Ceramics final

1/95

Earn XP

Description and Tags

fuq this bald headed rat bro

Name | Mastery | Learn | Test | Matching | Spaced |

|---|

No study sessions yet.

96 Terms

Ceramics

Ingorganic compound made with nonmetals properties typically composed of metallic (or semi-metallic) or non metallic elements

Composed of compounds including porcelain and similar ceramic material

Dental ceramics

materials part of a system designed with the purpose of producing dental prostheses that in turn are used to replace damaged or missing dental structure

why do we use ceramics?

Strength: resists wear

Biocompatibility: thermal properties, impervious to oral fluids, chemically inert

Form: ability to form complex shapes

Esthetics: multitude of colours and effects

Indications of ceramics

copings

Bridge frameworks

Splinted teeth

Inlays, onlays

Crowns

Implants

Veneers

Denture teeth

Orthodontic brackets

Post and cores

what can be made of dental ceramics?

Metal Ceramic Restorations ( crowns, bridges, Maryland bridges) - known as porcelain fused to metal (PFM)

Advantage of strength as well as esthetic

CAD/CAM: Veeners, crowns, inlays, onlays, bridges, implants - can be designed and milled - all ceramic

Pressable/Castable Dental Ceramics: Veeners, crowns, inlays, onlays, bridges - ceramic ingots are brought to high temperature and pressed into an investment mold using lost wax technique - all ceramic

Other restorations like implants, orthodontic brackets, and denture teeth.

What is the fusing temperature of high fusing ceramics? (Denture teeth, sintered alumina and zirconia)

1315-1370 degrees celcius

What is the fusing temperature for medium fusing ceramics? (All ceramic restorations)

1090-1260 degrees celcius

What is the temperature for low fusing ceramics? (Metal ceramic restorations)

870-1065 degrees celcius

What is the fusing temperature for ultra low fusing ceramics? (Layering overall ceramic, or low melting point alloys)

< 850 degrees celcius

Feldspar (KAISI3O8):

layering ceramic (mined)

Leucite (KAISi2o6):

Used for pressable frameworks

Lithium Disilicate (Li2Si2O5)

Can be pressed or milled

Alumina (Al2o3):

used for frameworks only, always milled

Zirconia (ZrSiO4):

always milled, can be used for single units, multi units or frameworks

Porcelain:

tooth colored dental ceramic materials that are composed of feldspar, quartz, kaolin and pigments

Porcelain more closely resembles glass

Feldspar chemical composition

Mixture of two substances : Potash feldspar (K2O-Al2-O3-6Sio2) AND Sodium feldspar (Na2O-Al2O3-6SiO2)

What are the properties of potash feldspar?

Translucent

Fuses with quartz to become glass

Aka potassium sodium silicate

Increases viscosity, controls pyroplastic flow during sintering

What are the properties of sodium feldspar?

Lowers fusion temperature

Increases pyroplastic flow

Aka sodium aluminum silicate

No optical qualities, does not contribute to translucency

What are the properties of quartz? (SiO2)

Aka silica

High fusion temperature

Framework

Prevents pyroplastic flow during sintering

Strengthens fired porcelain

What are the properties of Alumina (Al2O3):

Hardest and strongest oxide

Increases strength and viscosity of dental porcelain

What are the properties of Kaolin (Al2O3-2SiO2-2H2O:

Initially added to act as a binder and increase mold ability

Gave greater mass

Enabled for it to be carved

Opaquing qualities

Has been removed from composition of metal ceramic porcelain

Sintering:

to bring the agglomeration (stick- togetherness) of certain materials through heating

Clay particles sinter before they begin to melt into a glassy state (Vitrification)

Furnaces

firing furnaces are programmed according to type of porcelain being fired and the manufacturers recommendation for each

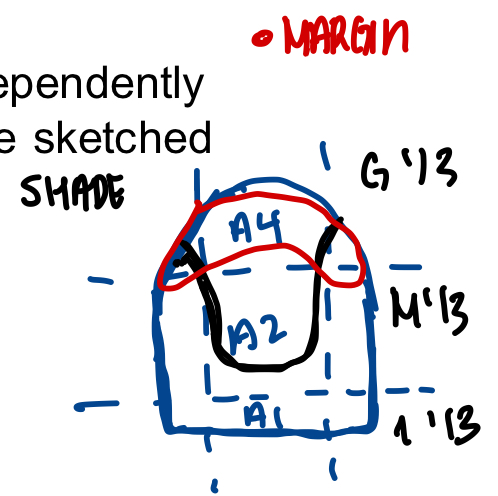

Components of metal ceramic restoration

Metal Substructure

Oxide layer (key role in bonding, alloy specific)

Opaque layer (establish porcelain - metal bond, masks substructure, initiate shade selection

Dentin (bulk of restoration, initial porcelain layer, associated with gingival 2/3 of shade, major shade contribution)

Enamel: (provides natural translucency, incisal 1/3 and interproximal, restricted range of shades

External glaze (Final step, provides natural lustre)

What are the other types of porcelain?

Opaceous dentin (deep dentin) - used to mask silhouette of the coping, used when minimal porcelain is required

Body modifiers - more color concentrated (internal color modification) , used for custom shading

Stains and glazes - surface characterization and color modification, fill surface porosities and irregularities, recreate sheen and natural appearance

Armamentarium (equipment lol)

Facial tissue

Sponge

Distilled water

Porcelain brushes

Glass/slab tile

Porcelain separator

Serrated instrument

Whipping brush

Spatula (glass)

Red pencil

Hemostats

Sagger tray

Oxidation

Process of heat treating a metal ceramic alloy to produce an oxide layer for porcelain bonding

Dispels gases absorbed by metal during casting (potentially causing bubbles in porcelain)

What are the four theories? (Mechanisms)

Van der waals forces

Mechanical retention

Compression bonding

Direct chemical bonding

Van der waals forces

attraction between charged atoms that are in intimate contact yet do not actually change electrons

Weak attraction, increased by wetting

Mechanical retention

Areas of metal casting where porcelain is applied has microscopic irregularities into which the porcelain will flow when fired

compression bonding

dental porcelain is strongest under compression and weakest under tension

chemical bonding

oxide layer is permanently bonded to metal substructure while porcelain on other side,

Surface oxides dissolve or are dissolved by opaque layer

What is the purpose of opaquing metal substructures?

To establish the porcelain to metal bond

Mask color of metal substructure

Initiate developement of selected shade

Why porcelain margins?

esthetics

Marginal accuracy

Biocompatibility

Porcelain margin (recap)

Porcelain margin helps avoid metal visibility, tissue discoloration and possible over building of the gingiva

What is the most common type of margin prep?

Chamfer

Whats another type of margin used?

deep shoulder

Translucency

effect that is characteristic with a material that does not allow the object behind it to be readily visible

Translucency most evident on incisal 1/3rd and proximal surfaces of natural teeth

More thinner - more translucent

(Bakes at different temps and initiates diff levels of thickness)

Surface texture - light reflection

surface texture of porcelain must be adapted to the adjacent natural teeth

perichymata

fine, transverse wavelike grooves believed to be the external manifestations of the striae of retzius

Colour influenced by 3 main factors

object - physical properties

Observer - assessment

Light - nature of incident

relationship to other coloured objects

What are the 3 types of quality of light?

incandescent light

Fluorescent light

Natural daylight

Which quality of light is more ideal?

natural daylight

Incandescent light

emits high concentration of yellow waves

Not suitable for shade matching

Fluorescent light

emits high concentration of blue waves

Not suitable for shade matching

Natural daylight

Ideal

Closest to emitting full spectrum of white light

Used as standard

What Are the 3 dimensions of colour?

Hue

Chroma

Value

Hue

Dimension that describes colour

Chroma

the dimension which describes intensity, strength or saturation of a given hue

Value

dimension that describes the proportion of white or grey in a hue (the more white in a hue, the higher the value (bright), the more grey the lower the value (dull).

Can also be referred to as brilliance

Opaque

will not permit passage of light

transparent

will permit passage of light with little or no distortion

translucent (light)

will permit the passage of light

Translucency of natural teeth

light diffuses through various layers, illustrating different degrees of translucency

Shade selection

subjective evaluation with considerable variation

Subtle variations can exist without causing disharmony in smile (restoration color)

Value of restoration

Process improved by applying principles of light and color

Would the value be higher (brighter) if a tooth is dehydrated?

yes

can a patient have up to 4 shades?

yes

Monochromatic

one color

monolythic

one single, solid uniformed material

Vita Classic Shade Guide

A - red yellow

B - yellow

C- grey

D- red - yellow - grey

Ex: A3 - hue of red-yellow, chroma of 3

Factors of accurate shade taking

Lighting - daylight or neutral light

Gingival colour - darker gingiva = greater contrast on colour tab

Background colours - disruptive influence

Colours of surrounding - grey is most neutral

shade mapping

Tooth is divided into 3 regions, 9 segments

Each region matched independently

Craze lines

Hypocalcifications

Proximal discolorations

Translucency

What pressure should the sandblasting machine be set to?

125um at a pressure bar of 2

What causes a dark margin on a new crown?

excess separator absorbed into the powder when creating a porcelain margin

Incorrect opaquing of margin

How do you condense porcelain?

vibrating the ceramic or drying the die underneath a warm furnace of 250 - 300 C > 30s to remove excess moisture

T or F? The more moisture in a ceramic powder, the more shrinkage in the furnace

True

Can you seal a margin in one bake?

no, standard for margin porcelain is 2 margin applications

T or F? Establishing emergence profile with margin powder, the gingival 1/3rd of the crown should establish with margin material - the rest of ceramic over margin material will feather out

True

Why would you need to check the inside of a crown when removing it from furnace?

can chip the die/affect the fit

T or F? Bands on PFMS should align with marginal ridge/central groove of adjacent teeth

True

T or F? Do you need to create a 360 band when given a 360 knife edge?

True, cannot bring material to a point (results in an over contoured emergence profile)

Do you place margin powder on a Pontic to mimic the same natural appearance?

yes, can help achieve a natural look

What should you do when doing a second firing? (Margin)

add margin powder on the die rather than adding it separately on crown and then pushing it down on the die

What type of margin can accept porcelain margin?

chamfer (ideal) shoulder, rounded shoulder

T or F? Margins are finished in either metal or ceramic

True

fluorescents

imitate way natural teeth look at cervical

True or False? Shape and contour is NOT important, especially on anterior tooth

False

True or False - incisal edge does not influence the long axis?

False - if one is off, the other is also off

What is a line angle?

angle where proximal meets facial

Mesial line angle

mirror image of adjacent tooth

Distal line angle

can be adjusted slightly to create symmetry, depending on the restorative space available

Lingual concavity

Often undertrimmed/preserved by dentist due to pulp being close to surface

Lingual area is delicate which is why we trim to min required thickness on copings (0.3mm)

Layering on lingual concavity

do not add all layers of porcelain in lingual concavity to avoid over contouring

True or false? Each powder has specific optical properties designed to mimic natural teeth

true

Can you later all the powders during application?

no, it will not look natural

What is minimum thickness for metal preparation?

0.3mm for noble metal alloys

0.2mm for base metal alloys due to higher melting ranges and yield strenght

Polychromatic

more than one colour (gradient)

What variables can affect crown fit?

impression material

Gympsum type

Degree of movement in mouth (periodontal ligaments does not exist on model)

Temporary crown (improper fit: too high, effects VDO or patient losing temp crown can result in overruption of teeth)

Model equilibration : to mitigate these variables, equilibrium the model multiple times for proper contacts

what is the purpose for a second pour?

replicates soft tissue, able to check emergence profile, also aids in checking fit/esthetics of crown on a complete model

Dentists rely on second pour to verify crowns fit

what are the 3 glazing methods?

manual glaze (paste or powder glaze)

Self glaze (ceramic glazes itself after firing)

Manually polish

True or False? can you use add on powder to make minor corrections?

True - use 50-50 mix

What temperature for oxidation?

925C

What temperature for opaque?

870Cw

what temperature for margin?

840C

what temperature for Deep dentin, dentin and incisal?

790C

What temperature for glaze?

740C