manufacturing class notes

1/81

There's no tags or description

Looks like no tags are added yet.

Name | Mastery | Learn | Test | Matching | Spaced |

|---|

No study sessions yet.

82 Terms

Single crystals

Polycrystalline structure

Most common atomic arrangements (lattice structures) in crystalline materials

FCC

BCC

HCP

UNIT

Material deformations

slip plans or twinning - permanent deformation

Line defects - dislocations

Point defects - impurities, vacancies, interstitial

Permanent deformation

Slipping and twinning

Line defects

Dislocations

Point defects

vacancy

Interstitial/impurity

Larger grain size causes

rougher surface

Increases ductility

High creep resistance

Lower strength

Microporosity increases

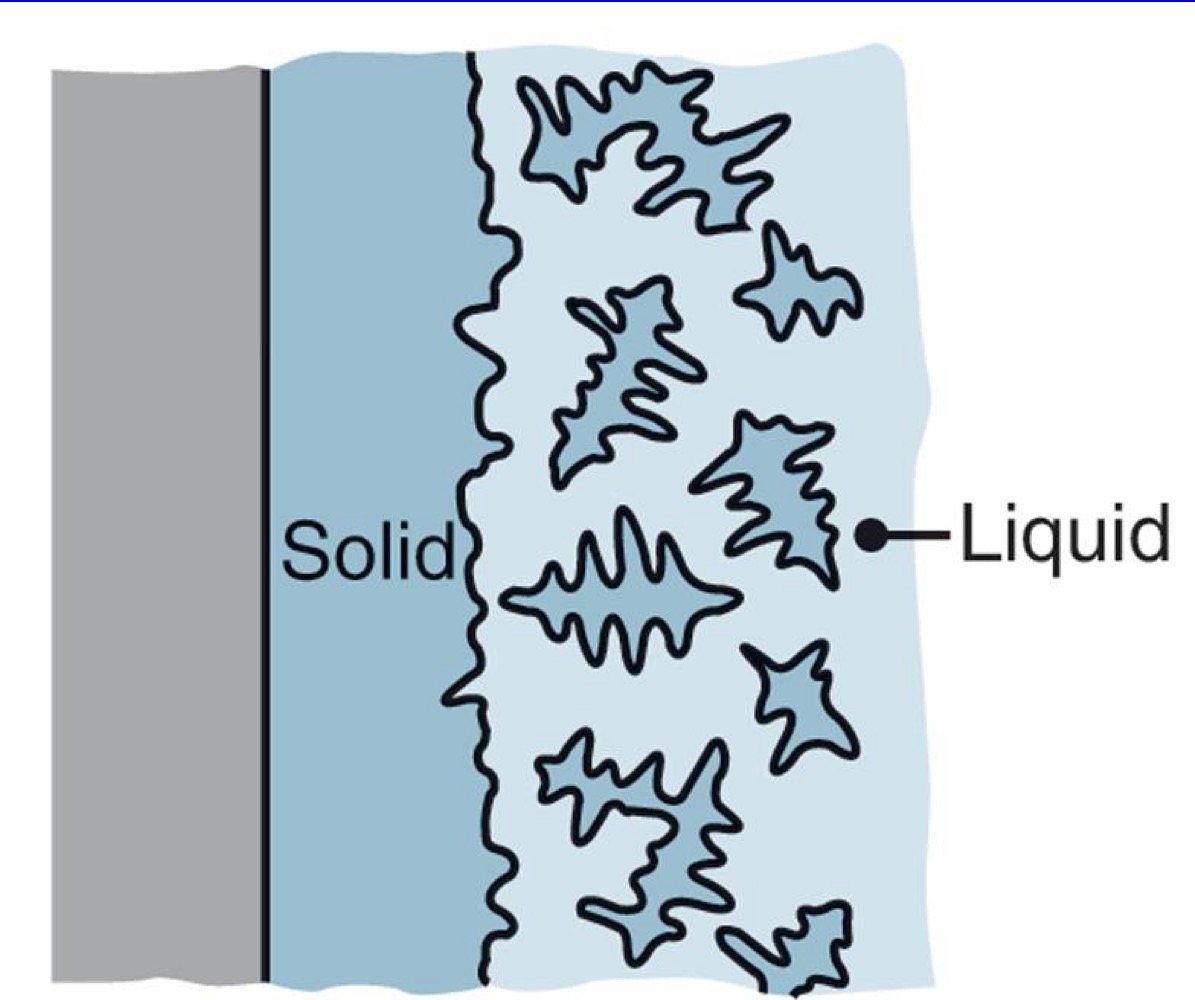

Equiaxed dendritic growth

Dendrites grow freely often with a shape with all equal dimensions

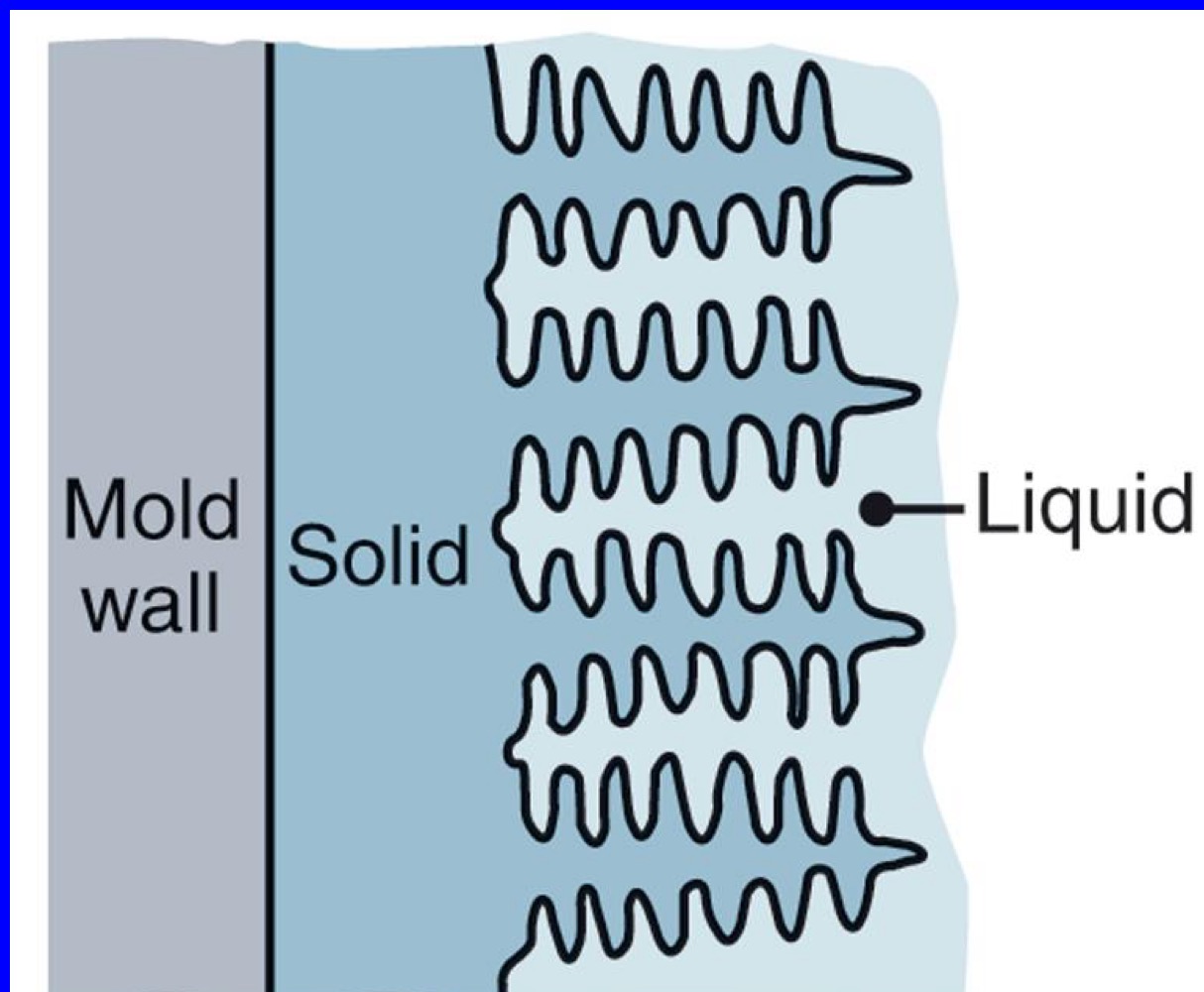

Columnar dendritic growth

Dendrites growth in long columns with direction of temp gradient

Cold working

Plastic deformation at room temp

Smaller grain size causes

increases strength

Microporosity decreases

Ductility decreases

Hot working

Deformation occurs above recrystallization temp

Dislocations make plastic deformation easier true/false

True

Dislocation movement is impeded by __?

Grain boundaries

FCC

12 slip planes

Shear stress required for slip is low

Moderate strength

Good ductility

BCC

48 slip systems

High shear stress required for slip

Good strength

Moderate ductility

HCP

3 slip planes

Low probability of a slip

Brittle at room temp

Forging

metal working using compression, often with heat

Rolling

Metal working with rotating cylindrical rollers to reduce thickness of metal and enhance mechanical properties

Extrusion

Material pushed through die with a specific shape to create continuous product

Drawing

Uses tensile forces to stretch and shape materials by pulling through die

Increasing temperature effects on stress strain curves

Ductility and toughness increase

Yield stress and the modulus of elasticity decrease

Yield stress

Max stress a material can withstand before plastic deformation (permanent)

Elastic vs plastic deformation

Elastic the material cans go back to its OG shape

Plastic the material permanently deforms

Ultimate tensile strength

Max stress a material can withstand before it fractures

Residual stresses

Stresses that remain within a part after it has been formed and all forces removed

Hardness

Resistance to indentation

Strain hardening

Material becomes harder and stronger from plastic deformation

True strain at the onset of necking

E=n

True strain

Measure of deformation that considers the changing length during deformation

true stress

Measures stress and considers the change in cross sectional area during deformation

Engineering stress

Force applied without considering change in cross sectional area but rather uses the PG area

Engineering strain

measure of deformation without considering change in length during deformation but rather uses the end and OG

Alloy

Composition of two or more chemical elements at least one is a metal

Phase

Chemically and structurally homogenous area (solid, liquid, gas)

Solution

Homogenous mixture where solute dissolved in solvent

Pure metals have a wide range of properties true/false

False

Alloying metals produces a wide/narrow range of material properties?

WIDE

Solid solutions of alloys

interstitial

Substitutional

Interstitial solid solution

Impurities are located in spaces between the solvent atoms

Substitutional

Impurities are located in sites normally occupied by solvent atoms

Intermetallic compounds

Substances combine in definite properties

strong

Hard

Brittle

good high temp strength

Provide oxidation resistance

Crystal structures differ than constituents

Binary alloys

Mixture of two different metallic elements to Create materials with improved material properties

Iron has what lattice structure?

BCC

Ferrite

Max solid solubility of carbon

soft

Ductile

Austenite

Iron structure changes BCC to FCC

FCC has more interstitial positions

Cementite

Iron carbide (Fe3C)

intermetallic compound

Hard and brittle

Can include other alloying elements

What determines the microstructure?

Combination of different iron carbon solid phases

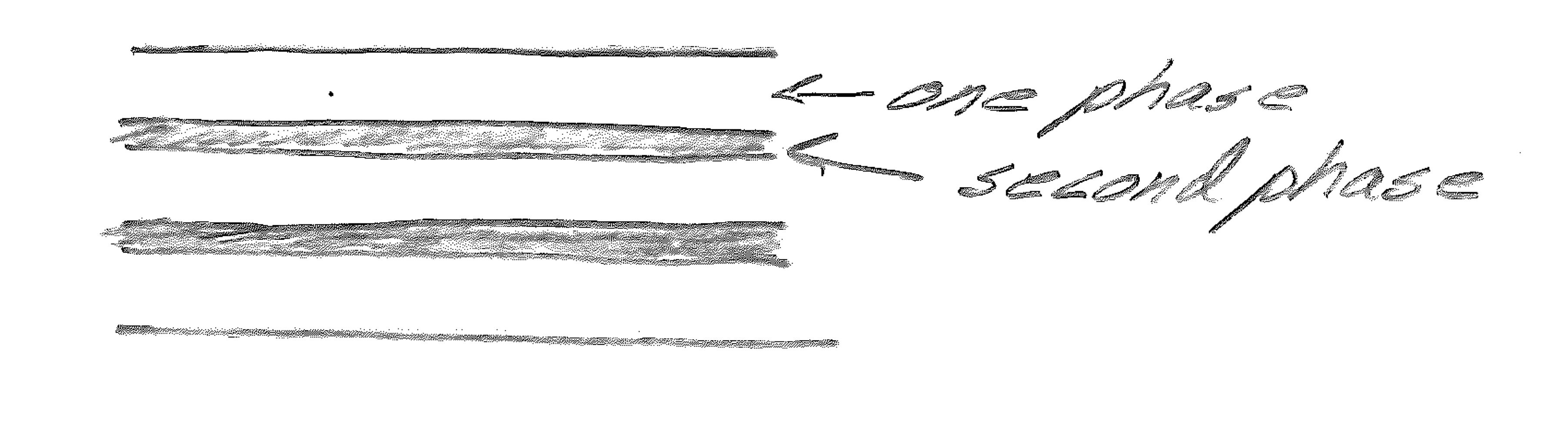

Lamellar structure

Heat treatment modifies

Microstructure

strength

Hardness

Ductility

Toughness

Heat treatment controlled by

Heating and cooling at different rates

Pearlite

From Austenite

ferrite/cementite lamellae structure

Sphearoidite

From Pearlite

cementite becomes spherical

Has ferrite and cementite

Bainite

Similar to Pearlite with different shapes

ferrite cementite

Feathery needle shape

Martensite

From quenching Austenite rapidly

fcc structure transforms to BCC

Super solid solution of carbon iron

Time temperature transformation (TTT) diagrams

provide information required to design heat treatment schedules to obtain desired microstructures

Heat treatment of ferrous alloys

Controlled cooling and heating of alloys Induces solid phase transformation and changes the microstructure

Affects:

strength

Hardness

Ductility

Toughness

Wear

Thermal conditions

temp

Time

Cooling/heating rate

Quenching

cooling at rapid rate

Important properties for quenching

specific heat

Thermal conductivity

Annealing

Heat to specific heat T (usually in furnace)

hold at T for specific time

Cool at specific rate in gas (air) - usually occurs at slow rate

Usually reduced hardness

USED TO INCREASE DUCTILITY

Tempering

Controlled heating used to reduce brittleness and increase toughness

High strength low alloy steels (HSLA) designations

BH bake hardenable

DP -dual phase

TRIP - transformation induced plasticity

TWIP - twinning induced plasticity

CP - complex phase - mixed ferrite/martensite structure

Ferrous alloys exs

carbon steels

Alloy steels

Stainless steels

Tool steels

Die steels

Casting process

creating a pattern

Creating a mold

Pouring molten metal into mold

Allowing to solidify (cool)

Removing part from the mold

Must consider what for casting

Molten metal reached all regions on the mold

Cooling of the mold - conduction, convection, radiation

Type of solidification - dendritic, single crystal or polycrystalline, amorphous (no crystal structure)

Causes of porosity in casting

shrinkage

Dissolved gas

Characteristics of molten metal that influence fluidity

surface tension

Viscosity

Inclusions

Solidification pattern of the alloys

Mold design

Mold material

Degree of superheat

Rate of pouring

Heat transfer

Turbulent vs laminar flow

laminar is smooth ordered fluid motion

Turbulent is chaotic and irregular

Fluidity

The ability to flow into the mold cavities

Pure metals have the best fluidity true/false

True

Alloys are supplied at what temps?

Superheated temps

Solidification rate is controlled by what?

Rate that heat can be absorbed by the mold

From an energy balance, Heat transfer for an arbitrary shape is related to what?

Volume/area

SMAW shielded metal arc

Consumable

GTAW gas tungsten arc

Nonconsumable

GMAW gas metal arc

Consumable

SAW submerged arc

Consumable

PAW plasma arc

Nonconsmable

DCEN weld shape (negative)

Shallow wide

DCEP weld shape (positive)

Deep narrow

AC weld shape

Not too deep not too wide