chemistry - separate chemistry: transition metals, alloys & corrosion (5.1 - 5.7)

1/22

There's no tags or description

Looks like no tags are added yet.

Name | Mastery | Learn | Test | Matching | Spaced |

|---|

No study sessions yet.

23 Terms

5.1 most metals are what kind of metals?

transition metals

5.1 typical properties of transition metals

high melting point

high density

form coloured compounds

catalytic activity of metals & their compounds (e.g. by iron)

5.2 what does oxidation of metals result in?

corrosion

rusting definition

corrosion of iron (or steel = mostly iron)

what is needed for rusting?

iron rusts when reacts with oxygen & water

5.3 preventing rusting of iron - exclusion of oxygen

keep air away

store metal in unreactive atmosphere of nitrogen/argon

paint metal

coat metal with plastic

oil metal

grease metal

5.3 preventing rusting of iron - exclusion of water

keep water away

use desiccant powder - absorbs water vapour

paint metal

coat metal with plastic

oil metal

grease metal

5.3 preventing rusting of iron - sacrificial protection

attach piece of magnesium/zinc to iron/steel object

magnesium & zinc oxidise more easily than iron (higher in reactivity series)

oxygen reacts with them not iron/steel object

protection continues until sacrificial metal corrodes away

5.4 electroplating definition

coat surface of one metal with thin layer of another metal

5.4 electroplating process - what you need

anode (+ electrode) - plating metal

electrolyte - solution containing ions of plating metal

cathode (- electrode) - metal object

5.4 electroplating process - what happens (e.g. electroplating copper ring with silver)

direct current flows through electrodes & electrolyte

silver anode (+): silver atoms —lose electrons→ silver ions in electrolyte

+ silver ions in electrolyte → - copper ring

+ silver ions —gain electrons→ deposited as silver atoms

current flows for longer = silver layer on ring becomes thicker

5.4 electroplating - improve appearance of metal objects

silver & gold: attractive transition metals; expensive

silver/gold electroplated onto cheaper ‘base metals’ (e.g. copper/nickel)

produces jewellery: attractive; cheaper than solid silver/gold

5.4 electroplating - improve resistance to corrosion of metal objects (e.g. chromium)

chromium: transition metal; resists corrosion

steel objects (e.g. vehicle parts) ‘chrome plated’ by electroplating

thin chromium layer stops air & water reaching steel - prevents rusting

5.4 electroplating - improve resistance to corrosion of metal objects (e.g. zinc)

iron/steel objects coated with zinc - galvanising

thin zinc layer stops water reaching iron/steel & acts as sacrificial metal - improves corrosion resistance

5.4 electroplating - improve resistance to corrosion of metal objects (e.g. tin)

food cans made from steel

inner surface protected from rusting - electroplating with tin

tin: doesn’t react with air/water (at room temp.)

tin layer stops air & water reaching steel

tin layer damaged = steel rusts faster - iron more reactive than tin, acts as sacrificial metal to protect tin

alloy definition

mixture of metal element with one/more elements (usually metals)

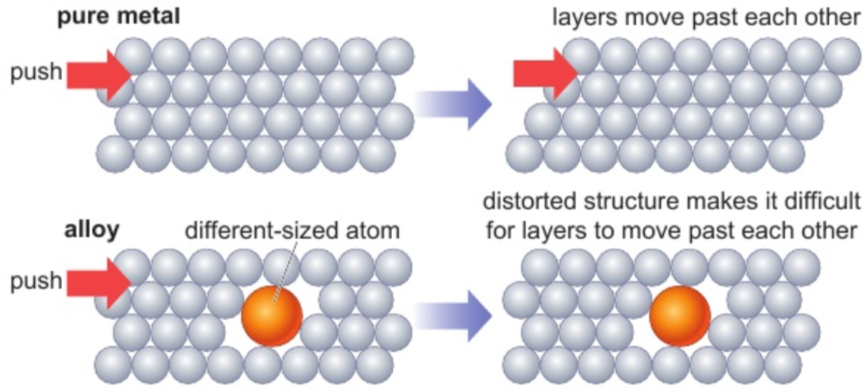

5.5 why does converting pure metals into alloys increase strength of product? (using models)

solid pure metal:

atoms all same size & regularly arranged in layers

layers move past each other if enough force applied (metals = malleable & ductile)

alloy:

atoms of other elements present may be diff. sizes

distort regular structure

more difficult for layers to slide past each other

alloys often stronger than pure metals they contain (even though usually still malleable & ductile)

5.6 why is iron alloyed with other metals to produce alloy steels?

alloy steels made by deliberately adding other elements to iron

can create large range of alloy steels with diff. properties by varying their composition

e.g. stainless steels:

contain chromium - reacts with oxygen in air

layer of chromium oxide forms

thick enough to stop air & water reaching metal

thin enough to be transparent

metal scratched - more chromium reacts to replace layer

what do uses of metal/alloy depend on?

chemical properties - e.g. resistance to corrosion

physical properties - e.g. density, ability to conduct electricity

5.7 how are uses of metals related to their properties (& vice versa) - aluminium vs copper

both:

resist corrosion

aluminium:

does not conduct electricity as well as copper

stronger, cheaper & less dense than copper - used for overhead electrical cables

5.7 how are uses of metals related to their properties (& vice versa) - copper vs gold

both:

resist corrosion

malleable

ductile

good conductors of electricity - can be used for electrical wiring

copper:

cheaper than gold - used for most electrical wiring

gold:

expensive - used in tiny amounts in computers

5.7 how are uses of metals related to their properties (& vice versa) - aluminium vs magnalium

magnalium:

less dense, stronger & better resistance to corrosion than aluminium - used to make strong but lightweight metal parts

5.7 how are uses of metals related to their properties (& vice versa) - copper vs brass

both:

resist corrosion

copper:

better conductor of electricity than brass

brass (alloy of copper & zinc):

stronger than copper - used for making electrical plug pins