MAINTENANCE DOCUMENTATIONS 2

1/25

There's no tags or description

Looks like no tags are added yet.

Name | Mastery | Learn | Test | Matching | Spaced |

|---|

No study sessions yet.

26 Terms

MAINTENANCE DOCUMENTATIONS

➢ The documentation for maintenance is required by the FAA. Advisory Circular AC 120-16E, Air Carrier Maintenance Programs, refers to the air carrier maintenance manual system, maintenance record/documentation keeping system, and various other requirements.

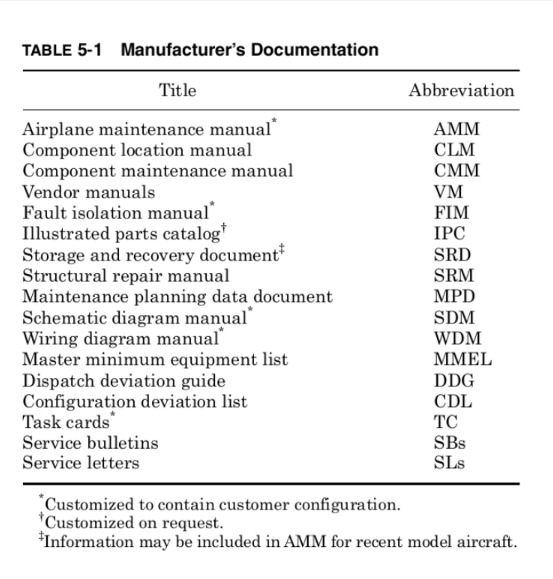

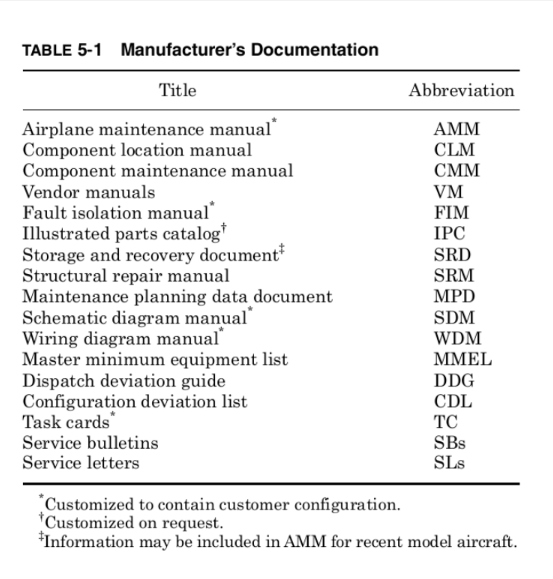

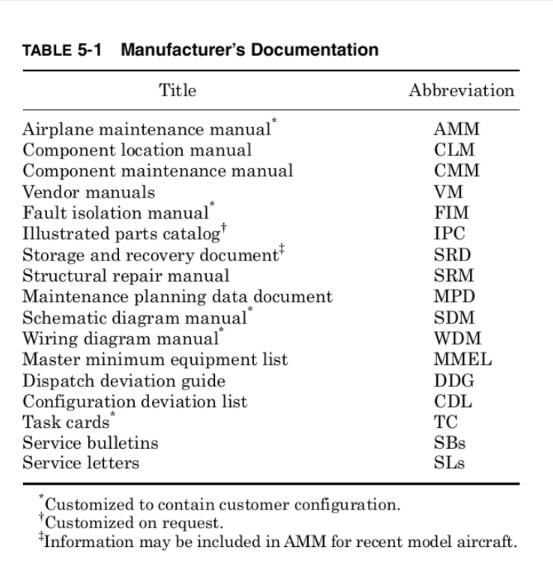

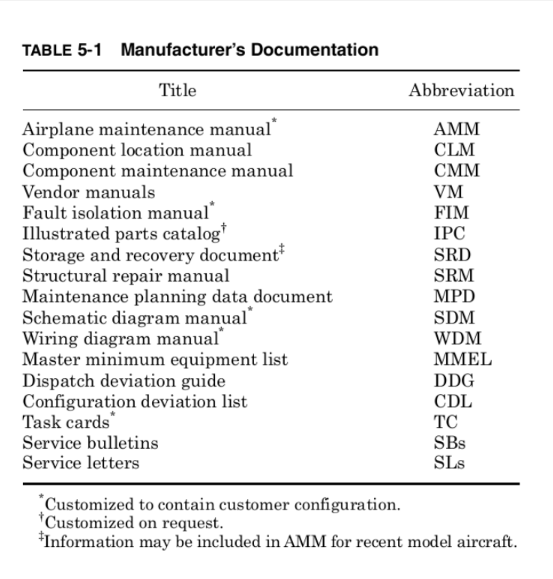

• Manufacturer’s documentation

• Regulatory documentation

• Airline-generated documentation

• ATA document standard

Controlled Documents

Non-Controlled Documents

TYPES OF DOCUMENTATION

Controlled Documents

• Used for operation and/or maintenance of

aircraft in accordance with FAA regulations.

• Have limited distribution within airlines and

require regular modifications and must

include list of revisions, active, and revoked

page numbers in document.

Non-Controlled Documents

• Provided by the operators and manufacturers.

AMM, FIM/TSM, CMM

Maintenance

WDM, ASM, SRM, SB

Engineering

MPD, IPC

Planning

MMEL, CDL, DDG

Operations

Aircraft Maintenance Manual

➢ It contains basic information required to

service, repair, replace, adjust, inspect, and

check equipment and systems on the

aircraft.

• Description and operation of each

system

• Basic maintenance and servicing actions

• Functional and operational tests

• Adjustments

• Replenishing various fluids and other

servicing tasks

Component Maintenance Manual

➢ It contains information required to check, repair,

adjust, test and/or overhaul units or assemblies,

normally performed away from the airplane

because of the need for special equipment.

System Description Manual (Boeing) /

Component Location Manual (Airbus)

➢ It contains information on component location,

system operation, and Training Information Points

for all systems and equipment installed in the

aircraft.

Fault Isolation Manual (Boeing) /

Trouble Shooting Manual (Airbus)

➢ It contains information required to isolate

and correct faults in the systems and

equipment installed in the aircraft.

Non-Destructive Testing Manual

(NTM / NDTM)

➢ Gives instructions with regard to specific

nondestructive testing procedures for the

aircraft.

Wiring Diagram Manual

➢ For Boeing, it is a collection of diagrams, drawings,

and lists that define the wiring of associated

equipment installed on the aircraft.

➢ For Airbus, WDM is divided into AWL, AWM and

ASM.

➢ It gives a full understanding of the electrical,

electronic and electro-mechanical system

installation and physical connections of the aircraft.

➢ Aircraft Wiring List

➢ Aircraft Wiring Manual

➢ Aircraft Schematic Manual (Airbus) /

System Schematic Manual (Boeing)

Aircraft Wiring List

➢ Provides list of wires,

connectors, terminals, strip locations, wire routings,

and clamping diagrams.

Aircraft Wiring Manual

➢ Provides a physical

view of systems and subsystems. It reflects the

definition of the wiring installation.

Aircraft Schematic Manual (Airbus) / System Schematic Manual (Boeing)

➢ Provides schematic diagrams and functional views

of electrical, electronic, and hydraulic systems and

other subsystems on the aircraft.

Structural Repair Manual

➢ It contains general data and special instructions for

the repair of airplane structures and structural

components.

➢ Provides information regarding the aircraft skin and

other specific tolerances and procedures in the

event of minor structural damage.

➢ Contains simple repairs which are approved by the

FAA and to be completed by the operator. Some

other structural repairs must be done by the

airframe manufacturer or other FAA designated

repair facilities.

Maintenance Planning Document

➢ List of maintenance and servicing tasks to be

performed on the aircraft.

➢ Contains all items of the MRB Report along with

other information such as CMRs and ALs.

Illustrated Parts Catalog

➢ Produced by manufacturers and describes in

comprehensive detail every component of the

aircraft, along with illustrations and their part

numbers.

➢ Contains lists and location diagrams of all parts

with their part numbers used in the aircraft.

Service Bulletins

➢ ~~~~ is the document used by manufacturers of

aircraft, engines or their components to

communicate details of modifications, maintenance,

or product improvement which can be embodied

in aircraft.

➢ It includes instructions for modifications,

substitution of parts, special inspections/checks

applicable on in-service aircraft.

➢ Compliance may or may not be mandatory.

Service Letters

➢ Usually provides information to improve

maintenance actions without equipment

modification.

MaintenanceTips

➢ A suggestion to maintenance personnel to assist in

their work or improve conditions.

Master Minimum Equipment List

➢ Provided by the manufacturer and approved by the

authorities.

➢ Identifies instruments, systems, or equipment

which may be inoperative at the commencement

of a flight.

➢ May be associated with special operating

conditions, limitations, or procedures.

Configuration Deviation List

➢ Provided by the manufacturer and approved by the

authorities.

➢ A listing of regulator-approved non-structural

external parts that may be missing but the airplane

remains airworthy.

Dispatch Deviation Guide

➢ Guide document intended to secure the aircraft

and systems against inadvertent operation when

some MMEL items are inoperative.