Fundamentals of Amalgam Restorations

1/21

There's no tags or description

Looks like no tags are added yet.

Name | Mastery | Learn | Test | Matching | Spaced | Call with Kai |

|---|

No analytics yet

Send a link to your students to track their progress

22 Terms

dental amalgam

-silver-tin-copper alloys are amalgamated with mercury

-amalgam has been used as a direct restorative material in the US for over 150 years

-benefits of amalgam as a direct restorative material: cost-effective, less technique sensitive, more moisture tolerant than composite

“self-sealing” property of amalgam

-only restorative material with a seal that improves over time

-occurs when microleakage between the amalgam restoration and teh prepared cavity walls results in corrosion of the amalgam and accumulation of corrosion products in the microscopic space

-process is self-limiting and is completed after several months

amalgam use decline

-popularity of amalgam as a direct restorative material has decreased and some countries no longer use amalgam

-decline can be attributed to patient preference for tooth colored restorations, perceived health and environmental concerns regarding mercury, and the inability to perform minimally invasive preparations with amalgam

-some evidence suggests that particularly in high caries risk patients it is more likely that recurrent (secondary) caries will occur with a composite restoration v. an amalgam

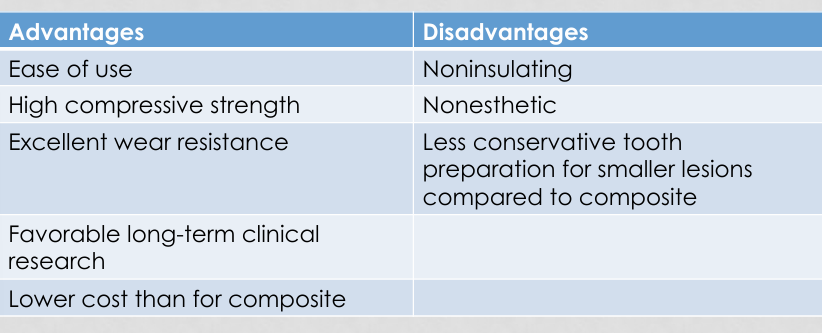

advantages and disadvantages of amalgam

amalgam preparations

-preparation must allow for a minimum thickness of 1.5-2.0mm so the amalgam will not flex and fracture when under occlusal load

-most amalgams fail by bulk fracture

-has limited edge strength and cannot be placed in a beveled preparation; also critical to not have excess flare in a preparation

-remember: amalgam is mechanically retained and does not bond to tooth structure

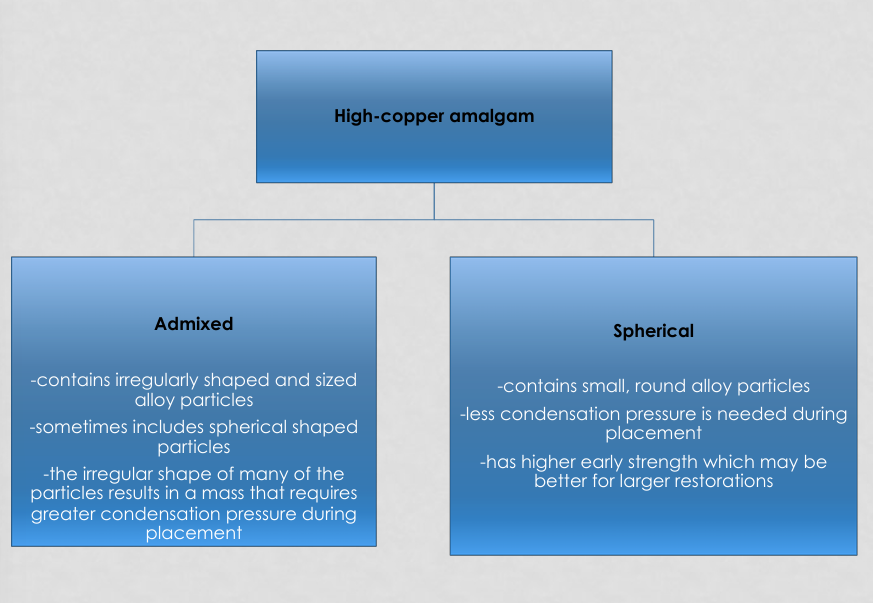

types of amalgam

-high-copper amalgam (copper content of 12% or greater) is predominant amalgam in use today

-advantage of the added copper: preferentially reacts with tin to reduce the more corrosive and weak gamma-2 phase within the amalgam

-high-copper amalgam can be admixed or spherical

high-copper amalgam: admixed v. spherical

dispersalloy

-admixed

-contains 50% mercury by weight

-alloy composition: silver 70%, tin 18%, copper 12%, zinc 1%

-compressive strength after 24 hours: >300MPa

-working time- regular set: 3 min 30 sec - 4 min 30 sec

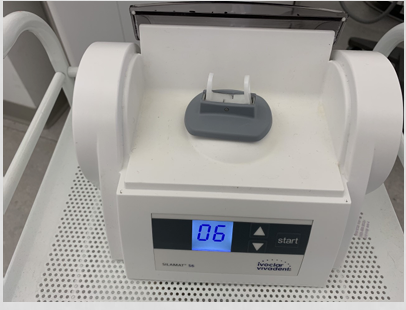

amalgamator

-speed setting: 3800 cycles per minute (cpm)

-time setting: 12-15 sec

trituration

-decrease trituration time if amalgam is too dry or too hot; decrease in trituration time lengthens the working time

-increase trituration time if amalgam is too wet; increase in trituration time shortens the working time

-capsules are self-activating and require a twist to open

-in addition to the amalgam, you will find a plastic mixing pestle upon opening; should be disposed of with the capsule

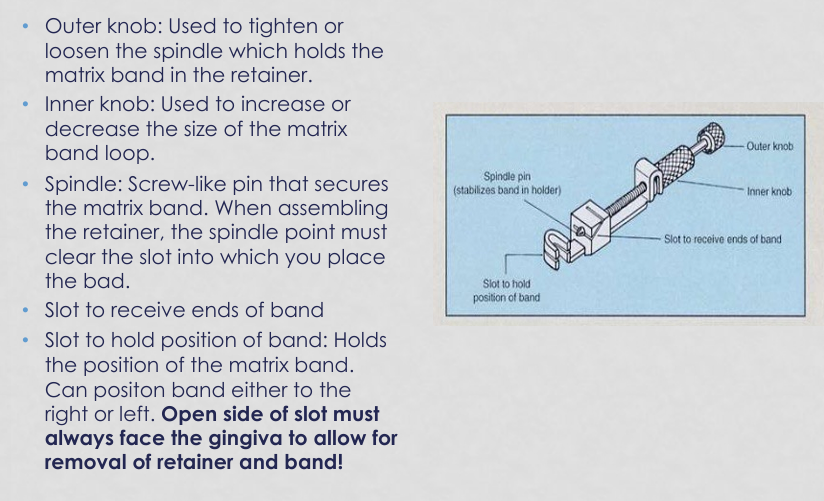

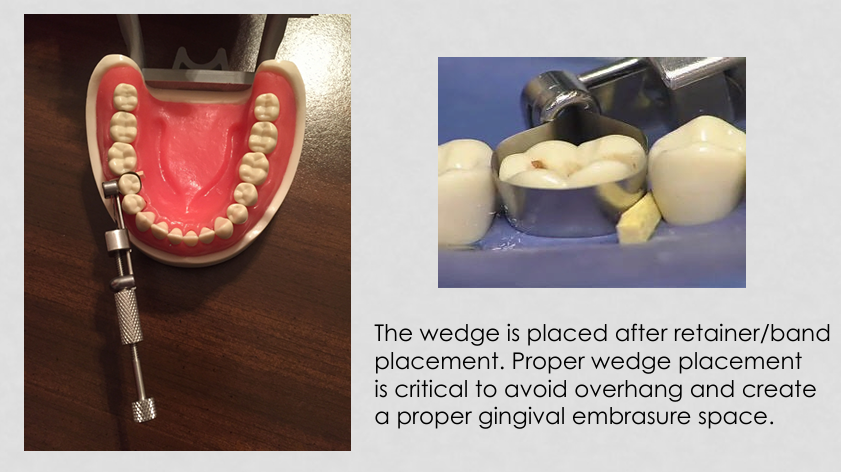

-matrix band retainer (tofflemire retainer)

retainer parts

retainer and matrix band quadrants

-quadrants 1 and 3: upper right and lower left

-quadrants 2 and 4: upper left and lower right

-note that smaller matrix band circumference must always face gingivally

matrix band and retainer after placement

matrix bands

-2 main sizes

-thicknesses of 0.05mm and 0.038mm

-burnishing a thinner band to create contour is more difficult and the band is less likely to retain its contour when tightened around the tooth

-burnishing the band means intentionally deforming the band to produce a rounded or convex surface; burnishing should be done on a non-rigid surface such as a mixing pad

-after placement, the matrix band should extend 0.5-1.0mm occlusal to the proximal cavosurface margin

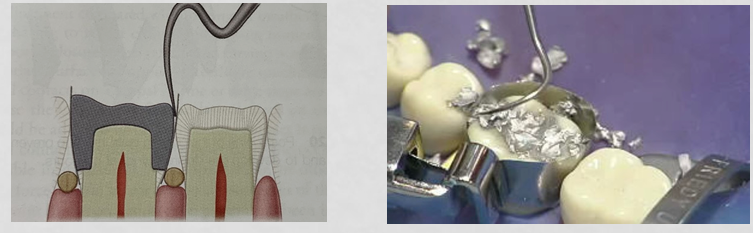

amalgam placement

-after trituration, the amalgam is placed in a well

-amalgam carrier used to transfer amalgam to the tooth preparation

-principal objective during placement: adapt the amalgam to the preparation walls and to the matrix band

-a smaller condenser is indicated for the initial increment of admixed amalgam because it is more resistant to condensation pressure

-amalgam placement does not require a jiggling motion and requires more force than placement of composite

-lateral condensation (buccally, lingually, and proximally) is important to ensure adaptation of the amalgam to the preparation walls; thorough condensation needed to prevent voids, minimize marginal leakage, and minimize mercury content of the restoration

-a smaller condenser should be used first which allows the amalgam to be properly condensed into the internal line angles

-preparation should be slightly overfilled to ensure adequate condensation on the occlusal surface

-each increment should be thoroughly condensed before placing the next increment

-if the mix becomes too dry, a new mix should be made

burnishing

-precarve burnishing is performed to ensure the marginal amalgam is well condensed before carving

-amalgam should be burnished immediately after condensing; finalizes the condensation process, removes excess mercury rich amalgam, and initiates the carving process

carving

-amalgam should show some resistance before carving is initiated

-a cleoid-discoid instrument is used to carve the occlusal surface; rounded end (discoid) positioned on the unprepared enamel adjacent to the amalgam margin and pulled parallel to the margin; removes the excess amalgam at the margin while preventing the amalgam from being carved below the preparation margin (submargination)

-pointed end (cleoid) used to define the primary grooves, fossae, and cuspal inclines; hollenback carver may also be used for this purpose

carving continued- explorer

-explorer should be used to properly carve and shape the marginal ridge and occlusal embrasure as soon as the amalgam shows resistance to carving

-marginal ridge must be rounded and must be the same height as the adjacent marginal ridge

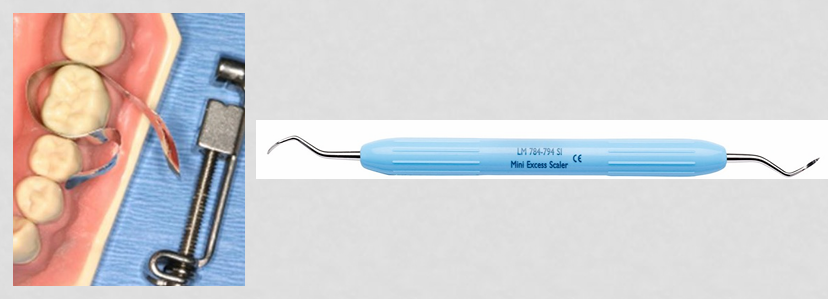

matrix band removal

-retainer removed first by loosening the outer knob

-matrix band bent away from the restoration and gently removed while the marginal ridge is stabilized by your thumb

-proximal excess can be removed with an explorer and if any gingival excess exists it can be removed with an explorer or proximal carver

finishing and polishing

-most amalgams do not require further finishing or polishing

-if necessary, it is usually in order to refined the anatomy, contours, marginal integrity, or surface texture of the restoration

-cannot be done for at least 24 hours because crystallization of the restoration will not be complete until that point

-process is achieved using a carborundum or fine grit alumina stone

amalgam disposal

-scrap amalgam, the pestle, and the capsule must be disposed of properly

-rubber dam must always be used