Biodegradable Polymers

1/63

There's no tags or description

Looks like no tags are added yet.

Name | Mastery | Learn | Test | Matching | Spaced | Call with Kai |

|---|

No study sessions yet.

64 Terms

polymers

covalently bound, repeating unis of smaller molecules

polymers properties

viscosity, hardness, toughness, and flammability

natural protein polymers

polypeptides, collagen

natural sugar polymer

polysaccharides, glycosaminoglycans, cellulose

nucleic acid polymer

dna, rna

synthetic polymers

polyethylene glycol, polyester, polyanhydride, polyurethane

natural polymers

hyaluronic acid, dermatan sulfate, chondrotitin 6-sulfate, keratan sulfate, heparan sulfate, heparin

pet; pete; recycling 1

plastic water and soda bottles

hdpe (high density polyethylene); 2

laundry/dish detergent containers

vinyl or pvc; 3

pipes, shower curtains

ldpe (low density polyethylene); 4

grocery and sandwich bag

pp (polypropylene); 5

tupperware, syrup bottles, yogurt cups

ps (polystyrene); 6

coffee cups, disposable cutlery

low density pe mw

1000-2000

high-density pe mw

10,000-100,000

ultra high mw pe

2-6 million

mn =

sum(xi) Mi

mw

sum(wi) Mi

pdi

mw/mn

polymer breaks down into smaller units

with hydrolysis and enzyme action

smaller units themselves can be

metabolized; excreted

plga breaks down into

lactic acid and glycolic acid

bioeliminable

non-degradable, water soluble, kidney excretable

peg attach to protein, hydrophobic drug

to make water soluble, shield dug, increase circulation

permanent/retrievable polymers

non-degradable, non-excretable

permanent polymers

polyethylene and non-poylmers like metals

biodegradable polymers usage

need of material is temporary, time-dependent, no follow-up surgery, avoid chronic inflammation, cell-mediated healing

polymers

monomer → residue, repeating unit

M =

nM0; chain length/degree of polymerization

when chain length/dp = n+m

M = nMn0 + mMm0

types of copolymers

homopolymer, random, graft, alternating, block

copolymers vary

mechanical strength, hydrophobicicty, functional groups, degradation, crystallinity

polymer skeletal structure

linear, branched, network

applications of structural polymer

sutures, artificial heart

polymer delivery

plga microspheres and pbae nanoparticles

polymer tissue engineering

polymeric scaffolds, nanofibers

doxil

polyethylene glycol

gliadel wafer

polyanhydrides

biodegradable suture

plga

pacemaker?

polyurethanes

degradation mechanism

oxidation, microorganism

hydrolysis susceptible bonds

esters, anhydrides, carbonates, amides

poylmer bond stability

polyanhydrides least, polyamides most

cleavage of crosslinks

between water soluble polymer chain

transformation/cleavage of side chains

leading to the formation of polar or charged groups

cleavage of backbone linkages

between polymer repeat units

surface erosion

erosion of outer surface only

inner layers do not see water

until outer layers are eroded

surface erosion exhibits

zero order release when surface area doesn’t change substantially

surface erosion looks like

a bar of soap

bulk erosion

erosion throughout the volume of the material simultaneously

entire mass

encounters water

results in bursts of release

once polymers degrade into small sized oligomers

parameters that affect erosion

water diffusion, hydrophobicity, steric effects, bonds/forces that maintain structure, length scale, density, mcirostructure, environemtal conditions

rate of degradation

1/M = 1/M0 + kefft

M/M0

e^-kefft

degradation products are catalytic and don’t diffuse away

degradation will be autocatalytic

driving force of erosion

degradation of polymer bonds

poisson kinetics

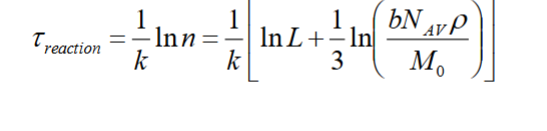

t reaction = 1/k * ln n

t reaction

t diffusion

L²/D

t diffusion

pi * L² / ($D)

L ~

sqrt(Dt)

erosion number