Chapter 08 - Operations Management

1/129

There's no tags or description

Looks like no tags are added yet.

Name | Mastery | Learn | Test | Matching | Spaced |

|---|

No study sessions yet.

130 Terms

What is Operations Management?

The process of converting resources into goods and services efficiently and effectively while controlling costs.

What are the key components of Manufacturing?

Transforming raw materials into finished products using processes, machines, and personnel.

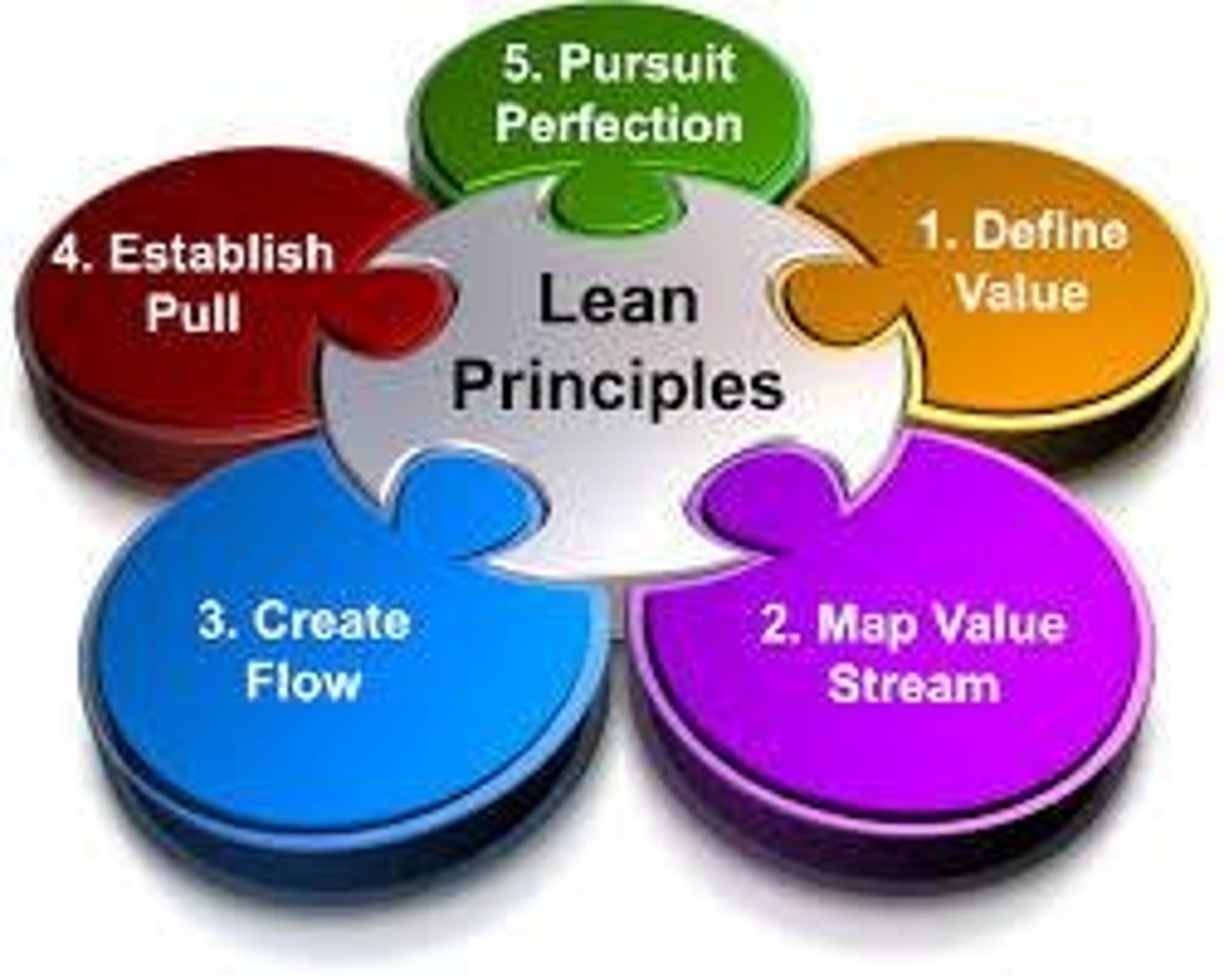

What is LEAN in Operations Management?

An operating philosophy focused on waste reduction and value enhancement.

What does Six Sigma aim to achieve?

It aims to identify and remove causes of defects and minimize variability in processes.

What is the Make-to-Stock (MTS) strategy?

Manufacturing products based on demand forecasts, creating inventory before orders are received.

What is the Make-to-Order (MTO) strategy?

Manufacturing begins only after a customer's order is received, allowing for customization.

What is the Assemble-to-Order (ATO) strategy?

Products are assembled quickly from pre-manufactured parts once an order is received.

What is the Engineer-to-Order (ETO) strategy?

Products are designed and built to customer specifications after an order is received.

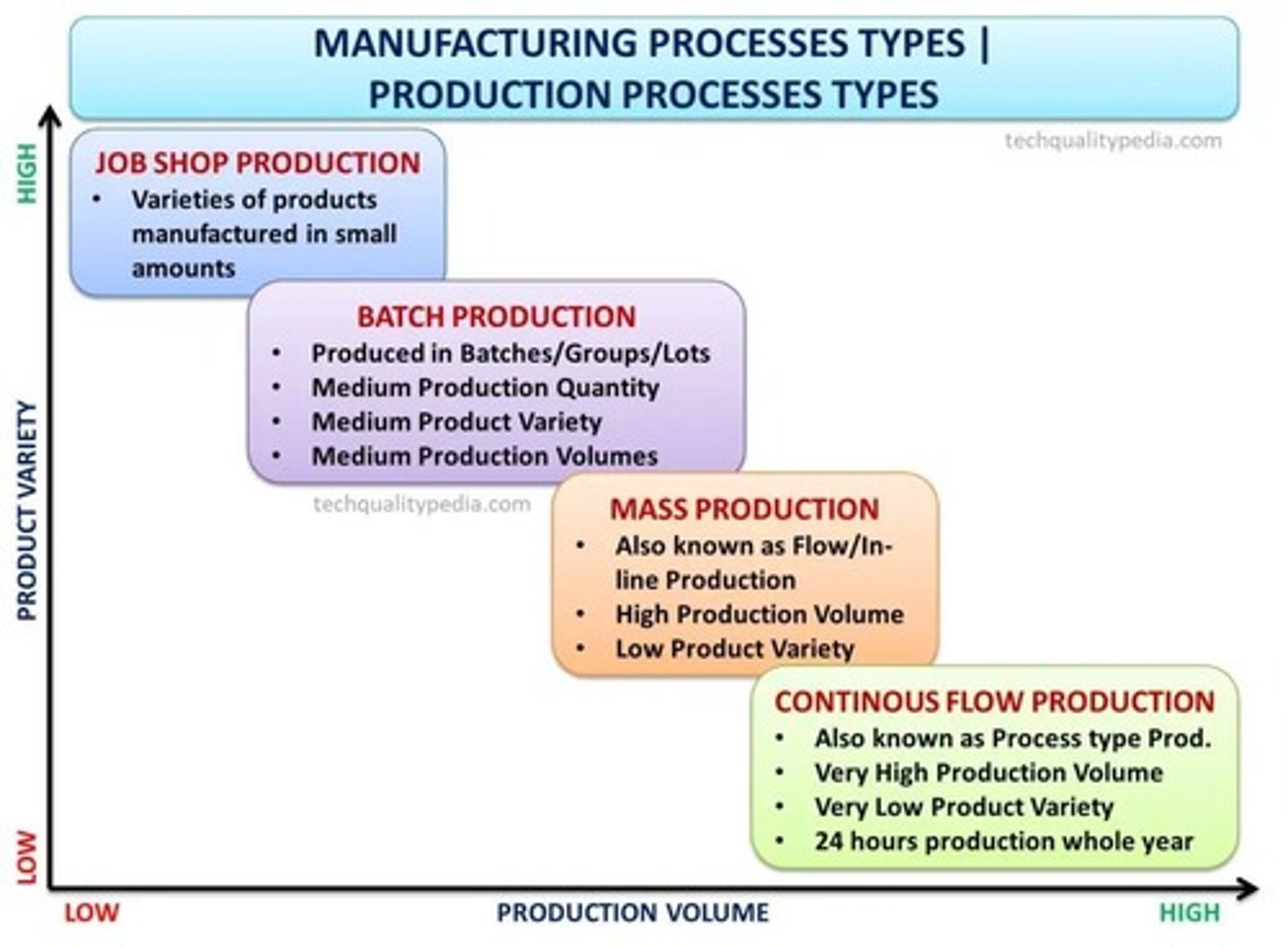

What is the difference between Intermittent and Repetitive Processes?

Intermittent processes produce various products in lower volumes, while repetitive processes produce standardized products in high volumes.

What is Job Shop Production?

A production method that creates custom products for each customer, typically in small quantities.

What is Batch Production?

Manufacturing a fixed quantity of an item in a single production run, with each item going through stages together.

What is Line Flow Production?

A mass production method where products move through an assembly line with standardized tasks.

What is Continuous Flow Production?

A highly automated process where raw materials flow through a series of inflexible processes.

What is Total Quality Management (TQM)?

An approach focused on long-term success through customer satisfaction and continuous improvement.

What are the elements of LEAN Manufacturing?

Focus on waste reduction, value enhancement, and respect for people.

What is the role of forecasting in Make-to-Stock?

Accurate forecasting prevents excess inventory and stockouts.

Why might Make-to-Order not be suitable for all products?

It creates additional wait time and is not ideal for products needing immediate availability.

What is a hybrid strategy in manufacturing?

A strategy like Assemble-to-Order that combines benefits of both Make-to-Stock and Make-to-Order.

What is the significance of manufacturing strategy?

It defines the cycle time (lead time) customers experience for delivery.

What challenges do companies face with Make-to-Stock?

They struggle to manage inventory levels and avoid excess stock.

What is the impact of poor quality in Engineer-to-Order?

High costs associated with warranty claims and rework can significantly affect profit margins.

How do LEAN and Six Sigma complement each other?

LEAN focuses on waste reduction while Six Sigma reduces process variation.

What is the primary goal of Operations Management?

To manage processes efficiently while aligning with the company's business strategy.

What types of products are typically produced using Batch Production?

Items like baked goods, textiles, and pharmaceuticals.

What is the importance of manufacturing processes?

They ensure the creation of products that meet design specifications.

What is the role of personnel in Manufacturing Management?

To manage all processes and resources involved in manufacturing operations.

What is the relationship between manufacturing strategies and customer expectations?

Manufacturing strategies must align with customer needs and company strengths.

What is the primary goal of automation in manufacturing?

To increase efficiency, productivity, and accuracy while reducing manual labor and minimizing human error.

Define Artificial Intelligence (AI) in the context of manufacturing.

AI is the capability of a machine to imitate intelligent human behavior and perform complex tasks similar to human problem-solving.

What is Machine Learning (ML)?

ML is a subfield of AI that involves using algorithms and statistical models to analyze data and draw inferences without explicit instructions.

How does IoT benefit manufacturing?

IoT devices monitor machine performance, detect equipment failures, and optimize production processes.

What is 3D Printing?

An additive manufacturing process that creates physical objects from digital designs by printing thin layers of material.

What is the Total Cost of Manufacturing (TCM)?

TCM is the aggregate cost of producing and delivering products, including fixed and variable costs.

What are the components included in Total Cost of Manufacturing?

Manufacturing and procurement activities, inventory and warehousing activities, and transportation activities.

What does LEAN Manufacturing aim to achieve?

The elimination of waste and minimization of resources used in a company's operations.

Who coined the term 'LEAN'?

John Krafcik in 1988.

What was the significance of Henry Ford's mass production line?

It was the first breakthrough in using continuous assembly systems for manufacturing.

What is the Toyota Production System (TPS)?

A manufacturing system developed by Taichi Ohno and Shigeo Shingo that incorporates various techniques to form the basis of LEAN.

What is the purpose of Just-in-Time (JIT) inventory strategy?

To decrease waste by receiving materials only as needed in the production process, thus reducing inventory costs.

What are Keiretsu Relationships?

Relationships between companies in a manufacturing process that remain independent but work closely together for mutual benefit.

What is a Value Added Process?

Process steps that transform or shape a product or service, which is eventually sold to a customer.

What is a Non-Value Added Process?

Process steps that take time, resources, or space but do not transform or shape the product or service.

What are some benefits of implementing LEAN Manufacturing?

Large cost reductions, improved quality, and increased customer service.

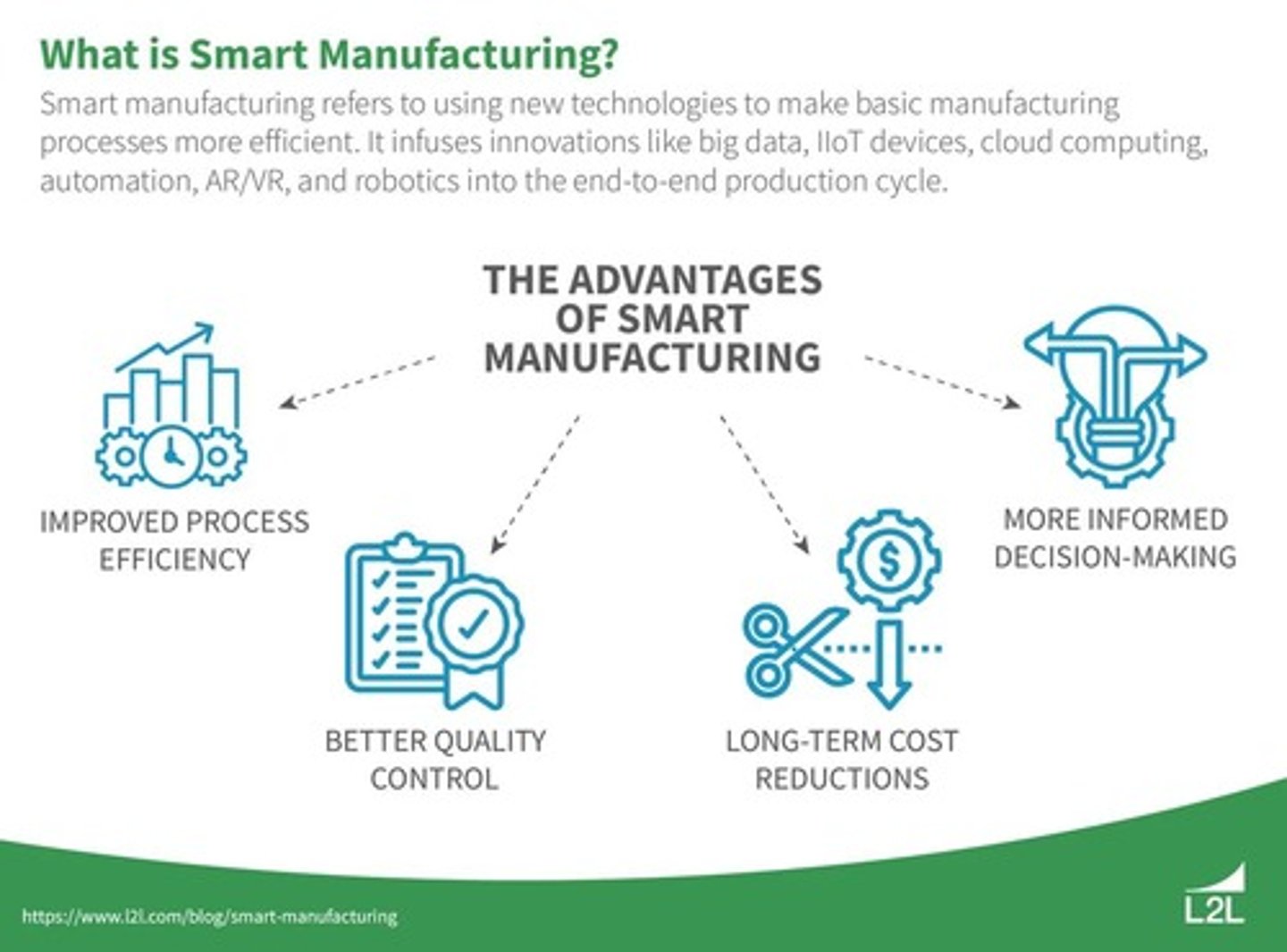

What technologies are included in Smart Manufacturing?

Cloud Computing, Machine Learning, Augmented Reality, Sensors, Automation, and Additive Manufacturing.

What is the role of predictive maintenance in manufacturing?

To analyze data from sensors and machinery to predict when failures and breakdowns are likely to occur.

How does automation improve manufacturing processes?

By using technology and machines to perform specific tasks without human intervention, increasing efficiency and accuracy.

What is the relationship between production volume and manufacturing costs?

As production volume increases, manufacturing and procurement costs generally decrease due to economies of scale.

What challenges does the Internet of Things (IoT) present?

Security and privacy risks, interoperability issues, data overload, cost and complexity, and regulatory challenges.

What is the impact of 3D printing on product development?

It allows for limitless customization, reduces reliance on suppliers, and speeds up the time to market for complex designs.

What is the significance of the 1990 book 'The Machine that Changed the World'?

It expanded the definition of LEAN and highlighted its principles and practices.

What does 'value' refer to in manufacturing?

The inherent worth of a product as judged by the customer, reflected in its selling price and market demand.

What is the purpose of monitoring production quality in manufacturing?

To improve production quality and reduce waste of materials.

What is the role of demand forecasting in manufacturing?

To predict fluctuations in market demand to optimize production planning.

What is LEAN Manufacturing?

A manufacturing approach focused on waste reduction and efficiency in the supply chain.

What are the three components of LEAN?

LEAN Manufacturing, Respect for People, Total Quality Management.

What is the primary goal of LEAN Manufacturing?

To facilitate an efficient and effective supply chain.

What does waste encompass in manufacturing?

Wait times, inventories, unnecessary movement, processing steps, variability, and other non-value-adding activities.

What does the acronym 'DOWN TIME' represent in waste categories?

Defects, Overproduction, Extra Processing, Waiting, Motion, Inventory, Non-Utilized Talent, Transportation.

What are the benefits of LEAN waste reduction?

Reduced cycle times, greater throughput, better productivity, improved quality, and reduced costs.

What is a LEAN Layout?

A layout that optimizes the movement of people and materials, ensuring visibility and efficiency.

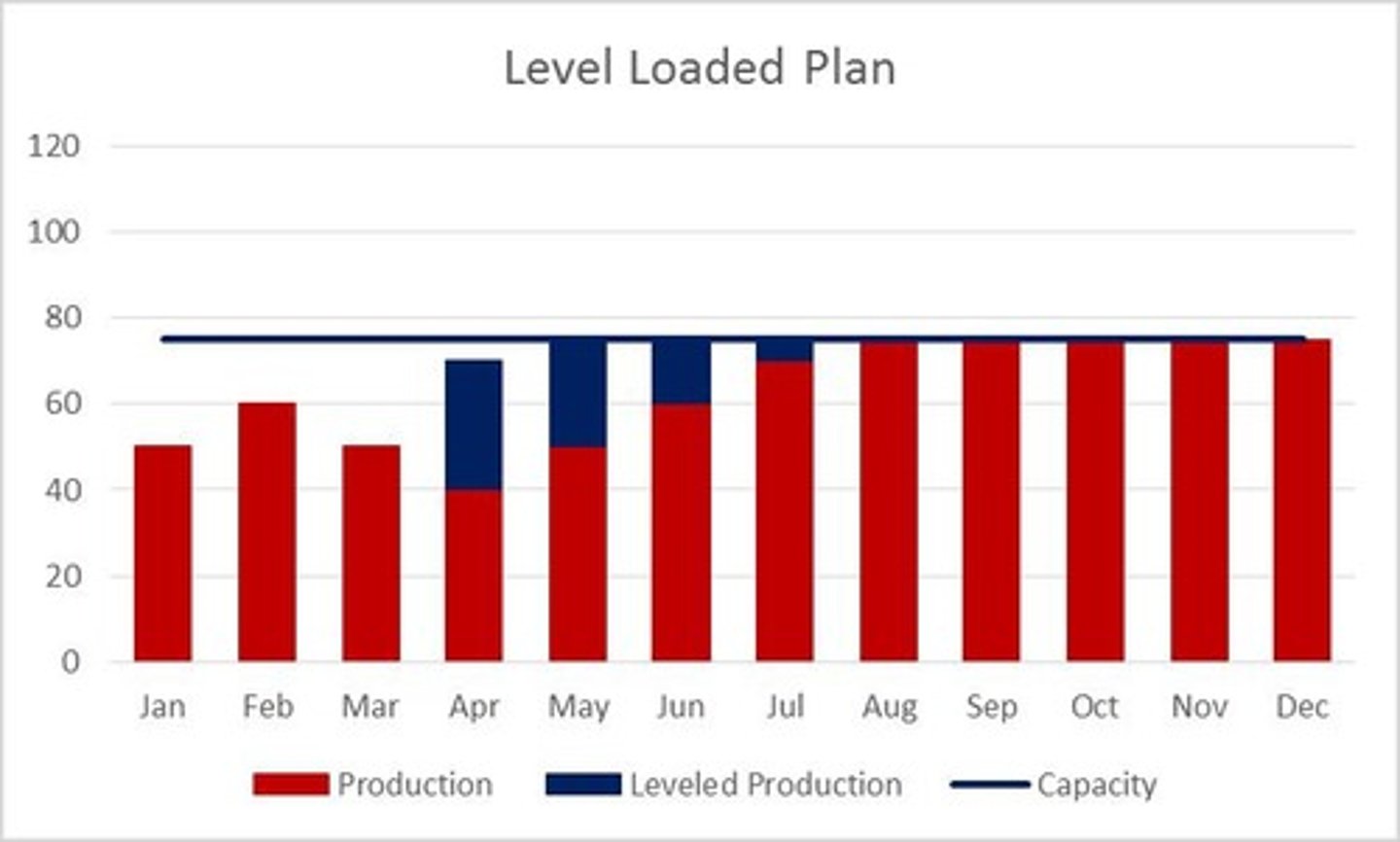

What is the purpose of small batch scheduling in LEAN Manufacturing?

To produce at the same rate as customer demand, reducing waste and increasing flexibility.

What is uniform plant loading?

Planning production up to capacity earlier to meet future demand, also known as 'front-loading' the plan.

What is setup time in manufacturing?

The time required to prepare manufacturing equipment for production.

What is changeover time?

The time taken to adapt manufacturing equipment to produce a different product.

How does excess inventory affect a business?

It ties up financial capital and increases holding costs, potentially leading to waste from obsolescence or damage.

What is the impact of reducing inventory levels?

It exposes hidden problems in the supply chain and can lead to a smoother-running operation.

What does workforce empowerment mean in the context of LEAN?

Increasing the capabilities and flexibility of the workforce through cross-training and involvement in decision-making.

What is Six Sigma?

A set of techniques and tools for process improvement aimed at reducing defects and variability.

How does LEAN Manufacturing relate to Supply Chain Management?

LEAN principles help streamline processes and improve efficiency across the supply chain.

What is the role of communication in LEAN Manufacturing?

To ensure accurate demand forecasts and production schedules are shared throughout the supply chain.

What is the significance of the 'Speedee Service System' in LEAN?

It applied LEAN principles to fast food preparation, enhancing efficiency and service speed.

What is the relationship between LEAN and customer satisfaction?

Implementing LEAN practices can lead to higher quality products and services, improving customer satisfaction.

What is the Bullwhip Effect?

A phenomenon where small fluctuations in demand at the retail level cause larger fluctuations in demand at the wholesale, distributor, and manufacturer levels.

What is the importance of continuous improvement in LEAN?

It fosters an environment where processes are regularly evaluated and improved to enhance efficiency and quality.

What does 'respect for people' mean in LEAN Manufacturing?

Valuing employees' contributions and fostering a culture of collaboration and engagement.

What is the primary focus of waste reduction in LEAN?

To eliminate non-value-adding activities and streamline processes for better efficiency.

What are LEAN supply chain relationships?

Collaborative partnerships with key customers and suppliers to enhance efficiency and reduce waste.

What is the impact of reducing setup and changeover times?

It increases production efficiency by maximizing equipment utilization and minimizing downtime.

What is the visual aspect of a LEAN Layout?

It promotes unobstructed lines of visibility for operators to monitor work processes effectively.

How does LEAN Manufacturing enhance flexibility?

By enabling quicker responses to changes in customer demand through small batch production.

What is the primary goal of a LEAN supply chain relationship?

To allow customers and suppliers to easily exchange information, demand data, and visibility of status.

What are the key benefits of mutual dependency in a LEAN supply chain?

It allows partners to remove waste, reduce costs, and improve quality and customer service.

What is the role of managers in supporting LEAN Manufacturing?

Managers must provide skills, tools, time, and resources to identify problems and implement solutions.

What is Kaizen?

A system involving every employee to make small, regular changes to reduce process, delivery, and quality problems.

What is the purpose of cross-training employees in LEAN Manufacturing?

To adjust capacities as needed when machines break down or when workers are absent.

What does 'Respect for People' mean in the context of LEAN?

It emphasizes the importance of respecting all individuals in an organization and empowering them.

What is the role of workers in a LEAN environment?

Workers perform tasks, improve production processes, correct quality problems, and work in teams.

How does management contribute to a successful LEAN culture?

By creating an atmosphere of cooperation and empowering workers to take action based on their ideas.

Who is considered the father of TQM?

W. Edwards Deming.

What is the Plan-Do-Check-Act model?

A model created by W. Edwards Deming to guide companies in quality improvement.

What are Philip Crosby's four absolutes of quality?

1. Quality is conformance to requirements. 2. The system of quality is prevention. 3. Performance standard is zero defects. 4. The measure of quality is the price of nonconformance.

What is the Cause-and-Effect Diagram?

A tool developed by Kaoru Ishikawa to identify all possible causes of a problem to find the root cause.

What is the Voice of the Customer (VOC)?

The process of capturing internal and external customer expectations, preferences, likes, and dislikes.

What are some methods to capture the Voice of the Customer?

Customer interviews, market surveys, focus groups, customer specifications, observation, warranty data, field reports, and complaint logs.

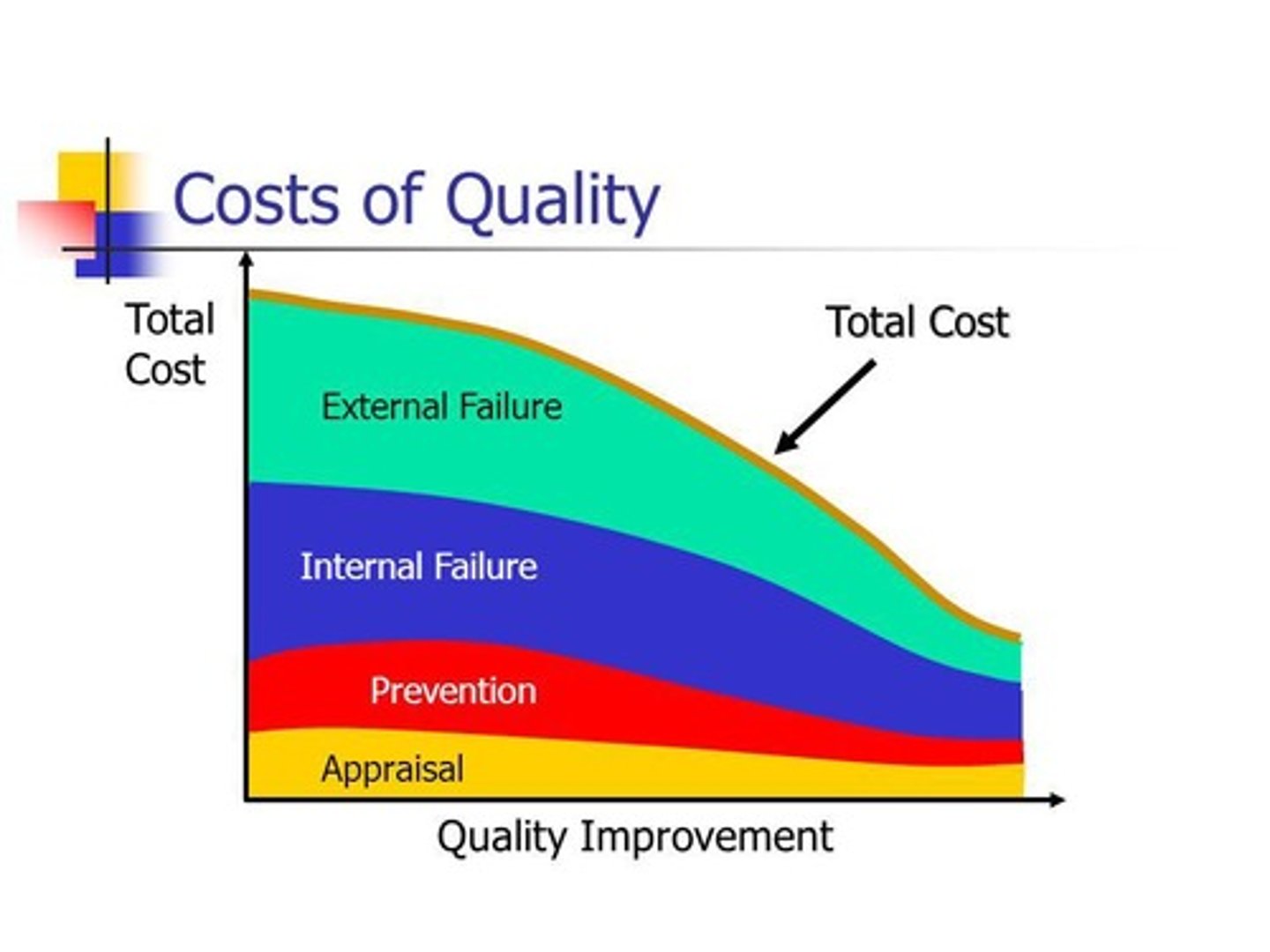

What is the Cost of Quality?

An approach to determine the resources necessary to prevent poor quality and evaluate the quality of products and services.

What are Appraisal Costs?

Costs associated with evaluating materials, processes, products, and services to ensure they conform to specifications.

What are Prevention Costs?

Costs related to the design, implementation, and maintenance of the quality management system.

What are Internal Failure Costs?

Costs that occur when a product or service does not meet quality standards and are identified before delivery to the customer.

What is the main focus of Six Sigma?

To improve quality by identifying and removing causes of defects and minimizing variability in manufacturing and business processes.

What is the significance of continuous improvement in LEAN Manufacturing?

It involves making small, incremental changes that lead to significant improvements over time.