Chapter 7: Inventory Management Concepts and Models

1/70

There's no tags or description

Looks like no tags are added yet.

Name | Mastery | Learn | Test | Matching | Spaced |

|---|

No study sessions yet.

71 Terms

Dependent Demand

Internal demand for parts based on final product demand.

Independent Demand

Demand for end products influenced by market conditions.

Raw Materials

Unprocessed inputs purchased for production.

Work-in-Process (WIP)

Partially processed materials not ready for sale.

Finished Goods

Completed products prepared for shipment.

Maintenance, Repair, and Operating (MRO)

Supplies used in production processes.

Direct Costs

Costs directly traceable to produced units.

Indirect Costs

Costs not directly traceable to produced units. (factory overhead, indirect labor-managers/maintenance, indirect materials, etc)

Fixed Costs

Costs independent of output quantity. (rent, equipment)

Variable Costs

Costs that vary with output levels. (martials cost)

Setup Costs

Costs related to preparing equipment for production.

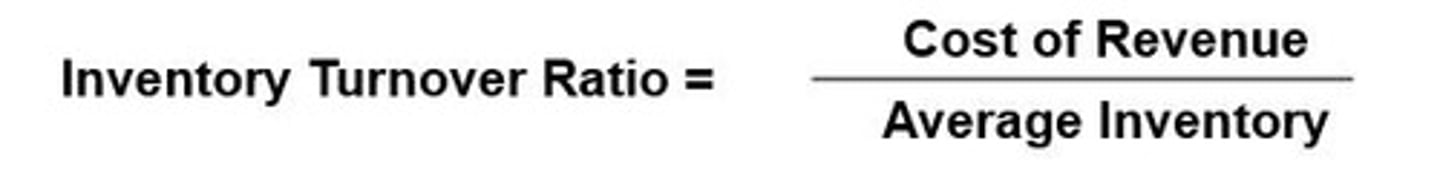

Inventory Turnover Ratio

Frequency of inventory turnover in a period. Cost of revenue/ Average inventory

Cycle Counting

Periodic physical counting of inventory.

ABC Inventory Control System

Classifies inventory into A, B, and C categories. Tells which inventories should be monitored more closely.

A Items

High priority items, 20% of items, 80% Inventory cost.

B Items

Medium priority items, 40% of items, 15% inventory cost.

C Items

Low priority items with minimal value. remaining 40% of items with only 5% inventory cost.

Pareto rule/ Analysis or 80/20 Rule

80% of results from 20% of efforts, while remaining 20% of results are achieved by 80% of tasks

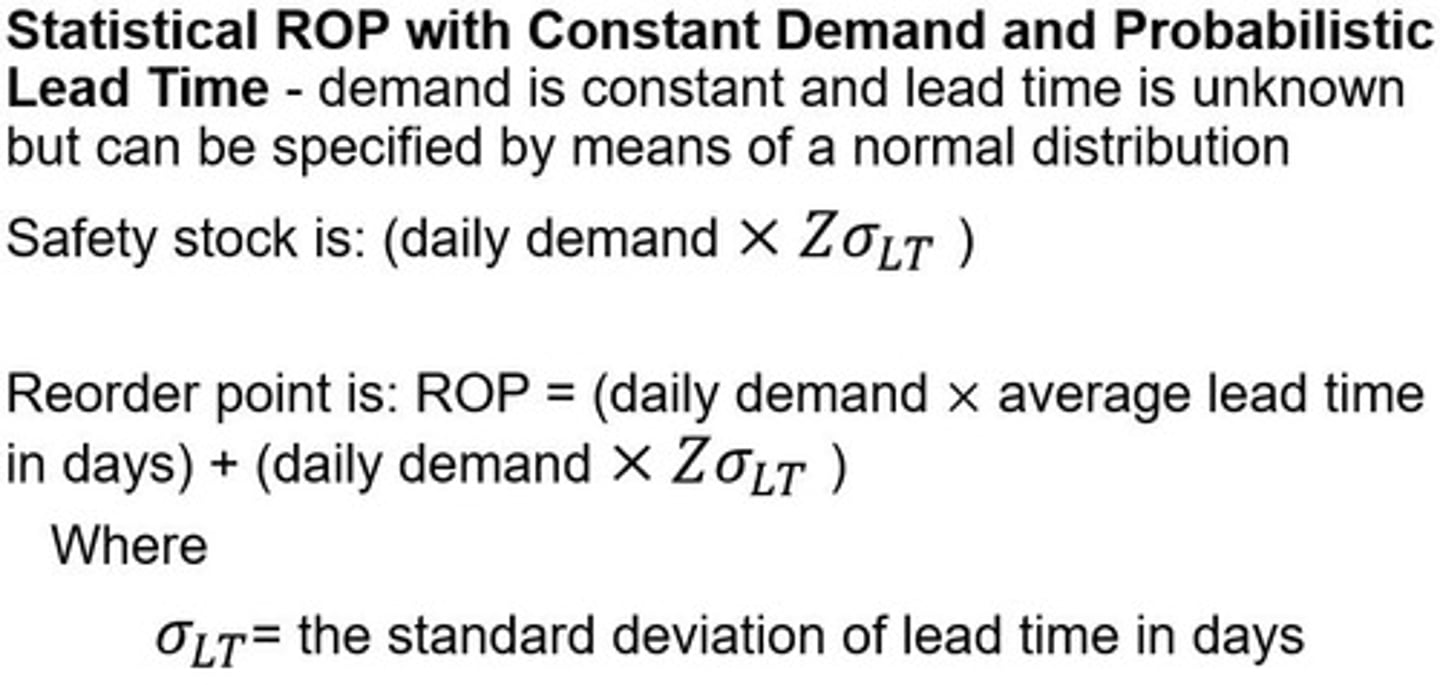

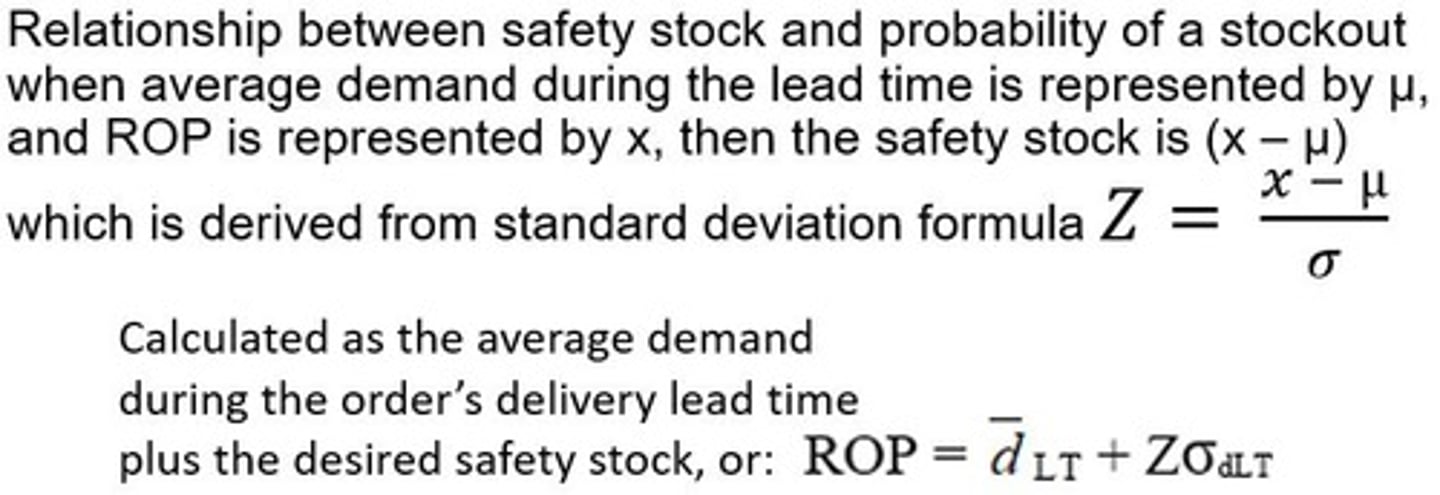

Safety Stock

Extra inventory to prevent stock outs. Formula=Daily Demand x standard deviation of lead items in days

ROP Models

Statistical models for determining reorder points.

RFID

Tracks goods without direct line of sight.

RFID Tag

Computer chip with antenna for wireless communication.

RFID Reader

Device that reads RFID tags, handheld or fixed.

Communication Network

Connects RFID readers to enterprise information systems.

RFID Software

Manages data collection and synchronization in inventory, ERP, and supply chain planning systems.

Near field Data Communication

Secure data exchange between NFC tags and Android devices.

EPC Standard

Standard for RFID tags developed by EPCglobal, Inc.

Passive RFID Tags

Classes 0, 1, 2; no power source. No boosted range

Active RFID Tags

Classes 3, 4; contain power source for Boosted range.

Class 5 Tags

Communicate with other Class 5 tags and devices.

ISO 18000-6C

Standard for RFID communication protocols.

Materials Management

Automated logging of goods entering supply warehouses.

Manufacturing Automation

Customer configurations encoded on tags for production.

Distribution Center Automation

Updates ERP for replenishment upon shipment.

Retail Store Automation

Triggers replenishment when items reach reorder point.

Global RFID Challenges (5)

Consumer privacy issues + China privacy issues, reginal strategies, differences in radio frequencies round the world, signals deflected by metal and absorbed by water, and costs hinder RFID adoption.

Big Data

Large data sets requiring advanced processing tools.

Order Cost

Direct variable cost associated with placing an order.

Deterministic Parameters

Price, demand, and other factors that determine if you should use EOQ, EMQ or price-break model.

Replenishment Assumption

Assumes instantaneous replenishment in EOQ model.

Price Assumption

Assumes price remains constant in EOQ model.

Replenishment

Restocking inventory occurs instantly without delay.

Price Constancy

Price remains unchanged during inventory management.

Holding Cost

Cost incurred for storing inventory over time.

Stockouts

Situations where inventory runs out completely.

Total Annual Inventory Cost (TAIC)

Sum of purchase, holding, and order costs annually.

Annual Purchase Cost (APC)

Total cost of purchasing inventory for a year.

Annual Holding Cost (AHC)

Total cost of holding inventory for a year.

Annual Order Cost (AOC)

Total cost of placing orders annually.

Economic Order Quantity (EOQ)

Optimal order quantity minimizing total inventory costs. Quantitative model based on trade-off between annual inventory cost and annual order cost

Seeks OPTIMAL order quantity

Order cost is direct variable

Holding cost is incurred for holding storage

Assumptions for the EOQ model:

Demand is known and constant

Order lead time is known and constant

replenishment is instantaneous

Price is constant

hold cost is known and constant

Order cost is known and constant

Stock outs are not allowed.

Quantity Discount Model

EOQ variation allowing discounts for larger purchases.

Trade-off in Inventory

Balancing purchase quantity discounts against holding costs.

Economic Manufacturing Quantity (EMQ)

Model allowing gradual inventory build during production.

Simultaneous consumption and manufacturing

Relaxes instantaneous replenishment assumption by allowing for partial delivery during production

Production Rate (P)

Rate at which inventory is produced over time.

Maximum Inventory (Q M)

Peak inventory level during production period.

Safety Stock

Extra inventory held to prevent stockouts.

In-stock Probability

Likelihood of having inventory available when needed.

Continuous Review System

Ongoing inventory checks to determine reorder needs.

Shows stock records and actual inventory differ

need continuous review to know when to re-order

can be difficult to implement and very expense to implement

Periodic Review System

Inventory checked at set intervals for restocking. (weekly, monthly, etc.

Requires more safety stock that continuous review system

(s, Q) Policy (First CR)

Reorder fixed quantity, Q, when inventory hits reorder point, s.

(s, S) Policy (Second CR)

When current inventory falls below the reorder point, s, sufficient resources re ordered to bring inventory back up to pre-determined level, S.

(nQ, s, R) Policy (First PR)

when review happens, if inv level is equal to or less that reorder point, s, the quantity, nQ, is ordered to bring inventory back up to a level between s and (s + Q) to restore inventory above reorder point.

(s, S, R) Policy (Third PR)

When reviewed, if inventory is = to or less than or equal to reorder point, s, order enough to reach maximum inventory, S

Primary functions of inventory

Add buffer from uncertainty in the market and Decouple (reduce) dependencies in the supply chain (safety stock)

4 broad categories of inventories

Raw Materials, WIP, Fished goods, and MRO

Absolute Value of inventory

value of inventory on the balance sheet

How RFID can automate a supply chain (4)

Materials management- good automatically counted and logged as they enter warehouse

Manufacturing- Customer configuration encoded on stage to be incorporated automatically during the production process

Distribution center- Shipment leaving the DC automatically updates ERP to trigger a replenishment order and notifies the customer of the delivery

Retail- Reader placed on shelf to trigger automatic replnishent when items reach reorder point. Help with cycle counting.

Big Data Decision-Making

- Big data broadly refers to collections of data sets too large and complex to be processed by traditional database management tools or data processing software applications.

- instead, massive parallel software applications running on hundreds, or thousands of servers simultaneously are required to store and process the data.

- Big data technology helps process data in real time to take advantage of information captured by RFID.

Fixed order quantity models

-determines the amount to order based on demand, delivery time, and other determinants

EOQ, EMQ, Quantity discount/Price/break model

Service Level

In-stock probability

(S, R) (second PR)

At each review, enough is ordered to bring it back up to the pre-determine maximum inventory levels, S