4.4 Manufacturing Processes

0.0(0)

Card Sorting

1/15

Earn XP

Description and Tags

Last updated 3:50 AM on 5/22/23

Name | Mastery | Learn | Test | Matching | Spaced | Call with Kai |

|---|

No analytics yet

Send a link to your students to track their progress

16 Terms

1

New cards

Examples of Additive techniques

**Paper-based rapid prototyping**

**Laminated object manufacture (LOM)**

**Stereolithography**

**Laminated object manufacture (LOM)**

**Stereolithography**

2

New cards

Paper-based rapid prototyping

Layers of paper cut and glued together to create a 3D shape. Low-fidelity.

3

New cards

Laminated object manufacture (LOM)

3D printing technique that involves the layer-by-layer construction of objects using sheets of material, typically paper, plastic film, or metal foil

4

New cards

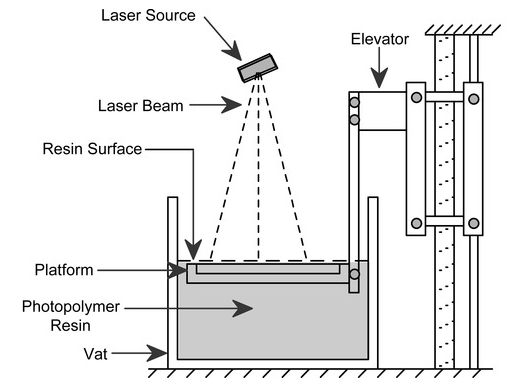

Stereolithography

Solidification of powder using 3D printing

5

New cards

Examples of subtractive techniques

**Cutting** (Laser, Saws, Chiseling, Drilling)

**Machining** (Router or Milling machine)

**Turning** (Metal or Wood Lathe)

**Abrading** (Sanding, Filing, Grinding)

**Machining** (Router or Milling machine)

**Turning** (Metal or Wood Lathe)

**Abrading** (Sanding, Filing, Grinding)

6

New cards

Examples of shaping techniques

**Moulding**

**Thermoforming**

**Laminating**

**Knitting**

**Weaving**

**Thermoforming**

**Laminating**

**Knitting**

**Weaving**

7

New cards

Moulding

Injection moulding, extrusion

8

New cards

Thermoforming

Heating plastics and vacuum forming, or using a strip heater to heat and bend acrylic

9

New cards

Laminating

Flexi-plywood by gluing layers together over a former/shaped mould

10

New cards

**Casting**

Sand casting, Die casting- usually solid to liquid then cooled

11

New cards

Examples of Joining techniques

**Permanent**

**Temporary**

**Adhering- Gluing**

**Fusing (welding)**

**Temporary**

**Adhering- Gluing**

**Fusing (welding)**

12

New cards

Permanent

\

Methods used to permanently bond or join materials together, creating a strong and lasting connection.

e.g. Welding, Brazing, Soldering (joining metals by melting a filler metal), Pop riveting

Methods used to permanently bond or join materials together, creating a strong and lasting connection.

e.g. Welding, Brazing, Soldering (joining metals by melting a filler metal), Pop riveting

13

New cards

**Adhering- Gluing**

once formed, cannot easily be separated

14

New cards

**Fusing (welding)**

Permanent process involving the heating of the surfaces such as metals and plastics. This process isn’t recommended when considering design for disassembly

15

New cards

Temporary

(non-permanent fastening)

Fastening or joining materials mechanically through the use of screws, rivets, bolts, pins, clips, nails, press studs and snaps.

Fastening or joining materials mechanically through the use of screws, rivets, bolts, pins, clips, nails, press studs and snaps.

16

New cards

Adv and Disadvantages of permanent vs temporary

Temporary:

ease for disassembly at the expense of permanent damage to the materials used eg. installing screws

Adjustability: Temporary joining methods offer flexibility in terms of adjustment and alignment of the joined parts.

\

Permanent:

Strength and durability: Permanent joining techniques, such as welding or adhesive bonding, can create strong and durable connections between materials.

Seamless appearance

Load distribution: Permanent joining techniques distribute the load across the entire joint, minimizing stress concentration.

ease for disassembly at the expense of permanent damage to the materials used eg. installing screws

Adjustability: Temporary joining methods offer flexibility in terms of adjustment and alignment of the joined parts.

\

Permanent:

Strength and durability: Permanent joining techniques, such as welding or adhesive bonding, can create strong and durable connections between materials.

Seamless appearance

Load distribution: Permanent joining techniques distribute the load across the entire joint, minimizing stress concentration.

Explore top notes

Explore top flashcards

CRISC - Certified in Risk and Information Systems Control term definition - Part 53

20Updated 1207d ago0.0(0)

CRISC - Certified in Risk and Information Systems Control term definition - Part 53

20Updated 1207d ago0.0(0)