Manufacturing Processes

1/191

Earn XP

Description and Tags

For test 2.

Name | Mastery | Learn | Test | Matching | Spaced | Call with Kai |

|---|

No analytics yet

Send a link to your students to track their progress

192 Terms

Additive Manufacturing

Material addition process by addign layers.

Parts of additive rapid prototyping process

Pre-process (software, CAM and CAD)

Fabrication (layer method and starting form)

Post process (cleaning, support removal etc)

Steps in AM

CAD file

Convert solid to STL and slice

Supports

Set tools directions and path

What does layer thickness represent?

Vertical tolerances (resolution)

Types of Supports

Gussets, Island, Ceiling with arch, Ceiling

Classifications of AM

Liquid

Powder

Solid

Liquid Printing Types

STL or SLA

PolyJet Technology

Powder Printing Types

3D printing with binder

Selective laser sintering

Selective laser melting

Electron beam melting

Laser engineered net shaping (LENS)

Solid Printing Types

Fused deposition modelling

Laser metal deposition - wire

Bound metal deposition

Laminated object manufacturing

How does SLA or STL work

Uses focussed light (UV Laser) to cure hardened layers of liquid resin (liquid photopolymers) into a solid 3D shape. I.E. by photopolymerisation.

Advantages of SLA/STL

Precision

Accuracy

Smooth Finish

Disadvantages of SLA/STL

Limited colours

Expensive resins

Post process curing

Support removal

Mechanically weak

Examples of SLA use

In orthodontics to produce custom aligners to help with teeth alignment.

How does PolyJet printing work

Use photopolymerisation to solidify layers, but works as a line instead of a point.

PolyJet Advantages

A variety of colours

Easy to remove support

No post-process curing

Smooth surface

Very thin layers

How does 3D Binder Printing work?

Roller flattens out powders while binders are being deposited by a nozzle which solidifies the powder.

Advantages of 3D Binder Printing

Very fast

No heat

No support

Large parts possible

Full colour

Non-toxic materials

Disadvantages of 3D Binder Printing

Mechanically weak (plaster)

Average resolution

Porous structures

What is sintering?

The process by which the porosity of a 3D printed metal is reduced through coalescence and the fusing together of particles

Selective Laser Sintering

Uses lasers to sinter decreasing porosity of the material.

Direct Metal Fabrication

Prototyping using metallic powders and know binders.

What are the types of direct metal fabrication

Powder Bed

Powder Fed

Powder bed types

Selective laser melting (SLM)

Electron beam melting (EBM)

Direct metal laser sintering (DMLS)

Powder fed (Coaxial powder (melt pool)) types

Laser engineered net shaping (LENSTM)

Direct metal deposition (DMDTM)

Direct Metal Fabrication

Using metallic powders without binders in additive RP.

Selective Laser Melting (SLM)

Melts and fuses metallic powders

Properties of Selective Laser Melting

Workpiece produced in inert gas

Stainless steel and Al, Ti, Co-Cr, Ni alloys

Density between 98-100%

Heat treatment and finish machining often required

Laser-engineered Net Shaping (LENS)

Deposits metal powder from tip using a laser to melt and fuse metals onto substrate.

Advantages of LENS

Fully dense metallic parts

Repair of critical components

Freeform fabrication

Disadvantages of LENS

Slow

Poor surface finish

Heat affected zones

Electron Beam Melting

Uses energy from electron beam to melt powders Can melt titanium and cobalt chrome alloys.

(Vacuum condition.)

Fused Deposition Modelling (FDM)

Solid filament melted and deposited to create 3D structures.

Advantages of FDM

Inexpensive Material

Good mechanical properties

Disadvantages of FDM

Supports needed

Slow process

Laser Metal Deposition-Wire (LMD-W)

Wire delivered from a side nozzle. Laser uses heat (melt) to bond wire and substrate.

Advantages of LMD

Higher deposition rate than LENS

Bound Metal Deposition (BMD)

Metal components constructed by extrusion of powder filled thermoplastic media. Uses bound metal rods (metal powders held with wax/polymers).

Laminated Object Manufacturing (LOM)

Uses rolls of material to build up material layer by layer.

Advantages of LOM

Inexpensive material

Disadvantages of LOM

Supports Needed

Sealing Edges

Time consuming

Advantages of Additive Manufacturing

Products on demand or unique.

Customised products (dental crowns, hearing aids, etc)

Faster and less costly for low volume production

Complicated shapes without assembly

Efficient use of material and energy

Scrap metal can be recycled

No requirement of tooling, preforms or moulds.

Disadvantages of Additive Manufacturing

High raw material costs

Limited materials with limited properties

Large production is uneconomical

Performance may decrease due to fatigue and wear

Limitations to accuracy and surface quality.

Metal Forming

Utilises the properties of metals (which flow plastically) to change their shape.

Advantages of forming characteristics

Good mechanical properties of formed material

Favourable grain flow

Little waste

No handling of molten material

No solidification problems

Cast structure improved and defects eliminated.

Disadvantages of forming characteristics

High forces required to deform materials

Machinery and tooling often expensive

Most economical for large quantities and repeat manufacturing.

Bulk Deformation Operations

Rolling

Forging

Extrusion

Drawing (wire, bar, tube)

Squeezing Processes

Sheet-metal forming

Bending

Shearing

Drawing (deep, shallow)

Stretching

Stresses in rolling

biaxial compression

Stresses in Forging

Triaxial compression

Stresses in extrusion

Triaxial compression

Stresses in wire drawing

biaxial compression, tension

Stresses in deep drawing

At flange:

Biaxial tension, compression

At wall:

uniaxial tension

Stresses in straight bending

biaxial tension or compression

Desired material properties in forming

High Ductility (large plastic deformation)

Low yield strength (lower forces to deform)

Value of strain hardening (depends on application)

Other name for desired properties

Malleable

Good formability

Good workability

Independent variable in forming

Starting material

Starting geometry

Tool or die geometry

Lubrication

Starting temp

Speed of operation

Amount of deformation

Dependent variables in forming

Force/Power requirments

Material properties of product

Final temp

Surface finish

Nature of material flow

Link between tensile strain and temp

Higher temp allows more tensile strain/streching.

General parameters in forming

Speed of deformation

Friction

Lubrication

Temperature

Speed of deformation in forming

Rate of change in strain.

Speed-sensitive materials may crack/shatter.

Other materials may be stronger when quickly deformed.

Greatest sensitivity at elevated temps.

Friction in forming

retards metal flow and increases forces, power, tool wear and degrades finish.

More severe at higher temps.

Lubrication in forming

Reduced forces and power

Better finish

Thermal barrier and heat removal

Temperature in forming

higher temp:

decreases strength and strain hardening rate

increases ductility and ease of deformation

Types of working conditions (temperature)

Hot Working

Warm Working

Cold Working

Hot working

Tw > Trecy

Tw > 0.5Tm

Warm working

Tw < Trecy

0.3Tm < Tw < 0.5Tm

Cold working

Tw < Trecy

Tw < 0.3Tm

Isothermal

Working temp constant

Recrystilisation

the formation of new sets of strain-free grains within a previously cold-worked metal

Advantages of hot working

Lower forces and power

Large change in shape

Isotropic properties

For low workability materisl

Disadvantages of hot working

Higher total energy

Lower dimensional accuracy

Surface oxidation

Shorter tool life

Advantages of cold working

no heating

good surface finish

good dimensional accuracy

Disadvantages of cold working

Higher forces

Pre-cleaning required

Small deformation

Intermediate annealing

Isothermal forming

successful deformation of temperature-sensitive materials. Heat up dies to workpiece temp. Slow deformation speed.

Primary forming process

reduce a cast material into intermediate shapes (slabs, blooms, billets)

Secondary forming process

convert slabs, blooms, billets to semi-finished products.

Classification of bulk deformation

Shape and/or surface area change significantly

Thickness is reduced

Classification of sheet-metal forming

shape changes significantly

very small changes to thickness and surface area

Rolling

Metal is passed between two work rolls that rotate in opposite directions, decreasing thickness or cross sectional area.

Hot rolling

most common, large amounts of deformation are required. Material properties uniform. No residual stresses.

Cold rolling

produces finished sheet and plate stock with good surface finish and dimensional accuracy. Significantly changes metal properties such as strength and ductility.

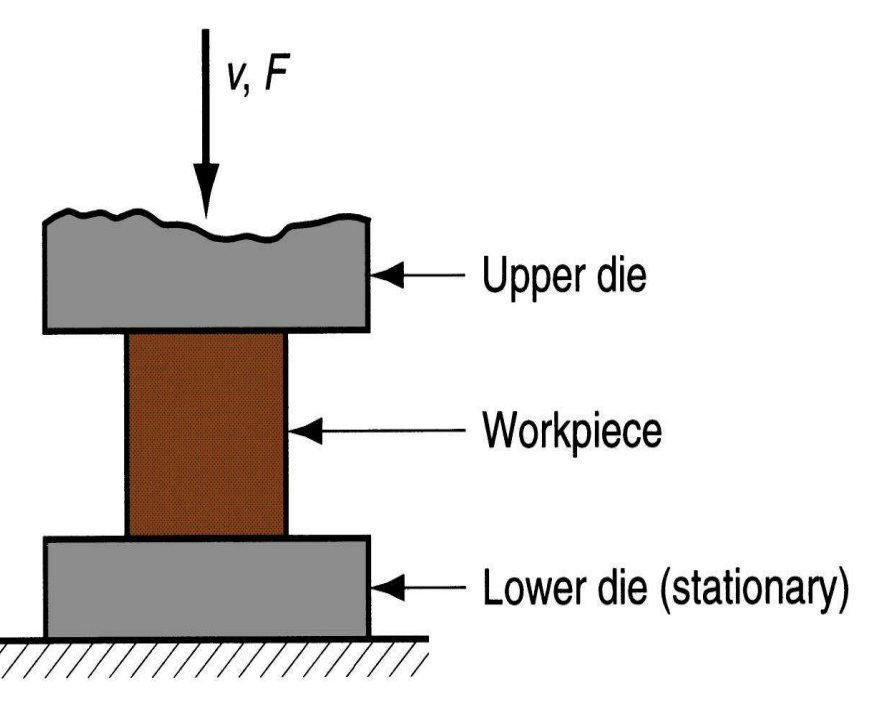

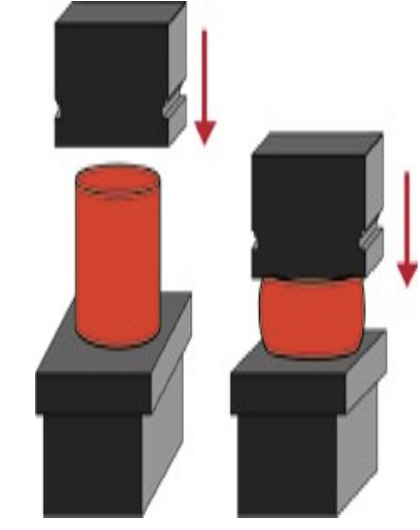

Open-Die Drop Hammer Forging

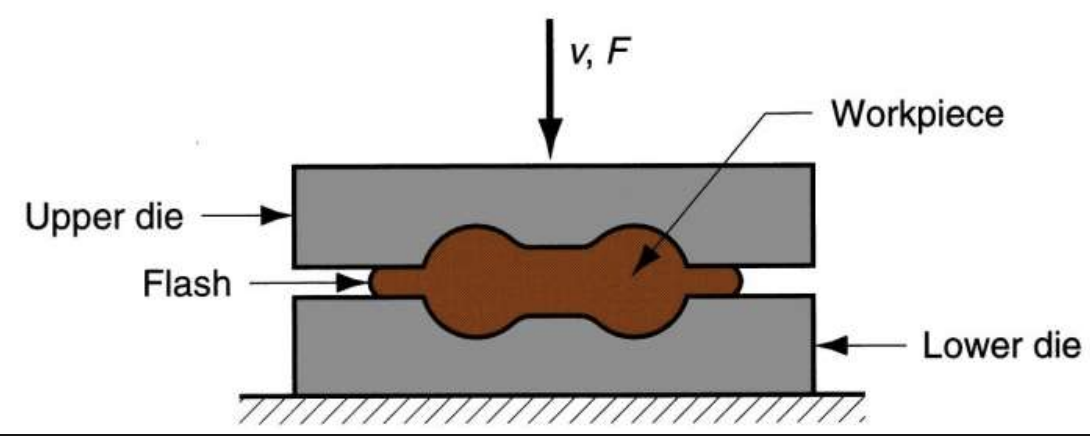

Impression-Die (Close-Die) Drop-Hammer Forging

Excess metal squeezed out to form flash. Must be trimmed from final forging.

Flashless forging

Doesn’t form flash

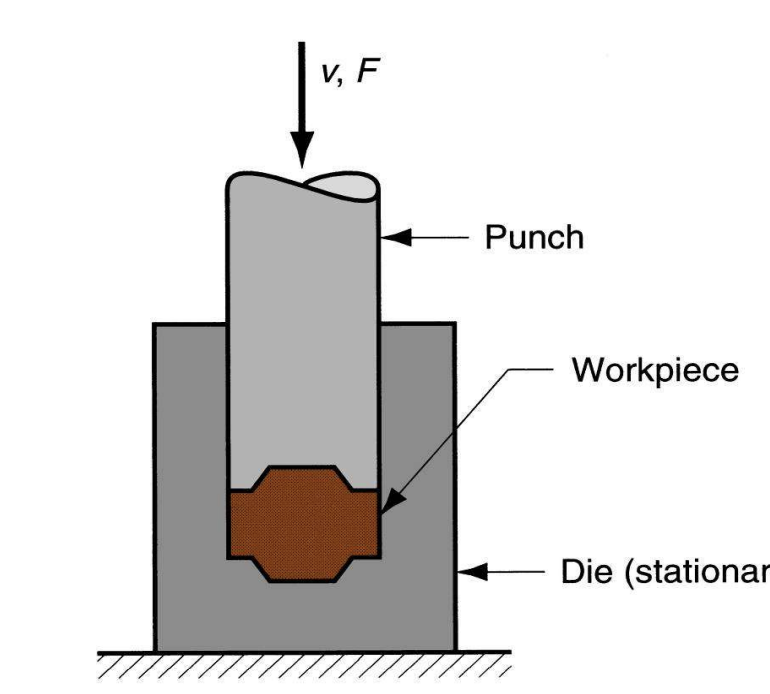

Upset Forging

Increase diameter by compressing length

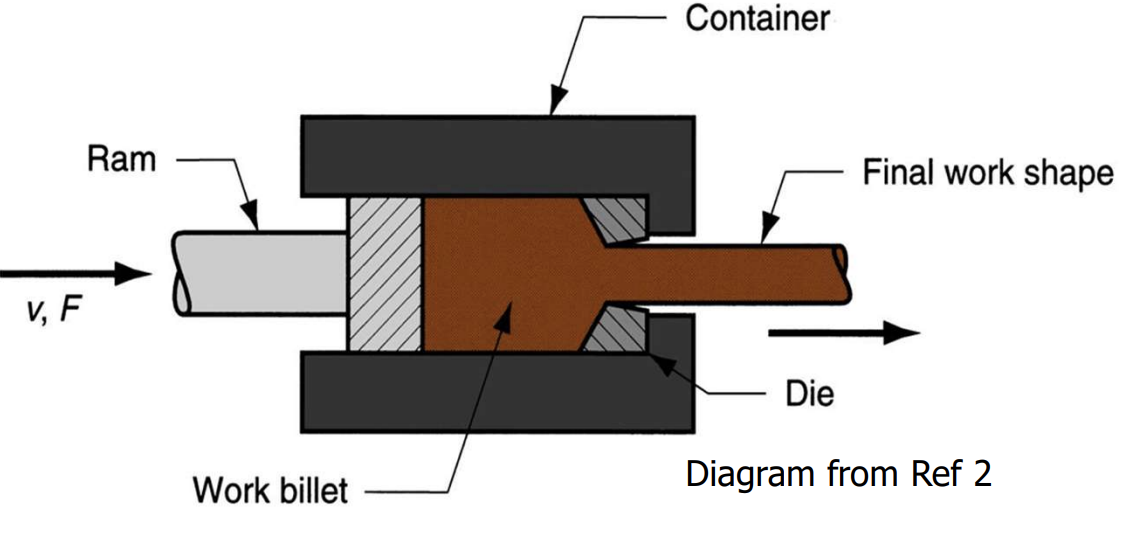

Direct Extrusion

Forward extrusion.

Die opening determines final shape

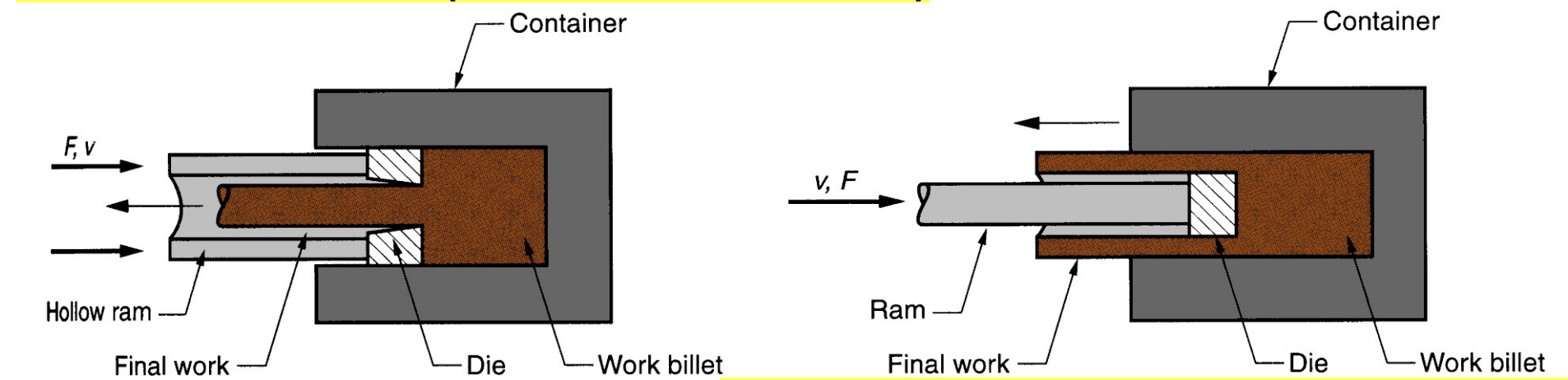

Indirect Extrusion

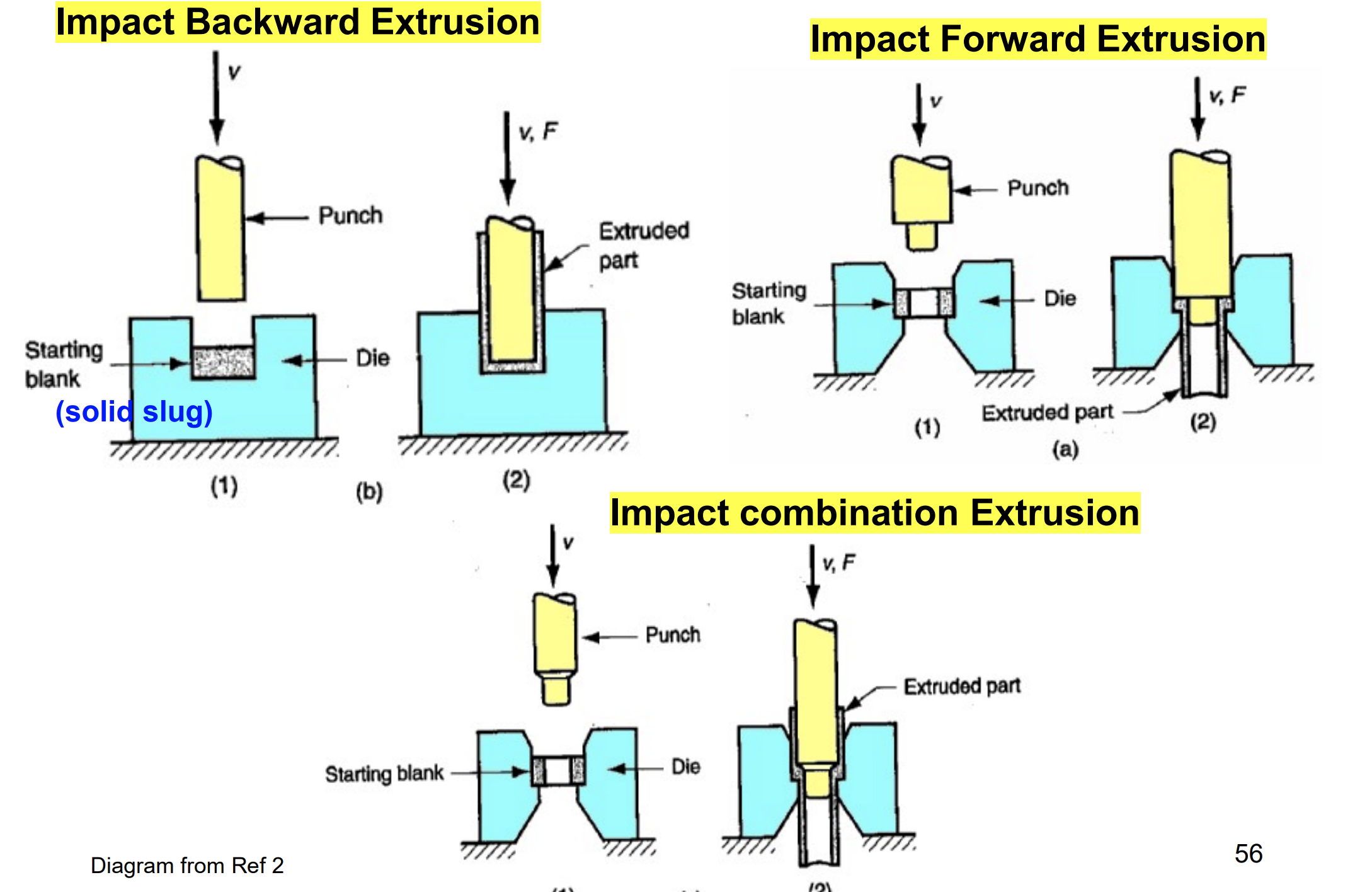

Impact extrusion

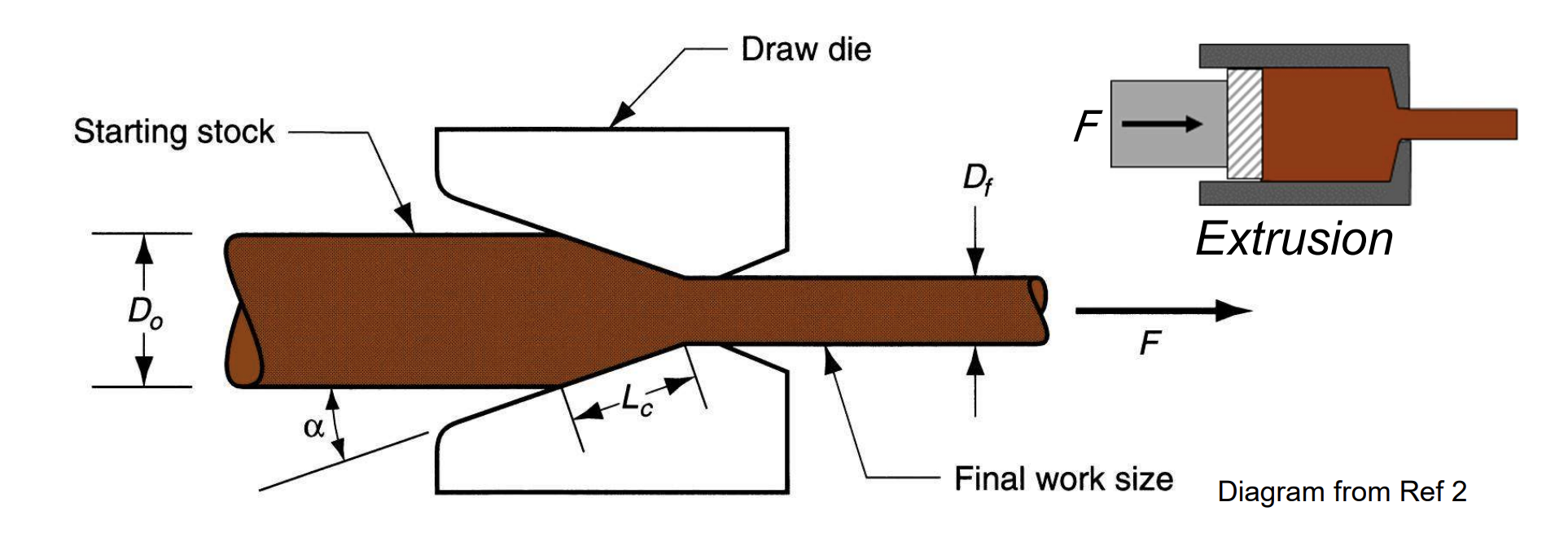

Drawing

Pulling through a die as opposed to pushing in extrusion

cross section reduced, length increased

Tube Drawing

Thickness of wall and tube diameter reduced.

essential die lubrication to reduce friction.

Tube sinking

doesn’t control internal diameter

Fixed/Floating plug drawing

control inner diameter using plug or mandrel.

Sheet metal forming

deformation of material where the thickness and surface area remain constant but the shape changes.

start with sheets, strips and coils

Includes, shearing, bending and deep drawing.

High SA means lose heat quickly

Bending

Deforming the material around a straight axis.

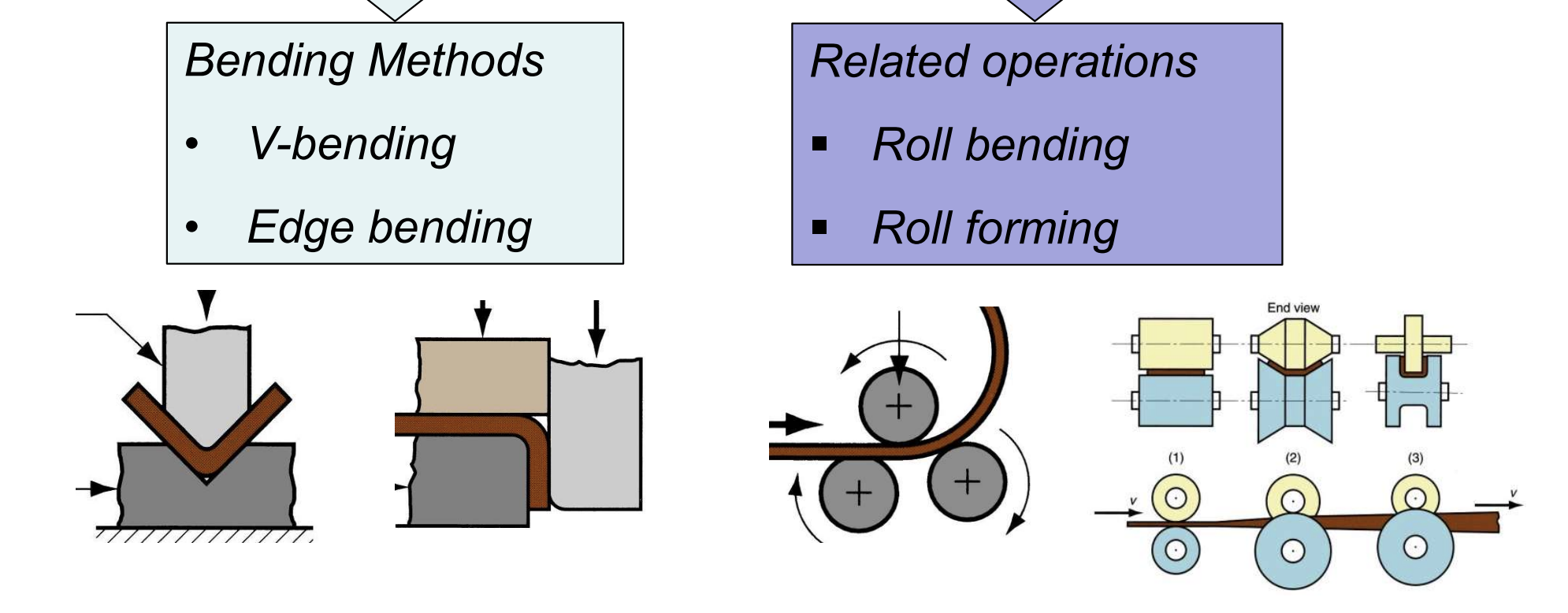

V-bending, edge bending, roll bending, roll forming.

Springback

decrease in bend angle of a bent part after tool is removed.

Residual elastic energy is recovered and causes part to partially revert to original shape.

Large radius = large springback

Shearing

mechanical cutting of material without the formation of chips.

When the two cutting blades are straight, the process is called shearing

When the blades are curved, the processes have special names, such as blanking, piercing (punching), notching, and trimming

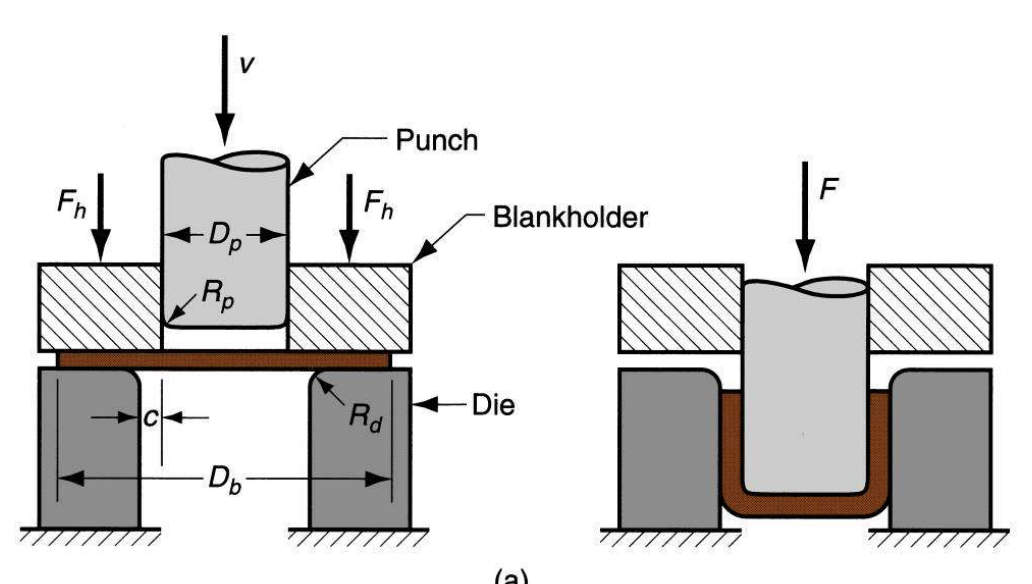

Sheet metal drawing

plastic deformation about a curved axis

depth much greater than thickness

Steps in powder metallurgy

Metal powder production

Blending

Hot/Cold Compaction

Sintering

Secondary/Finishing Operations

Powder production methods

Atomisation

Reduction

Electrolytic Deposition

Carbonyls

Comminution

Mechanical alloying

Atomisation

a liquid-metal stream is produced by injecting molten metal into a small orifice.

The stream is broken up into droplets by jets of inert gas, air or water.

Size and shape of the particles formed depend on the temperature of the molten metal, rate of flow, nozzle size and jet characteristics.