Block 5 - Manufacture of Modern Firearms

1/94

There's no tags or description

Looks like no tags are added yet.

Name | Mastery | Learn | Test | Matching | Spaced |

|---|

No study sessions yet.

95 Terms

What is one of the more common methods used in firearms manufacturing?

Broaching

In which machining process is the barrel held in place and rotated at the desired twist rate while a broach passes through it?

Broaching

Parallel lines on lands/grooves can be indicative of which machining process?

Broaching

What are some advantages of broaching?

Fast

Less stress on barrel

What are some disadvantages of broaching?

Broaches are expensive

New configurations require new broaches

Broached barrels must be lapped

Increased potential for subclass carryover

In which machining process is a button bearing a negative form of the finished lands and grooves pushed/pulled through a smooth bore of slightly smaller diameter?

Button rifling

What are some advantages of button rifling?

Fast and economical

Doesn’t require lapping

Barrel easier to clean and maintain due to smooth surfaces

Consistent and accurate

What are some disadvantages of button rifling?

Buttons are expensive to make

Different groove/twist configurations require a new button

Barrels must be stress relieved after rifling

Button rifling is a _____ working process.

Cold forming

Button rifling typically creates _____ marks that are often removed from the grooves but remain on the lands.

Perpendicular

In which machining process is a drilled and reamed barrel compressed onto a mandrel which bears the negative shape of the finishing rifling?

Hammer forging

What are some advantages of hammer forging?

More durable barrels

More consistent barrels

What are some disadvantages of hammer forging?

Machinery and mandrels are expensive

Can introduce stress into the barrel

Leaves few individual characteristics

Hammer forging can leave what type of marks on the outside of the barrel?

Peening

Hammer forging can also form the _____ and _____ if desired.

Chamber; throat

True or false: Hammer forging can produce both polygonal and traditional rifling.

True

In which machining process is a single point hook shaped cutter pulled through a barrel, cutting one groove at a time?

Hook cutting

What are some advantages of hook cutting?

Groove characteristics can be changed easily

Consistent twist

Little stress on barrel

What are some disadvantages of hook cutting?

Slow method

More expensive

Increased potential for subclass carryover

_____ is one of the oldest barrel rifling machining methods.

Hook cutting

In which machining method is a multi-point cutter pushed/pulled into a barrel to cut/scrape two opposed grooves simultaneously?

Scrape cutting

What is the main disadvantage of scrape cutting?

Increased potential for subclass carryover

In which machining method are the barrel and electrode placed in electrolyte, followed by the electrode travelling down the barrel at the desired rate of twist, removing the metal using electrolysis?

ECM

What are some advantages of ECM machining?

Short timeframe

No tool wear

More consistent/accurate

Can cut any metal

What are some disadvantages of ECM machining?

High equipment costs

Requires strong acids and neutralizers

What company uses ECM machining for rifling revolver barrels?

Smith & Wesson

True or False: In ECM machining, the barrel and electrode come into contact.

False

What type of machining can leave randomized pock marks/voids in grooves, creating a lower potential for subclass carryover?

ECM

In which machining method are both the workpiece and tool electrode immersed in dielectric fluid and moved close together, generating sparks that vaporize tiny pieces of both electrodes?

EDM

What are some advantages of EDM machining?

Precise

Useful for hard material

What are some disadvantages of EDM machining?

Slow

High electricity consumption

Expensive machinery

EDM machining is also known as _____.

Spark machining

EDM machining is more likely to be used to create dies for other manufacturers, such as _____.

Bunter tools

What type of machining can leave a pitted/granular appearance, resulting in a lower potential for subclass carryover?

EDM

In which machining process is wax injected into a die forming a wax pattern, which is then attached to a tree that is coated in a ceramic slurry that creates a mold?

Investment casting

What are some advantages of investment casting?

Potentially good surface finish

Material versatility

What are some disadvantages of investment casting?

Poorly defined rifling

Presence of deformities

No distinctive directional twist

Some potential for subclass

What manufacturer uses investment casting for some parts?

Ruger

The reaming out of a chamber in the end of a barrel blank

Chambering

Any of various forms of muzzle treatment meant primarily to protect rifling.

Crown

Beveling a sharp external edge

Chamfering

The smoothing of the tops of the lands of a rifled barrel by the forced passage of a hardened steel ball of appropriate diameter

Ball Burnishing/Ballizing

The process of driving a piece of lead through the bore of a rifled barrel to determine the minimum bore and groove diameters

Bore Slugging

_____ is a multi-step manufacturing process that combines metal powders with a plastic binder into a solid metal part through molding, debinding, and sintering.

Metal injection molding

What are some advantages of MIM?

Form small, complex shapes

Significant cost savings

Comparable hardness to traditional molds

What are some disadvantages of MIM?

Expensive equipment

Long manufacturing times

Dedicated, single part molds

What are some parts commonly manufacturing using MIM?

Trigger

Hammer

Sear

Extractor

In MIM, a ____ is the initial molded form created by injecting a mixture of metal powder and binder into a mold?

Green part

In MIM, a _____ is porous, fragile part left behind after the debinding process.

Brown part

_____ carries an increased potential for subclass carryover due to reusing the same mold.

MIM

What are the two categories of metal forming?

Gross

Fine

_____ reduces raw metal stock to a rough form that is intermediate to the required shape.

Gross forming

_____ renders the intermediate form to its final dimensions, with the exception of parts requiring hand fitting.

Fine forming

What are the two main types of gross forming?

Casting

Forging

_____ is a subcategory of forging.

Stamping

What are the different types of casting used in the manufacture of firearms?

Sand

Wax

Investment

Die

What are the two different types of machine forging used in the manufacture of firearms?

Hammer

Press

In _____, force is applied via a ram or drop hammer in one or two sharp blows

Hammer forging

In _____, force is applied slowly, providing greater control of the material

Press forging

What are some benefits of machine forging?

Better strength/durability

Minimal variations in grain structure

List five types of fine forming operations.

Drilling

Turning

Grinding

Milling

Broaching

List the 8 basic steps of manufacturing a barrel from a steel blank.

Cut to length

Deep hole drilling

Reaming

Rifling

Lapping

Straightening

Contouring/Profiling

Chambering/Throating

List four types of common cosmetic finishing applications on firearm parts.

Bluing

Electroplating

Anodizing

Parkerization

_____ is used as protective anti-corrosive on steel parts and imparts a blue-black appearance.

Bluing

_____ adds a protective coating and bright finish.

Electroplating

_____ provides a protective coating for aluminum/titanium by using an electrical current.

Anodizing

_____ converts iron on the surface of metal by using phosphoric acid and imparts a gray/black matte coloring.

Parkerization

_____ refers to helical grooves cut or impressed into the bore of a firearm barrel to impart rotary motion to a projectile when fired.

Rifling

What is rifling twist rate?

The rate at which the rifling of the firearm turns within the bore

What is rifling pitch?

The angle at which the rifling is cut in relation to the axis of the bore

A higher rifling pitch will create _____ angled rifling on the projectile.

More

_____ is the typical type of rifling found in many barrels and has sharp, defined lands and grooves.

Conventional

_____ refers to rifling in which the lands and grooves have a more rounded profile than in conventional rifling.

Polygonal

Name three common manufacturers that manufacture polygonally rifled barrels.

Glock

HK

Walther

What are the five major contributors to the workpiece surface?

BUE

Shearing

Plowing

Sideflow

Tool wear

_____ is the source of individual characteristics.

Surface roughness

_____ is when a piece of BUE is displaced into the workpiece rather than forming a chip, creating an uneven surface.

Plowing

_____ is the plastic deformation of workpiece material displaced to the side of the area being cut by the tool.

Sideflow

_____ involves the complete removal of metal being cut and extracted from the surface.

Shearing

_____ occurs when there is vibration either in the workpiece, tool, or both during machining.

Chatter

List three different types of tool wear.

Abrasive

Adhesive

Diffusive

_____ tool wear involves material loss due to rubbing/friction when a harder material contacts a softer one.

Abrasive

In _____ tool wear, the substrate being cut bonds to the cutting tool with enough strength to supersede the adherence of the cutting tool material to itself.

Adhesive

_____ tool wear is the progressive loss of material from one surface to another.

Diffusive

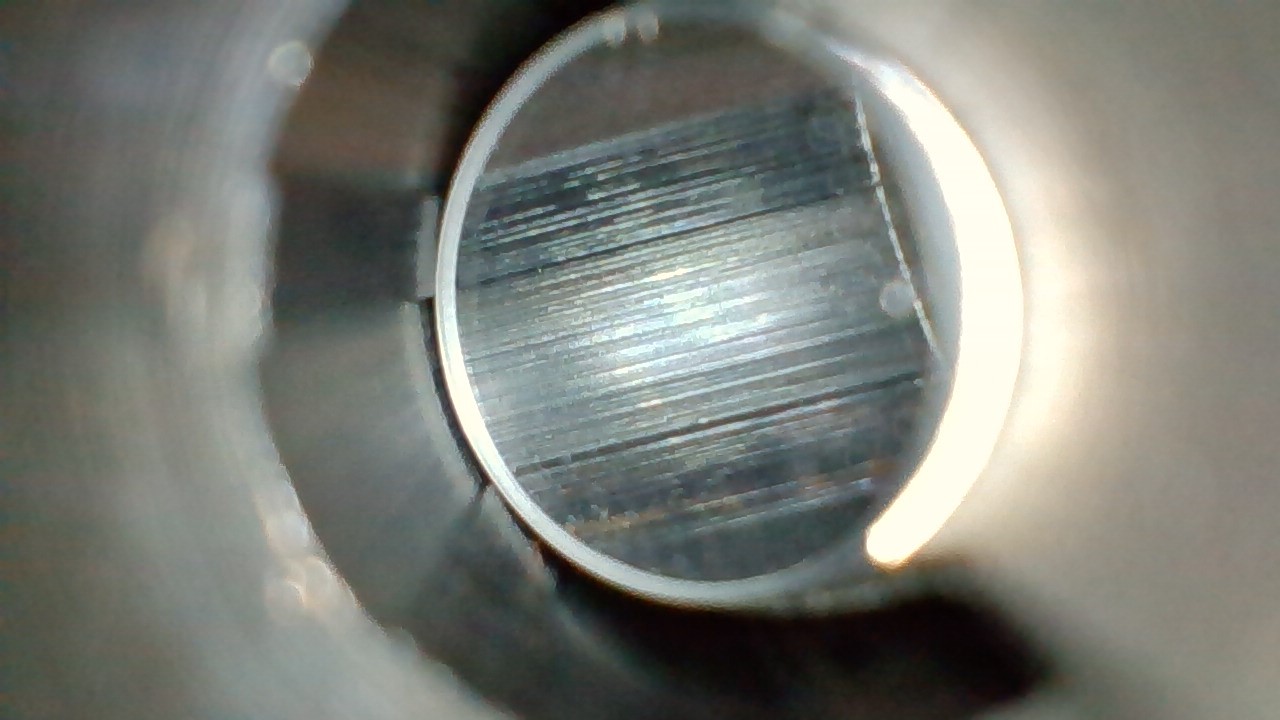

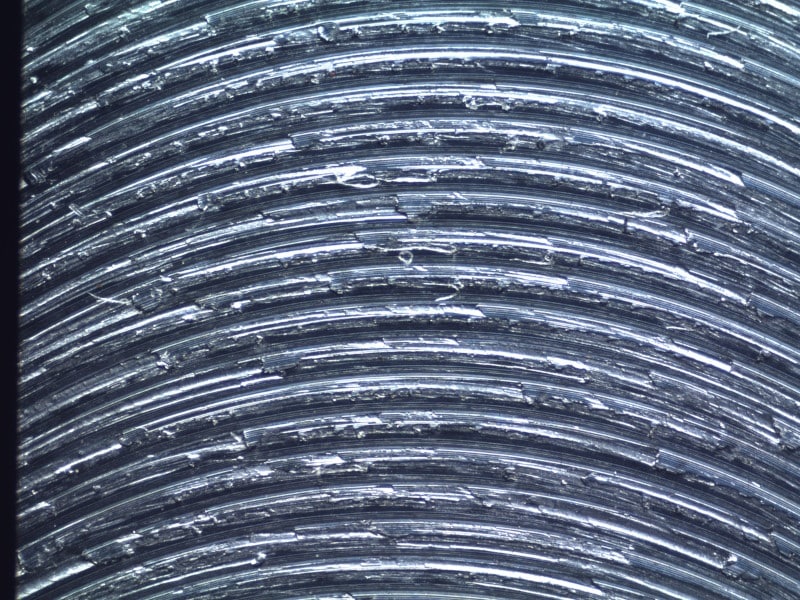

What type of machining likely created the continuous lines running parallel to the rifling (mostly on the lands) seen in this barrel?

Broaching

What type of machining likely created the continuous lines running parallel to the rifling (in the lands and grooves) seen in this barrel?

Double broaching

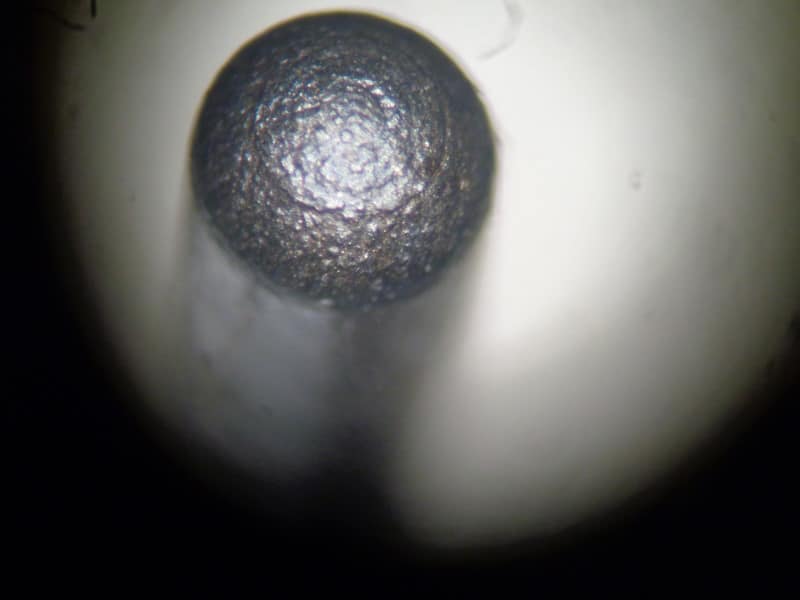

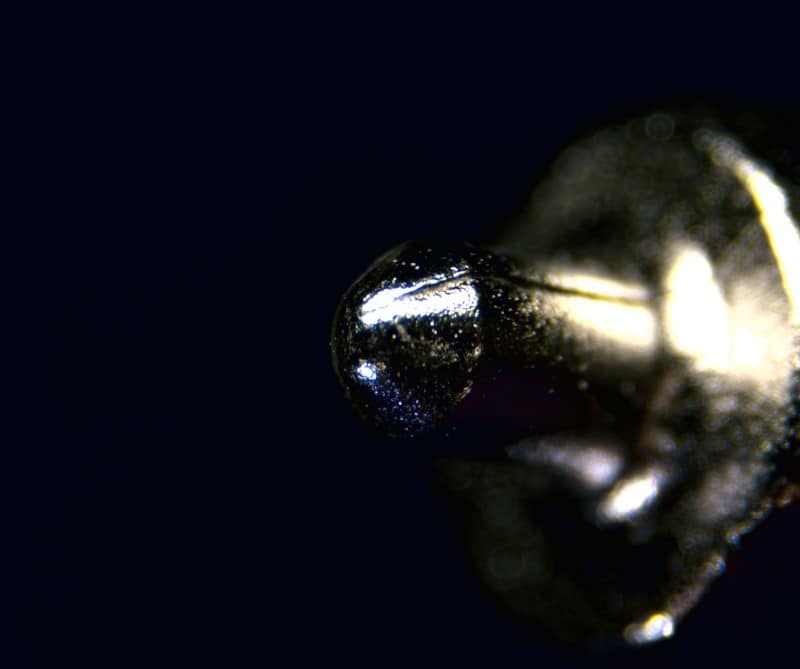

What type of machining likely created the granular pattern seen on this firing pin?

EDM

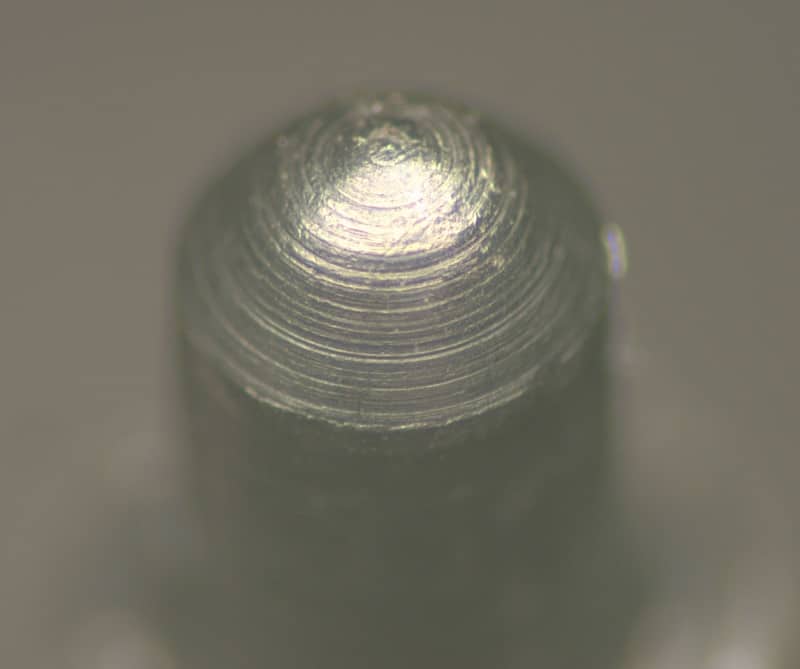

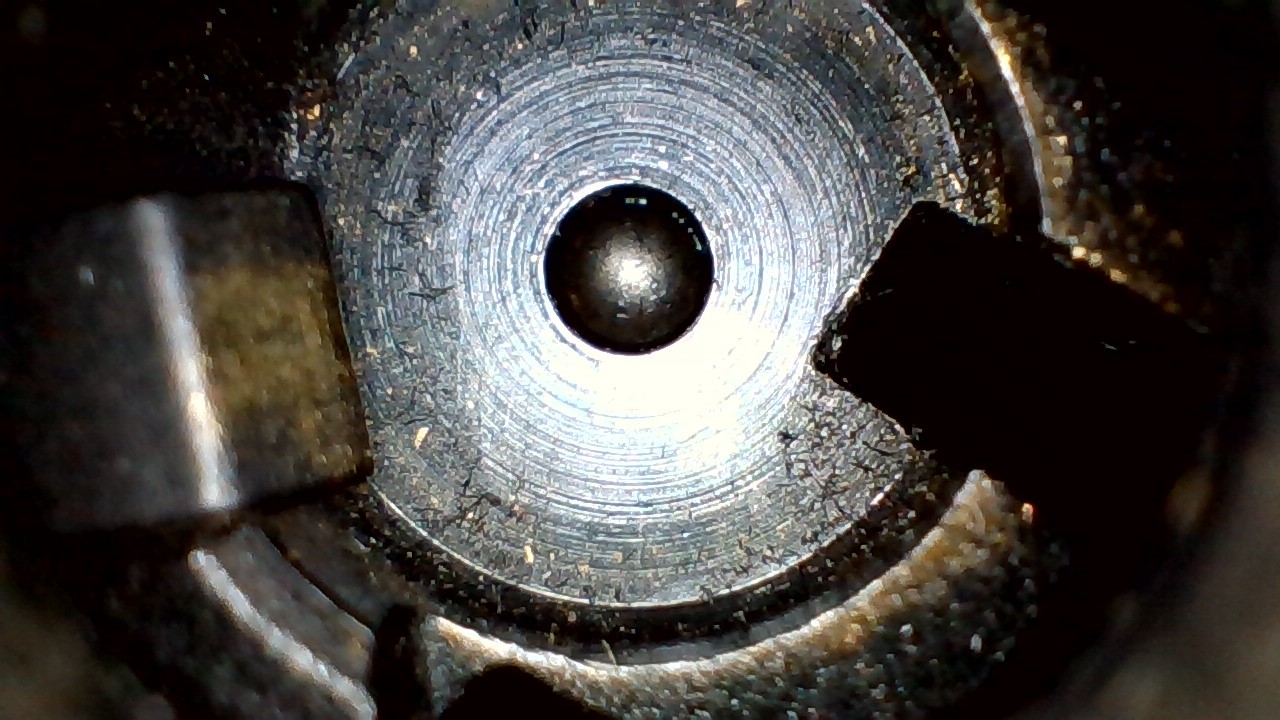

What type of machining likely created the concentric rings seen on this firing pin?

Lathe turning

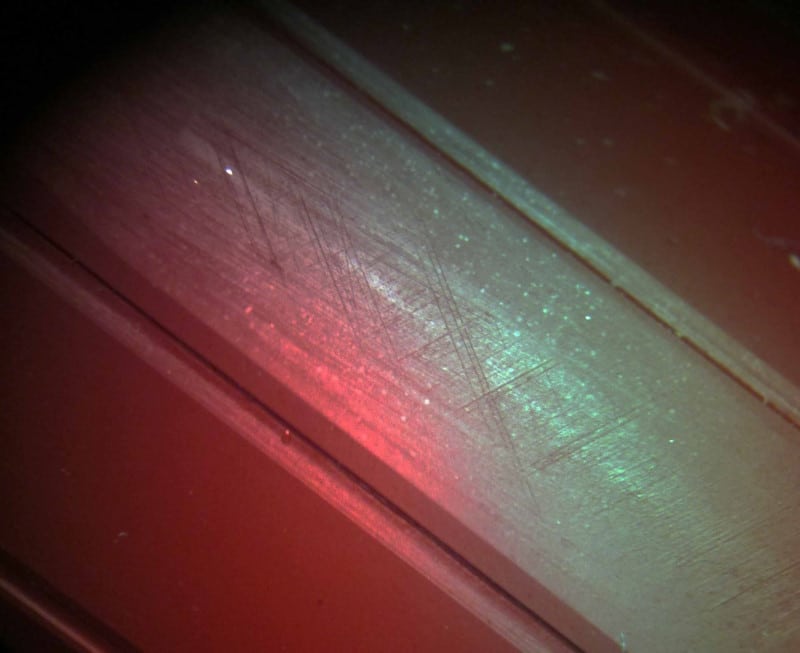

What type of machining likely created the continuous parallel lines seen on this breechface?

Gang broaching

What type of machining likely created the crosshatch marks seen in this barrel?

Honing

What type of machining often creates seams in metal, as seen on this firing pin?

MIM

What type of machining likely left these concentric rings on this bolt breechface?

Plunge milling

What type of machining likely left these perpendicular markings in the grooves of this barrel?

Reaming

What type of machining likely created these jagged, spaced apart arches?

Face milling (slow)

What type of machining likely left this pock marked finish on the rifling of this barrel?

ECM