G3 : Bioreactor operations and scale up

1/37

There's no tags or description

Looks like no tags are added yet.

Name | Mastery | Learn | Test | Matching | Spaced |

|---|

No study sessions yet.

38 Terms

what are challenges with scale-up challenges

changes in volume to surface ratio

what are some scale up rules?

keep following parameters constant

power input (Pg/V)

constant oxygen transfer rate

speeds at impeller tip

constant maximum shear

Explain the complexity of systems of variables

T, DO and pH control

setpoints, sensors, controllers

interaction between these and many other variables making it complex to analyze

What is the proecess from target to market

Discovery

Process Development

Clinical Supply Production

Process Development and scale up

Final Manufacturing Facility, Validation and Licensing

What is the Process Development Group responsible for?

process suitable for manufacturing equipment

accurately defined in process documents

operate properly at plant start up

What is the Manufacturing Group responsible for?

equipment work as designed

logistics

timely startup

facilities

staff

equipment

raw materials

Implement process as described in process documents

What are frequent problems in process transfers

cells do not grow at expected rate

product yields lower than expected

product less stable than expected

What are the key purposes of agitation?

Gas-Liquid Mass Transfer

smaller bubbles→ larger surface area

dispersing bubbles through the tank

maintaining concentration Gradient

Liquid-Liquid Mixing

mixing of acid/base to maintain pH

mixing feed solutions for fed-batch

Suspension of Solids

insoluble nutrients

cell aggregates

microcarriers

agitation prevents settling

cell aggregate size control

break up large clumps

prevents shear damage by controlling speed

balance between fragmentation and stability

Why do smaller bioreactors require external heating?

They lose heat to environment and need jacketed vessels to maintain temperature

What is the primary challenge with scaling up bioreactors

Removing excess heat from mechanical and metabolism processes

What is the purpose of jacketed vessels in bioreactors

Supply heat to the reactor by circulating hot fluids around it

Why is heat removal more critical in larger scale reactors

produce more heat that can accumulate and harm the system

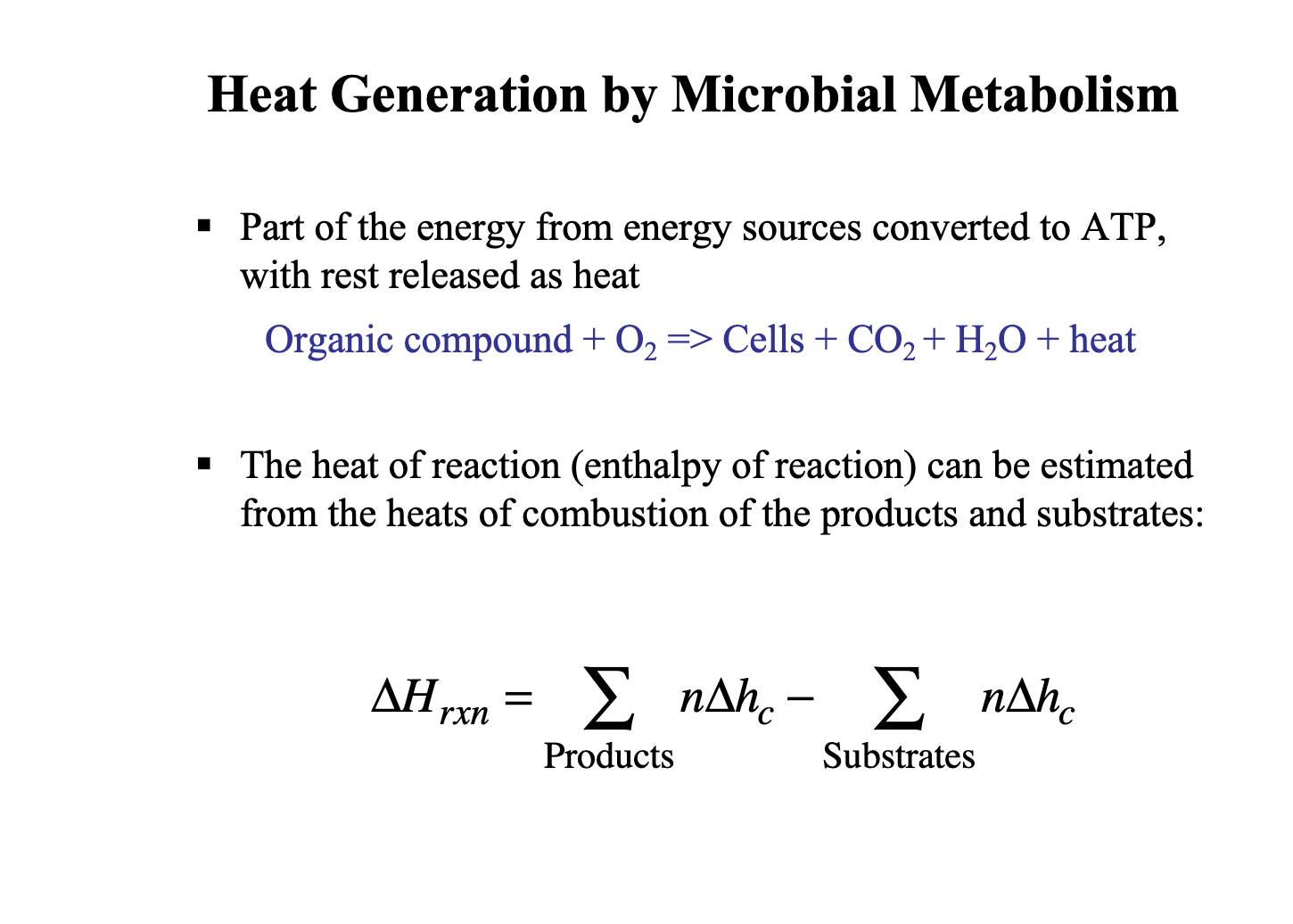

Heat Generation by microbial metabolism and enthalpy

What physical parameter is aerobic metabolic heat most closely correlated with?

Oxygen uptake rate (OUR).

Why is oxygen uptake rate used to estimate metabolic heat in aerobic fermentations?

Because it's easier to measure than heat directly and correlates well with metabolic activity.

How can oxygen uptake rate guide bioreactor heat exchanger design?

By estimating heat evolution from the OUR to size the heat exchanger accordingly.

Write the empirical relationship between volumetric heat evolution and oxygen uptake rate?

units:

f - kcal/Lh, o2 - mmol/Lh

Why is it important to reduce pCO₂ in mammalian cell cultures?

Because high CO₂ levels can harm cells and affect product quality.

Why is NaHCO₃ removed from the medium?

Because it contributes to CO₂ buildup.

What two buffering agents replaced NaHCO₃ in this strategy?

MOPS and histidine buffer

What is the benefit of using Na₂CO₃ instead of NaHCO₃ as a base?

Na₂CO₃ neutralizes more H⁺ per mole and produces less CO₂.

Why is NaOH not used in mammalian cell cultures?

It causes transient pH spikes that lead to cell aggregation.

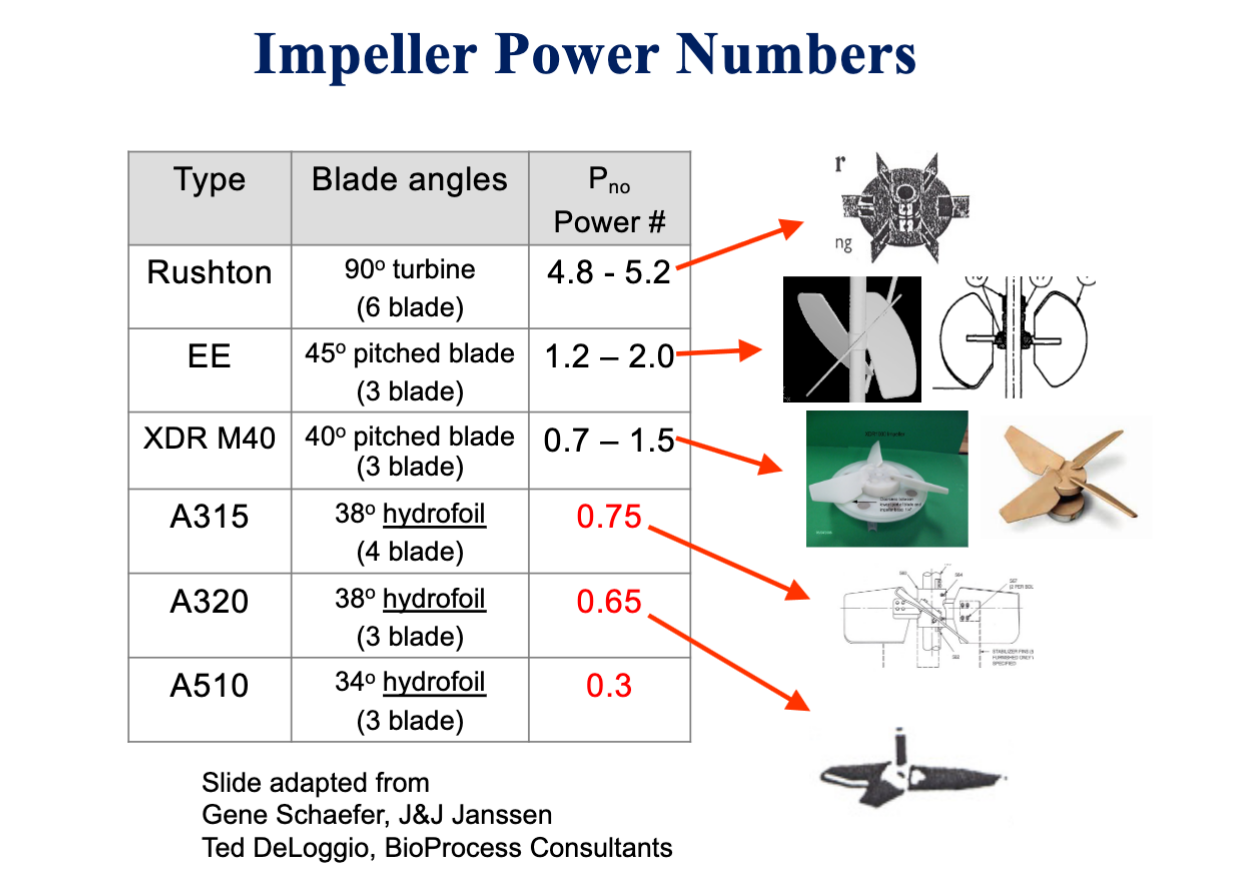

What is the main difference between radial and axial flow impellers?

Radial impellers pump fluid outward; axial impellers pump fluid along the shaft axis.

Why is the Rushton impeller less suitable for large-scale reactors?

slows top-down mixing

leads to poor base mixing

What is one advantage of the axial flow hydrofoil impeller over the Rushton type?

It requires less energy for the same oxygen transfer.

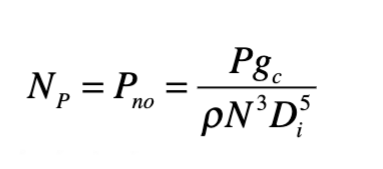

What power number is typical for Rushton and hydrofoil impellers, respectively?

Rushton: ~5; Hydrofoil: ≤ 1

What is the formula for power number dependence on impeller type

list different impeller power numbers

Why does scale-up present challenges in bioprocessing?

surface-to-volume ratio decreases, making it hard to replicate physical conditions like heat and mass transfer.

Why is Pg/V often kept constant during scale-up?

To maintain a constant oxygen transfer rate (OTR).

What does keeping impeller tip speed constant help maintain?

Constant maximum shear stress.

What variable is often kept constant to preserve kLa during scale-up?

N3D2

What are primary Variables?

pH

DO

What secondary variables are affected by efforts to control primary variables?

CO2 Accumulation

Osmolality ( salt concentration)

bubble-burst shear

mixing time

hydrodynamic shear

who is responsible for process transfer accountability?

process development group

manufacturing group

What is the process development group responsible for?

process must be suitable for larger-scale equipments

clear and complete process documentation

Process works properly at plant start up

What is the manufacturing group responsible for?

process equipment will work as designed

logistics in place for timely startup

facilities, staff, equipment, raw materials

implement process as described in process documents

What is the investigation and resolution game plan for startup problems?

collect all data and samples relating to the problem

make a list of hypothesis as to what could have happened

perform experiments and analyses to isolate the potential sources of the problem