ISAT 211 Exam 1

1/82

There's no tags or description

Looks like no tags are added yet.

Name | Mastery | Learn | Test | Matching | Spaced |

|---|

No study sessions yet.

83 Terms

OEM

original equipment manufacturing

Purposed of a scale

To show the relationship between the size of the object in the drawing and the size of the object in real life

In an engineering drawing, the scale of all views (orthographic and isometric) must be the same.

False, isometric and orthographic can be different. Orthographic views can also all be different. Have to indicate the views scales are different than the base

note that scales can be simplified ex. 6:2 can be reduced to 3:1

1:1 scale

drawing:real life or drawing/real life

What is the correct way of interpreting a drawing scale of 4:1?

The drawing is 4 times as big as the object

An engineering drawing shows a linear dimension of 38 mm for a part. If the scale of this drawing is 1:2, what is the length of this feature on the part in real life?

This is a trick question! The dimension shown in the drawing is the exact same dimension as the one in real life! The dimension in the drawing is the true/desired/intended/nominal dimension of that feature on the real life object.

Scale tells us the size of the graphical image on paper compared to the actual object. The dimensions of the part do not change, because the specification tells what size to manufacture it.

commercial product

any physical, tangible item that is developed, manufactured or provided by a business for the primary purpose of selling it in a market to make a profit

What are consumer goods?

households and daily people/things

made and bought by individuals and households for person use

ex. food, clothing, TVs, cars, furniture, washing machines

What are capital goods?

business goods, what is used by business for business

made for and bought by businesses and are needed for business to operate

ex. ATMs for banks, cash registers for stores, desk and chairs for schools, X-ray machines for hospitals

industry machinery, used for manufacuring

GDP

gross domestic product

Bill of materials

A reference list that manufacturers use to streamline and track their manufacturing process(es). It shows the assemblies(components used to build the end product directly) and the subassemblies(components used to build the components of the end product)

Tells you the level of a part, part number, material, and quantity

product tree

Similar to a BOM but it is simpler, it is a visual representation of the products part and what parts might have subparts

product life cycle

The cycle of deriving materials for a product all the way to when it becomes waste or gets recycled

craft/artisanal vs manufacturing

manufacturing is the application of physical and chemical processes to alter the geometry, properties, and/or appearance of a given starting material to make parts or products and included assembly of multiple parts to make products. These products can be massed produced and typically cost less because they are available in large quantities. More cookie cutter. Ex. cars, appliances, big brand clothes, packaged foods, etc.

craft/artisanal: Products that are harder to or can’t be mass produced. Skilled individuals or small groups make these items. Can be more expensive due to the labor intensity of handmade/made-to-order products. Techniques to make these things are learned or passed down. ex. handmade pottery, handcrafted furniture, certain foods, etc.

at scale

Scale is a fraction or ratio it would be drawing : real life or drawing/real life

If something is drawn at scale the ration is 1:1 meaning the size it is on the page or screen is how big it will be in real life once it is made. If the scale is something else such as 2:1 the drawing is 2x bigger than the real life object will be or 1:2 the drawing is half the size of the real life thing.

value-added

a product is useful to its buyers in some way, fulfills a purpose

refers to the increase in worth or utility that occurs at each stage of the production process

represents that difference between the value of the final product or service and the cost of the inputs or raw materials used to create it

Flow chart notation

oval: the terminator, the start and end of a process ex. rolled sheet steel

rectangle: a step in the process ex. flatten sheet

arrows: indicate the direction of flow

diamond: represent a binary decision, yes/no or true/false, is required to move on ex. is an the angle 28 degrees?

You only need to show things that are directly happening to the work piece

additive manufacturing

Adds material, material can be deposited, solidified, or joined, and of the 4 traditional solids, this is what 3D printing is

4 traditional solids

metals, polymers, ceramics, and composites (a combination of any of the previous 3)

subtractive manufacturing

material is being remove also called material removal involved cutting, grinding, etc. to get desired form and dimension

fabrication

altering material physically or chemically to get something else, giving shape and form to a worked on material

transforming selected raw materials into individual components or the desired end product

3 kinds:

shaping: forming 3D form according to dimensions

property enhancing: doing physical or chemical process to make it perform better

surface processing: Altering external surface, normally cleaning

assembly

joining parts together

composed of multiple individual componets

8 elements of design

Form: What you see and physically interact with

Functionality: Intended features & purpose

Aesthetics: How does it appeal to the 5 senses?

Materials: Intentionality of what it’s made of, why are those chosen?

How it works: How it’s engineered to deliver its functionality

Safety: Safe for intended use and intended user

Manufacturing: Design to be manufactured easily

Sustainability: Reduced impact on natural world and how it’s made

form design

elements include: physical and tangible parts, shape (2D geometric), form (3D properties of object/shape), dimension measurement (length(linear), angle, diameter/radius of arch or hole), texture and color, material selection, aesthetics

functional design

What is the intended features and purpose, ex. toaster

timer, food type options, defrost, crumb tray

production design

How a product is designed specifically for users and people, there is 8 elements of product design which are form, functionality, aesthetics, materials, how it works, safety, manufacturability, and sustainability

Some other concepts are redesign (What matters? how much will it cost to manufacture? How can it function better, does it work?, etc.), getting written requirements (customer, and design/engineering), and what to base materials on (cost, function, kinds of technology available, risks, etc.)

dimension

Defines form, size, location of features and components

ex. Size: length, width, thickness Location: where a part feature is

3 ways dimension is specified: linear (always horizontal or vertical), angular, radii or diameters

size specification of a geometry. size and measurement of a 2D geographic shape or feature

types: lines, diameter, radius

nominal dimension

The ideal dimensions, what we want if we could get it perfect

fit and clearance

fit: fitted parts, slide into/fit together. types: transition (move with some resistance) and interference (won’t move)

clearance: Want a pen to fin into the hole and fit all the way in, sleeve through, fit in clearly and slide through

tolerance

Want to define certain dimensions with a range ± a number, a small range

How off we can be for the real life element but still fit the expected clearance

can be symmetrical (the same + and -) or bilateral (+ and - are different)

BOM

bill of materials

parts tree

Visually shows the levels of the parts and subparts in an assembly

CAD, CAM

CAD: computer aided design, use of computers to develop, modify, and analyze a design

CAM: computer aided manufacturing, computer software is used to handle and control tools used in the manufacturing process

CAM uses what CAD provides to make machine code so that it can make the product or component designed in CAD real

product specifications

All the info needed to make a product and to be sure it meets its intended purpose

Provides the detailed information and data that allows a design to become real

Provide exact data and details that enable the product to work, to meet performance requirements, and to be manufactured in a highly consistent and standardized way

geometric dimensioning & tolerancing

Used in CAD and it tells the person who reads it the different sizes and dimensions of a component and it tells you what aspects of a component will have variation which is the tolerances

nominal dimension

The ideal dimensions if we could get it perfect

fits & the different kinds

fits: multiple components have to come together in some way, they are mated and have to fit into each other

types:

press/interference fit: the pin and hole stay in place and don’t come apart without force or at all. No intent to come apart

In between/transition fit: the pin and hole are connected with a very small clearance. Held in place but can come apart still

clearance fit: the pin and hole can move easily

work drawings

assembly: All parts are together and explode to show discrete components needs every detail so it can be made properly. Represents that shape and position of parts to show relationships in a realistic way. A BOM is often on this drawing in the title block

detail: shows the hidden parts of a component, this is a single part that cannot be further disassembled. Includes all necessary info required to define that part has tolerances, finishes, material, etc.

least material conditions

least material, largest hole, largest pin

most material conditions

also called max material condition, the most material, smallest hole, largest pin

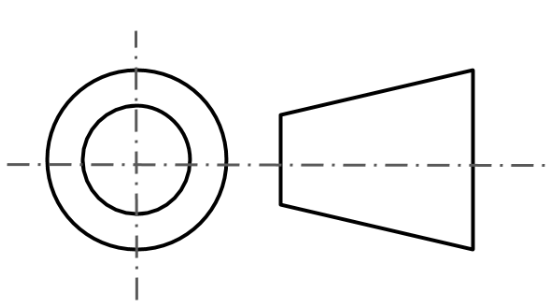

isometric views

a drawing of one part, both 2D and 3D shown and displays details

orthographic views

6 possible views: front, back, top, bottom, left, right

angel of projection

Picks views and sizes, in the U.S. and Canada use the 3rd angle (pictured), everywhere else uses the 1st. It tells you things like quadrant, plane of projection, which is the front view (3rd is the bottom of the horizontal axis), right is the vertical axis, etc.

unit operation

One act on an object, when something is done to a work piece it is called this and they happen one after the other, in a process map it is a linear sequence. ex. work piece is a steel sheet and the unit operation is it being flattened

forging

Hot and cold forging are both a thing, normally it is hot. The work material is heated below its melting point and then force is applied to shape it. This is normally done with metal working, think a black smith. It can also be done when two dies are squeezed together to form the shape

milling

A machine can either remove or deform material this way. Material is cut away into the desired shape. A material removal process, the machine normally turn to do this

machining

Material Removal process, operations include turning, drilling, and milling

work part/workpiece

The thing at a machine, an object being worked on by a machine or tool

casting

Metal is the primary material used for this, it is liquified/semi-liquid and poured into a mold which it will solidify into the desired shape and then is removed

molding

plastics are the primary material used, similar to casting. The material is heated to be a liquid or semi-liquid and then poured into the mold and solidifies in the mold of the desired shape before being removed

injection molding

Often used for plastics, they are heated above their melting point to be fully molten and then is mechanically forced into a mold of the desired shape and allowed to cool. LEGOs are made this way.

blow molding

Also used for plastics, the plastic is a molten tube which is then inflated or blown up by a tube which is inserted in a closed molds so that the plastics takes the shape as it is blown. This is the method of extrusion

extrusion

A billet is forced to flow through a die orifice and will take the cross sectional shape of that orifice. Think blow molding, something without shape is put into a mold and the blown until it holds the shape it is in

PET

a type of polyester, but it plastic #1, Polyethylene Terephthalate, it is used to make containers for food and beverages, household items, personal items, etc.

engineered materials

5 classes of engineered materials:

metals (alloys which are 2+ elements, iron, gold, aluminum, etc.)

ceramics (clay, glass, mineral compounds) contains metallic, semi-metallic and nonmetallic elements

polymers (monomer chains) repeating structural unites called mers, long organic molecules

composites (made up 2 of the previously listed, non-homogenous mixtures) each category is united by chemical or physical properties, traditional solids

advanced materials

metals

alloys used normally and are made up of 2 or more elements with at least one being metallic and there is two groups

ferrous: based on iron, most important commercially

nonferrous: other metallic elements and their alloys, alloys are more important than pure metals commercially

ceramics

a compound containing metallic or semi-metallic and nonmetallic elements. Oxygen, nitrogen, and carbon are typical non-metallic elements. Clay, alumia, and silicon carbide are traditional

polymers

A compound formed of repeating structural units called mers, whose atoms share electrons to form very large molecules. Normally consist of carbon and one or more other elements. Three categories:

thermoplastic polymers: can be subjected to multiple heating and cooling cycles without substantially altering the molecular structure

thermosetting polymers: chemically transformed into a rigid structure due to cooling from a heated plastic condition

elastomers: polymers with significant elastic behavior

composites

material that consist of two or more phases that are processed separately and then are bonded together to to achieve properties superior to those of its constituents. Found in nature and can be produced synthetically

advanced materials

Novel, high-value-added substances with advanced properties. Normally created which high specialized manufacturing techniques. Not really a class because there is no shared properties or characteristics.

Material properties of solids

mechanical: how the material behaves when subjected to forces or stress ex. tensile and compressive strength

physical: the physical characteristics of the material ex. thermal and electrical

chemical: how the material behaves at the molecular level when interacting with other substances ex. flammability and hydrophilic/hydrophobic

material properties: the 6 basic types

Mechanical: tensile, hardness, elasticity, ductility, etc.

Thermal: thermal conductivity, thermal expansion, thermal insolation, etc.

Electrical: electrical insolation, electrical conductivity, resistivity, etc.

Optical: reflectivity, opacity, luminosity, etc.

Magnetic: magnetic permeability, magnetic susceptibility, etc.

Chemical: flammability, toxicity, oxidation, etc.

annealing

a heat treatment that changes the physical and sometimes chemical properties of a material normally glass or metal in order to increase ductility and reduce hardness to make the material easier to work with. This is how you can unharden a metal and make it soft again.

work hardening

This is used for metals to make them useful materials. You deform a metal throught processes such as bending or polishing.

primary sector

Cultivate and exploit natural resources

ex. agriculture, forestry, livestock, fishing, mining

secondary sector

takes the outputs of the primary industries and converts them into consumer and capital goods. manufacturing is the principal activity in this category but construction and power utilities are also included

ex. apparel, chemicals, basic metals, textiles, plastics, glass/ceramics, paper, computers

tertiary sector

the service sector of the economy

ex. insurance, banking, communications, hotel information, wholesale trade, real estate, restaurants, repair and maintenance

feedstock

natural resources that have been processed physically and chemically so that are uniform. Have been made with desired chemical and physical properties so that they turn into products with the desired performance, safety, quality, and manufacturing specifications.

polymerization

when molecule chains are formed to make monomers which are then combined chemically to make chains or a network molecule called a polymer

nurdles/chips/beads/granules

These are examples of feedstock for plastics

thermoplastics

Chemically bonded so that they can melt when head and pressure is applied. They are inherently recyclable

biodegradable

Has to decompose to a natural stare in 6 months in natural, normal conditions. Digested and turned into metals are not but natural polymers are plastics that are required some industrial composting process or speiclized recyling faciltiy

biobased

materials made from renewable biomass sources ex. a cup made from plants

ingots, sheets, slab

ways metals are prepared, it can be left in these forms or work into each other. Ingots are melted into slabs and then slabs are rolled into sheets

product life cycle

The cycle in which something is made all the way through when it is done being used and becomes waste. Often called the cradle-to-grave life circuit of a material

Raw materials → synthesis and processing → engineered materials → product design, manufacture, assembly → applications → waste (if possible) → recycle/reuse → synthesis processing

What are the subdivisions of the manufacturing process?

processing operations and assembly operations

what are the divisions of the processing operation?

shaping, property enhancing, and surface processing

What are the divisions of the shaping process?

solidification processes (casting and molding), deformation processes (forging and extrusion), and material removal (machining: drilling, turning, milling, and grinding)

What are the divisions of property enhancing processes?

heat treatment

What are the divisions of surface processing operations?

cleaning and surface treatments and coating and deposition processes

What are the divisions of assembly operations?

permanent joining processes and mechanical fastening

What are the divisions of the permanent joining processes?

welding, brazing and soldering, and adhesive bonding

What are the divisions of mechanical fastening?

threaded fasteners and permanent fastening methods