Turbine Engine Overhaul (Jeppesen Powerplant 4-B)

0.0(0)

Card Sorting

1/32

Earn XP

Description and Tags

4-18 through 4-40, only the overhaul portions and terms related to overhaul.

Last updated 7:56 PM on 4/30/23

Name | Mastery | Learn | Test | Matching | Spaced | Call with Kai |

|---|

No analytics yet

Send a link to your students to track their progress

33 Terms

1

New cards

Who can overhaul a turbine engine?

* The Manufacturer

* An approved overhaul facility (Repair station)

* An approved overhaul facility (Repair station)

2

New cards

What are the general steps in an engine overhaul?

1. Disassembly

2. Cleaning

3. Inspection

4. Remove & Replace

5. Reassembly

6. Testing

3

New cards

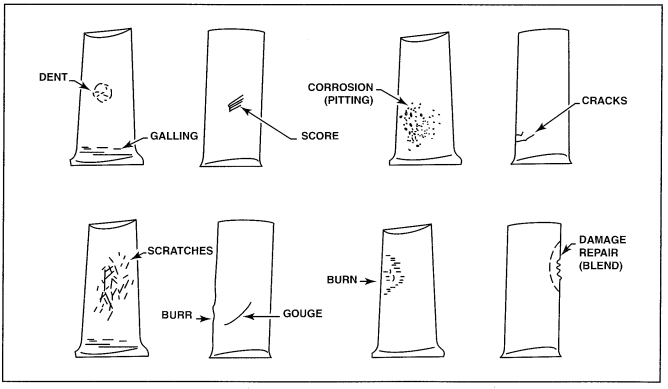

INSPECTION TERMS

__**Blending**__

__**Blending**__

A method of filing compressor or turbine blades and vanes to remove damage and reestablishing the appropriate contour for an aerodynamic shape.

4

New cards

INSPECTION TERMS

__**Blistering**__

__**Blistering**__

Raised areas that indicate a separation of a surface layer from a base metal. Blistering is often evident as peeling (or flaking) of a metal plating.

5

New cards

INSPECTION TERMS

__**Bow**__

__**Bow**__

A stress-induced bend or curve in a blade's contour.

6

New cards

INSPECTION TERMS

__**Bulge**__

__**Bulge**__

An outward bending or swelling caused by excessive pressure or weakening due to excessive heat.

7

New cards

INSPECTION TERMS

__**Compression**__

__**Compression**__

A squeezing force produced by two opposing forces acting on a part.

8

New cards

INSPECTION TERMS

__**Creep**__

__**Creep**__

A condition of permanent elongation in rotating airfoils resulting from thermal stress and centrifugal loading. Creep is also referred to as growth.

9

New cards

INSPECTION TERMS

__**Dynamic Balancing**__

__**Dynamic Balancing**__

A procedure used to balance the main rotating assembly of a turbine engine along both its rotational plane and the rotor axis.

10

New cards

INSPECTION TERMS

__**Electrolytic Action**__

__**Electrolytic Action**__

Breakdown of surfaces caused by electrical activity between dissimilar metals. Electrolytic action is also known as galvanic corrosion.

11

New cards

INSPECTION TERMS

__**Flowing**__

__**Flowing**__

The spreading out of a plated or painted surface caused by poor adhesion to the base or excessive loading on the part's surface

12

New cards

INSPECTION TERMS

__**Galling**__

__**Galling**__

The fretting ( or chafing) of a mating surface by sliding contact with another surface or body.

13

New cards

INSPECTION TERMS

__**Glazing**__

__**Glazing**__

The development of a hard, glossy surface on bearing surfaces in the presence of oil, heat, and pressure.

14

New cards

INSPECTION TERMS

__**Growth**__

__**Growth**__

A term synonymous with creep.

15

New cards

INSPECTION TERMS

__**Guttering**__

__**Guttering**__

Deep concentrated erosion that results from an enlargement of cracks or repeated exposure to a concentrated flame.

16

New cards

INSPECTION TERMS

__**Profile**__

__**Profile**__

The contour or aerodynamic shape of a blade or surface.

17

New cards

INSPECTION TERMS

__**Shear**__

__**Shear**__

A tearing force produced by two opposing, parallel forces acting on a part.

18

New cards

INSPECTION TERMS

Static Balancing

Static Balancing

A procedure that balances the main rotating assembly of a turbine engine to reduce vibration

19

New cards

INSPECTION TERMS

Tension

Tension

A force that tends to pull an object apart.

20

New cards

INSPECTION TERMS

Untwist

Untwist

A straightening and loss of blade curvature that results from gas loads, thermal stress, and centrifugal loading.

21

New cards

What is a blisk?

A turbine wheel that incorporates the blades and disk in one piece

22

New cards

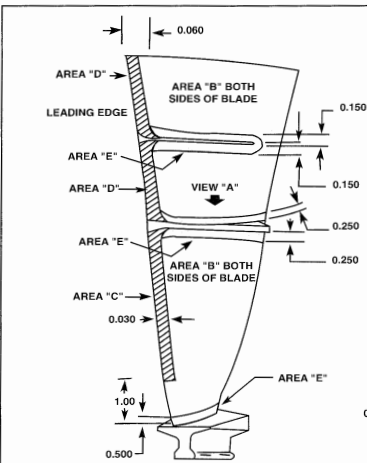

What is the purpose of blending a compressor or turbine blade?

* Reduce concentrated stresses at sharp points in the blade

* reduce the possibility of the crack or defect spreading

* reduce the possibility of the crack or defect spreading

23

New cards

Common defects found in the combustion section of a turbine engine

* Cracks

* Burner-can shift

* Hot spots or scorched areas

* Warpage

* Erosion

* Excess weld material over welded repair seams

* Burner-can shift

* Hot spots or scorched areas

* Warpage

* Erosion

* Excess weld material over welded repair seams

24

New cards

Hottest part of a turbine engine?

The first set of turbine nozzle vanes

This makes them susceptible to the most cracking and stress

This makes them susceptible to the most cracking and stress

25

New cards

You should replace a cracked component whenever cracks appear to be ________

Converging

26

New cards

What is Primary Creep?

Creep related to an engines first run

27

New cards

What is Secondary Creep?

Creep that happens slowly over many hours of operation

28

New cards

What is Tertiary Creep?

Creep related to hot starts, overtemp events, and extended high power operation

\

**This is the one that is dangerous and warrants Turbine Over Temperature (TOT) inspections.**

\

**This is the one that is dangerous and warrants Turbine Over Temperature (TOT) inspections.**

29

New cards

As a general rule, where on a turbine or compressor blade is NO damage allowed?

Near the blades base or, if shrouded, where the blade meets the shroud

30

New cards

What are the typical options when repairing a combustion liner?

* Weld (or reweld) cracks

* Replace liner

* Replace liner

31

New cards

Why is balancing critical for rotating assemblies on a turbine engine?

High rotational speeds can cause severe vibration if parts are unbalanced

32

New cards

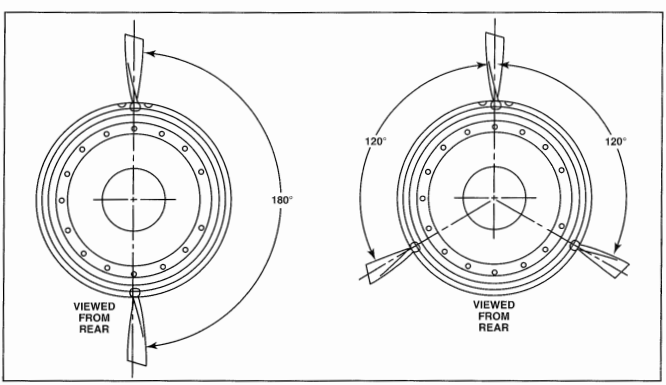

When replacing turbine or compressor blades, what is the general procedure?

If the blades are marked with their weight, you can install just one, given the weights of the other blades are approximately the same. you may have to install more than one new blade if the engine blades have been worn over time. This is done to ensure proper balancing.

\

On wheels that have an even number of blades, 2 blades can be installed 180 degrees apart

On wheels that have an odd number of blades, 3 blades can be installed 120 degrees apart

\

On wheels that have an even number of blades, 2 blades can be installed 180 degrees apart

On wheels that have an odd number of blades, 3 blades can be installed 120 degrees apart

33

New cards