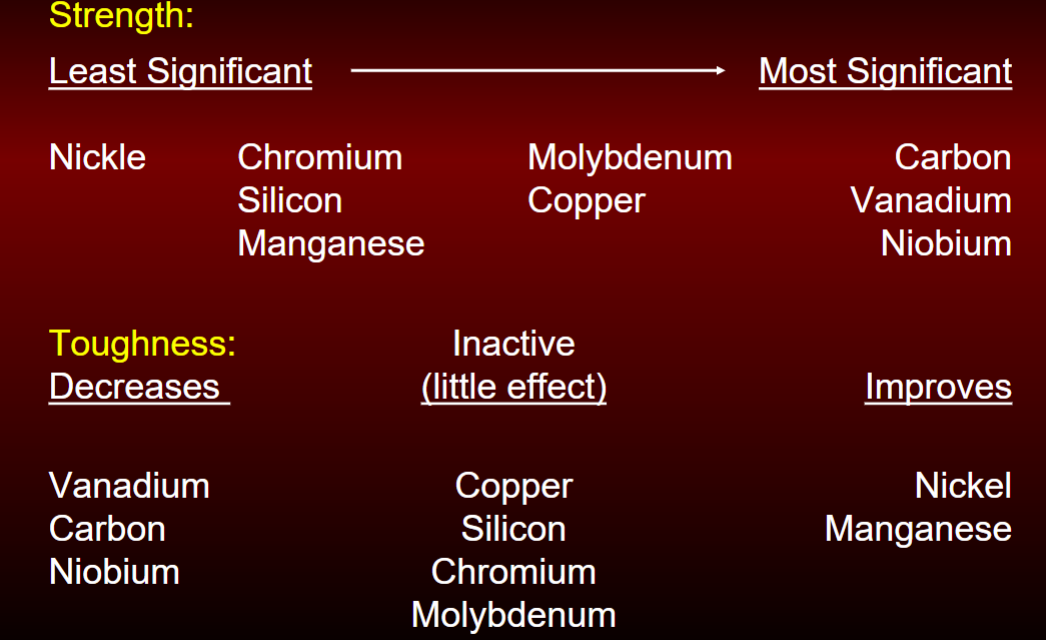

Alloy effect on strength vs toughness

look at image

heat treatment of steels

max yield strength through alloying is 75 ksi

high strength steels obtained by heat treating

done to enhance desired properties of steel

performed on rolled plate not shapes

Normalizing

purpose: to produce a uniform, fine-graded microstructure

procedure: air cooled form austensite stable range

quenching

purpose: to harden

procedure: rapid cooling from austensite to form martensite (strong but brittle)

tempering

purpose: to toughen

procedure: reheat martensite to form tempered martensite

austempering

purpose: to harden

procedure: quench, followed by isothermal transformation above martensite to form bainite

quenching and tempered process

plate put in furance at temp above austenite temp and then removed when reach uniform temp

plate immediately water-quenched to form martensite

plate is tempered in furnace to form tempered martensite

plate air-cooled after removed from tempering furnace

similar to high strength bolts

fine grain practice

process which final steel has smaller grain size than normal

increases strength of steel as it prevents impurities from segregating to few grain boundaries

impurities more widely dispersed and can’t accumulate in great quantities

Al typically used to achieve fine grain microstructure with Nb and V

steel solidification process

killed

semi-killed

rimmed

Killed

steel completely deoxidized

done by addition of an agent before casting so no evolution of gas during solidification but shrinkage occurs

high degree of chemical homogeneity and free from gas porosity

steel will quietly solidify in the mold w no gas bubbling out (get its name)

continuously casted steels are always killed

semi-killed

mostly deoxidized

carbon monoxide leave blowhole type porosity

when hot-rolled, porosities are closed

evolution of gas tends to partial compensate for shrinkage that occurs during solidification

Rimmed

little or no deoxidizing agent added

causes carbon monoxide to evolve rapidly resulting in small blowholes on surface which will close during hot rolling

elements like C, P, S segregate to center leaving almost pure iron at rim

Steel making process: Blast furnace

process used to convert iron ore into liquid iron and is unfinished steel

iron ore, coke, limestone fed into top of blast furnace and preheated air is blown up from bottom

takes 6-8 hours for raw materials to descent to bottom of furance where become final product of liquid iron and liquid slag

continuous process: raw material fed at top and liquid iron tapped from bottom

Steel making process: Basic Oxygen Furnace

70-80% liquid steel from blast furnace w balance being scrap steel

liquid hot metal and scrap are charged w near pure oxygen which is blown into the mix at supersonic velocities

oxidizes carbon and silicon contained in hot metal which liberates great quantities of heat, which melts the scrap

after sample taken and analyzed for its chemical composition, carbon and other alloying elements added

Steel making process: Electric Arc Furnace

can use 100% scrap steel but often some liquid steel left from previous run

graphite electrodes used to produce voltage differential which melts steel scrap

when scrap is molten, oxygen fed into liquid bath to oxidize P, S, Al, Si, Mn, and C

after sample is taken and analyzed, carbon and other alloying elements added

Mill Report

steel resulting from once cycle from basic oxygen furnace or electric arc furnace is called Heat

each heat analyzed for its chemical composition and mechanical properties

results in mill report

def weld

localized coalescence of metals or nonmetals produced by heating the material to suitable temps w/ or w/o application of pressure and filler metal

welding process - steel

oxyfuel gas - not used a lot

electric arc

friction - small length

resistance - automobile industry, press together to weld

casting - rails in railroads

electric arc welding

shielded metal arc welding (SMAW)

flux cored arc welding (FCAW)

gas metal arc welding (GMAW)/MIG

Gas Tungsten Arc Welding (GTAW)

Submerged Arc Welding (SAW) - automated

arc welding components

power source (modifies and controls input electrical current)

electrode (consumable or non-consumable)

shielding (gas or solid that forms gas as it burns)

Electrical Current

W = V x A

wattage - measure of work (controls width and depth of weld bead)

voltage - measure electrical pressure (controls max length of arc across gap)

amperage - measure of rate of flow of electron (controls arc size)

Types of welding current

AC - alternating current - plug into wall

DCSP: direct current - straight polarity

DCRP: Direct current - reverse polarity

power source either AC or both DCSP and DCRP

Arc temperature

Approx 9000 F - HOT

affected by resistance to current flow - want resistance

large gap = large resistance which increase temp

Resistance

function of arc length and chemical composition of gases formed or introduced during welding process

Arc stabilization

important that current flow stable so that uniform and consistent weld is formed

modern day power supplies digitally controlled

shielding gases used to stabilize arc in addition to protecting weld pool from atmosphere (protect from O)

Straight Polarity DCSP

electrode negative (DCEN) - greater penetration

more heat at base plate

electrode negative contains 1/3 heat

base plate positive contains 2/3 heat

flow from negative to positive

Reverse Polarity (DCSP)

more heat at electrode (greater deposition)

electrode positive contains 2/3 heat

base plate negative contains 1/3 heat

this is faster bc depositing weld metal onto base plate faster

Arc Blow

deflection of an electric arc from its normal path bc of magnetic forces

uneven flux lines can cause arc to move during weld

more noticeable in corners, at end plates, when work lead is connected to only one side of plate

not a problem w AC current

Fillet Welds

simplest and least expensive

prefered

weld produced by depositing weld metal at corner formed by intersecting or lapping plates

Complete Joint Penetration Groove Weld (CJP)

used in application were maximum strength of connection is required

weld produced by cutting or grinding chamfer or bevel on edge of plate

no stress calc involved for weld

usually do fillet weld at end bc shear flow

Partial Joint Penetration Groove Welds (PJP)

similar to CJP where plate edges are beveled prior to welding

finished weld doesn’t fully penetrate plate thickness due to reduced strength requirement

problem in tension bc lack of fusion and can behave like crack

Plug and Slot Welds

connect lapped plates

plut or slot cut into one of the plates

plates are then lapped and hole filled with weld metal

SMAW

on drawing specifiy electrode strength

FCAW and GMAW

use same eqiuipment

FCAW - flux-core hollow wire can automate but hard to clean up; no additional shielding gas required

GMAW - solid wire pump use w gas

Welding Parameters

current (volts/amps)

travel wire speed

electrode (solid or flux-cored)

shielding gas

Shielding Gas

Ar - stable arc, high density gas envelope, difficult to disturb but expensive

CO2 - less expensive but less dense; great heat conductivity - allow arc burn hotter

Mix - compromise in density and heat conductivity

He - result in unstable arc, low density gas envelope; expensive

MIG Solid Wire Welding

must be used w CO2 or mix

CO2: economical and results in deeper penetration

mix: less splatter and better bead appearance

Indoor use, no wind

can weld relatively thin material (22 gauge)

MIG Flux-Core Wire Welding

no sheidling gas required provide as flux in the core

can use outdoors in windy conditions

good w dirty, rusted, painted materials

Runs hotter than solid wire, limited to 18 gauge or thicker

Mig Power Supply

AC input current converted to DC using rectifiers

rectifier - allows current to flow in one direction

heat generated and lost in rectifiers making DC less efficient than AC

transformer used to step-down voltage of input current and increase amp

input current is 230V and 26A

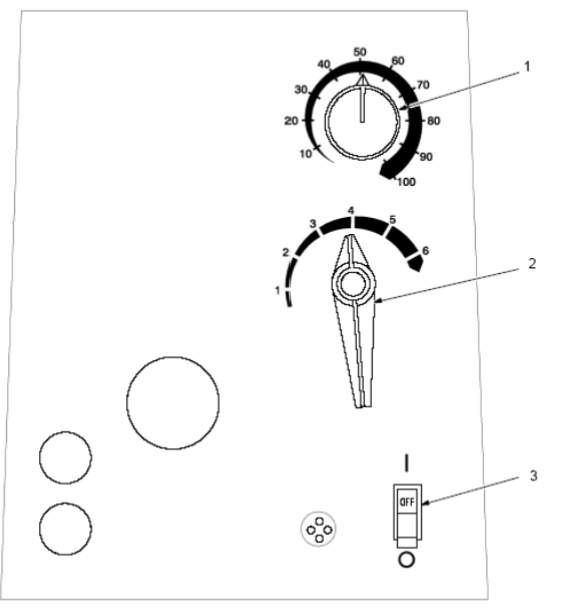

Millermatic 185 Control Panel

wire speed control - can switch while welding

Voltage switch TAP - DO NOT switch while welding; higher number for thicker material

Power Switch

Poor Weld Bead Characteristic

large spatter deposits

rough uneven bead

slight crater during welding

bad overlap

poor penetration

Good Weld Bead Characteristic

fine spatter

uniform bead

moderate crater during welding

no overlap

good penetration into base metal

weld new bead/layer for each 1/8 in thickness in metal

Possible Troubles welding

Excessive Splatter

Porosity

Excessive Penetration

Lack of Penetration

Incomplete Fusion

Waviness of Beam

Burn Through

Distortion - can cause residual stresses if clamped

discontinuity

interruption in uniformity of a material

all steels and welds contain discontinuities

Metallurgical discontinuity

slag particles

void

shrinkage cracks

inclusions

quenching cracks

cracked carburized layer

process discontinuity

seams

scratches

dents

weld-related

grinding

cracks

design discontinuity

holes

notches

stress concentrations

fatigue cracks

Metallurgical Considerations

weld metal should be low in gas content and low in oxides to avoid porosity

weld metal will solidify very rapidly and therefore, be fine-grained

base metal adjacent to liquid weld pools will be heated into austenitic state and cool rapidly - happens w thick plates bc large heat absorption so need to keep carbon low

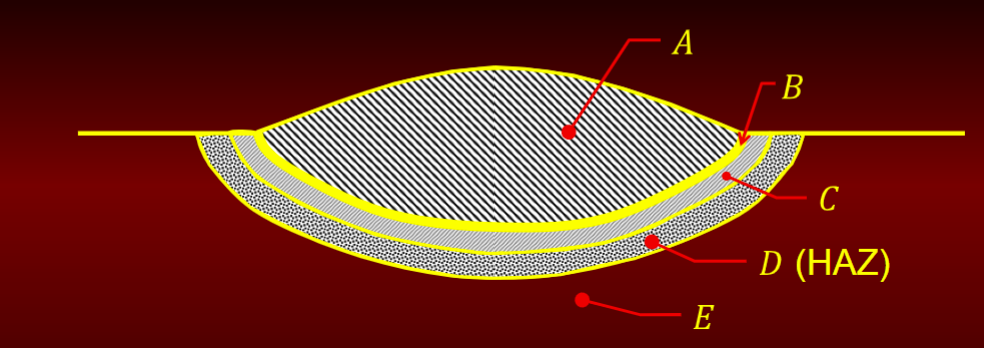

metallurgical zone of weldments

A. Composite Zone

B. Unmixed Zone

C. Partially Melted Zone

D. Heat Affected Zone (HAZ)

E. Unaffected Base Metal - area unaffected by welding process

composite zone

admixture of base metal and filler metal

homogeneous with respect to composition

rich chemistry

can contain weld defects such as porosity, blow holes

unmixed zone

boundary layer of melted base metal that wasn’t mixed w filler metal

composition of base metal