Topic 10_Design of Goods and Services

1/58

There's no tags or description

Looks like no tags are added yet.

Name | Mastery | Learn | Test | Matching | Spaced | Call with Kai |

|---|

No analytics yet

Send a link to your students to track their progress

59 Terms

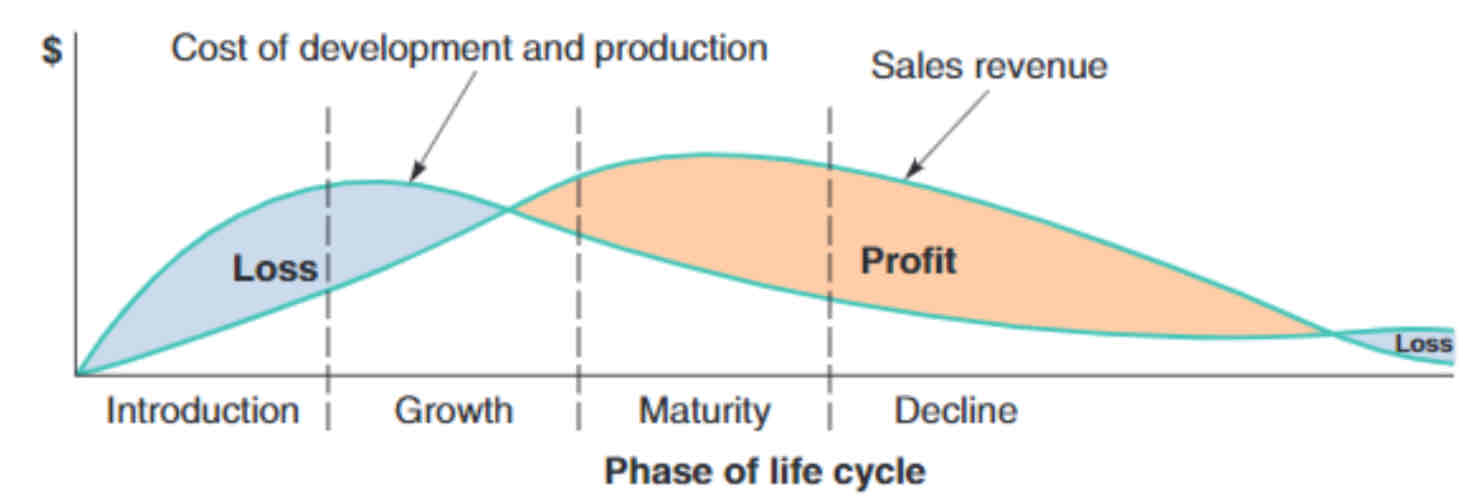

4 phases of product life cycles

Introduction

Growth

Maturity

Decline

Introduction

First time customers are introduced to the new product

Growth

Characterized by growing demand, increase in production, and expansion

Maturity

Most profitable stage

cost of producing and marketing declines

Decline

As the product takes on an increased competition, the product may lose market share and begin its decline

Product-by-value analysis

lists products in descending order of their individual dollar contribution to the firm

Lists the total annual dollar contribution of the product

Provides the management with strategies for each product

Possible strategies for each product

Increasing cash flow

Increasing market penetration

Reducing costs

Generating New Products (Opportunities)

Understanding the customer

Economic change

Sociological and demographic change

Technological change

Political and legal change

Other changes - market practice, professional standards, etc.

Product Development System

Determine not only product success but also the firm’s future

9 Stages of Product Development

Concept

Feasibility

Customer Requirements

Functional Specifications

Product Specifications and Manufacturability

Design Review

Test Market

Introduction to Market

Evaluation

Quality Function Deployment

A process for determining customer requirements (“wants”) and translating them into attributes (“hows”) that each functional area can understand and act on

House of Quality

one of the tools of QFD

The part of QFD process that utilizes a planning matrix to relate customer wants to how the firm is going to meet those wants

7 Basic Steps of House of Quality

Identify customer wants

Identify how the good or service will satisfy customer wants

Relate customer wants to product hows

Identify relationships between the firm’s hows

Develop important ratings

Evaluate competing products

Determine the desirable technical attributes

6 Issues for Product Design

Robust Design

Modular Design

Computer-Aided Design (CAD) and Computer-Aided Manufacturing (CAM)

Virtual Reality Technology

Value Analysis

Sustainability and Life Cycle Assessment (LCA)

Robust Design

a design that can be produced to requirements even with unfavorable conditions in the production process

Product is designed so small variations do not adversely affect the product

Modular Design

A design in which parts or components of a product are subdivided into modules that are easily interchanged or replaced

CAD

Computer-Aided Design

CAM

Computer-Aided Manufacturing

Computer-Aided Design (CAD)

Interactive use of a computer to develop and document a product

Computer-Aided Manufacturing (CAM)

The use of information technology to control machinery

DFMA

Design For Manufacture and Assembly

Design for Manufacture and Assembly (DFMA)

Software that allows designers to look at the effect of design on manufacturing of the product

STEP

Standard for the Exchange of Product Data

Standard for the Exchange of Product Data (STEP)

A standard that provides a format allowing electronic transmission of three-dimensional data

3-D Printing

An extension of CAD that builds prototypes and small lots

Virtual Reality

A visual form of communication in which images substitute for reality and typically allow the user to respond interactively

Value Analysis

A review of successful products that takes place during the production process

Sustainability

Meeting the needs of present without compromising the ability of future generations to meet their needs

LCA

Life Cycle Assessment

Life Cycle Assessment (LCA)

A formal evaluation of the environmental impact of a product.

Time-Based Competition

Competition based on time; rapidly developing products and moving them to market

Joint Ventures

Firms establishing joint ownership to pursue new products or markets

Alliances

Cooperative agreements that allow firms to remain independent

Engineering Drawing

A drawing that shows the dimensions, tolerances, material, and finishes of a component

Bill of Material (BOM)

A list of the components, their description, and the quantity of each required to make one unit of a product

Make or Buy Decisions

The choice between producing a component or a service and purchasing it from an outside source.

Group Technology

A product and component coding system that specifies the size, shape, and type of processing

5 Documents for Production

Assembly Drawing

Assembly Chart

Route Sheet

Work Order

Engineering Change Notices (ECNs)

Assembly Drawing

An exploded view of a product

Assembly Chart

A graphic means of identifying how components flow into subassemblies and final products

Route Sheet

A list of the operations necessary to produce a component with the material specified in the bill of material

Work Order

An instruction to make a given quantity of a particular item

Engineering Change Notice (ECN)

A correction or modification of an engineering drawing or bill of material

Configuration Management

A system by which a product’s planned and changing components are accurately identified

PLM

Product Life-Cycle Management

Product Life-Cycle Management (PLM)

Software programs that tie together many phases of product design and manufacture

Process-Chain-Network (PCN) Analysis

Analysis that focuses on the ways in which processes can be designed to optimize interaction between firms and their customers

Process Chain

A sequence of steps that accomplishes an identifiable purpose

Process Participant

Can be a manufacturer, a service provider, or a customer

Network

A set of participants

Process Domain

The set of activities over which it has control

3 Process Regions

Direct Interaction Region

Surrogate (Substitute) Interaction Region

Independent Processing Region

Direct Interaction Region

Process steps that involve interaction between participants

Surrogate (Substitute) Interaction Region

Process steps in which one participant is acting on another participant’s resources

Independent Processing Region

Steps in which the sandwich supplier and or the sandwich customer is acting on resources where each has maximum control

5 Ways to Increase Service Efficiency

Limit the Options

Delay Customization

Modularization

Automation

Moment of Truth

Decision Trees

Used for new-product decisions as well as for wide variety of other management problems when uncertainty is present

EMV

Expected Monetary Value

Transition to Production

Knowing when to move a product from development to production