SM 143 Stress and Strain

1/13

There's no tags or description

Looks like no tags are added yet.

Name | Mastery | Learn | Test | Matching | Spaced |

|---|

No study sessions yet.

14 Terms

Stress

intensity of internal force acting on specific plane passing through a point

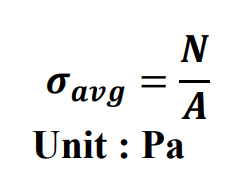

Normal stress & Average Axial/Normal stress σ

intensity of force acting normal to A

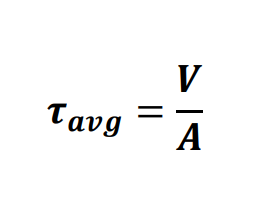

Shear stress & Average shear stress τ

intensity of force acting tangent to A.

Can have single and double shear; number of seperate areas being sheared.

Assumptions

Bar remains straight

Deforms uniformly

Loaded on centroid

Material assumption:

continuous (no voids) and cohesive (all portions connected – no breaks)

Homogeneous & Isotropic

Material has the same physical and mechanical properties throughout its volume

Material has the same properties in all directions

Strain

the effect/result of force. A measure of deformation.

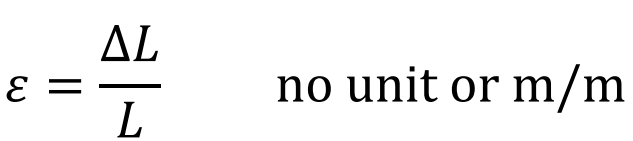

Normal strain ε

result of normal forces (change in volume)

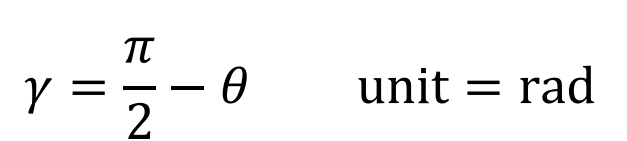

Shear strain γ

result of shear forces (change in shape/angle).

Increase in γ is negative & decrease in γ is positive.

For small angles: tanγ ≈ γ

Hooke’s Law

σ = Eε, E is Young’s modulus.

Only applies to elastic region or for elastic deformation of material.

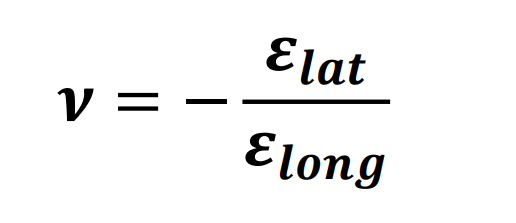

Poisson’s ratio

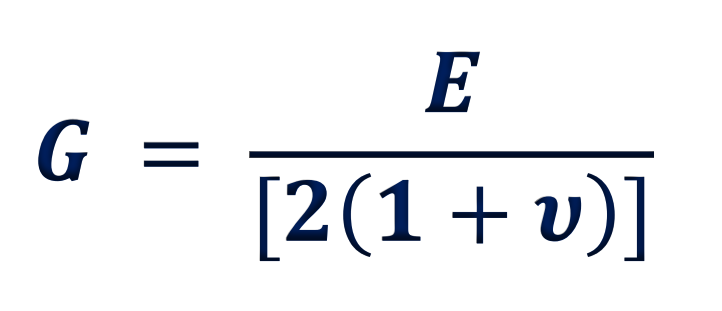

Shear stress-strain ratio

Shear modulus

v is Poisson’s ratio

Saint-Venant’s principle

Local deformation & stress concentrations occur where load is applied. Move far enough away from load, effect starts to disappear

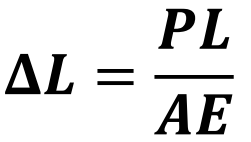

Change in axial length

P - internal axial force, L - element length, A - cross-sectional area, E - Young’s modulus.

Tensile Stress is +, deformation caused by tensile stress is +, therefore lengthening is +.

Formula derived from Hooke’s Law.