L6 - Secondary glass processing

1/21

Earn XP

Description and Tags

Toughened glass & Laminated glass - how they break. Coatings and colourants. Principal glass types

Name | Mastery | Learn | Test | Matching | Spaced | Call with Kai |

|---|

No analytics yet

Send a link to your students to track their progress

22 Terms

What are the finishing processes done to glass?

Toughening or tempering

coating

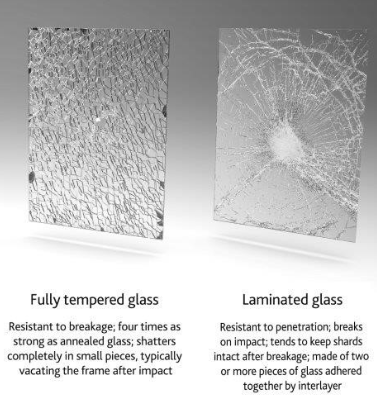

How is toughened or tempered glass made?

Stronger than ordinary window glass

By introducing stress through rapid heating & cooling of glass surface

Resistant to breaking under stress

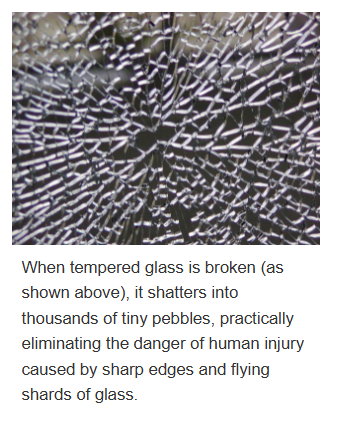

How does tempered glass break?

does not shatter

fragments into small squares

with little splintering

= small blunt pieces reduces risk of serious injury

What is laminated glass?

One layer of plastic

Sandwiched between two layers of glass permanently bonded with a tough, clear polymer interlayer, such as PVB.

Used in automotive windshields

How does laminated glass break?

it cracks in a "spiderweb" pattern, with the broken glass shards remaining stuck to the inner polymer layer.

the outer layers of glass break but are held together by the strong, adhesive plastic interlayer (PVB)

No sharp shards = safety

Continued cracking: Over time, the cracks can spread further as more stress is applied to the damaged glass.

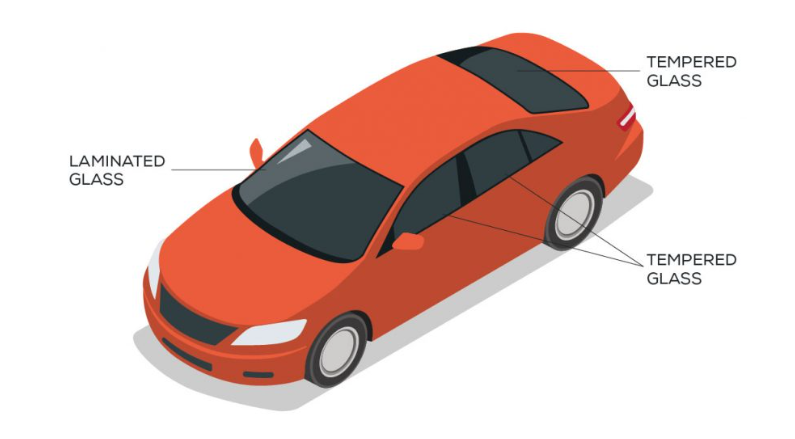

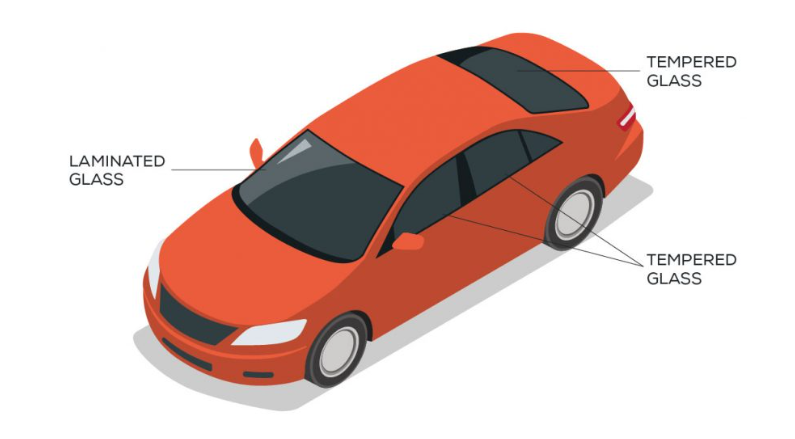

Where is toughened glass used in automotives?

Rear & side windows

Where is laminated glass used in automotives?

Windscreens

Why is coating used for glass?

Decoration

Protection

Strengthening

How is coating applied ?

= 2 stages

Hot end coatings

Cold end coatings

When is hot end coatings applied?

Applied just after the glass has left forming machine

Compounds of tin or titanium

When is cold end coatings applied?

Applied just before the annealed glass leaves lehr

Organic waxes, polyethylene emulsions, polyethylene glycols, fatty acid esters, fatty acids

What is the natural colour of glass?

Unless raw materials (silica etc.) very pure

Resultant glass normally has green tint

Primarily caused by iron oxide

Has effect in 1 in 1000 part

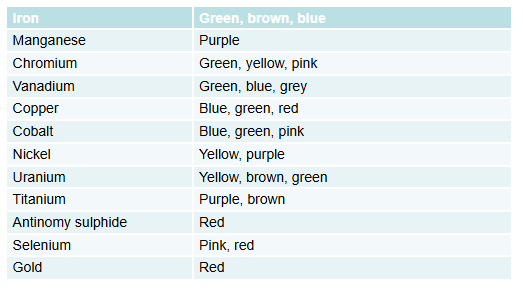

What are the colourants used in glass?

What are the principal glass types?

Fused Silica

Soda lime silicate glasses

Borate silicate glasses

Lead glass

Aluminosilicate glasses

Alkali barium silicate glasses

Borate glass

Phosphate glass

What is fused silica glass?

Silica can be melted and cooled to form glass

Very high processing temperatures

Products

Good temperature resistance

Low thermal expansion

Hence good resistance to thermal shock

Excellent chemical durability

What is soda lime silicate glass?

Silica (SiO2) Soda (Na2O) & lime (CaO)

Used in wide range of applications

Containers, flat, domestic glassware

Greatest tonnage for containers (bottles and jars)

Container glass is made in three colours:

White (also known as flint)

Green

Amber

What is borate silicate glass?

Mainly silica and boric oxide (B2O3) + smaller amounts of alkalis and aluminium oxide

Good chemical stability

Low thermal expansion

Good resistance to thermal shock

Used in kitchenware, laboratory glassware

What is lead glass?

Lead oxide (PbO)

Excellent hand-working and optical properties

Used in manufacture crystal glass

Over 24% PbO can be described as Lead Crystal [European Directive 69/493]

What is insulating lead glass?

Good insulating and dielectric properties

Lead oxide + potassium and sodium oxides

What is optical glass?

Lead imparts high refractive index without colouring glass

What is Aluminosilicate glasse?

Small but important group of glasses

Contain 20% aluminium oxide (alumina Al2O3)

Often include calcium and magnesium oxides

small amounts of boric oxide

Very small amounts of soda or potash

Able to withstand high temperatures with good resistance to thermal shock

Applications: combustion tubes, gauge glasses for high pressure steam boilers, envelopes of halogen-tungsten lamps (operate as high as 750oC

What is Alkali barium silicate glass?

Used to shield X-rays (e.g. cathode-ray tubes)

Contain heavy metal oxides

Lead

Barium

Strontium