P1 LESSON 1 Introduction to Pre-stressed Concrete

1/42

There's no tags or description

Looks like no tags are added yet.

Name | Mastery | Learn | Test | Matching | Spaced | Call with Kai |

|---|

No study sessions yet.

43 Terms

Reinforced Concrete

uses concrete to resist compression and

to hold the steel bars in place, and

uses steel to resist all of the tension

Concrete

strong in compression but weak in tension

Steel

strong in tension (as well as compression)

Prestressing

a method in which compression force is applied to the reinforced concrete section.

Reinforced Concrete

Tensile strength of concrete is neglected (i.e. zero)

___ beam always crack under service load

Prestressing

reduce the tensile stress in the section to the point that the tensile stress is below the cracking stress. Thus, the concrete does not crack!

Yes

It is then possible to treat concrete as an elastic material??

Internal Prestressing Forces

External Forces (from DL, LL, etc...)

The concrete can be visualized to have 2 force systems

Pre-stressed Concrete

Internal stresses are induced to counteract external stresses.

Pre stressing

permanent acting forces in concrete to resist elastic forces under loads

1904

Freyssinet attempted to introduce permanent acting forces in concrete to resist elastic forces under loads and was named “Pre stressing”

Reinforced Concrete (RC)

Cracked with deflection under dead load and full service load

Prestressed Concrete (PC)

Uncracked with likely camber under dead load and prestress

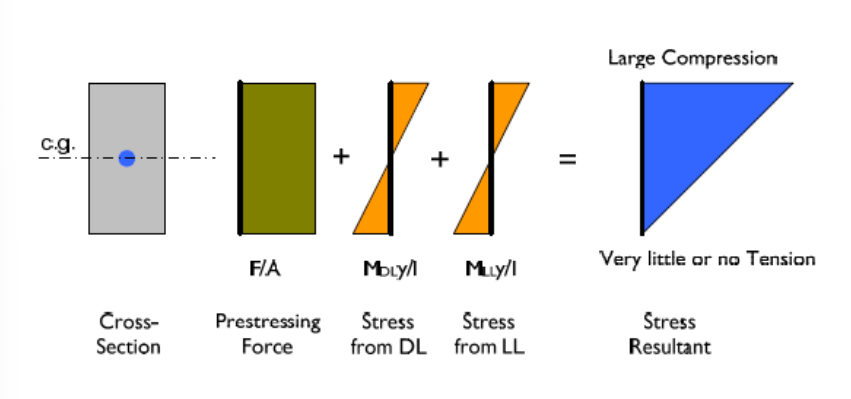

Stress in concrete section (simple case)

when the prestressing force is applied at the c.g. of the section

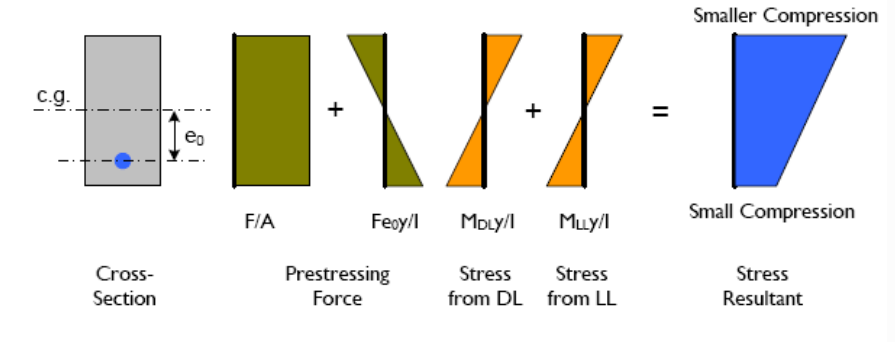

Stress in concrete section (typical case)

when the prestressing force is applied eccentrically with respect to the c.g. of the section

No

does the concept of prestressed concrete is new?

1886

a patent was granted for tightening steel tie rods in concrete blocks. This is analogous to modern day segmental constructions.

low strength of steel at that time

Early attempts were not very successful due to?

Since we cannot prestress at high stress level, the prestress losses due to creep and shrinkage of concrete quickly reduce the effectiveness of prestressing.

Early attempts were not very successful due to? (another reason)

Eugene Freyssinet (1879-1962)

first to propose that we should use very high strength steel which permit high elongation of steel.

Eugene Freyssinet

First prestressed concrete bridge in 1941 in France

First prestressed concrete bridge in US: Walnut Lane Bridge in Pennsylvania. Built in 1949. 47 meter span.

Bridges

Slabs in buildings

Water Tank

Concrete Pile

Thin Shell Structures

Offshore Platform

Nuclear Power Plant

Repair and Rehabilitations

Applications of Prestressed Concrete

Pretensioning

Posttensioning

External

Internal

Linear

Circular

End-Anchored

Non End-Anchored

Bonded

Unbonded Tendon

Precast

Cast-In-Place

Composite

Partial

Full Prestressing

Classification and Types of Prestressing

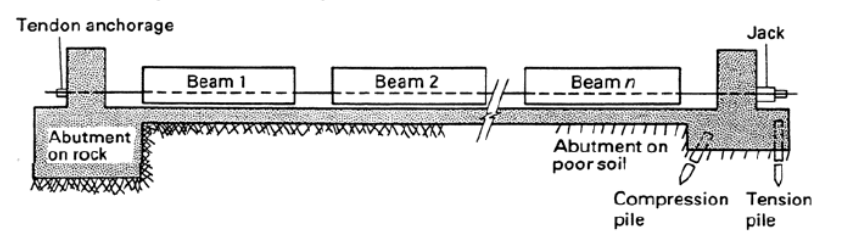

Pretensioning

the tendons are tensioned against some abutments before the concrete is place.

After the concrete hardened, the tension force is released.

The tendon tries to shrink back to the initial length but the concrete resists it through the bond between them, thus, compression force is induced in concrete.

___ is usually done with precast members.

Posttensioning

the tendons are tensioned after the concrete has hardened.

Commonly, metal or plastic ducts are placed inside the concrete before casting.

After the concrete hardened and had enough strength, the tendon was placed inside the duct, stressed, and anchored against concrete. Grout may be injected into the duct later.

This can be done either as precast or cast-in-place.

External Prestressing

Prestressing may be done outside

Internal Prestressing

Prestressing may be done inside

Linear Prestressing

Prestressing can be done in a straight structure such as beams

Circular Prestressing

Prestressing can be done in a around a circular structures, such as tank or silo.

Bonded Tendon

The tendon may be ___ to concrete (pretensioning or posttensioning with grouting)

helps prevent corrosion of tendon.

Unbonded Tendon

The tendon may be __ concrete (posttensioning without grouting).

allows readjustment of prestressing force at later times.

Non-End-Anchored tendons

In Pretensioning, tendons transfer the prestress through the bond actions along the tendon

End-Anchored tendons

In Posttensioning, tendons are anchored at their ends using mechanical devices to transfer the prestress to concrete; (Grouting or not is irrelevant)

Full Prestressing

Prestressing tendon may be used in combination with regular reinforcing steel.

Thus, it is something between ___ prestressed concrete (PC) and reinforced concrete (RC).

The goal is to allow some tension and cracking under full service load while ensuring sufficient ultimate strength.

Partial Prestressing

use to control camber and deflection, increase ductility, and save costs.

Uncracked under dead load; cracked under full service load

Takes full advantage of high strength concrete and high strength steel

Need less materials

Smaller and lighter structure

No cracks

Use the entire section to resist the load

Better corrosion resistance

Good for water tanks and nuclear plant

Very effective for deflection control

Better shear resistance

Advantages of PC

Initial Loading

Service Loading

Stages of Loading

Initial (Immediately after Transfer of Prestress)

Full prestress force

No MLL (may or may not have MDL depending on construction type)

Service

Prestress loss has occurred

MDL+MLL

Bulkheads

high-strength steel tendons are pulled between two end abutments

Anchoring of tendons against the end abutments

Placing of jacks

Applying tension to the tendons

Casting of concrete

Cutting of the tendons

Various stages of the pre-tensioning operation are summarized as follow

Improving the performance of the building under various service condition.

Allow to carry a greater load or span a greater distance then ordinary reinforce concrete.

It permits steel to be used at stresses several times larger than those permitted for reinforcing bars

Pre-tensioned Concrete

Large reduction in traditional reinforcement requirements as tendons cannot distress in accidents

Tendons can be easily "woven" allowing a more efficient design approach.

Higher ultimate strength due to bond generated between the strand and concrete

Strong against compression

Post-tensioned Concrete