Specialist Technical Principles

1/58

Earn XP

Description and Tags

AQA GCSE Design & Technology Specialist Technical Principles

Name | Mastery | Learn | Test | Matching | Spaced | Call with Kai |

|---|

No analytics yet

Send a link to your students to track their progress

59 Terms

Wood Pulp

Wood fibers processed & reduced down with chemicals or mechanically broken down into smaller parts to make paper.

Cellulose

A carbohydrate, forming cell walls in plant cells.

Total cost (formula)

= individual price x quantity needed

A designer requires 300 sheets of embossed A4 paper, costing 15p per sheet. What is the total cost?

= 300 × 0.15 = £45.00

Tensile strength

Ability to resist pulling forces without snapping.

Lamination

Using at least 2 layers of materials to be bonded together.

Recycle

Break down & process a discarded product, so a new material is produced

Deforestation

Cutting down of trees & forests to allow a different land use

Hardwood trees

Grow slowly and are deciduous (drop their leaves)

Forest Stewardship Council (FSC)

International organization dedicated to promoting responsible management of forests. They provide a certification for products.

Reduce

Making decisions that decrease the amount of waste produced.

Reuse

Use a product again rather than replacing it with a new one.

Rethink

Change the design of a product to be more environmentally friendly.

Refuse

Avoid using a product to save on waste.

Repair

To fix a broken product.

How is paper made?

Paper is made from fibers or recycled materials. Wood pulp is obtained and the bark & chip[pings are removed to extract the cellulose fibers. The pulp is filtered squeezed & bleached. Excess water is drained out through calenders.

Debarking

Removing chippings and ground down.

Cooking with chemicals

Wood pulp is cooked with chemicals to extract the cellulose fibers.

Sizing

The addition of chemicals that are applied to paper to make the paper resistant to liquid.

Draining

The excess water and chemicals are removed from the pulp, as it is pushed through calendars (a set of rollers)

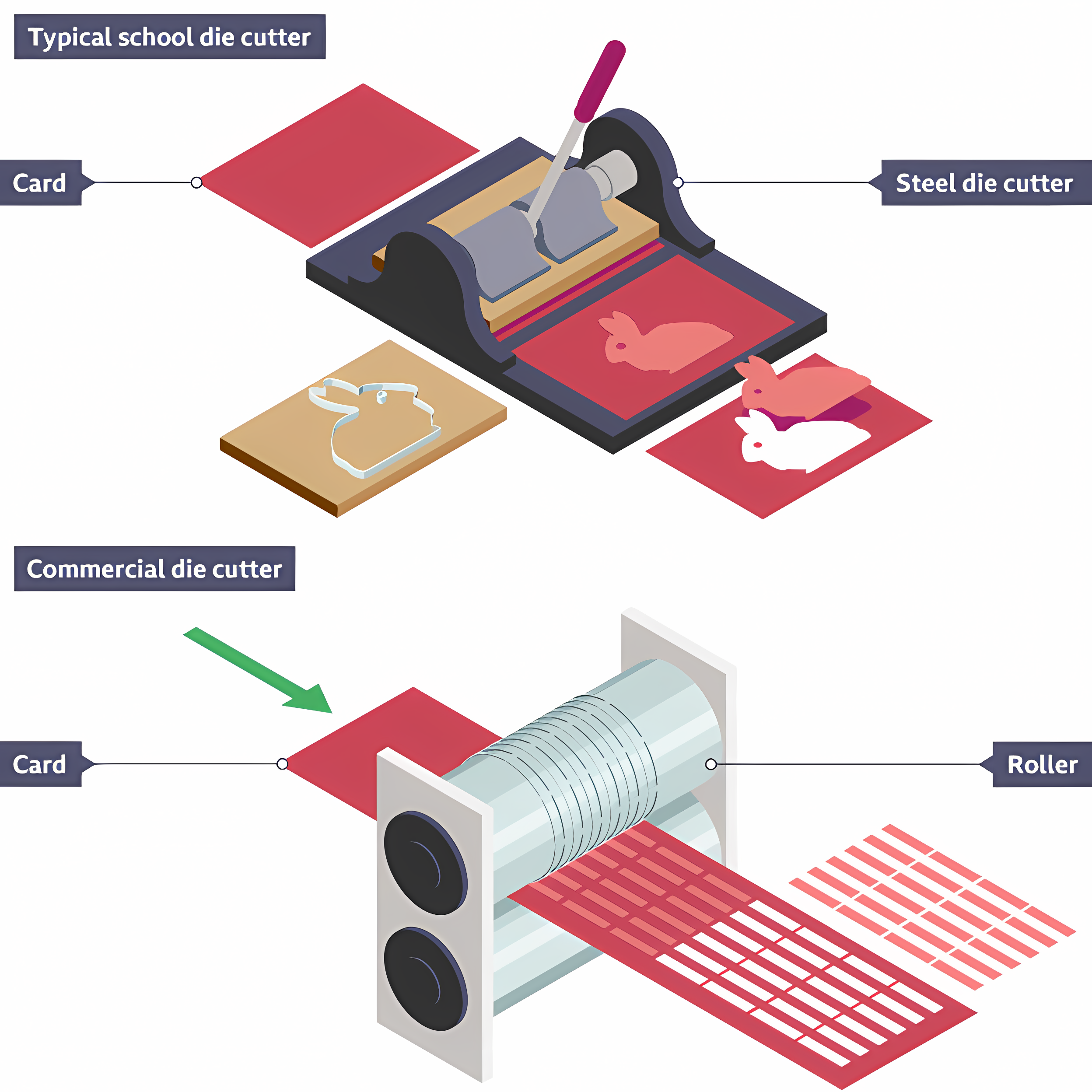

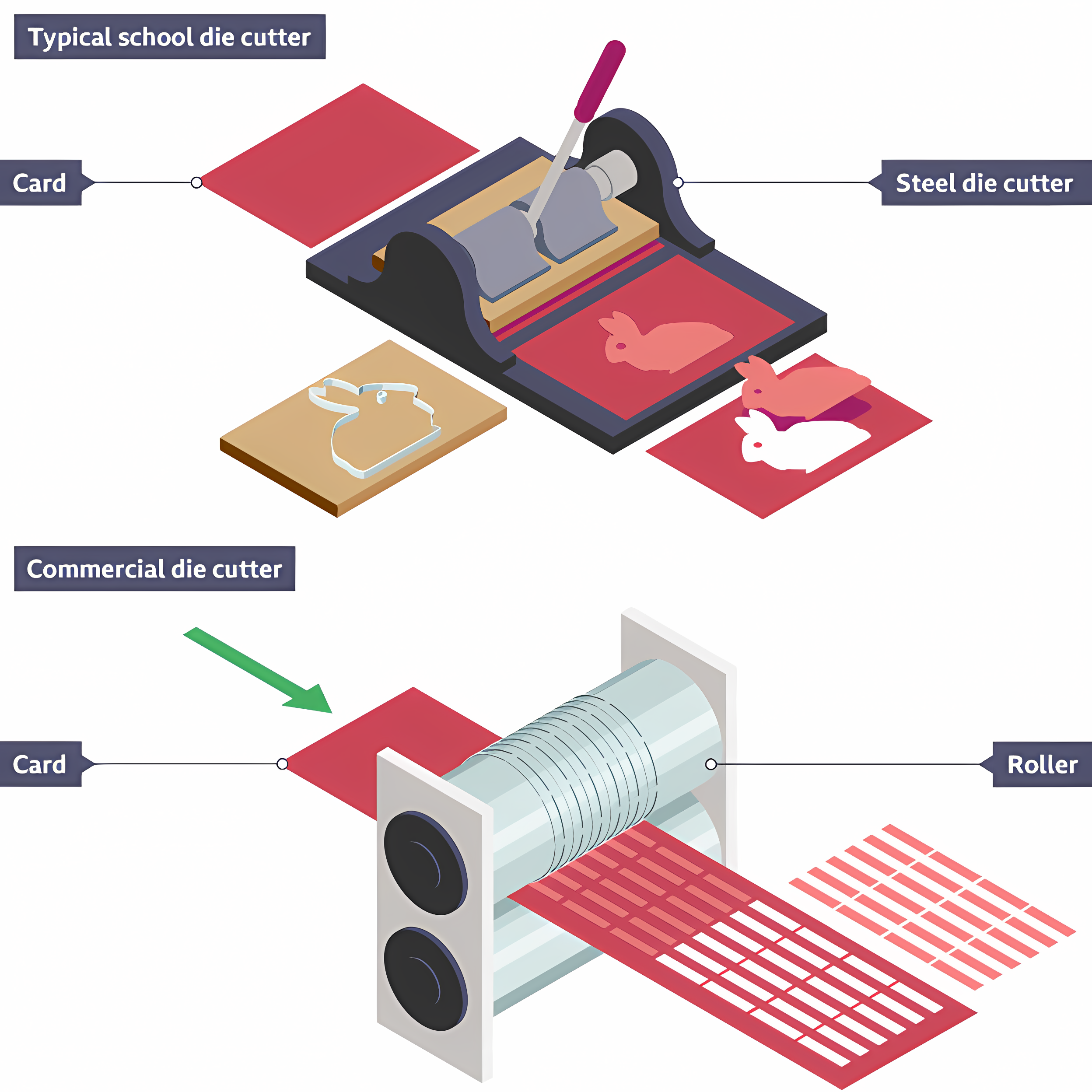

Die cutting

Method of cutting paper or card by pushing a blade through the material.

Scoring

Indented scratch allowing paper or card to fold with ease.

Offset Lithography

Commercial printing method using 4 colors:

Cyan, Magenta, Yellow, and Black (CMYK)

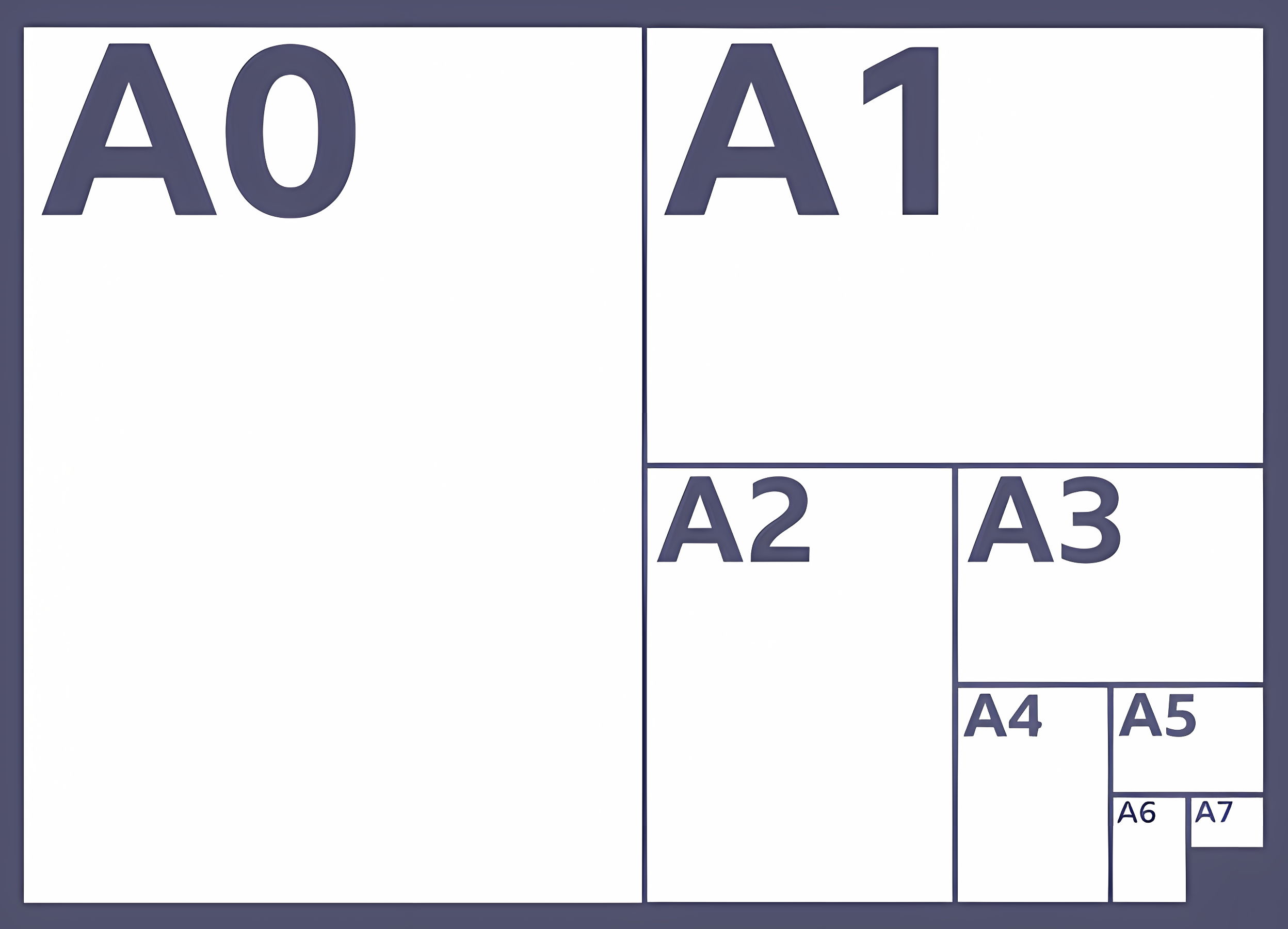

Types of paper

A0, A1, A2, A3, A4, A5, A6, A7

Layout paper

Properties: Lightweight, thin, cheap, smooth surface

Uses: Graphic drawings, animations

Bleed proof (marker) paper

Properties Contains more chalk, smooth, hard, doesn’t absorb ink, doesn’t bleed

Uses: Creating special effects for designers or artists

Tracing paper

Properties: Good transparency, expensive

Uses: For seeing an image underneath

Grid paper

Properties: Covered with continuous square grid

Uses: Used in many mathematical contexts

Cartridge paper

Properties: Heavier weight, good quality, opaque

Uses: Writing and sketching

Types of board

Board is selected by its thickness, measured in microns.

One micron is 1/1,000th of 1 mm

Corrugated cardboard

Properties: Strong, lightweight

Uses: Packaging protection in transportation of products and used to package some hot food such as a pizza due to its insulating properties.

Duplex board

Properties: Cheaper than white board, available with different finishes (metallic, holographic etc.)

Uses: Food packaging, eg biscuit boxes or containers

Solid white board

Properties: Top quality, range of thicknesses, excellent to print on

Uses: Hardback books

Foil-lined board

Properties: Expensive, good quality, aluminium foil lining, excellent barrier against moisture

Uses: Pre-packed food packages, cosmetic cartons

Inkjet board

Properties: Expensive, printable, photo quality

Uses: Posters, photography, art reproductions

Foam-core board (foam board)

Properties: Strong, lightweight, paper face, foam core

Uses: Model making, mounting photographs

Prototype

First working model of a design used for testing, development, and evaluation.

Batch production

A group of identical products are made at the same time.

Mass production

Same product is manufactured multiple times.

Continuous production

Leads to many similar products being made, continuously.

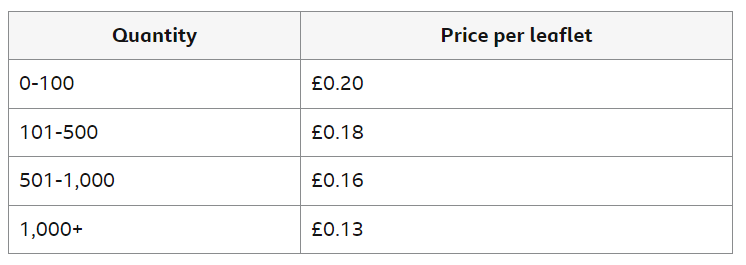

Using the information shown above, calculate the total cost if 1,500 leaflets were needed.

= 0.13 × 1,500 = £195.00

Designing template

Form used to ensure other parts are made to match.

Pattern

Repeated design or recurring sequence.

Ruler

Used to measure a distance & draw a straight line.

Protractor

Used to measure angles.

Set square

Used to draw lines at specific angles.

French curve

Used to draw curves of different sizes.

Guillotine

Used to cut a large number of paper sheets at once with a straight edge.

Craft knife

Used to cut and score paper & cardboard, particularly useful when cutting internal shapes.

Compass cutter

Used to cut a circle or an arc from thin paper or cardboard.

Rotary cutter

Used to cut a circle or an arc from thicker paper or cardboard.

Die cutter

Used to cut, crease, and perforate paper and card at high speeds and accuracy/

Laser cutter

Performs perfect intricate cuts to paper and card, if the speed and power are set correctly.

What are the 4 colors used for in offset lithography?

The 4 colors in offset lithography are used for:

Checking the alignment of the printer using a registration mark.

Registration mark

Circular pattern that is printed using CMYK. When all 4 overlap (when they’re aligned), they create a black circle.

Tolerance

The amount of error a measurement can vary without affecting the product.

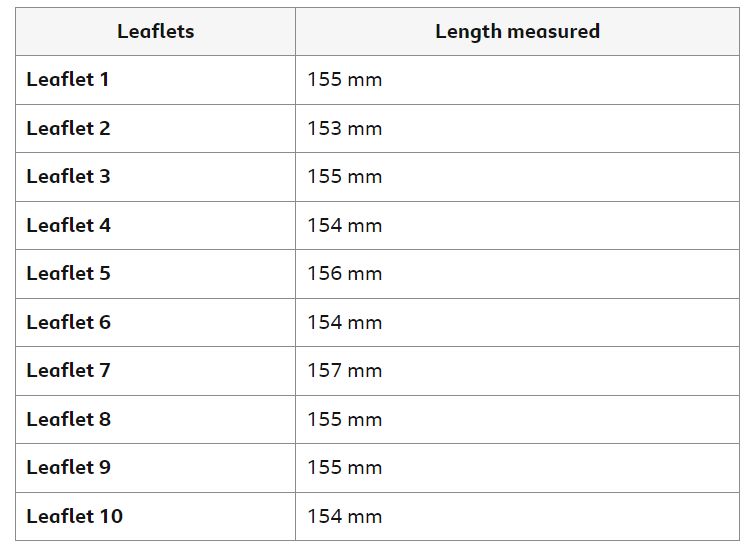

A quality control check is made on a random sample of leaflets. Each leaflet should be 155 mm in length +/- 1mm.

Table of the lengths recorded of a sample of ten leaflets:

How many leaflets were out of tolerance and should not be used, and which leaflets are they?

Two leaflets were produced out of tolerance. These were leaflet 2 and leaflet 7.

Crop marks

Small lines in each corner of paper or board, indicating where it needs to be cut.

Color bars

Reference chart on a sheet of paper to check whether the color is printed to the correct intensity.