Welding A

1/36

There's no tags or description

Looks like no tags are added yet.

Name | Mastery | Learn | Test | Matching | Spaced | Call with Kai |

|---|

No analytics yet

Send a link to your students to track their progress

37 Terms

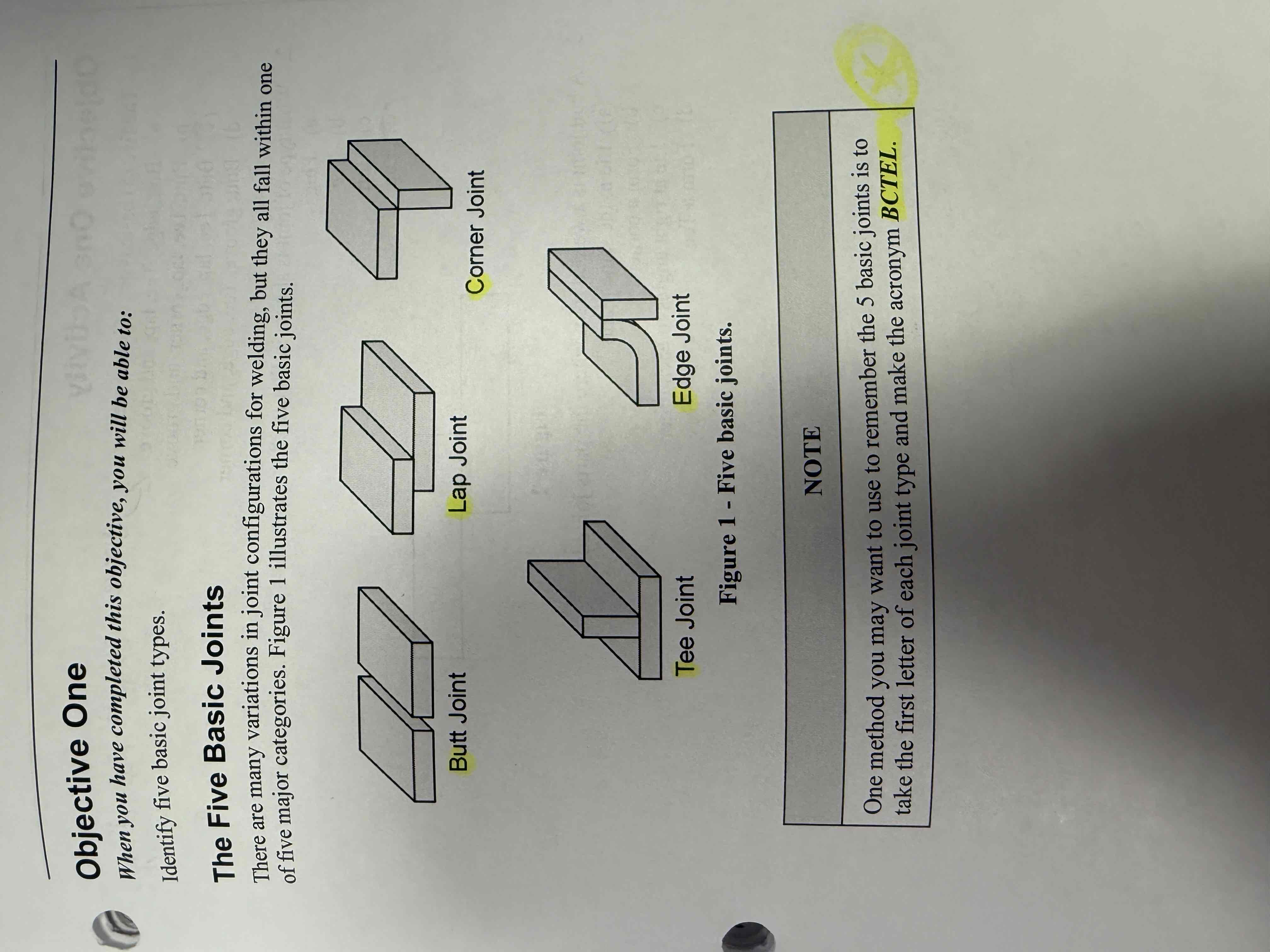

List the 5 basic joint types and application

Butt joint

used extensively in welding industry

Gives maximum strength of joint (full strength weld)

Used when joint is subject to high stress, cyclic, changing loads, critical applications.

Corner joint

Widely used on sheet metal fab

Can be flush corner, half open corner, open corner

Tee joint

often joined via fillet welds

Edge joint

Used extensively to join light gauge sheet metal fabs

Less danger of burn through and reduce distortion

Limitation is that it cannot withstand heavy or dynamic loads

Often welded autogenously (without filler metals)

Lap joint

fillet welds

Highly successful of joining materials of different thicknesses

No special prep

Can be single or double welded

(BCTEL)

What are the 4 weld types

Surfacing weld

beads over a surface

Usually to economically reclaim a metal surface or to return original equipment thickness

2 step: 1. Layer softer and less expensive metal to get thickness required, 2. Layer of hard surface metal over first layer for durability

Plug or slot weld

Drill or flame cut a hole or slot in the plate

common on lap joints

Difference between plug or slot is the shape of the hole in the metal

Fillet weld

Used extensively because no prep needed, but do not produce the highest possible weld strength

found on lap, tee, corner joints

One or more layers of weld metal

Shape of triangle

Groove weld

common on butt joints

Several variations (square groove, bevel groove, vee groove, U groove, J groove)

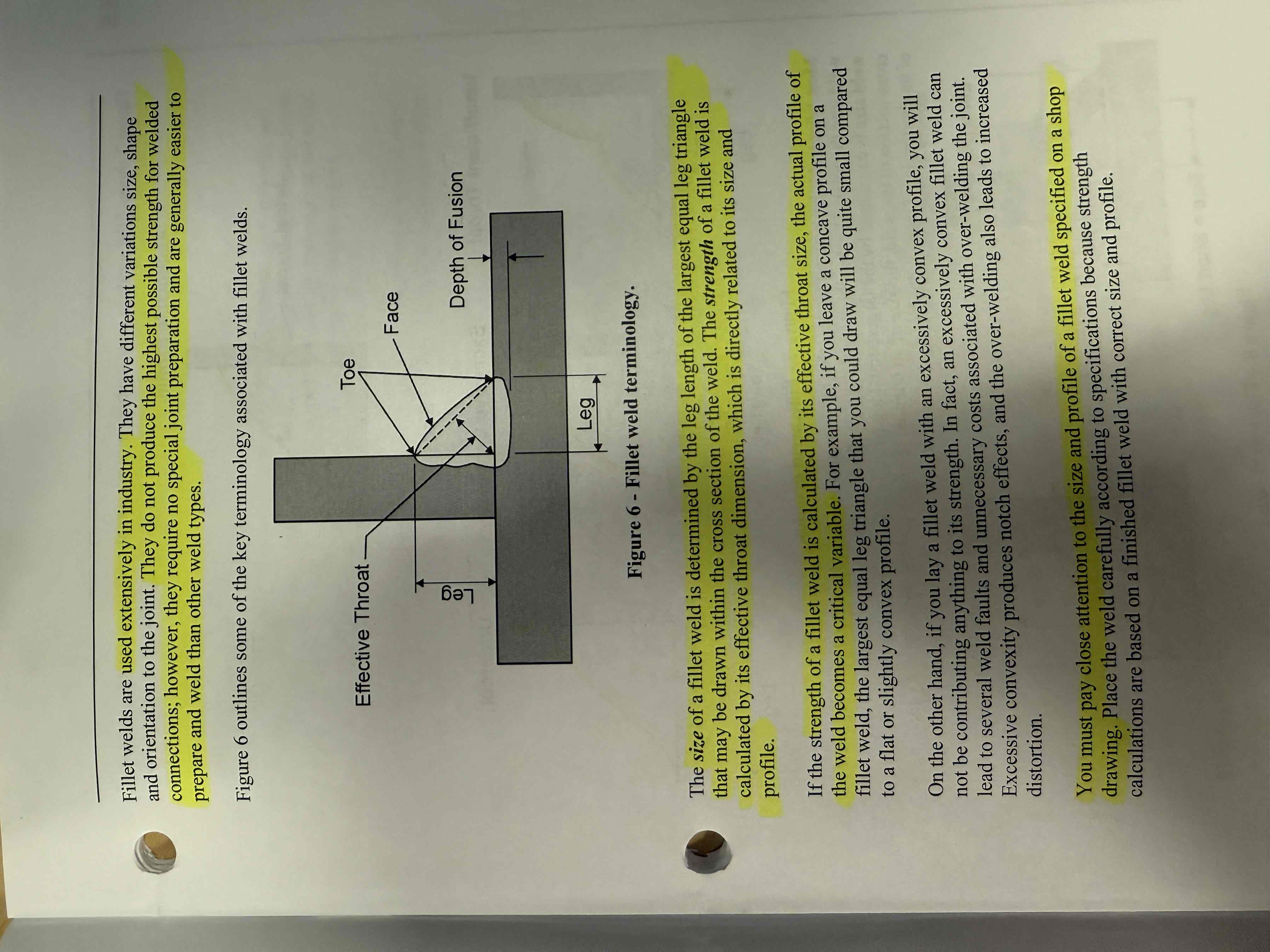

Fillet weld anatomy image (see answer)

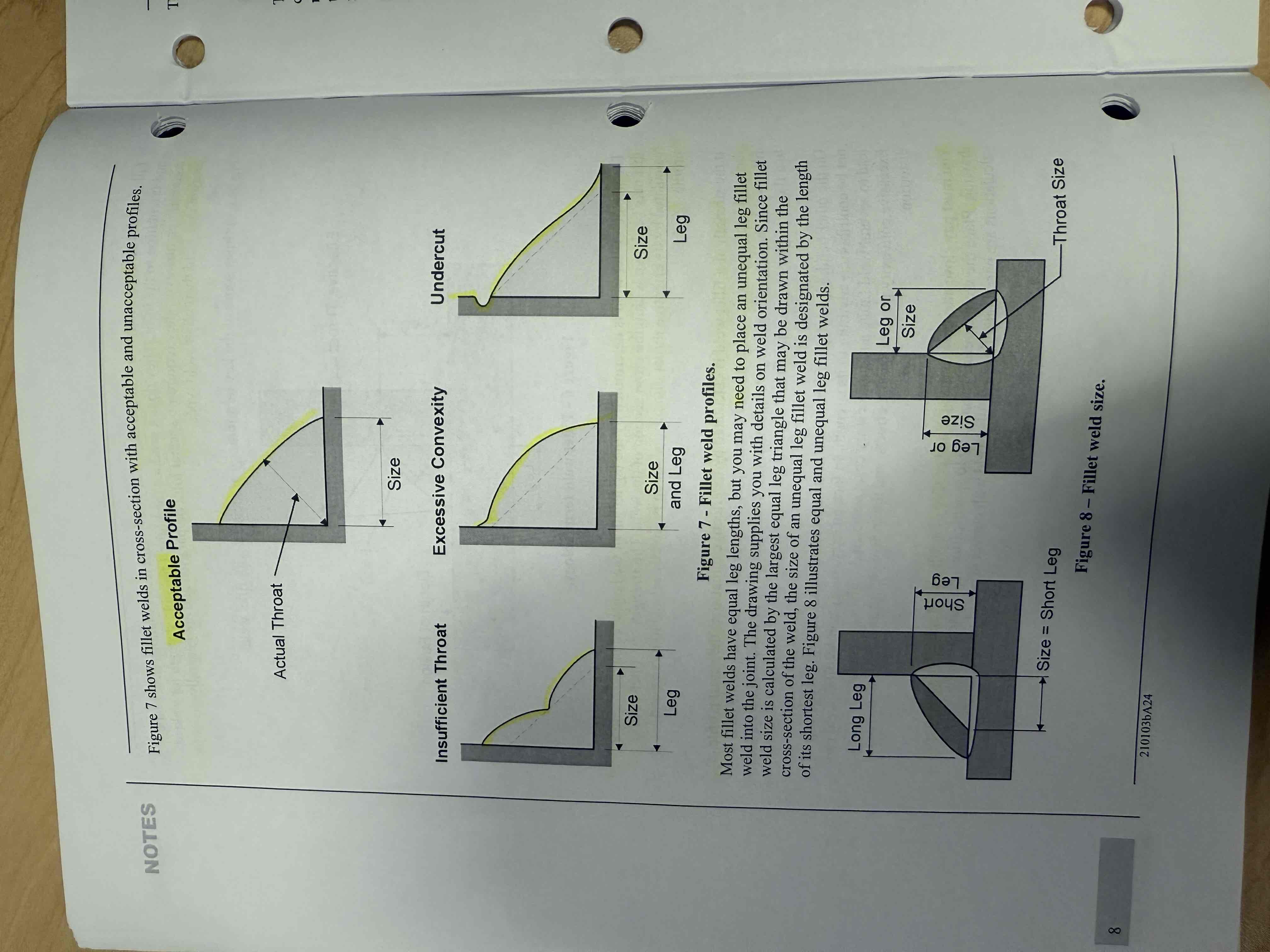

How is the size and strength of a fillet weld determined?

Strength: calculated by “effective throat dimension” which is based off the size and profile of it.

Size: determined by leg length of largest “equal leg triangle” Both legs of the triangle need to be equal for the weld to mean something. You can do this by “stacking welds”

Undercut vs excessive convexity vs insufficient throat image

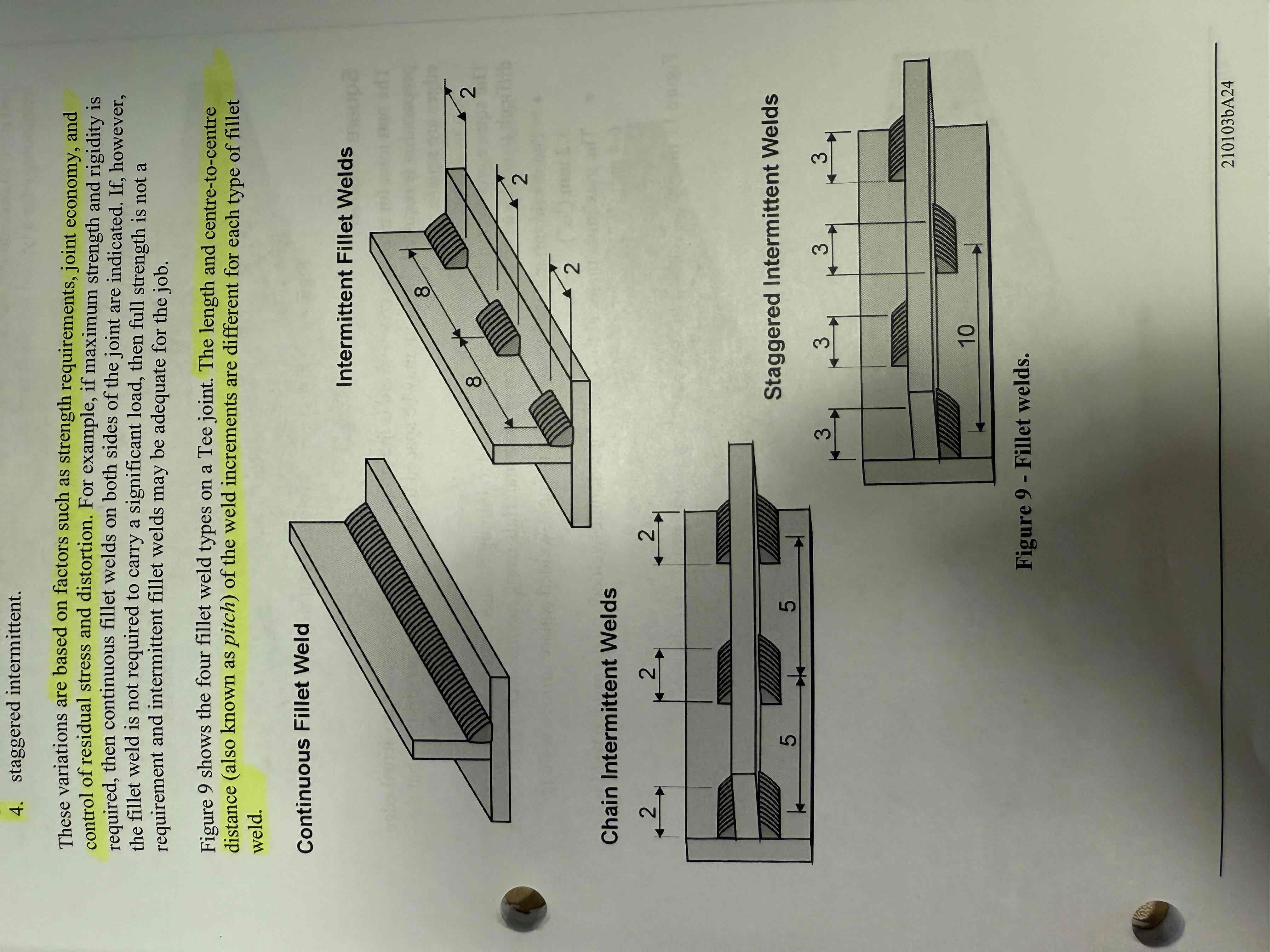

What are the 4 basic variations of a fillet weld?

Continuous

Intermittent

Chain intermittent

Staggered intermittent

based on strength, joint economy, control of distortion/stress

What is the length and centre to centre distanced of weld increments called (when fillet welding)

Pitch

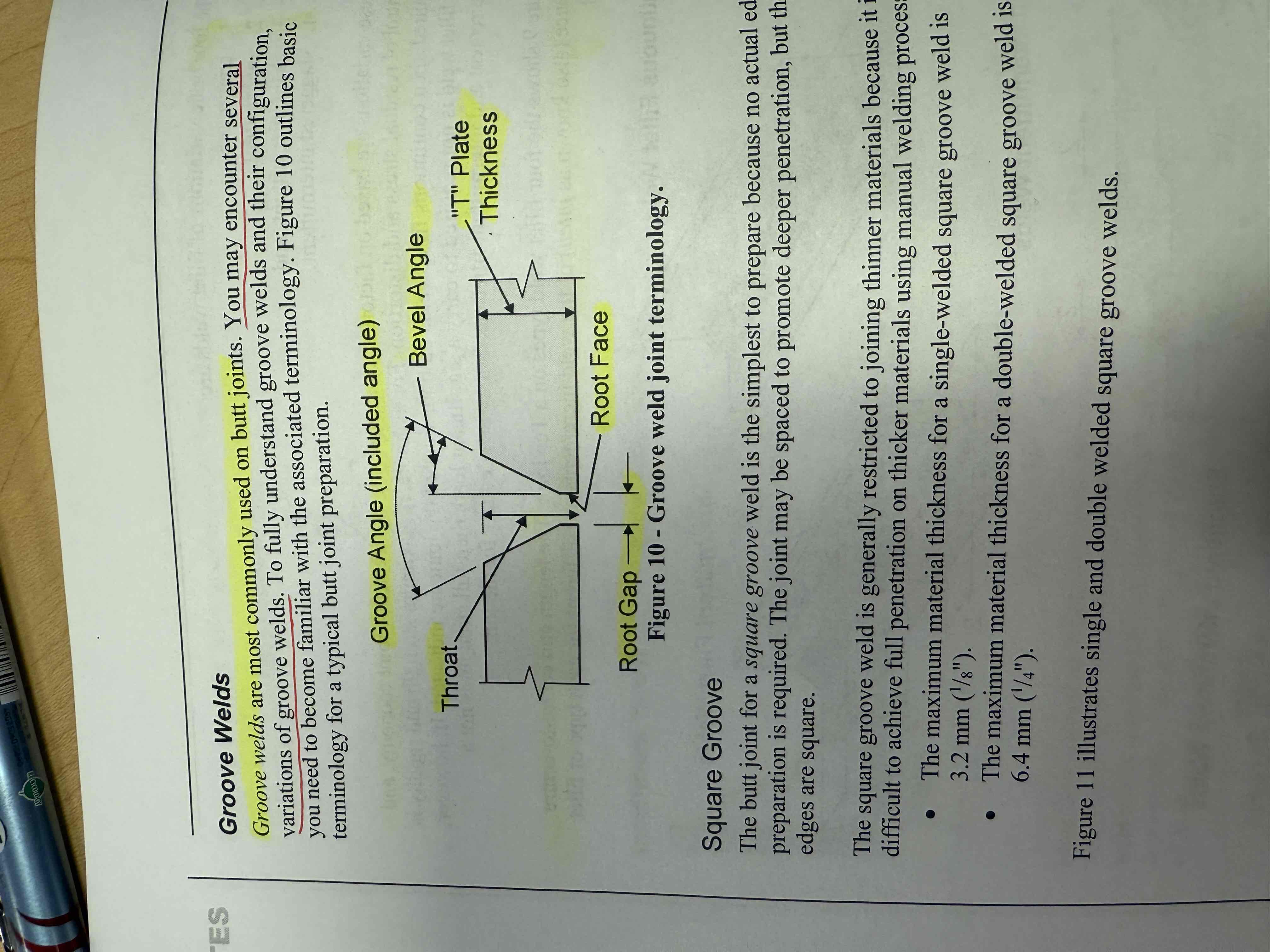

Anatomy of a groove weld image

What are the 5 variations if groove welds and applications?

Square groove

simple to prepare as there is no edge prep

Thin material only (difficult to achieve full penetration)

single welded square groove max material thickness (1/8”)

Double welded square groove max material thickness (1/4”)

Bevel groove

only one side is beveled and the other is square

When you have access to only one member of the joint.

Less prep and welding time

You must ensure complete fusion.

Can be single or double bevel

Vee Groove

3/8 to 1” thickness range

Easy to prepare and good accessibility for full penetration

Double vee used if thicker material and access to both sides- minimizes distortion by equalizing shrinking forces

U groove

similar to vee groove but smaller included angle (less filler than a Vee groove)

J Groove

used if access to only one member of joint in horizontal position

J groove is better than bevel as it gives better welding access for better penetration at bottom of joint

Usually expensive prep. Generally used on thicker material

Which vee groove welds uses less material? Single or double?

Double Vee Groove weld uses less weld metal than a single.

Vee Groove vs U Groove weld?

U groove is smaller included angle which uses less filler metal than a Vee groove. BUT a U groove takes longer to prepare.

It is generally cheaper to prepare Vee groove but it uses more filler metal compared to a U groove. Ensure you factor in prep time and material costs.

What is a backup strip in a butt joint?

Used where welding can take place from one side only. Or where root opening is too wide to join easily across open gap.

What does CSA and ASME stand for?

Canadian Standards Association

American Society of Mechanical Engineers

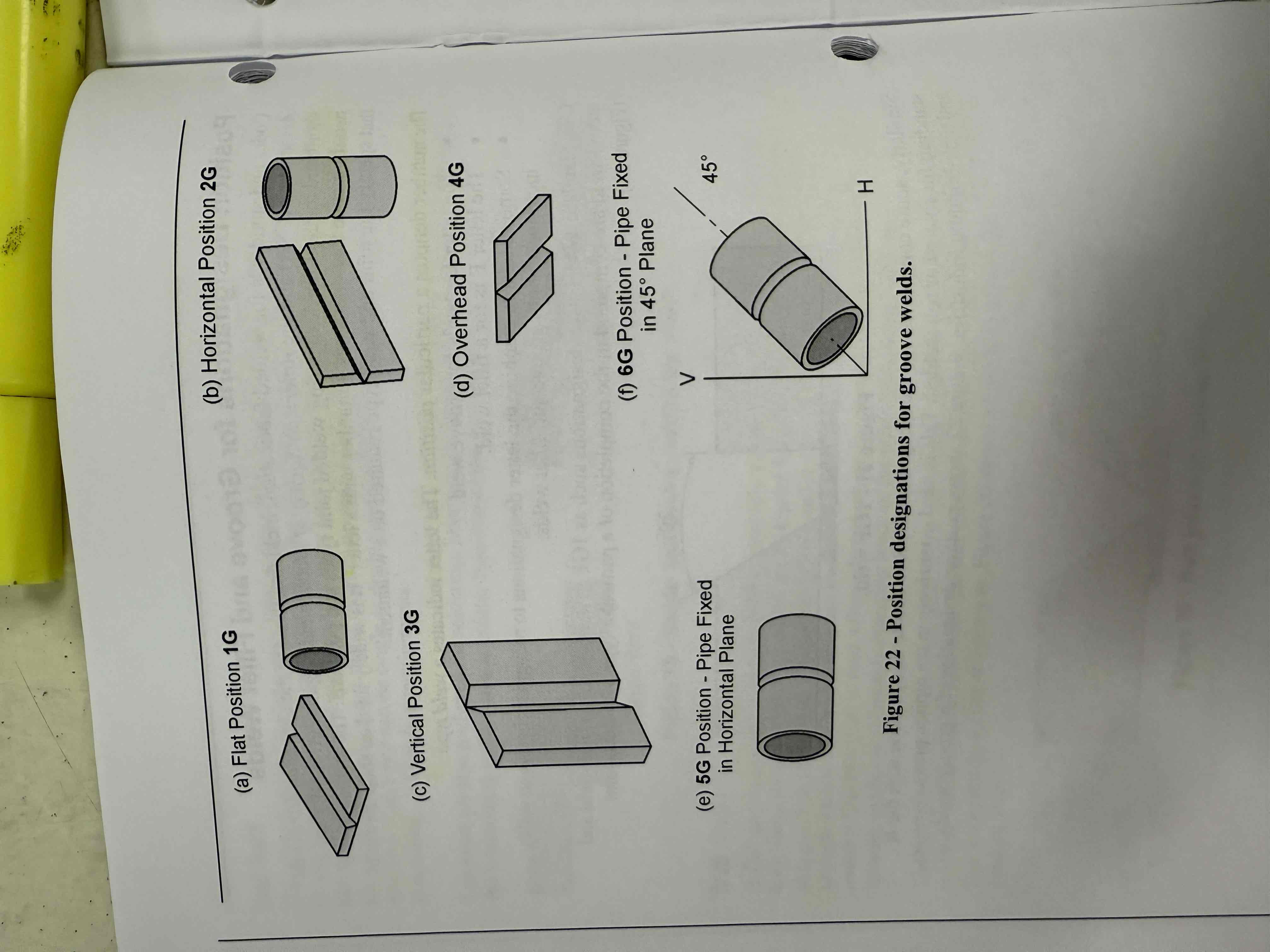

What is the CSA and ASME designation for joint types and positions?

Number denotes position, letter denotes weld type.

Ex: 1GF: G groove weld, F is fillet weld, R at the end stands for rotating.

1: flat or pipe

2: horizontal

3: vertical

4: overheat

5: pipe fixed horizontal plane

6: pipe fixed 45 deg plane

Weld design considerations (7)

Joint using least amount of filler metal with complete penetration.

Joint config must be suitable for thickness of material

Different thicknesses - size weld by thinnest material to avoid over welding

Joint accessibility for welding

Welded flat if possible

Consider joint prep needed

Consider Double joint if accessible from both sides.

Define Tensile strength and how it’s calculated.

How much pull a material stands without fracture.

Tested by pulling material apart with machine

Divide the load by cross sectional area of test specimen:

If it takes 15,000 lbs to break a ½ by ½ “ square →

15,000 / 0.25inch area= 60,000

Define Yield Strength and how it is tested.

Stress point at which permanent deformation takes place. Tested with a tensile strength machine.

Define ductility and how it is tested?

Ability of a material to stretch or deform under load without breaking.

Tested during tensile or a bend test and expressed in % elongation. (If it is 2” and breaks after stretching to 2 1/2”, it is at 25% elongation).

Define Elasticity

Ability of metal to return to original shape and dimension once load is removed.

Define Malleability

Metal ability to be cold worked without alot of resistance.

Define Impact Strength. How is it tested?

Ability of a metal to withstand sharp, fast blows.

2 Ways to test - Izod and Charpy tests

Both use a weighted swinging pendulum to break specimen.

Define Toughness. How can it be increased?

Ability of a metal to withstand a rapidly applied load and deform without breaking. Ability to absorb energy without fracturing.

Tempering usually reduces hardness to promote toughness

Define Hardess, how can the max hardness be pre-determined, how is it tested?

-Hardness: ability to resist penetration or indentation (scratching and abrasion)

-Max hardness can be pre-determined by the carbon content in the metal

-2 ways of testing is the Rockwell or the Brinell tests.

What 2 types of loading can a weld be subjected to?

Dynamic- vibration, movement, shock

Static - storage, supports

What are the 5 characteristics of most metals?

Solid at room temp

Opaque

Conduct heat and electricity

Reflect light when polished

Expands when hot, contracts when cold

What are the 3 ways to identify metal?

Visual appearance and color:

hot roll with black mill scale vs cold rool shiny and smooth

Aluminum oxidizing rapidly

Copper and brass are reddish/yellowish

Fractured Surface

examine exposed grain structure

Aluminum fractures whiter than othwrs

Low carbon steels bright grey fracture, high carbon steel whiter and finer grain structure

Relative weight

magnesium 109 lb/ft3, carbon steel 490, copper 558, gold 1205

What tests can you do to identify metals if the other methods don’t work?

Chip test

chisel and see how the chips look

Softer material = longer chip pieces

More carbon = steel is more difficult to cut and chips are smaller and brittle

Spark test

studying spark stream when grinding, mainly used to test carbon content in steels

Low carbon steel: bright, long, straight, yellow. Little branching and few carbon bursts

High carbon steel: darker, yellow-orange, burst near wheel. More branching and sparks follow wheel

Cast iron: red bursts near grinder, orange-yellow further out. Spark stream is shorter. Needs considerably more pressure

File Hardness Test

scratching the metal and using the Rockwell or Brinell scale to accurately measure hardness.

Lower carbon = lower number on scale

What is a Mill Test Report

-Most precise method of identifying a metal

-Required for some specific jobs

-Contains heat number stamped into material- should be transferred if the material is ever cut!

-Metal identification tags usually accompany it.

How can you reinforce welds on a lap joints.

Place plug or slot welds along the joint

A lap joint should overlap by?

Thickness of the work piece.

Main factor in determining type of joint for welding?

Strength and loading req.

Size of groove weld is determined by ?

Throat dimension

What do ferrous metals contain?

Iron

What does a higher carbon content do for the metal?

Increases the hardness and strength but decreases ductility

What steel is harder than a file?

Hardened tool steel

When welding edge joint on thin gauge, how much filler is usually used?

Usually none