L3- Fracture Resistance as Energy Release Rate

1/23

There's no tags or description

Looks like no tags are added yet.

Name | Mastery | Learn | Test | Matching | Spaced | Call with Kai |

|---|

No analytics yet

Send a link to your students to track their progress

24 Terms

Fracture energy in an ideal system

twice the surface energy ( must create 2 surfaces during fracture)

i.e. G = 2γ

Fracture energy, G

energy needed to propagate a crack

Equation for energy release rate, G

G = -dΠ/dA

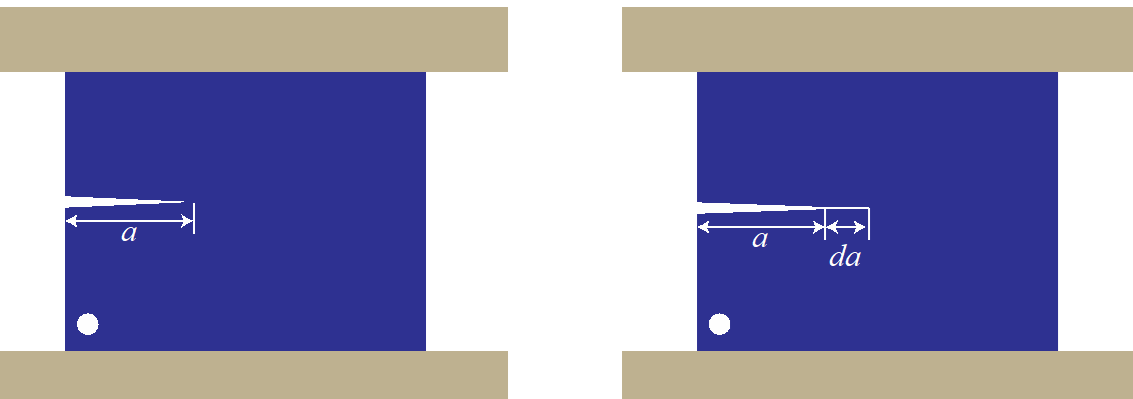

A = area of crack plane ( 2aB)

B = width of plane

P=UE-F

Gc

measure of the fracture toughness of a material

Equation for Gc (Jm^-2)

Gc= dWs/dA = 2wf

Wf = fracture energy

When will crack growth occur ?

when G = Gc= 2wf

Conditions for stable crack growth

G=R

dG/da ≤ dR/da

, R = material resistance to crack extension

a = crack length

Conditions for unstable crack growth

dG/da > dR/da

Assuming 2Wf = R:

Consider 2 possibilities:

R = constant + so independent of crack length

R increases as crack length increases

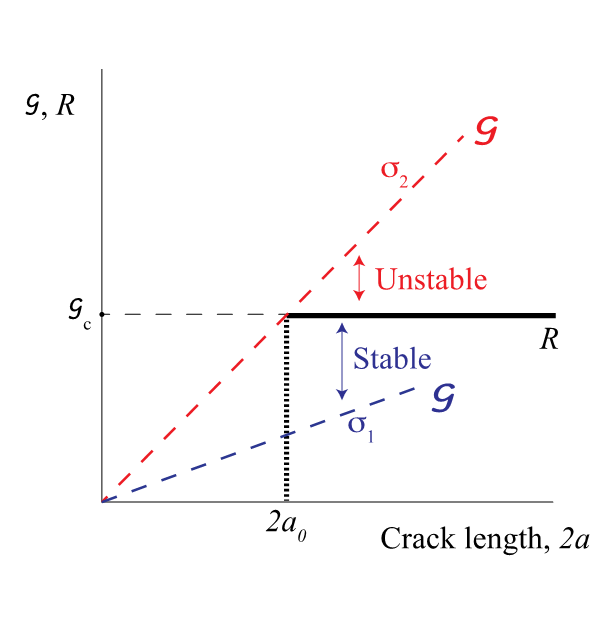

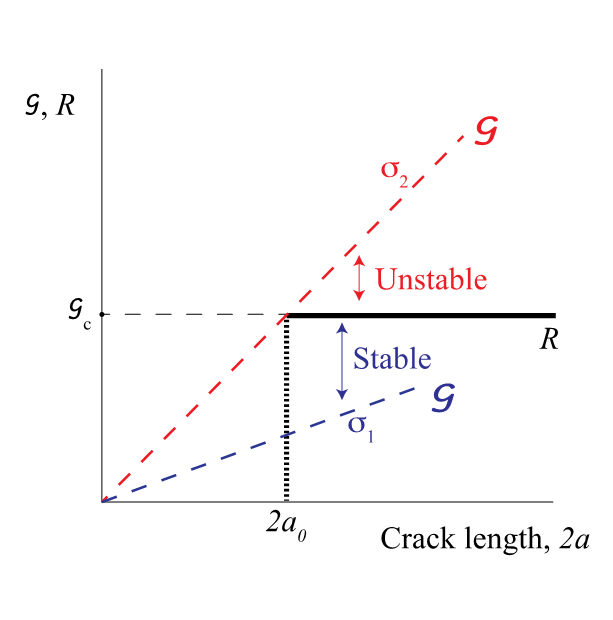

Case 1: R independent of crack size

If G below R, crack will not grow hence stable until Gc = reached, Gc = R

At σ2 fracture occurs + crack propagation = unstable i.e. G grows but R stays constant

2ao = defect size

Effect of size of defect on energy release rate, G

The bigger the defect, the greater the energy release rate

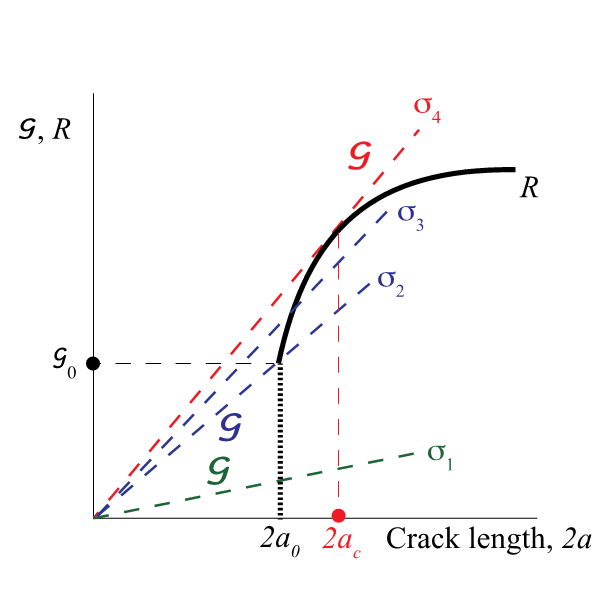

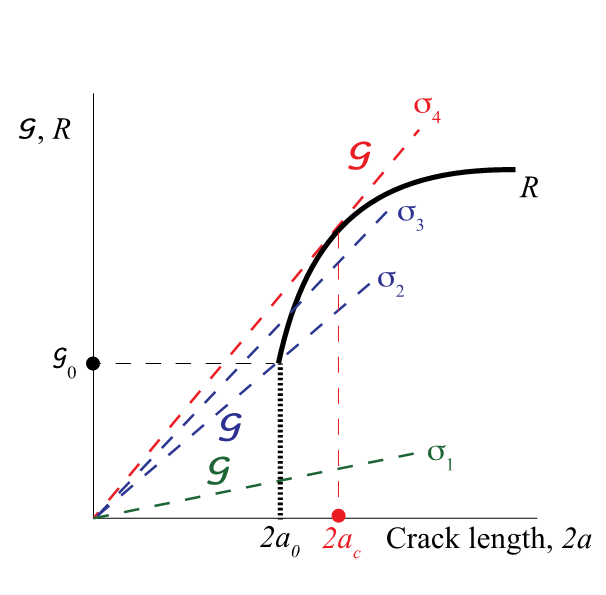

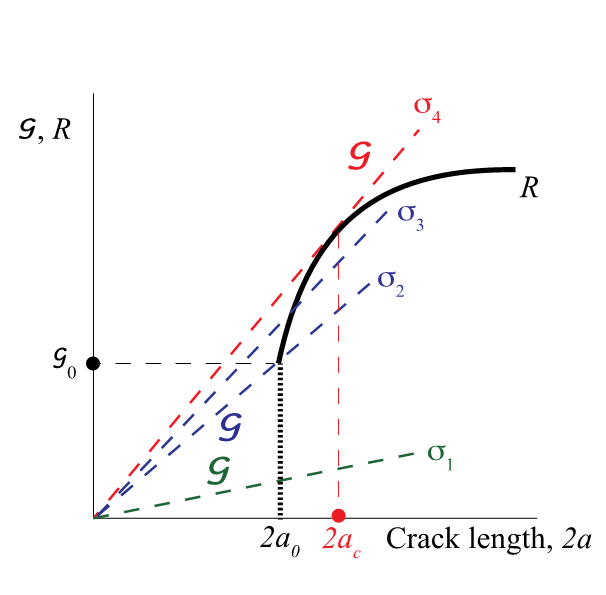

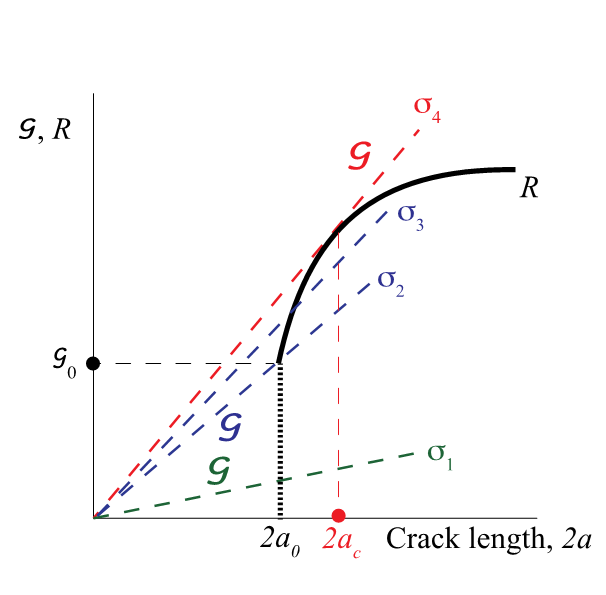

Case 2: R grows with crack size

For applied σ1, crack = stable

At σ2 → cracks starts growing but stops as rate of growth of R > G

At σ3 → crack propagates further but stops immediately as rate of growth R > G

At σ4 ( critical stress at which crack = unstable) → crack unstable as G grows faster than R.

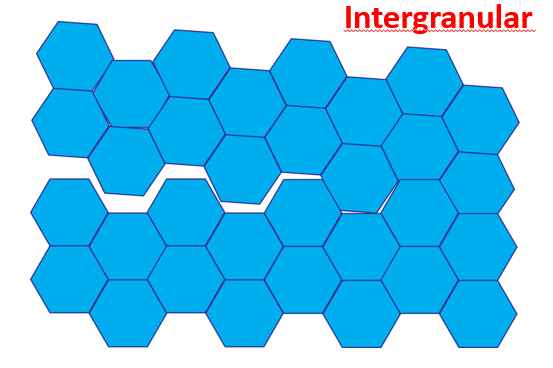

Types of fracture in polycrystalline materials:

Transgranular/intragranular

Intergranular

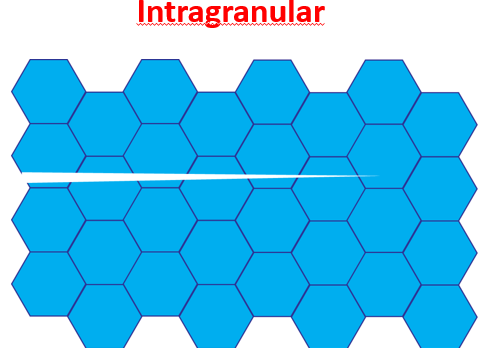

Transgranular/intragranular fracture

Crack propagates across grains

Intergranular

Crack propagates along grain boundaries

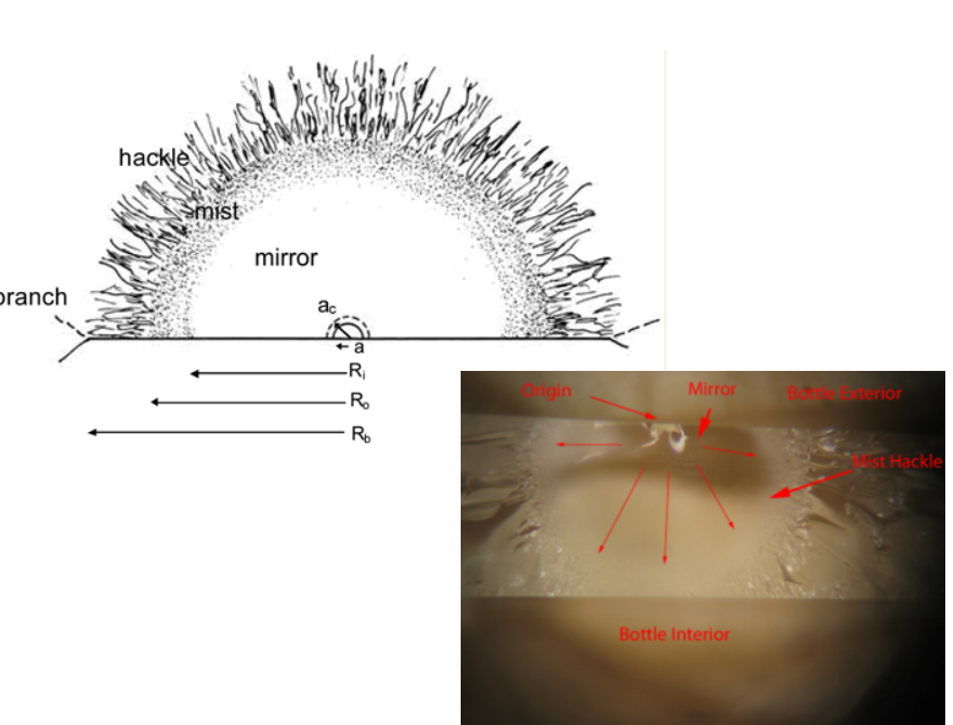

3 zones in fracture surfaces

Mirror

Mist

Hackle

Mirror

smooth regions surrounding + centred on fracture origin

Mist

Markings on surface of accelerating crack close to term velocity

First has misty appearance

As v increases, fibrous texture, elongated in direction of cracking

Hackle

A line on surface, running in local direction of cracking

separating parallel but noncoplanar portions of crack surface

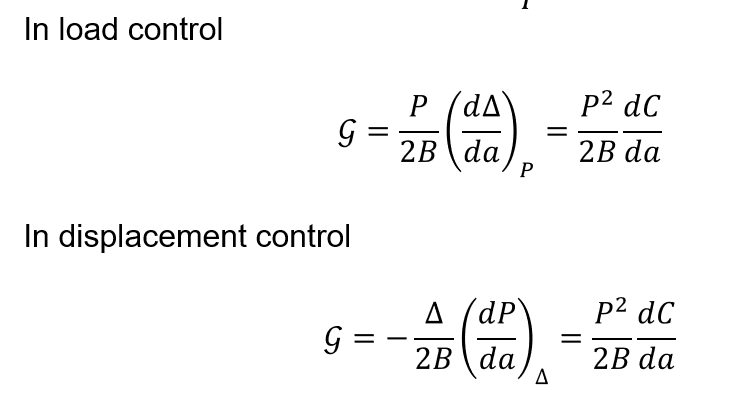

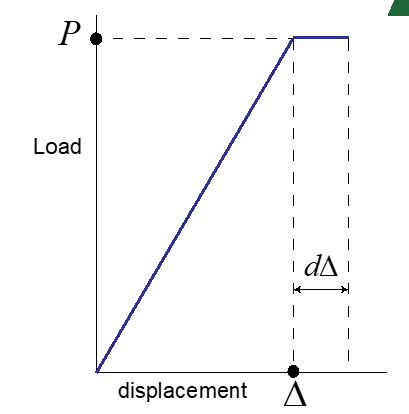

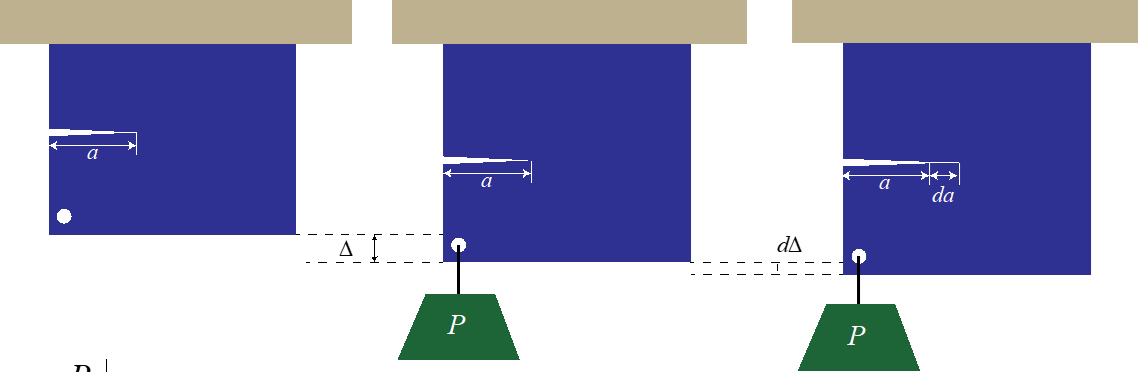

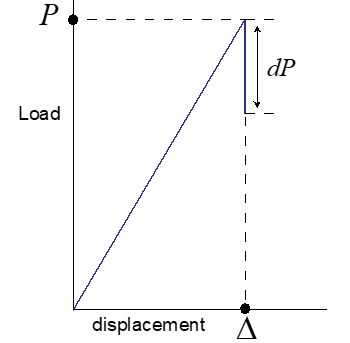

Load control

If the thickness of the sample is B, dA=Bda

Then

G=1/B (dUE/da) at constant P=P/2B (d∆/da) at constant P

Displacement control

Recording how load changes as crack grows

G=-1/B (dUE/da) const∆=-∆/2B (dP/da) const∆

B = thickness

Compliance

Inverse of stiffness

Eqn for Compliance

∆/P

∆ = displacement

P = load

Equation for G in load/ displacement control