General Lab Practice SOLO 3

1/75

Earn XP

Name | Mastery | Learn | Test | Matching | Spaced | Call with Kai |

|---|

No analytics yet

Send a link to your students to track their progress

76 Terms

total quality management

the management philosophy and approach that focuses on processes and their improvements as the means to satisfy customer needs and requirements

Five Q framework

defines how quality is managed objectively with the scientific method or PDSA cycle

PDSA stands for..

plan systems improvement, the 5 phrases

do a test pilot of the change

study the results

act or implement the change

Quality Laboratory processes (QLP)

include analytical processes and the general policies, practices, and procedures that define how all aspects of the work are done

establishes standard processes for the way things are done

new process implemented through this

Quality control (QC)

emphasizes statistical control procedures

includes non-statistical check procedures

linearity checks

reagent and standard checks

temperature monitoring

new process measured and monitored through this

Quality assessment (QA)

provides broader measures of laboratory performance

turnaround time

specimen identification

patient identification

test utility

new process measured and monitored through this

Quality improvement (QI)

provides a structured problem solving process to help identify the root cause of a problem and a remedy for that problem

the new process is improved through this

Quality planning (QP)

standardizes the remedy

establish measures for performance monitoring

ensure that the performance achieved satisfies quality requirements

document the new QLP

provides the planning to eliminate performance problems

the new process is re-planned through this

total quality control measures

a surveillance process which monitors the performance of

personnel

instrumentation

methods

materials

Quality control program

monitor consistency of performance

detection of nonconformity to standards

documentation is the backbone

Why have a QC program?

necessity

communication

application

Labs should perform an analysis of it’s testing process to…

identify areas of potential error

Inventory of control materials inncludes…

adequate supply

proper ID (lot, dates, initials)

proper storage

parallel or comparison testing

standard materials

determine the concentration of an unknown quantity

assess patient values by means of reference range

verify measurement assignment of values

instrument calibration

control materials

verify the precision or reproducibility of lab procedures

evaluate methodology and instrumentation

closely resembles unknown test specimens

Stable, same matrix, normal and abnormal

Lyophlized controls

reconstituted by the addition of water or a specific diluent solution

assayed controls

come with expected values of concentration, means, and standard deviation from the manufacturer

may be expensive

preferable for a reference method used to measure a particular analyte

unassayed controls

do not have assigned analyte values provided by the manufacturer and are not linked to specific assay systems by labeling or other means

frequency of internal quality control

regulatory requirements

manufacturer instructions

analytical stability

risk of harm

event based (recalibration or maintenance)

dispersion

increased frequency of both high and low outliers

trend

a series of values that continue to increase or decrease above or below the mean over a period of several concecutive days

shift

sudden upward or downward change in values

Which Westgard rules result in a warning?

1-2s

Which westgard rules result in a rejections?

1-3s

2-2

4-1s

10x

R-4s

clinical laboratory improvement act of 1967

federal goverment account for variation in pahses of testing as part of overall quality assessment and assurance requirements

clinical laboratory improvement act of 1988

mandats proficiency testing as a major part of accreditation process

six sigma process

business management strategy that seeks to improve the quality of process outputs by identifying and removing the causes of defects and variation

approach to TQM and the performance goal that siz standard deviation should fit with the tolerance limits for the process

lean production

a process management philosophy derived from the toyota production system

focused on creating more value by eliminating wasteful activities

Joint Committee for Traceability in Lab Medicine (JCTLM)

created to meet the requirement for a worldwide platform to promote and give guidance on internationally recognized equivalence of measurements in lab medicine and traceability to appropriate measurement standards

ISO 9000

set of four standards enacted to ensure quality management and assessment in manufacturing and service industries

type 1 reagent water

most pure

reagent grade water

of highest quality and is used in test methodologies where minimum interference and maximum precision and accuracy are needed

pre-filters, activated carbon, submicron filter, UV oxidation, reverse osmosis and ion exchange all used

special reagent water

may require different preparation that reagent grade water according to intended us, such as sterility specification for tissue of organ culture, nucleic acid content for DNA testing, metal content for trace metal analysis

type II reagent water

used in most areas of the lab

water for lab dishwashers and autoclaves; purified to contain only low levels of organics, inorganics, and aprticulate matter so it does not leave residue on glassware or contaminate material in autoclave

type III reagent water

used to make type I and II water

might be used in qualitative areas such as urinalysis

standard of purity

many grades of chemicals are available, it is essential to understand which grade or type should be used for a specific chemical method

analytical reagent grade chemicals

contains a high degree of purity in accordance to the American Chemical Society specifications

used often in the preparation of solutions in the clinical laboratory

recommended for quantitative or qualitative analysis

ultra pure reagents

may be used in some clinical laboratories

additional processing makes them suitable for special procedures

labeled according to used: spectrograde, nanograde, or HPLC pure

Do not use chemicals labeled what?

purified, practical, technical, or commercial

primary standards

highly purified chemicals that are weighed or measured to produce a solution with an exact concentration

used for calibration of definitive methods

secondary standards

solutions whose concentration cannot be prepared by weighing the solute and dissolving a known amount into a volume of solution

its values are determines by repeated analyses, using a reference method calibrated by primary standard

National Institute of Standards and Technology

produces and provides standard reference materals for purchase

Standard reference materials and certified reference materials

have values determined by high-quality analysis and the chemical composition is certified

used for calibration of an instrument, verification of a measurement mehtod or assignment of values to materials

To contain pipette

calibrated for the total volume

must be washed out comepltely with the diluting fluid to obtain the desired amount

holds exactly the volume indicated on its side

to deliver pipette

calibrated from the volume delivered

can measure and deliver the indicated volume into another container

blow-out pipette

last drop should be dispensed

continuous etched ring or two small rings near bulb

self-draining pipette

allow the contents to drain freely

tip should make contact with side of the container

transfer pipette

designed to transfer a known volume of liquid

volumetric pipette

calibrated to deliver accurately a fixed volume of a dillute aqueous solution

TD

drain by gravity

bubble-like enlargement of stem

ostwald-folin pipette

specific type of transfer pipette

blow-out

buld closer to delivery tip

TD

viscous fluids

measuring/graduated pipette

designed to deliver various volumes by means of multiple graduations uniformly along its length

Mohr pipette

calibrated between two marks on the stem

straight with multiple graduations

capable of dispensing various volumes

TD

drain by gravity

serologic pipette

graduated marks down to the tip

TD

etched rings: blow out

micropipettes

used for measurements of microliter volumes

TC

proper use requires rinsing with final solution

gravimetric pipette calibration

a specific amount of water is pipetted, the weight of the water is determined and proportional to the volume

volumetric pipette calibration

a specific amount of dye is pipetted into a specific volume of water

the absorbance of the solution will determine the solume of the pipette

desiccants

drying agents that absorb water from air or other material

used to provide dry environment for chemical materials

absorption of water changes color indicator from blue to pink

CLSI standard of centrifugation of blood

RCF of 1000-2000 x g for 5-15 minutes

relative centrifugal force

the amount of force required to separate two phases of a solution

Relative centrifugal force calculation

1.118 × 10-5 x r x rpm²

types of centrifuges

horzontal-head or swinging bucket

fixed-angle or angle-head

ultracentrifuges or high-speed

centrifuge maintenance

time check

temeprature check

tachometer or stroboscopic light

Henderson-Hasselbalch equation

used in calculating the acid or base to salt ratio required to establich a desired pH in a buffer solution

pH=pK+log([A-}(salt)/[HA](acid))

constant systematic error

error that is always in one direction and has the same magnitude regardless of the snample concentration

interference experiment

random error

due to chance

1 in every 20 tests falls out of ±2SD

replication experiment

proportional systematic error

has the same percentage of the concentration being measured so the absolute mangitude increases as the concentration increases

recovery experiment

ethical issues in the lab

confidentiality

allocation of resources

code of conduct

conflict of interest

publishing

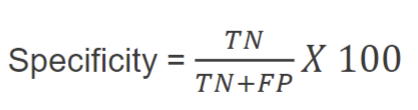

specificity

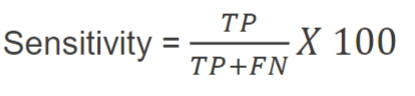

sensitivity

positive predictive prevalence

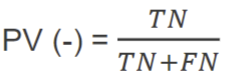

negative predictive prevalence

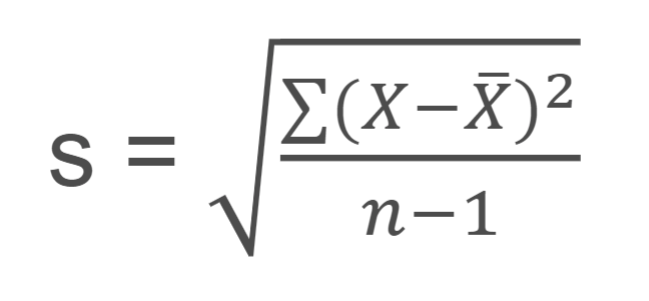

standard deviation

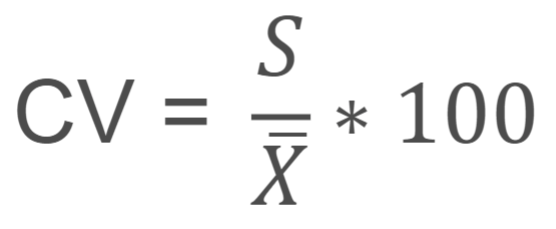

coefficient of variation

molarity

number of mols/numbers of liters

mols

mass/GMW

normality

Molarity x Valence

Equivalence

GMW/valence