BT3 - Finals (Reinforced Concrete)

1/115

Earn XP

Description and Tags

Handout 1: Reinforced Concrete Construction

Name | Mastery | Learn | Test | Matching | Spaced | Call with Kai |

|---|

No study sessions yet.

116 Terms

Reinforced Concrete

Concrete in which steel reinforcement is embedded in such a manner that the two materials act together in resisting forces,

Joseph Aspdin

Patented an artificial cement that he named portland cement after English Portland Limestone

Ancient Romans

Discovered mortar which contained all the essential ingredients of modern Portland Cement ; Inventors of Concrete Construction

True

True or False: Concrete has no form of its own

False

True or False: Concrete is strong in tension but weak in compression

Cement

A calcined mixture of clay and limestone, used as an ingredient in concrete and mortar

Mortar

Cement + sand + water

Plaster

Cement + Lime + Sand + Water

Grout

Cement + Sand + Considerable Amount of Water

True

True or False:: Too much water will weaken concrete

Abram’s Law

“The Compressive Strength of Concrete is Inversely Proportional to the Ratio of Water to Cement”

Pozzolanic Admixture

Used as substitute for cement (35%) for structures in high temperatures and seawater installation

Water Reducing Admixture

An agent or super plasticizers that improves workability and maintain consistency of concrete

Type I: Normal

Type of Cement: Portland Cement for General Construction

Type II: Moderate

Type Of Cement: Sulfate Resistant, where heat build up can damage the structure

Type III: High Early Strength (HES)

Type of Cement: Cures faster (3-7 Days) and gains earlier strength

Type IV: Low heat

Type of Cement: Generates less heat hydration where heat build-up can significantly damage the structure and used for massive concrete structures

Type V: Sulfate Resistant

Type of Cement: Used where resistance to severe sulfate action is required that damage the structure when it leach out from the soil

¼ in

Fine Aggregates / Sand consists of sand having a particle size smaller than _________ or 6.4mm

Coarse Aggregates

Consisting of crushed stone, gravel, or blast-furnace slag having particles larger than the ¼ in. (6.4mm)

6 Gallons per 40kg of Cement Bag

Average Water-Cement Ratio

Accelerator

Speeds up the setting of concrete to reduce the whole curing period or for early removal of forms

Retarder

Delays or extend the setting time of concrete especially during hot weather condition allowing more time to place, consolidate and finish the concrete

1:1:2:6

Concrete Ratio for Class AAA

1: 1 ½ : 3 : 6

Concrete Ratio for Class AA

1:2:4:6

Concrete Ratio for Class A

1:2 ½ : 5:6

Concrete Ratio for Class B

1:3:6:6

Concrete Ratio for Class C

1:3 ½ : 7 : 6

Concrete Ratio for Class D

28 Days

Concrete is normally considered fully cured after _______

Shrinkage

The end of the concrete curing process

Drying Shrinkage

A reduction in volume of concrete, mortar, or plaster caused by loss of moisture

Setting Shrinkage

A reduction in volume of concrete prior to the final set, caused by hydration of the cement paste.

Slump Test

Standard Test Method to measure the consistency of freshly mixed concrete including mortar and stucco

Compressive Cylinder Test

A quasi-quality control test based on 7-28 days curing period to determine the compressive strength of a concrete specimen.

Ready Mixed Concrete

Concrete mixed at batch plant for delivery by an agitator to construction site

Shrink Mixed

Concrete Partially mixed at the batch plant then mixed completely in a truck mixed en route to construction site

Transit Mixed

Concrete dry batch at a batch plant & mixed at the truck mixer en route to construction site.

Gunite

or ―”shotcrete” for lightweight construction, where concrete mix is pumped through a hose and sprayed at high velocity over reinforcement until desired thickness is reached.

True

Reinforced Concrete is also called Beton arme or Ferroconcrete

Plain Concrete

Concrete having no reinforcement, or reinforced only for drying shrinkage or thermal stresses

Balanced Section

A concrete section in which the tension reinforcement theoretically reaches its specified yield strength as the concrete in compression reaches its assumed ultimate strain.

Cast-in Place Concrete

Concrete which is deposited in the place where it is required to harden as part of the structure

True

True or False: Cast-in-Place concrete is also called Cast-In-Situ or In-Situ Concrete

Ferrocement

Constructed of cement-sand, mortar over wire mesh that has been preshaped over a mold

200mm (H) × 400mm (L)

Length and Height Measurements of CHB

Beton Brut

Concrete left in its natural state after formwork is removed, especially, when the concrete surface reflects the texture, joints, and fasteners of a form board.

Reinforcement

A system of steel bars, strands or wires for absorbing tensile, shearing and sometimes compressive stresses in a concrete member or structure.

Development Length

The length of embedded reinforcement required to develop the design strength of reinforcement at a critical section

Embedment Length

Length of a embedded reinforcement provide beyond a critical section

Beam

A rigid structural member designed to carry and transfer transverse loads across space to supporting elements

Simple Beam

Refers to a beam having a single span supported at its end without a restraint at the support

Semi-Continuous Beam

Refers to a beam with two spans with or without restraint at the two extreme ends.

Cantilever Beam

A beam supported on one end and the other end projecting beyond the support, beam or wall.

Continuous Beam

A term applied to a beam that rests on more than two supports

Concrete Cover

The amount of concrete required to protect steel reinforcement from fire and corrosion, measured from the surface of the reinforcement to the outer surface of the concrete section

Bond

The adhesion between two substances as concrete and reinforcing bar

Bond Stress

The adhesive force per unit area of contact between a reinforcing bar and the surrounding concrete developed at any section of a flexural member.

Hook

A bend or curve given to the end of a tension bar to develop an equivalent embedment length

Bottom Bar

any of the longitudinal bars serving as a tension reinforcement in the section of a concrete beam or slab subject to positive moment

Top Bar

any of the longitudinal bars serving as a tension reinforcement in the section of a concrete beam or slab subject to negative moment

Web Reinforcement

Reinforcement consisting of bent bars or stirrups, placed in a concrete beam to resist diagonal tension.

Stirrup

Any of the U-Shaped or closed-loop bars placed perpendicular to the longitudinal reinforcement of a concrete beam to resist the vertical component of a diagonal tension

True

True or False:

Cement shall conform to one of the following specifications for Portland Cement:

1. Specifications for Portland Cement (ASTM 150)

2. Specifications for Blended Hydraulic Cements (ASTM C595) excluding Types S and SA which are not intended as principal constituents of structural concrete.

False

True or False: Water used in a concrete mixture may be either dirty or clean.

True

Minimum clear spacing between parallel bars in a layer shall be not less than 25mm

75mm

Minimum Concrete Cover for Cast in Place Concrete Cast against and permanently exposed to earth

40mm

Minimum Concrete Cover for Cast in Place Concrete Beams, Columns, Primary reinforcement, ties, stirrups, spirals

Short Column

A column having an unsupported height not greater than 10 times the shortest lateral dimension of the cross section.

Long Column

A column having an unsupported height with more than 10 times the shortest lateral dimension of the cross section.

Vertical Reinforcement

Longitudinal Reinforcement placed in concrete column to absorb compressive stresses, resist bending stresses and reduce the effects of creep and shrinkage in the column

Lateral Reinforcement

Spiral reinforcement placed in a concrete column to laterally restrain the vertical reinforcement and prevent buckling

Spiral Reinforcement

Lateral reinforcement consisting of an evenly spaced continuous spiral held firmly in place by vertical spacers

Bundled Reinforcement

Reinforcement employed consisting of two to four bars tied in direct contact with each other

250mm

Minimum Diameter of SPIRAL Column

200mm

Minimum Thickness of TIED Column

4 - 16 mm ⌀

Minimum number of bars in TIED column

6 - 16mm ⌀

Minimum number of bars in a SPIRAL column

10 mm ⌀

Minimum Diameter of Lateral Ties in a TIED column

10 mm ⌀

Minimum Diameter of Spiral Ties for SPIRAL column

False

True or False: When the beam crosses a girder, rest beam bars below the girder bars

Composite Column

A type of column where structural steel is embedded into concrete core of a spiral column

Combined Column

A column with a structural steel encased in a concrete of at least 7cm thick reinforced with wire mesh surrounding the column at a distance of 3cm inside the outer surface of the concrete covering

Lally Column

A fabricated post made of steel provided with a plain flat steel bar or plate which holds girder, girt or beam.

Reinforced Concrete Slab

A rigid planar structure of concrete designed to act together with principal and secondary reinforcements in resisting applied forces

Live Load

Refers to those movable loads imposed on the floor

Dead Load

Refers to the static load such as the weight of the construction materials

Environmental Load

Consist of wind pressure and suction, earthquake load, rainwater on flat roof and forces caused by temperature changes or differentials

Construction Joint

A joint where two successive placements of concrete meet

Isolation Joint

Often called Expansion Joint, it allows movement between concrete slab and adjoining columns and walls of a building

Control Joint

Joint that creates lines of weakness so that cracking that may results from tensile stress occurs along predetermined lines

One-Way Slab

A concrete slab of uniform thickness reinforced in one direction ; Suitable only for relatively short spans

Two-Way Slab

A concrete slab of uniform thickness reinforced in two directions ; Economical for medium spans with intermediate to heavy loads

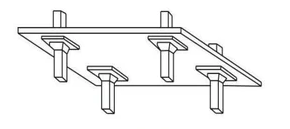

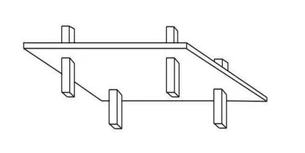

Waffle Slab

A concrete slab reinforced by ribs in two directions ; Can carry heavier loads and spans longer distances that flat slabs.

Continuous Slab

A reinforced concrete slab extending as a structural unit over three or more supports in a given direction ; Subject to lower bending moments than a series of simply supported slabs

Flat Slab

A flat plate thickened at its column supports with column capitals and drop panels to increase its shear strength and moment-resisting capacity

Flat Plate

A concrete slab of uniform thickness reinforced in two or more directions and supported directly by columns without beams or girders

Foundation

The lowest division of a building, its substructure or other construction, constructed partly or wholly below the surface of the ground, designed to support and anchor the superstructure above

Shallow Foundation

A foundation system type employed when the soil underlying is stable

Deep Foundation

A foundation system type employed when the soil underlying is unstable