principles of manufacturing service chapter 1

1/90

There's no tags or description

Looks like no tags are added yet.

Name | Mastery | Learn | Test | Matching | Spaced |

|---|

No study sessions yet.

91 Terms

The self-serve kiosk

The self-serve kiosk in a restaurant like McDonald's is a good example. Other examples combine the use of a smart machine or robot with the skills of people. Companies increasingly use technology to improve the efficiency of their business processes. As we discuss later in this chapter, efficiency relates to the speed and cost of getting something done.

Many popular quick-service restaurants have customers use self-ordering kiosks (and better yet restaurant apps) to speed ordering and

Page 2

paying for a meal. This greatly speeds up the ordering process and allows the restaurant to focus on food preparation and delivery. Taking orders takes time and is prone to errors due to miscommunication and entry errors. Making this the responsibility of the customer is a win for the customer and for the company.

Another example is self-checkout at retail stores. Kiosks are one common way to do this, and self-scanning using an app is even better since this eliminates the need for the kiosk. The problem of not having enough open registers can be greatly reduced with this technology.

In the context of major business functions, operations and supply chain management

involves specialists in product design, purchasing, manufacturing, service operations, logistics, and distribution. These specialists are mixed and matched in many different ways depending on the product or service.

For a firm that sells televisions, like Sony, these are the functions responsible for designing televisions, acquiring materials, coordinating equipment resources to convert material to products, moving the product, and exchanging the final product with the customer. Some firms are focused on services, such as hospitals. Here the context involves managing resources, including the operating rooms, labs, and hospital beds used to nurse patients back to health. In this context, acquiring materials, moving patients, and coordinating resource use are keys to success. Other firms are more specialized, such as Amazon. Here purchasing, website services, logistics, and distribution need to be carefully coordinated for success. In our increasingly interconnected and interdependent global economy, the process of delivering finished goods, services, and supplies from one place to another is accomplished by means of mind-boggling technological innovation, clever new applications of old ideas, seemingly magical mathematics, powerful software, and old-fashioned concrete, steel, and muscle.

Operations and supply chain management (OSCM)

is defined as the design, operation, and improvement of the systems that create and deliver the firm's primary products and services. Like marketing and finance, OSCM is a functional field of business with clear line management responsibilities. OSCM is concerned with the management of the entire system that produces a product or delivers a service.

Distinguishing Operations versus Supply Chain Processes

Success in today's global markets requires a business strategy that matches the preferences of customers with the realities imposed by complex supply networks. A sustainable strategy that meets the needs of shareholders and employees and preserves the environment is critical.

In the context of our discussion, the terms operations and supply chain take on special meaning. Operations refers to manufacturing and service processes that are used to transform the resources employed by a firm into products desired by customers. For example, a manufacturing process would produce some type of physical product, such as an automobile or a computer. A service process would produce an intangible product, such as a call center that provides information to customers stranded on the highway or a hospital that treats accident victims in an emergency room. Planning the use of these processes involves analyzing capacity, labor, and material needs over time. Ensuring quality and making ongoing improvements to these processes are needed to manage these processes.

Supply chain refers to processes that move information and material to and from the manufacturing and service processes of the firm. These include the logistics processes that physically move product, as well as the warehousing and storage processes that position products for quick delivery to the customer. Supply chain in this context refers to providing products and service to plants and warehouses at the input end and also to the supply of products and service to the customer on the output end of the supply chain.

We consider the topics included in this book to be the loundation or "core" material. Many other topics could be included, but these cover the fundamental concepts. All managers should understand these basic principles that guide the design of transformation processes. This includes understanding how different types of processes are organized, how to determine the capacity of a process, how long it should take a process to make a unit, how the quality of a process is monitored, and how information is used to make decisions related to the design and operation of these processes.

The field of operations and supply chain management is ever changing due to the dynamic nature of competing in global business and the constant evolution of information technology. So while many of the basic concepts have been around for years, their application in new and innovative ways is exciting. Internet

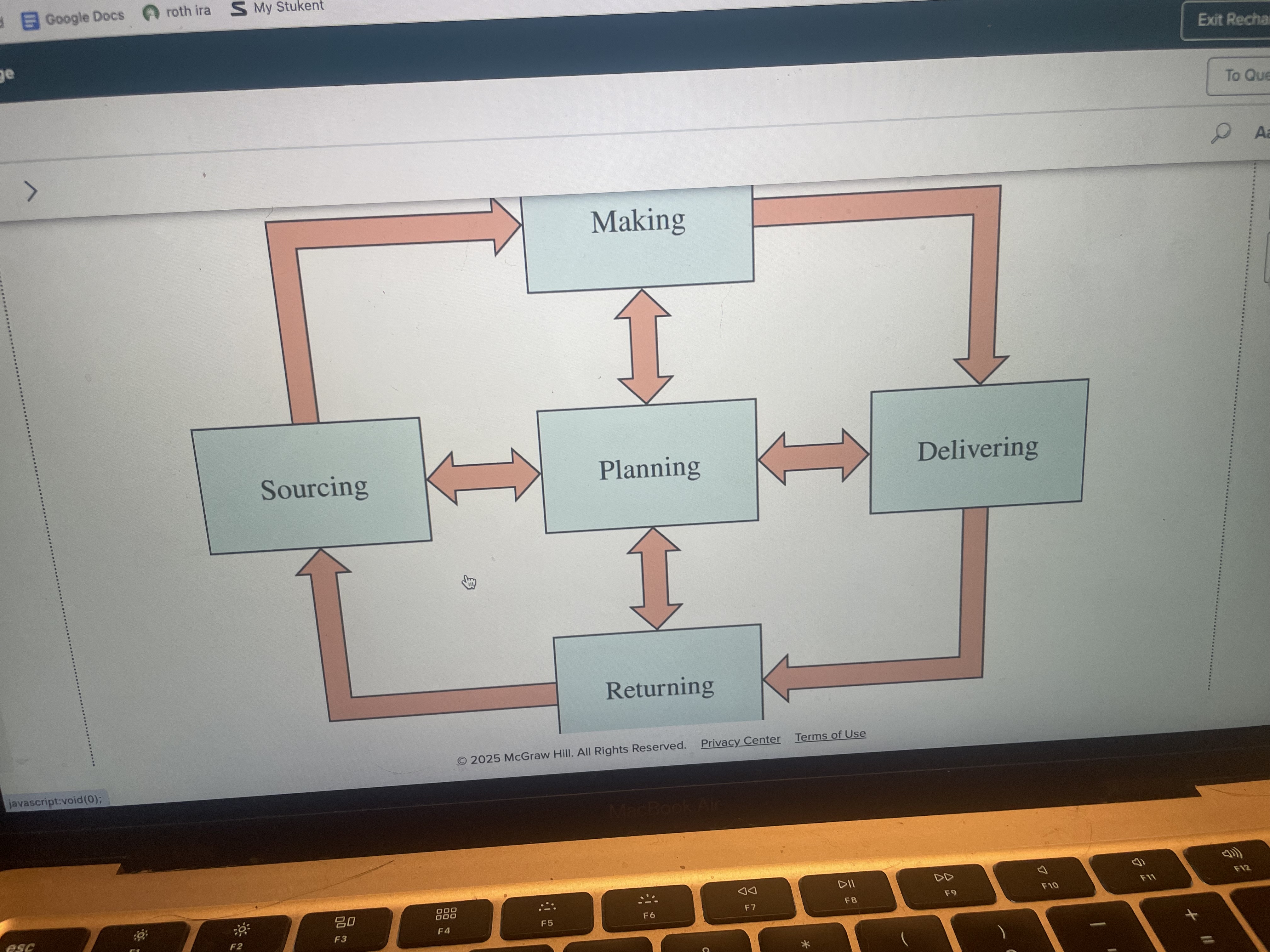

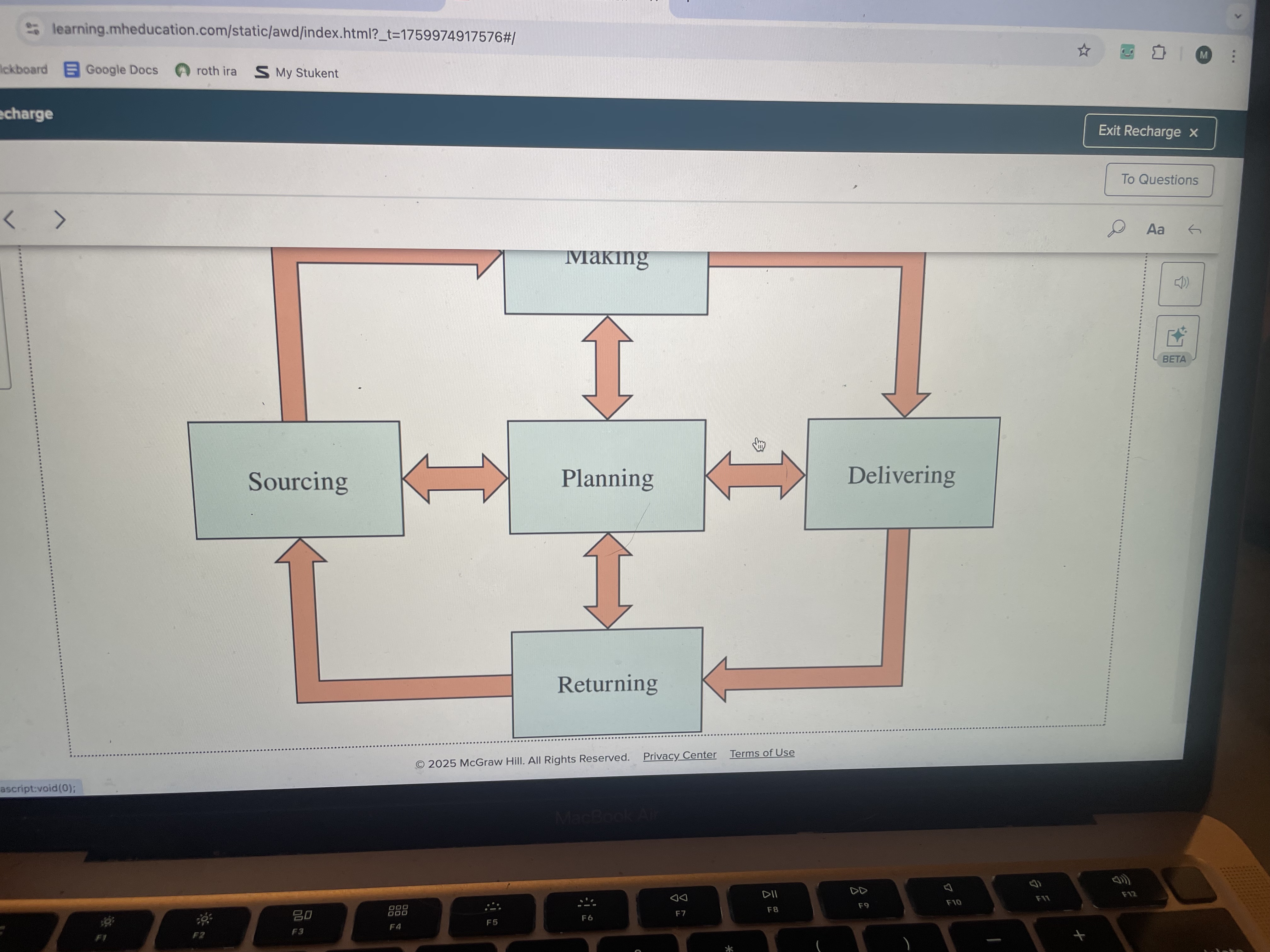

Operations and Supply Chain Processes

can be conveniently categorized, particularly from the view of a producer of consumer products and services, as planning. sourcing, making, delivering, and returning.

Exhibit 1.2 depicts how these processes are linked when operating in a supply chain. The following describes the

work involved in each type of process.

Planning

consists of the processes needed to operate an existing supply chain strategically. Here, a firm must determine how anticipated demand will be met with available resources. A major aspect of planning is developing a set of metrics to monitor the supply chain so that it is efficient and delivers high quality and value to customers.

Sourcing

involves the selection of suppliers that will deliver the goods and services needed to create the firm's product. A set of pricing, delivery, and payment processes are needed together with metrics for monitoring and improving the relationships between partners of the firm. These processes include receiving shipments, verifying them, transferring them to manufacturing facilities, and authorizing supplier payments.

Making

is where the major product is produced or the service is provided. The step requires scheduling processes for workers and coordinating material and other critical resources such as the equipment to support producing or providing the service. Metrics that measure speed, quality, and worker productivity are used to monitor these processes.

Delivering

is also referred to as a logistics process. Carriers are picked to move products to warehouses and customers, coordinate and schedule the movement of goods and information through the supply network, develop and operate a network of warehouses, and run the information systems that manage the receipt of orders from customers and the invoicing systems that collect payments from customers.

Returning

involves processes for receiving worn-out, defective, and excess products back from customers and support for customers who have problems with delivered products. In the case of services, this may involve all types of follow-up activities that are required for after-sales support.

Differences between Services and Goods

There are five essential differences between services and goods. The first is that a service is an intangible process that cannot be weighed or measured, whereas a good is a tangible output of a process that has physical dimensions. This distinction has important business implications since a service innovation, unlike a product innovation, cannot be patented. Thus, a company with a new concept must expand rapidly before competitors copy its procedures. Service intangibility also presents a problem for customers since, unlike with a physical product, customers cannot try it out and test it before purchase.

The second is that a service requires some degree of interaction with the customer for it to be a service. The interaction may be brief, but it must exist for the service to be complete. Where face-to-face service is required, the service facility must be designed to handle the customer's presence. Goods, on the other hand, are generally produced in a facility separate from the customer. They can be made according to a production schedule that is efficient for the company.

The third is that services, with the big exception of hard technologies such as automated teller machines (ATMs) and information technologies such as answering machines and automated Internet exchanges, are inherently heterogeneous-they vary from day to day and even hour by hour as a function of the attitudes of the customers and the servers. Thus, even highly scripted work, such as found in call centers, can produce unpredictable outcomes. Goods, in contrast, can be produced to meet very tight specifications day-in and day-out with essentially zero variability. In those cases where a defective good is produced, it can be reworked

BEI

or scrapped

The fourth is that services as a process are perishable and time dependent, and unlike goods, they can't be stored. You cannot "come back last week" for an air flight or a day on campus.

And fifth, the specifications of a service are defined and evaluated as a package of features that affect the five senses. These features relate to the location, decoration, and layout of the facility where the service is housed, for example. Other features are the training and attitude of employees, and the consistency of service performance. Such attributes as speed, privacy, and security are other features that define a service.

The first is that

a service is an intangible process that cannot be weighed or measured, whereas a good is a tangible output of a process that has physical dimensions. This distinction has important business implications since a service innovation, unlike a product innovation, cannot be patented. Thus, a company with a new concept must expand rapidly before competitors copy its procedures. Service intangibility also presents a problem for customers since, unlike with a physical product, customers cannot try it out and test it before purchase.

The second is

is that a service requires some degree of interaction with the customer for it to be a service. The interaction may be brief, but it must exist for the service to be complete. Where face-to-face service is required, the service facility must be designed to handle the customer's presence. Goods, on the other hand, are generally produced in a facility separate from the customer. They can be made according to a production schedule that is efficient for the company.

The third is

that services, with the big exception of hard technologies such as automated teller machines (ATMs) and information technologies such as answering machines and automated Internet exchanges, are inherently heterogeneous-they vary from day to day and even hour by hour as a function of the attitudes of the customers and the servers. Thus, even highly scripted work, such as found in call centers, can produce unpredictable outcomes. Goods, in contrast, can be produced to meet very tight specifications day-in and day-out with essentially zero variability. In those cases where a defective good is produced, it can be reworked

BEI

or scrapped

The fourth is

that services as a process are perishable and time dependent, and unlike goods, they can't be stored. You cannot "come back last week" for an air flight or a day on campus.

The fifth is

the specifications of a service are defined and evaluated as a package of features that affect the five senses. These features relate to the location, decoration, and layout of the facility where the service is housed, for example. Other features are the training and attitude of employees, and the consistency of service performance. Such attributes as speed, privacy, and security are other features that define a service.

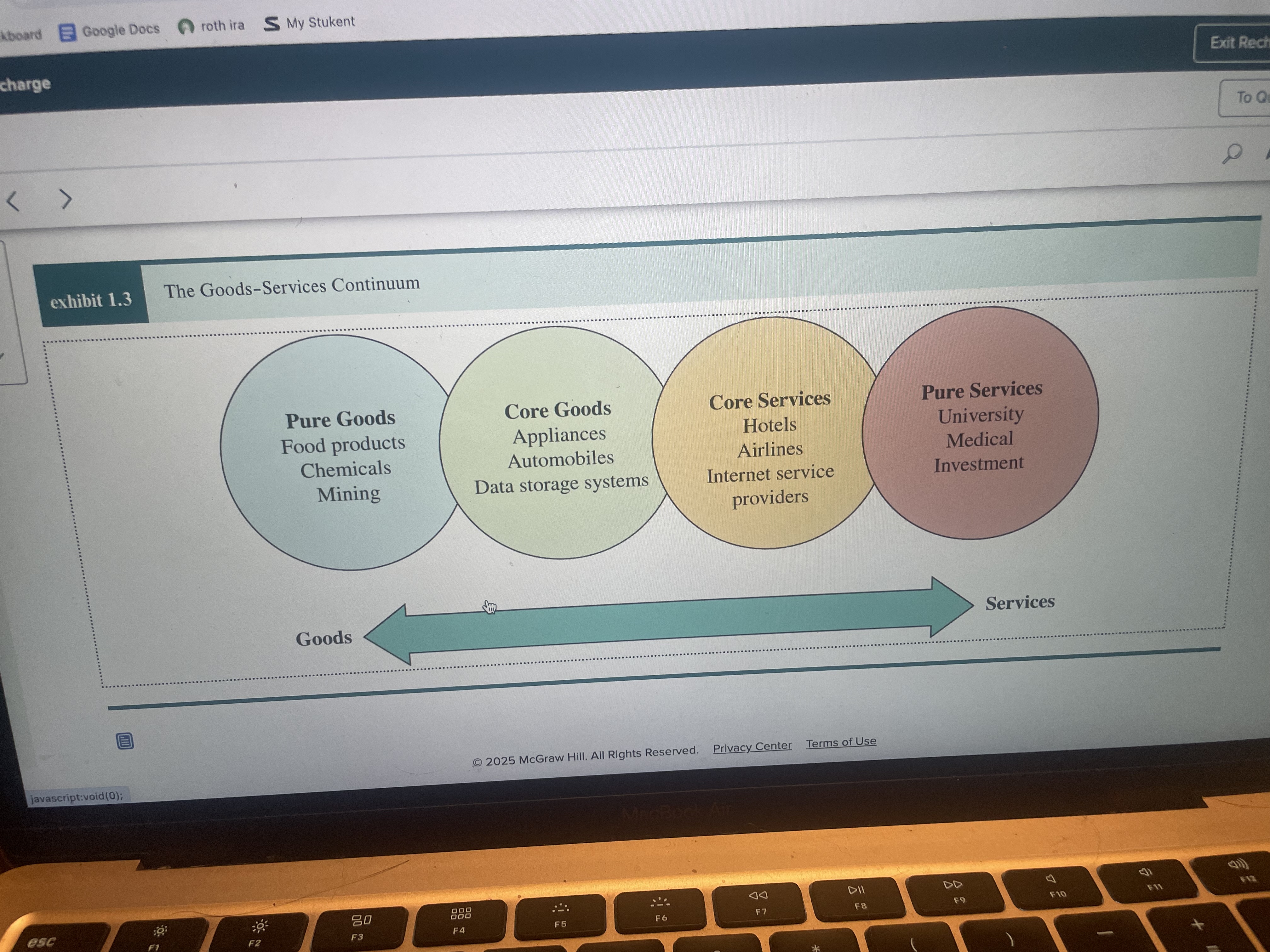

The Goods-Services Continuum

Almost any product offering is a combination of goods and services. In I Exhibit 1.3, we show this arrayed along a continuum of "pure goods" to "pure services."

The continuum captures the main focus of the business and spans from firms that just produce products to those that only provide services. Pure goods industries have become low-margin commodity businesses, and in order to differentiate, they are often adding some services. Some examples are providing help with logistical aspects of stocking items, maintaining extensive information databases, and providing consulting advice.

Pure goods

Highest Goods

Food products

Chemicals

Mining

Core goods

Second highest goods

Appliances Automobiles

Data storage systems

Core services

Third highest goods

Hotels

Airlines

Internet service providers

Pure services

Services

University

Medical

Investment

Product-service bundling

refers to a company building service activities into its product offerings for its customers.

Such services include maintenance, spare part provisioning, training, and in some cases, total systems design and R&D. A well-known pioneer in this area is IBM, which treats its business as a service business and views physical goods as a small part of the "business solutions" it provides to its customers. Companies that are most successful in implementing this strategy start by drawing together the service aspects of the business under one roof in order to create a consolidated service organization. The service evolves from a focus on enhancing the product's performance to developing systems and product modifications that support the company's move up the "value stream" into new markets. This type of strategy might not be the best approach for all product companies, however. Firms that offer product-service bundles typically generate higher revenues, and they tend to generate lower profits as a percentage of revenues when compared to focused firms. This is because they are often unable to generate revenues or margins high enough to cover the additional investment required to cover service-related costs.

Efficiency

means doing something at the lowest possible cost. Later in the book, we define this more thoroughly. But roughly speaking, the goal of an efficient process is to produce a good or provide a service by using the smallest input of resources. In general, these resources are the material, labor, equipment, and facilities used in the OSCM processes.

Effectiveness

means doing the right things to create the most value for the customer. For example, to be effective at a grocery store, it is important to have plenty of operating checkout lines even though they may often stand idle. This is a recognition that the customer's time is valuable and that they do not like waiting to be served in the checkout line. Often maximizing effectiveness and efficiency at the same time creates conflict between the two goals. We see this trade-off every day in our lives. At the checkout lines, being efficient means using the fewest people possible to ring up customers. Being effective, though, means minimizing the amount of time customers need to wait in line.

Value

Related to efficiency and effectiveness is the concept of value, which can be abstractly defined as quality divided by price. Here quality is the attractiveness of the product, considering its features and durability. If you can provide the customer with a better car without changing price, value has gone up. If you can give the customer a better car at a lower price, value goes way up. A major objective of this book is to show how smart management can achieve high levels of value.

Benchmarketing

is a process in which the processes of companies are compared to identify best practices. Wall Street uses a set of financial indications that are called management efficiency ratios to benchmark companies.

The operations and supply chain manager is out working with

people to figure out the best way to deliver the goods and services of the firm. Sure, OSCM people work with the marketing folks, but rather than being on the selling side, they are on the buying side: trying to select the best materials and hiring the greatest talent. They will use the data generated by the finance people and analyze processes to figure out how to produce those goods and services. OSCM jobs are hands-on, working with people and figuring out the best way to do things.

Jobs is oscm not important

Plant manager-Oversees the workforce and physical resources (inventory, equipment, and information technology) required to produce the organization's product. • Hospital administrator-Oversees human resource management, staffing, and finances at a health care facility. • Branch manager (bank)-Oversees all aspects of financial transactions at a branch. • Department store manager-Oversees all aspects of staffing and customer service at a store. • Call center manager-Oversees staffing and customer service activities at a call center. • Supply chain manager-Negotiates contracts with vendors and coordinates the flow of material inputs to the production process and the shipping of finished products to customers. • Purchasing manager-Manages the day-to-day aspects of purchasing, such as invoicing and follow-up. • Logistics manager-Oversees the movement of goods throughout the supply chain. • Warehouse/Distribution manager-Oversees all aspects of running a warehouse, including replenishment, customer order fulfillment, and staffing. • Business process improvement analyst-Applies the tools of lean production to reduce cycle time and eliminate waste in a process. • Quality control manager-Applies techniques of statistical quality control, such as acceptance sampling and control charts, to the firm's products. • Lean improvement manager-Trains organizational members in lean production and continuous improvement methods. • Project manager-Plans and coordinates staff activities, such as new-product development, new-technology deployment, and new-facility location. • Production control analyst-Plans and schedules day-to-day production. | ||

chief operating officer (COO)

So how far can you go in a career in OSCM? One goal would be to become the chief operating officer (COO) of a company. The COO works with the chief executive officer (CEO) and company president to determine the company's competitive strategy. The COO's ideas are filtered down through the rest of the company. COOs determine an organization's location, its facilities, which vendors to use, and how the hiring policy will be implemented. Once the key decisions are made, lower-level operations personnel carry them out. Operations personnel work to find solutions and then set about fixing the problems. Managing the supply chain, service, and support are particularly challenging aspects of a COO's job.

Our purpose in this section is not to go through all the details of OSCM;

that would require us to recount the entire Industrial Revolution. Rather, the focus is on major operations-related concepts that have been popular since the 1980s. L

Late 1970s

Manufacturing strategy developed

Early

1980s

Just-in-time (JIT) production pioneered by the Japanese

Mid- 1980s

Service quality and productivity

Early 1990s

Total quality management

(TQM) and quality certification programs

Six Sigma quality

Manufacturing Strategy Paradigm

The late 1970s and early 1980s saw the development

which emphasized how manufacturing executives could use their factories' capabilities as strategic competitive weapons. Central to this thinking was the notion of manufacturing trade-offs among such performance measures as low cost, high quality, and high flexibility.

Just-in-time (JIT)

production was the major breakthrough in manufacturing philosophy. Pioneered by the Japanese, JIT is an integrated set of activities designed to achieve high-volume production using minimal inventories of parts that arrive exactly when they are needed.

total quality control (TQC),

which aggressively seeks to eliminate causes of production defects-is now a cornerstone in many manufacturers' production practices,

Lean manufacturing

is used to refer to the set of concepts.

Total quality management (TQM)

Managing the entire organization so that it excels on all dimensions of products and services that are important to the customer.

Business process reengineering (BPR)

An approach to improving business processes that seeks to make revolutionary changes as opposed to evolutionary (small) changes.

Six sigma

A statistical term to describe the quality goal of no more than 3.4 defects out of every million units. Also refers to a quality improvement philosophy and program.

Supply Chain Management

The central idea of supply chain management is to apply a total system approach to managing the flow of information, materials, and services from raw material suppliers through factories and warehouses to the end customer. Trends such as outsourcing and mass customization are forcing companies to find flexible ways to meet customer demand. The focus is on optimizing core activities to maximize the speed of response to changes in customer expectations.

Electronic Commerce

The quick adoption of the Internet and the World Wide Web during the late 1990s was remarkable. The term electronic commerce refers to the use of the Internet as an essential element of business activity. The use of web pages, forms, and interactive search engines has changed the way people collect information, shop, and communicate. It has changed the way operations managers coordinate and execute production and distribution functions.

Business analytics

involves the analysis of data to better solve business problems. Not that this is something new. Data have always been used to solve business problems. What is new is the reality that so much more data are now captured and available for decision-making analysis than were available in the past. In addition, mathematical tools are now readily available that can be used to support the decision-making process.

In the past, most analysis involved the generation of standard and ad hoc reports that summarized the current state of the firm. Software allowed querying and

"drill down" analysis to the level of the individual transaction, useful features for understanding what happened in the past. Decision making was typically left to the decision maker based on judgment or simple alerting rules. The "analytics" movement takes this to a new level, using statistical analysis, artificial intelligence, forecasting to extrapolate what to expect in the future, and even optimization, possibly in real time, to support decisions. These mathematical results can be used either to support the decision maker or to automate decision making.

Take, for example, an airline manager presented with the task of setting price points for tickets on a flight. Real-time demand data, historic demand patterns, and powerful mathematical models can now be applied to setting price points for different classes of tickets. As it is closer to the time of departure for a particular flight, these price points can be adjusted based on how sales are going. These decisions have a major impact on the utilization of aircraft capacity, which impacts both revenue and costs for the airlines. These decisions can even be made using criteria related to weather conditions, fuel prices, crew sciedules, and other flights to maximize the profit of the firm.

Environmental, Social, and Governance (ESG)

is a set of specific measures used to assess a company's environment, social, and governance impact. Environmental criteria consider how a company safeguards the environment, including corporate policies addressing climate change, for example. Social criteria examine how it manages relationships with employees, suppliers, customers, and the communities where it operates. Governance deals with a company's leadership, executive pay, audits, internal controls, and shareholder rights. ESG metrics are used to evaluate specific areas such as carbon emissions, diversity and inclusion, and executive pay.

Current Issues in Operations and Supply Chain Management

OSCM is a dynamic field, and issues arising in global enterprise present exciting new challenges for operations and supply chain managers. Looking forward to the future, we believe the major challenges in the field will be as follows:

Risk Management and Supply Chain Resilience: Identifying and mitigating disruption risks, whether they are related to supply chain disruptions, geopolitical issues, or natural disasters, is a key concern today. Ensuring adequate supply while at the same time minimizing cost is difficult given the global cultural, legal, and political differences.

Artificial Intelligence and Advanced Technologies: Adopting advanced technology such as predictive analytics, machine learning, and data analytics can enhance visibility and efficiency in the supply chain. Incorporating these rapidly changing technologies in OSCM processes is a challenge.

Cross-Border Logistics and Trade Compliance: Efficient transportation and logistics management are critical for timely delivery and cost-effective operations.

Staying compliant with changing regulations, trade policies, and industry standards can be complex, especially in global supply chains.Sustainability and Environmental Concerns: Organizations are increasingly focused on making their supply chains more sustainable and environmentally friendly.

Talent Management: Recruiting, training, and retaining skilled professionals in OSCM is a critical problem. Management-level workers in the field need a set of skills that range from being technically savvy to being articulate with great communication skills. People with these skills are uniquand highly sought after. The opportunities are great for those up to the challenge.

Risk Management and Supply Chain Resilience:

Identifying and mitigating disruption risks, whether they are related to supply chain disruptions, geopolitical issues, or natural disasters, is a key concern today. Ensuring adequate supply while at the same time minimizing cost is difficult given the global cultural, legal, and political differences.

Artificial Intelligence and Advanced Technologies:

Adopting advanced technology such as predictive analytics, machine learning, and data analytics can enhance visibility and efficiency in the supply chain. Incorporating these rapidly changing technologies in OSCM processes is a challenge.

Cross-Border Logistics and Trade Compliance:

Efficient transportation and logistics management are critical for timely delivery and cost-effective operations.

Staying compliant with changing regulations, trade policies, and industry standards can be complex, especially in global supply chains.

Sustainability and Environmental Concerns:

Organizations are increasingly focused on making their supply chains more sustainable and environmentally friendly.

Talent Management

: Recruiting, training, and retaining skilled professionals in OSCM is a critical problem. Management-level workers in the field need a set of skills that range from being technically savvy to being articulate with great communication skills. People with these skills are uniquand highly sought after. The opportunities are great for those up to the challenge.

Just-in-time

An integrated set of activities designed to achieve high-volume production using minimal inventories of parts that arrive exactly when they are needed.

Total quality control

Aggressively seeks to eliminate causes of production detects.

Lean manufacturing

Term used to refer to the set of concepts relating to JiT and TQC.

Mass customization

The ability to produce a unique product exactly to a particular customer's requirements.

Profit margin

Net income/annual sales

Asset turnover

Net sales/total assets

Return on assets

Net income/total assets

Strategy, processes

that can deliver the products and services, and analytics that support the ongoing decisions needed to manage the firm. Our goal in this book is to introduce students to basic operations and supply chain concepts so they understand how things should be done and the importance of these functions to the success of the firm.

Cotton farming

is a process that typically runs on a yearly cycle with planting starting in the early spring. It takes 6 to 7 months for cotton to grow during which time farmers need to irrigate, fertilize, and weed their crops. The ripe cotton fiber from the plant is then harvested using a mechanical cotton picker. A cotton gin is then used to separate the seeds from the cotton fiber. Finally, the sticky cotton fiber is cleaned and packaged in bales for shipment to cotton markets. Cotton is a globally produced commodity and often sold before it is even produced using auctions with delivery set for dates in the future.

Denim fabric

is made by spinning cotton into thin strands of threadlike yarn. The classic denim fabric is blue in color, so some of the yarn is dyed with a blue indigo dye. Four strands of yarn, one white for every three blue, are woven to make the fabric that is then transported to a jeans manufacturing plant.

operations and supply chain

take on special meaning. Operations refers to manufacturing and service processes that are used to transform the resources employed by a firm into products desired by customers. For example, a manufacturing process would produce some type of physical product, such as an automobile or a computer. A service process would produce an intangible product, such as a call center that provides information to customers stranded on the highway or a hospital that treats accident victims in an emergency room. Planning the use of these processes involves analyzing capacity, labor, and material needs over time. Ensuring quality and making ongoing improvements to these processes are needed to manage these processes.

Supply chain refers

to processes that move information and material to and from the manufacturing and service processes of the firm. These include the logistics processes that physically move product, as well as the warehousing and storage processes that position products for quick delivery to the customer. Supply chain in this context refers to providing products and service to plants and warehouses at the input end and also to the supply of products and service to the customer on the output end of the supply chain.

Operations and supply chain processes can be conveniently categorized, particularly from the view of a producer of consumer products and services, as planning, sourcing, making, delivering, and returning. * Exhibit 1.2 depicts how these processes are linked when operating in a supply chain. The following describes the work involved in each type of process.

Planning

consists of the processes needed to operate an existing supply chain strategically. Here, a firm must determine how anticipated demand will be met with available resources. A major aspect of planning is developing a set of metrics to monitor the supply chain so that it is efficient and delivers high quality and value to customers.

Sourcing

involves the selection of suppliers that will deliver the goods and services needed to create the firm's product. A set of pricing, delivery, and payment processes are needed together with metrics for monitoring and improving the relationshipt between partners of the firm. These processes include receiving shipments, verifying them, transferring them to manufacturing facilities, and authorizing supplier payments.

Making

is where the major product is produced or the service is provided. The step requires scheduling processes for workers and coordinating material and other critical resources such as the equipment to support producing or providing the service. Metrics that measure speed, quality, and worker productivity are used to monitor these processes.

Delivering

also referred to as a logistics process. Carriers are picked to move products to warehouses and customers, coordinate and schedule the • movement of goods and information through the supply network, develop and operate a network of warehouses, and run the information systems that manage the receipt of orders from customers and the invoicing systems that collect payments from customers.

Returning

involves processes for receiving worn-out, defective, and excess products back from customers and support for customers who have problems with delivered products. In the case of services, this may involve all types of follow-up activities that are required for after-sales support.

Total quality management (TQM)

Managing the entire organization so that it excels on all dimensions of products and services that are

d recognizes companies

important to the customer.

Business process reengineering (BPR)

An approach to improving business processes that seeks to make revolutionary changes as opposed to evolutionary (small) changes.

Six Sigma

A statistical term to describe the quality goal of no more than 3.4 defects out of every million units. Also refers to a quality improvement philosophy and program.

What are the three elements that require integration to be successful in operations and supply chain management?

Multiple Choice

Products, processes, and people

Strategy, information, and processes

Strategy, products, and processes

Strategy, processes, and analytics

Strategy, processes, and analytics

Operations and supply chain management is concerned with the design and management of the entire system that has what function?

Multiple Choice

の

Operates the distribution of goods

Employs people and produces a product

Creates and delivers a firm's products and services

Procures, sells, and transports goods

Creates and delivers a firm's products and services

What is the name of the process in which one company studies the processes of another firm to identify best practices?

Scored

eBook

Multiple Choice

References

Benchmarking

Outsourcing

Continuous improvement

Business analytics

Benchmarking

A company has recently implemented an automated online billing and payment processing system for orders it ships to customers. As a result, it has reduced receivables by $500,000. What would be the expected directional change in the asset turnover ratio?

1/1

points awarded

Scored

eBook

References

Multiple Choice

It will remain the same.

It will increase.

It will decrease.

It may increase, decrease, or remain the same.

We need further information to answer this question.

It will increase.Here total assets would be reduced. Asset turnover is calculated as annual sales ÷ total assets. Since total assets are reduced, the asset turnover ratio would go up.

Plant manager

Oversees the workforce and resources required to produce the firm's products.

Supply chain manager |

Negotiates contracts with vendors and coordinates the flow of material inputs to the production process.

Project manager

Plans and coordinates staff activities such as new-product development and new-facility location.

Business process improvement analyst |

Applies the tools of lean production to reduce cycle time and eliminate waste in a process.

Logistics manager |

Oversees the movement of goods throughout the supply chain.

Quality control manager-

manager-Applies techniques of statistical quality control, such as acceptance sampling and control charts, to the firm's products.

Lean improvement manager

manager-Trains organizational members in lean production and continuous improvement methods.

Production control analyst

Plans and schedules day-to-day production.

What high-level OSCM position manager is responsible for working with the CEO and company president to determine the company's competitive strategy

Supply chain planner

Strategy consultant

Plant manager

Chief operating officer

Chief operating officer

Order the following major concepts that have helped define the OSCM field on a time line. Use 1 for the earliest concept to be introduced, and 5 for the most recent.

Supply chain management | |

Manufacturing strategy | |

Business analytics | |

Total quality management | |

Electronic commerce | |

Supply chain management | 3 |

Manufacturing strategy | 1 |

Business analytics | 5 |

Total quality management | 2 |

Electronic commerce 4 | |

Which major OSCM concept can be described as an integrated set of activities designed to achieve high-volume production using minimal inventories of parts that arrive at workstations exactly when they are needed?

Multiple Choice | |

Coordinated production planning | |

Integrated systems management | |

Supply chain management | |

Just in time production |

Just-in-time (JIT) production |

Operations and supply chain ______.

leverage the vast amount of data in enterprise resource planning systems to make decisions related to managing resources.

Multiple Choice

planning

processes

management

informatics

analytics

analytics

Which current issue in OSCM relates to the ability of a firm to reconfigure its retail stores, warehouses, and other facilities.

Multiple Choice

Accommodating the shift to online retail purchasing

Coordinating the relationships between mutually supportive but separate organizations

Optimizing giobal supplier, production, and distribution networks

Managing customer touch points

Accommodating the shift to online retall purchasing

Asset turnover is calculated

annual sales ÷ total assets.