Metals

1/39

Earn XP

Description and Tags

Module 3: Lecture 1

Name | Mastery | Learn | Test | Matching | Spaced |

|---|

No study sessions yet.

40 Terms

Metallic Bonding

final primary bonding type found in metals and their alloys

metallic materials have 1, 2, or 3 valence electrons

move through an electron cloud

remaining form ion cores = net positive charge of magnitude of # of valence

atoms in crystal structure (lattice)

good thermal and electrical conductivity

free electrons

glue that holds ion cores together

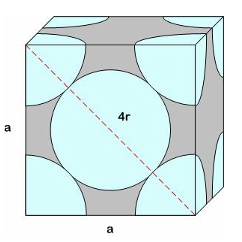

Face Centered Cubic (FCC)

atoms located at each of the corners and centers of all the cube faces

Ex) copper, silver, aluminum, gold, lead

4 atoms make up a FCC “unit cell”

Crystalline material

atoms are situated in a repeating order or periodic array over large atomic distances

convenient to subdivide the structure into small entities called “unit cells"

FCC, BCC, HCP

Body Centered Cubic (BCC)

center and corner atoms touch one another alone cube diagonals

Ex) chromium, Iron, Tungsten

2 atoms make up a BCC “unit cell”

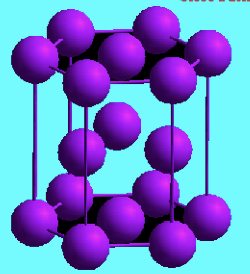

Hexagonal Close Packed (HCP)

top and bottom faces of the unit cells consist of 6 atoms in a hexagon shape that surround a single atom in the center

not symmetrical

Ex) cobalt, titanium, zinc, magnesium

6 atoms make up a HCP “unit cell”

Packing efficency

chemical, physical, and mechanical qualities, as well as a number of other attributes, are revealed by packing efficiency

FCC = 74%

BCC = 68%

Simple Cubic = 52%

Steel

an alloy composed of iron and carbon, along with additional alloying elements

amount of carbon & impurities determine the properties of the grade of steel

over 3500 grades

Alloy

material with metallic properties that is composed of 2 or more substances, of which at least one must be a metal

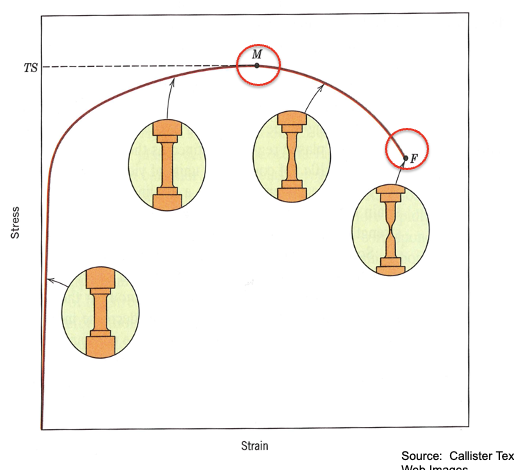

Stress-Strain behavior at fracture

F - fracture point or rupture stress

M- ultimate stress or tensile strength

elastic limit

the elastic limit is the limit beyond which the material will no longer go back to its original shape when the load is removed

proportional limit

maximum stress where the stress/strain relationship is linear elastic

elastic (Young’s) modulus

a measure of stiffness

E = stress / strain

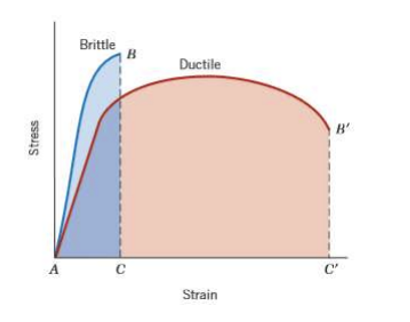

Toughness

materials ability to absorb energy before it breaks

Modulus of toughness

area under the stress/strain curve

Ductility

amount of strain (deformation) experienced before failure

Poissons Ratio

v = -Ex / Ey

yield strength

stress at which deformations increase without an increase in load

Use the 0.2% offset method

draw line parallel to the slope of the elastic modulus, E, but offset by 0.2%

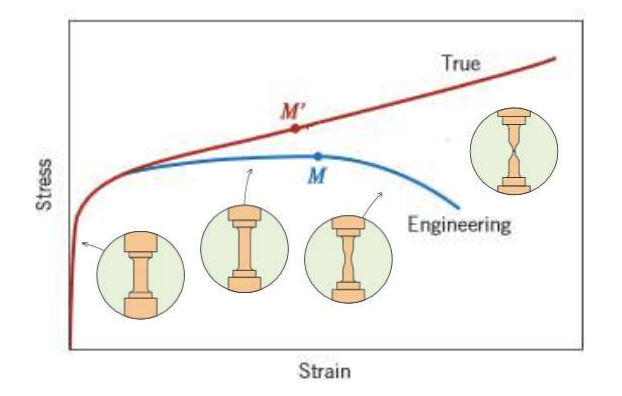

ultimate stress

maximum stress carried before failure, after this there is an increase in strain, but no increase in stress, “necking”

failure stress

stress at rupture

stress/strain curve

0.2% method

find 0.002 strain point on x axis

draw parallel line to the linear elastic portion of the curve

mark the intersection point of the line with the curve

this is yield stress

Ductility vs Toughness

Ductility - amount of strain (deformation) experienced before failure

Toughness - area under the curve, energy absorbed before failure

in the elastic region

the strain (deformation) is fully recoverable

elastic strain aka

bond stretching

plastic strain aka

bonds breaking

strain hardening

a metal is strained beyond the yield point

increasing stress is required to produce additional plastic deformation and the metal becomes stronger

“true” vs “engineering” stress strain curve

“true” - area decreases with loading, so stress increases

“engineering” - constant area assumed

Iron-based Alloys

wrought iron - very low carbon steel, less than 0.1% C by mass

steel - 0.01 t0 1% carbon, manganese, phosphorous, sulfur, silicon, other alloys

Rebar grades

deformed or plain bars are produced in four principal (minimum yield levels)

40,000 psi Grade 40

50,000 psi Grade 50

60,000 psi Grade 60

75,000 psi grade 75

increasing steel strength

decreases the ductility

Role of carbon in steel

attracts iron alloy, ferrous alloys

If C < 1.7% by mass, carbon steel

If C > 1.7% by mass, cast IRON

limitations of ferrous alloys

relatively high densities & versatile

generally poor corrosion resistance

ferrous alloys THINK STEEL!!!

epoxy coated steel reinforcement

delays or prevents corrosion due to chlorides

the coating should be free of breaks and defects

(galvanized) steel reinforcement

zinc coated

zinc layer corrodes, so steel is protected

good for concrete subjected to carbonation

stainless steel

a minimum of 10.5% chromium and a maximum of 1.2% carbon content

nickel and molybdenum additions

Nomenclature for steels

xx is wt% C x 100

Ex) 1060 steel — plain carbon steel with 0.60 wt% C

annealing

heat treatment method where a metal is heated to a specific temp, held at that temp, and then air cooled

increases ductility and decreases hardness

more workable

quenching

process of cooling a metal at a rapid rate, martensite forms

harder metal

tempering

heating steel below the lower critical temperature

increase toughness