FSM EOT

1/78

There's no tags or description

Looks like no tags are added yet.

Name | Mastery | Learn | Test | Matching | Spaced |

|---|

No study sessions yet.

79 Terms

knowledge of a food service dietitian

nutrient requirements

food legislation, regulation and standards

food preparation (recipes)

food service systems (menu ordering, procurement, preparation, plating, distribution and ware washing)

methods of data collection (KPIs)

change mment

Skills of a food service dietitian

advocacy for pts through menu planning, procurement, mment

translate knowledge into food safety and nutrition guidelines

develop and assess recipes and menus

utilise meal mment systems

develop, implement and assess the results of quality audits

adapt written and verbal communication to audiences

activities of a food service dietitian

develop and analyse recipes

develop and analyse menus

monitor for the impact of changes

monitor the quality of services

develop training programs for staff

lease with key stakeholders

advocate for improved food services

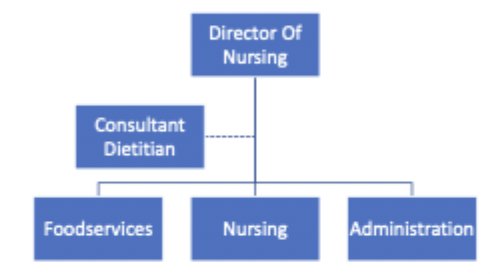

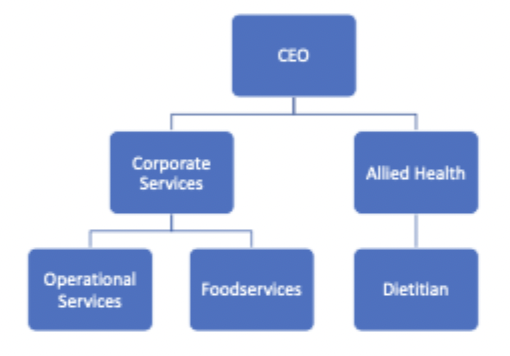

dietitian as consultant

dietitian alongside

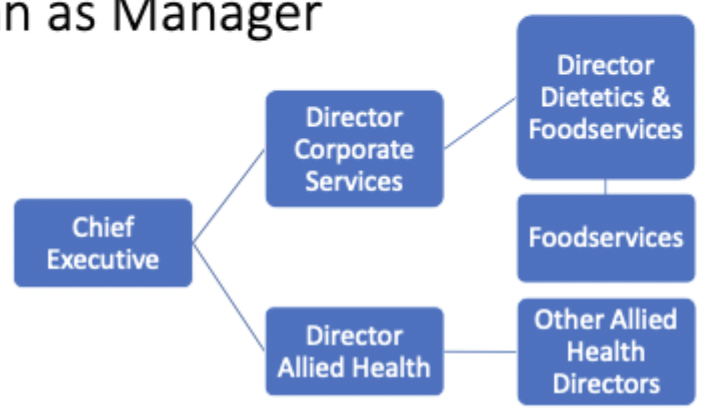

dietitian as manager

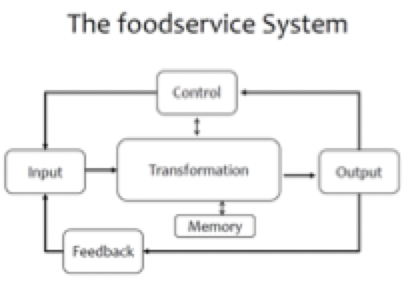

open vs closed system

open - interacts w environment

closed - do not interact w environment

systems thinking

key concepts of systems thinking

holistic approach

interconnectedness and interdependence

systems and subsystems

boundaries and environment

feedback loops

aims/goals/purpose of food system

produce safe nutritious meals of desired quality/quantity that meets client’s needs (social, cultural, medical)

happy/productive workforce

environmental sustainability

meet organisational and financial goals

transformation

the processes that convert inputs unto outputs

mment functions - planning, organising, staffing, leading, controlling

functional systems - procurement/purchasing, preparation and production, distribution and service, hygiene and maintenance

linking processes - decision making, communication, training

inputs

human - labour, skills

materials - food, supplies

facilities - space, equipment

operational - money, time, utilities (electricity, water), info

outputs

meals - quantity (standardised recipes), quality (meets safety standards)

client satisfaction

client needs - cultural, social, medical, nutritional

staff satisfaction and performance

financial accountability

sustainability - procurement, waste, donation

financial - budget targets

control

aims

standards

standardised menus

policies/procedures

programs

contracts

food control plans

audits

external controls - contractor, laws, regulations, FSANZ

memory

records

financial

staff

forecasting

inventory

procurement

staff memory

IT programs

software - holds feedback, survey results, KPIs

feedback

assessment of food service system

internal - client feedback, performance measures, plate waste, order frequency, audits

external - food service regulators, supplier feedback, union

continuous quality improvement cycle

plan - identify problem

do - benchmarking, collect data

check - compare to other FS and predictions

act - what changes next?

external quality systems

food safety

national food standards - FSANZ

state legislation - food act (QLD) 2006

systems safety

national safety and quality health service standards (accreditation standards)

internal quality systems

controls, memory, feed back

production waste

client feedback

audits

KPIs

inputs, transformation, outputs

recruitment processes

staff training audits

staff surveys

food procurement contracts

food quality (ingredients)

HACCP

KPIs

food safety standards

budget

resources used in QLD to improve food services

FS best practice

FEEDS

food quality: what are you measuring

patient acceptance of food

quality of the food/meals

efficiency of system

safety of food - allergens, therapeutic, bacteria

how to test patient acceptance of food

acute hospital foodservice patient satisfaction questionnaire

resident foodservice satisfaction questionnaire

hospital food experience questionnaire

meal assessment tool

meal quality audit tool

plate waste there food o

other food service measures

accuracy and non-patient waste

therapeutic diet accuracy

meal accuracy

production waste

quality and efficiency

staffing efficiency

cost per meal

meals per hour or meals per FTE

total cost of the system

nutrition care process

ADIME

CQI - NCP - assessment

plan, do and check

data from surveys, admin data sets, epidemiological or research studies

KPIs

CQI - NCP - Diagnosis

act

dietitian identifies problem needing to be treated

CQI - NCP - int, M and E

occurs through change mment when you make int, plan for change, monitor change, evaluate outcome

CQI tools

patient satisfaction

resident satisfaction (aged care)

meal assessment tool

plate waste

Meal quality audit tool

basic functions of management

planing

organising - determine objectives, work needed?

staffing - recruitment and retention

directing and coordinating - decision making, communication, follow up

reporting - inform everyone through records, research, reports, audits, inspections

budgeting - planning, accounting, controlling

why do we need change

shift from hospital care to outpatient

reduced lengths of stay in hospital

aging population

changes in gov

improvement in tech, food ordering, equipment, delivery systems

increasing costs of food and energy

economic climate

geopolitical events

environment e.g. climate change

pathogens and disease

change to transport and infrastructure

workforce changes

regulation and legislation change - alleged labelling

key components of change mment

communication - explain reasons and benefits of change

training and support

stakeholder engagement

monitoring and feedback

Lewis model of change

unfreeze

outline changes

speak w mment

develop presentation materials

consider employee reactions

connect changes to company goals

emphasise your support

change

determine how to measure progress

allow for increased communication for staff questions

contact staff who need more help

create anonymous surveys to collect feedback

refreeze

develop incentives and rewards

implement training programs

praise employees

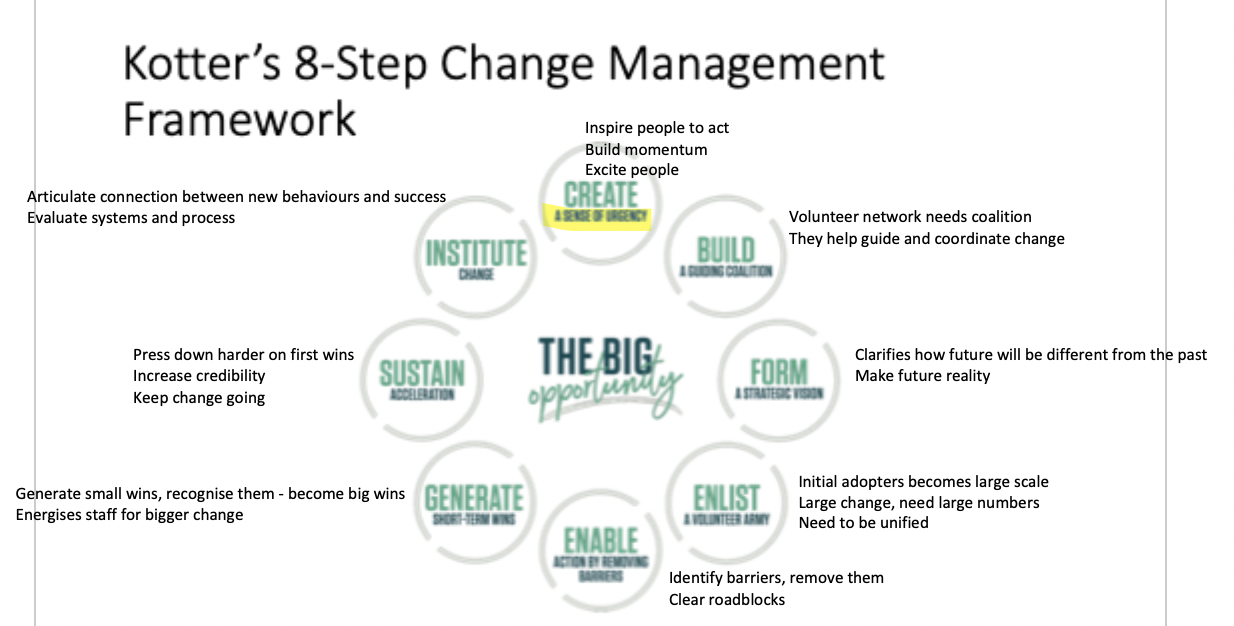

kotter’s 8 step change mment framework

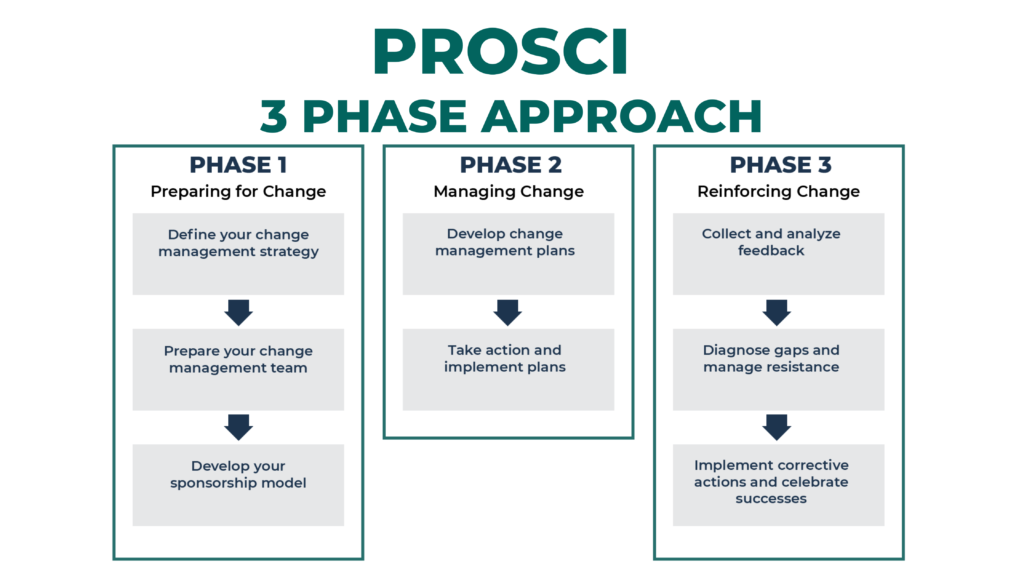

Prosci change mment

simple change management approach

phase 1 - prepare

understand why of change

plan for change

commence stakeholder engagement

phase 2 - manage

change resources

delivery change

monitor and adjust

phase 3 - sustain

assess change

embed change

monitor change

leadership theory; 5 dimension theory of leadership styles

a leader that can be flexible in

degree of control

concern for productivity

concern for people - clients and employees

structure

risk taken in decision making

attributes of successful FS manager - technical expertise and knowledge

standards, policies and procedures

process paperwork

manage work with resources allocated

environmental protection laws

political environment

marketing

CQI - surveys

work redesign, productivity, benchmarking

cost-containment measures

sustainability

disaster and emergency planning

cultural/generational diversity

attributes of successful FS manager - interpersonal skills

communication

empathy

understanding

ethical conduct

motivation

mentoring

trust

intelligence

share vision, goals, objectives

self-confidence

delegating

formal vs informal leader

formal - job title

informal - naturally forms

leadership styles

autocratic - unilateral decision making. effective in quick decision making but can lead to low morale of overused

democratic - e.g. participative leadership. encourages input from team members. fosters sense of ownership, can lead to higher job satisfaction, may slow down decision making

transformational - inspires and motivates team through shared vision and enthusiasm. focus on change and innovation, often leading to high levels of engagement and performance

transactional - system of rewards and punishments. effective in achieving short term tasks and maintaining routines. may not encourage creativity or long-term growth

laissez-faire - hands off approach, gives team members high degree of autonomy. can be empowering for self-motivated employees but may lead to lack of direction/accountability

servant - prioritises needs of team, focus on development and well-being. can build strong supportive relationships, can be less effective in high pressure situations

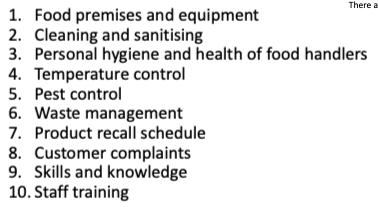

standard 3.3.3 for food premises and equipment

div 1 - interpretation and application

div 2 - design and construction of food premises

adequate space

can be cleaned and sanitised

reduces dirt, dust, pests

audit: windows sealed, self-closing doors, no holes for pests, storage space?

div 3 - floors, walls and ceilings

can be cleaned

can’t absorb grease, food particles

no water ponding

no harbourage of pests

audit: cracks/chips, wall joints sealed, cleanable materials?

div 4 - fixtures, fittings and equipment

no contamination

easily cleaned

no harbourage of pests

surfaces around can be easily cleaned

supply of hot/cold potable water?

div 5 - miscellaneous

enough storage w no contamination

toilets - ‘hands-free’ hand washing

food transport - safe food, can be cleaned

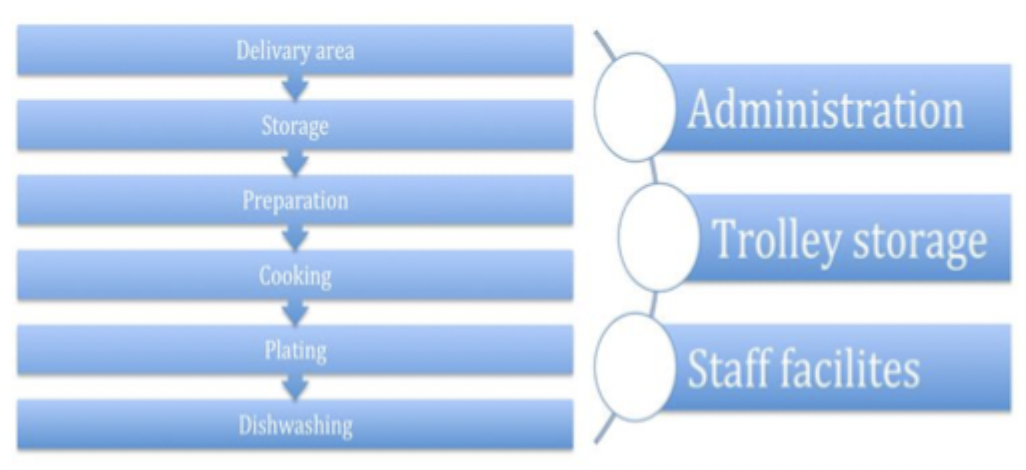

Workflow and functional areas

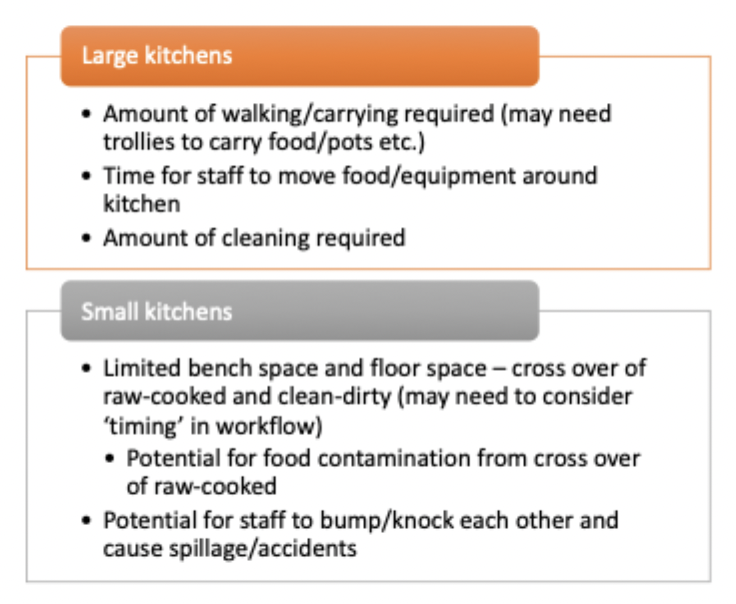

understand why we have workflow, seperate clean and dirty e.g. GCUH

workflow issues in different sized kitchens

How are the menu, kitchen design and workflow related?

menu

standard recipes, production processes

ingredients and storage (dry, cold, frozen)

equipment

task delegation/flow

shift/break times

how does workflow influence food safety

receiving/delivery

storage

preparation

cooking

holding/plating

serving

cooling - leftovers, bacteria

reheating

packaging

distribution

equipment - cooking ovens

convection - <40 meals

commercial convection oven - smaller than combo

combination/combi oven - steams, up to 40 trays

equipment - alternative cooking items

induction heating/hob - like home stove

bratt pan - tilting fryer: shallow pan, poach, stir fry

oven w cooktop

salamander - grill

steam jacketed pans - like double boiler (soups, casseroles)

blast chiller - extend product life

plating equipment - warmers, chillers, shelves, bays for serving

food delivery - carts/trollies (can have hot cold side), retherm trollies

thermal dinnerware - keeps food hot for longer

hostess trolleys - bur lodge and regethermic (decentralised, rolled to ward to self-serve/serve at ward)

robotic trolley delivery

pot washer

dishwasher - pass through (short cycle times), flight (high volume, magnets for cutlery, different compartments)

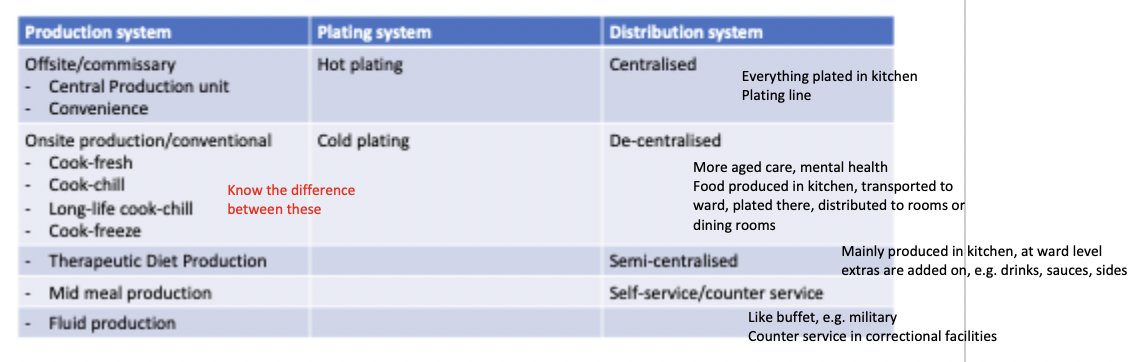

production, plating and distribution systems table

production systems

central - meals prepared for multiple facilities and transported

convenience - bought from supplier, heated etc. on site

cook-fresh - cooked fresh, served immediately

cook-chill - cook fresh, rapidly chilled <3C, can be held fro 5 days

long-life cook-chill - cook fresh, vacuum sealed before chilling. shelf life 20-45 days

cook-freeze - cook fresh, blast frozen to -20C. shelf life 12 months

therapeutic - big hospitals have seperate area - allergens, cultural, religious

mid meal

bought in preprepared - supplement w things on site

special diets maybe prepared on site

drinks prepared in ward pantry’s (tea, cordial…)

fluid

clear/full - portion packs cheaper

special reqr - e.g. ONS - purchased

instant formula - made in dedicated room (cross contamination)

plating systems

plating

hot - food cooked or reheated and put on plates hot

cold - plated cold, need cold environment, retherm trolley

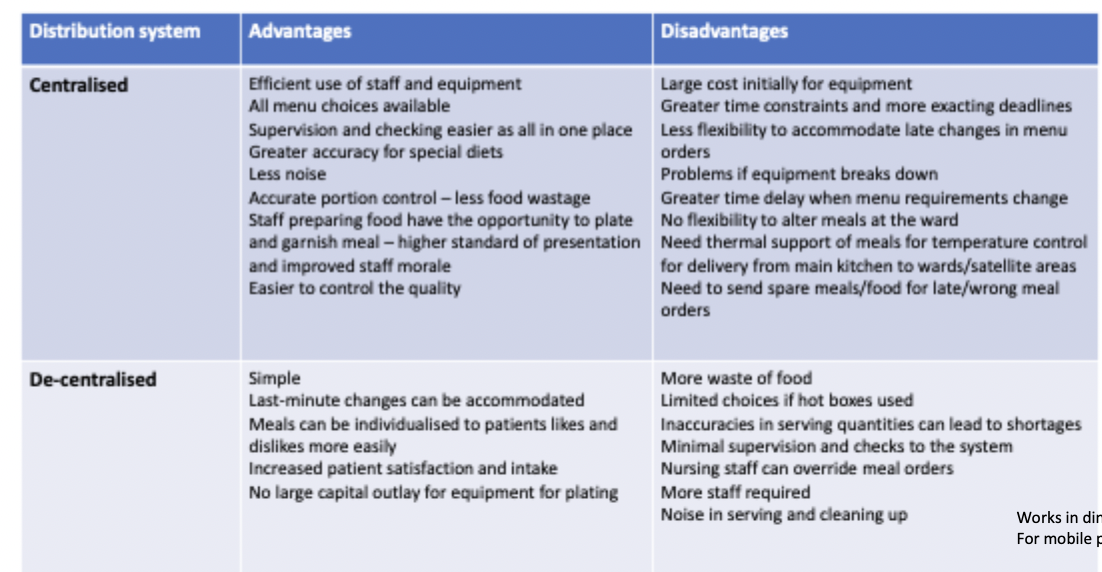

distribution systems

centralised - food is plated in central area

decentralised - plated from bulk trolleys or servers onto plates in ward/ding room

semi-centralised - plated centrally, finished at ward (e.g. add toast so not soggy)

self service

mid meal - usually de centralised, from trolleys at ward pantry

room service - always hot-plates, could be cook-fresh, cook-chill or cook-to-order, centralised distribution

factors to consider when planning menu

external environment - gov, budget, laws, availability, seasons, suppliers, sustainability

internal - mment, labour changes, standards, size, staff

people - pt demographic, nut reqr, cultural

why plan menus

improve nut intake

predictability

labour

costs

budget

purchasing

maximise efficiency

variety, less repetition

types of menus

a la carte (restaurants, room service, cafeteria)

cyclic

week/fortnight

non-selective

selective - choice every meal

semi-selective - some choice, some fixed

single use - ramadan Christmas

menu standards - aged care

14 day min menu

35 choices

14 x full

21 easy to chew (at least 1 vegetarian choice every day)hot, cold and fortified breakfast every day

protein at all 3 meals

supplementation available

finger food available

fortified soup

moulds where possible

HPLE for wt mment residents

fish 3x per week

25-35g/d of fibre

allow input from residents

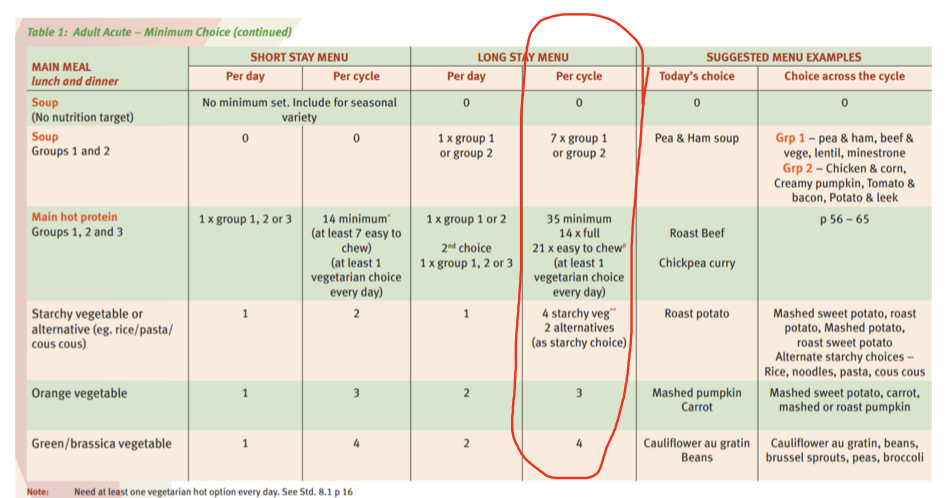

menu standards - acute long stay

min 35 hot main meals

choice of 3 main meals and 3 mid meals each day (at least 2 mid meals are substantial)

fortified hot cereal and soup

hot protein breakfast for all texture levels - full, easy to chew, minced moist, pureed

minimum menu choice - long stay adult acute (QHNSMM)

per cycle

7 soups

main hot protein

35 minimum

14 x full

21 x easy to chew

(at least 1 veg choice every day)

4 starchy veg (sweet/potato/mash) & 2 alternatives (rice, noodle, pasta)

3 orange veg

4 green/brassica veg (cauliflower, beans, Brussel, peas, broccoli)

why plan integrated menus

(includes common therapeutic diets w/in general menu)

more available for those w restrictions

supplies - less waste, storage

efficiency - less items, less time

less cost

assessing a menu

3 steps

verify info about menu and FS

verify info about people you are feeding

use appropriate tools to assess menu that meets standards/policies

QHNSMM

QH menu assessment tool

AGHE

therapeutic diet guidelines

menu analysis software - e.g. foodworks

DA food allergy intolerance menu assessment tool

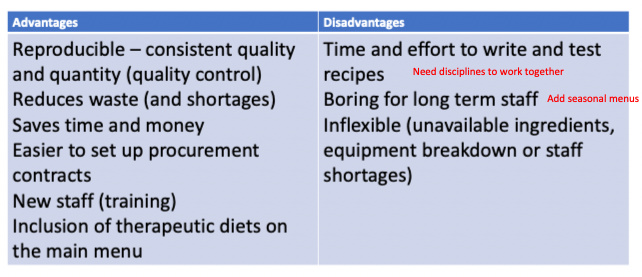

standardising recipes - advantages/disadvantages

standardising recipes - integrated vs non-int menus

int combines multiple diets - no added sugar, no added salt, HPHE, low fat (KJ), tex mod, high fibre, veg, gluten, lactose

steps to developing bulk standardised recipes

yield

weights (g) or measures (cup)

use easy figures - whole or half

standard abbreviations tsp, tbsp

list ingredients in order used

concise method

directions for serving

OR

watch cook

ingredients, quantity

procedures

equipment

go over w cook, change if needed

others cook w recipe, change if needed

mid meal groups

HPHE

LPHE

healthy snack

food safety program

hazards HACCP

food safety program needs to be audited

control reqr

storage, processing, packaging, distribution, disposal, recall

standard - food premise and equipment

layout reduces contamination

premise, fixtures, fittings, equipment, transport vehicles can be cleaned, water, ventilation, storage etc.

food safety program for vulnerable populations

must have documented and audited program

must be available on premise for staff

audited within 6 months of opening!

audits

staff

cleanliness

CCPs

support processes documented? - training, cleaning, pests, temps,

what is procurement

process for ordering

product info form PIF

process for receiving

inventory control

procurement - purchasing

ordering - identify product, characteristics (shelf life, delivery, size etc.), assess reqr, contracts

PIF - gives details: supplier, description, ingredients, country of origin, nutritional, allergen, shelf life

receiving - demo, correct product, storage

inventory control - FIFO, records in system, when stock reduced refill

FSP support programs in the tool

hour rule

0-2 hrs use immediately to fridge <5C

2-4 hrs use immediately

>4hrs throw away

military

dietitian role

production distribution

nut reqr

unique considerations

nut, FSM, therapeutic, education,

self-service, private contractors

reqr

PALs

gender

age

field kitchens, ration packs, allergies, culture, logistics, ration packs

correctional facilites

dietitian role

production distribution

nut reqr

unique considerations

menu planning, therapeutic, nut ed, FS

centralised or counter service (lower security)

meet basic needs, diet guidelines, mental health

cost effective, security levels, alc, Vegemite, coffee, bones, allergens, no luxury items

child care

dietitian role

production distribution

nut reqr

unique considerations

puree, solid

unique - growth level, iron, cultural, breast milk, high risk allergies, involve children in food prep

aged care

dietitian role

production distribution

nut reqr

unique considerations

nut reqr QHNSMM

unique - texture, malnt, dining room , aged care quality standards

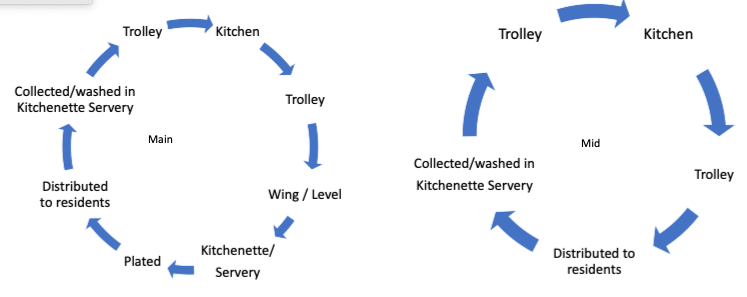

food service cycle main vs mid aged care

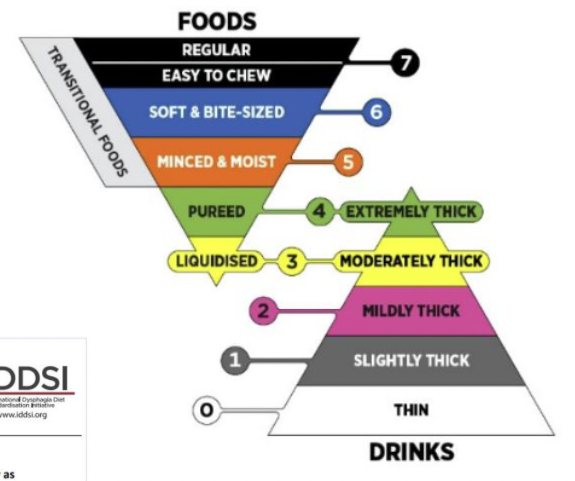

dysphagia

causes

incidence

nut impact

IDSSI and purpose

swallowing difficulty

stroke, cancer, ABI, Muscular sclerosis

hosp - ICU 7.9%

older pts/rehab - 50%

community 65+ 15-30% (lots of silent aspiration)

aged care 50%

reduced food intake

dehydration malnt

QoL

text-mod diets

standard initiative

IDDSI chart

test methods

spoon, fork, syringe flow

allergen labelling

ingredients

summary statement

warning statement - uncommon ingredient, warn of allergen chance

advisory statement

exemptions - glucose syrup gluten

food allergen mment in FS

identify - CCPs

assess

manage - CQI

audit

support programs - trainmen etc.

tips for sustainable health care

local produce, products

seperate organic, recyclable landfill

equipment low energy

minimise water usage, utilise grey water

menu planning - e.g. reduce meat