Rapid Prototyping and Composites (L26)

1/31

There's no tags or description

Looks like no tags are added yet.

Name | Mastery | Learn | Test | Matching | Spaced | Call with Kai |

|---|

No study sessions yet.

32 Terms

Multi Jet Fusion (MJF) Printer

Multicolor Prints

Material: Nylon

Fused Deposition Modeling (FDM) Print

Material: PLA, PETG, & TPU

Layer Thickness: 0.002”

Low Force Stereolithography (SLA) Printer

Material: Too many to list!

Layer Thickness: 0.001”

polymer matrix composite (PMC)

a composite material consisting of a polymer imbedded with a reinforcing phase such as fibers or powders

Fiber-reinforced polymers (FRPs)

can be designed with very high strength-to-weight ratios

rovings

collections of untwisted continuous strands

Starting materials of a polymer matrix composite

a polymer and a reinforcing phase

Two methods for combining matrix and reinforcement

The starting materials arrive at the fabrication operation as separate entities and are combined into the composite during shaping

The two component materials are combined into some starting form that is convenient for use in the shaping process

Prepregs

Fibers impregnated with partially cured thermosetting resins to facilitate shape processing

Available as tapes or cross-plied sheets or fabrics

Curing is completed during and/or after shaping

Advantage: prepregs are fabricated with continuous filaments rather than chopped random fibers, thus increasing strength and modulus

Open-Mold Processes

Family of FRP shaping processes that use a single positive or negative mold surface to produce

laminated FRP structures

Starting materials (resins, fibers, mats, and wove rovings) are applied to the mold in layers, building up to the desired thickness

This is followed by curing and part removal

Common resins are unsaturated polyesters and epoxies, using fiberglass as the reinforcement

Open-Mold Fiber Reinforced Polymer Processes

Hand lay-up

Spray-up

Automated lay-up

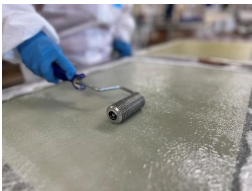

Hand Lay-Up Method

Open-mold shaping method in which successive layers of resin and reinforcement are manually applied to an open mold to build the laminated FRP structure

Labor Intensive

Hand Lay-Up Method Steps

1. Mold is treated with mold release agent

2. Thin gel coat (resin) is applied to outside surface of mold

3. When gel coat has partially set, layers of resin and fiber mat are applied, each layer is rolled to impregnate the fiber with resin and remove air

4. Part is cured

5. Fully hardened part is removed from mold

Spray-Up Method

Liquid resin and chopped fibers are sprayed onto an open mold to build successive FRP laminations

not as strong as those made by hand lay-up, in which the fibers are continuous and directed

Automated Lay-Up

Automation of the lay-up process using computer numerical control (CNC)

Two types of automated machines:

1. Automated tape-laying machines

2. Automated fiber placement machines

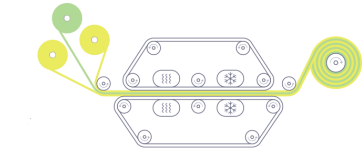

Automated Tape-Laying (ATL) Machines

Machines that operate by dispensing a prepreg tape onto an open mold following a programmed path

Automated Fiber Placement (AFP) Machine

Machines that dispense prepregs in the form of flat bundles of fibers impregnated with resin, called tows, onto the surface of a mold

Tows

re narrower than the tapes used in ATL machines

The narrower prepreg enables lay-up over more complex mold geometries

Advantages of closed mold

Good finish on all part surfaces

2. Higher production rates

3. Closer control over tolerances

4. More complex three-dimensional shapes are possible

3 types of Closed Mold Process

1. Compression molding

2. Transfer molding

3. Injection molding

Compression Molding PMC

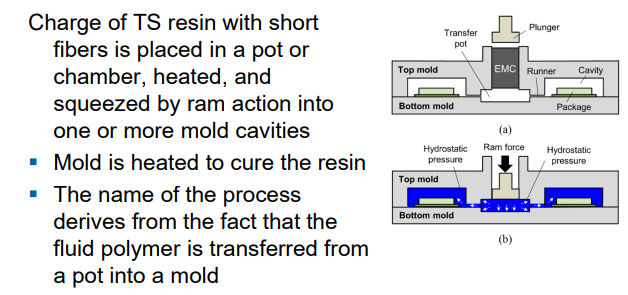

Transfer Molding PMC Process

Injection Molding PMC Processes

▪ Conventional injection molding

▪ Reinforced reaction injection molding

Conventional Injection Molding

▪ Used for both TP and TS FRPs

▪ Virtually all TPs can be reinforced with fibers

▪ Chopped fibers must be used

▪ During injection into the mold cavity, fibers tend to become aligned as they pass through the nozzle

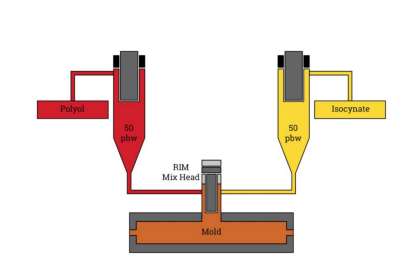

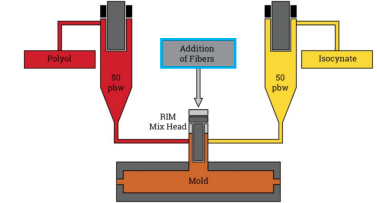

Conventional Reaction Injection Molding

two reactive ingredients are mixed and injected into a mold cavity where curing and solidification occur

Reinforced Reaction

similar to RIM but includes reinforcing fibers, typically glass fibers, in the mixture

▪ Advantages: similar to RIM (no heat energy required, lower cost mold), but with fiber-reinforcement

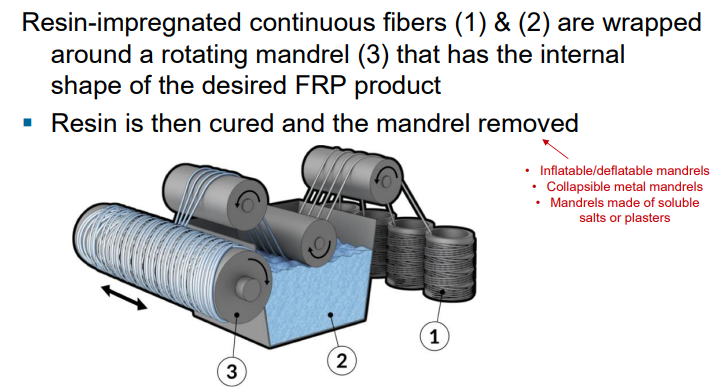

Filament Winding

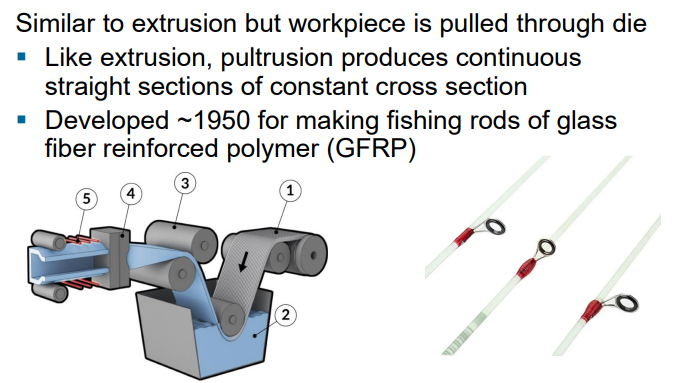

Pultrusion Process

1. Filament feeding

2. Resin impregnation

3. Pre-die forming

4. Shaping and curing

Heated die, 3-5 feet long

Inside surface, highly polished

5. Pulling and cutting

Pulforming

Pultrusion with additional steps to form the length into a semicircular contour and alter the cross section at one or more locations along the length

Tube Rolling

FRP tubes can be fabricated from prepreg sheets by a rolling technique

▪ Used in bicycle frames and space trusses

▪ Operation is simple and tooling costs are low

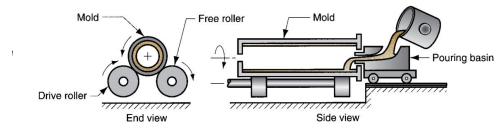

Centrifugal Casting

Process is similar to its metal casting counterpart

▪ Ideal for making pipes and tanks

▪ Chopped fibers combined with liquid resin are poured into a fast-rotating cylindrical mold that is heated

Continuous Laminating

Used to create fiber-reinforced plastic panels

▪ Impregnation: Reinforcing materials are impregnated with a resin

▪ Forming: The reinforced material is passed through a conveyor system with forming rollers that compress it to the desired thickness and resin content, often sandwiched between two plastic films.

▪ Curing: The composite laminate is moved through a heated zone where the resin cures to create a solid, strong panel.