Capacity Planning and Resource Allocation

1/34

There's no tags or description

Looks like no tags are added yet.

Name | Mastery | Learn | Test | Matching | Spaced | Call with Kai |

|---|

No study sessions yet.

35 Terms

Capacity

the amount of outputs that a process can produce given the amount of inputs and resources in a given period of time

Can be viewed as: the maximum rate of output per unit of time OR units of resource availability

Economies of scale

As production volume increases with increases in capacity, the per unit cost to product a product decreases because fixed cost is spread over more units

Diseconomies of scale

When capacity and production volume grow too high, inefficiencies arise as managing the larger operation becomes more complex and costly

Learning curve

As volume increases there is greater learning because there are more opportunities to acquire new skills. However, the rate of learning diminishes over time as employees gain experience.

Capacity utilization

percentage of available time that equipment, space, or labor is used

Capacity flexibility

ability to provide a wide range of products and volumes with short lead times

Capacity cushion

percentage difference between average output and maximum output, reserved for unanticipated events such as demand surges, material shortages, equipment breakdowns, etc.

Outputs

units coming out of the process

Inputs

resources that are put into the process

Maximum capacity

the highest amounts of output when all conditions are ideal, e.g. no delays, no quality issues with parts, etc.

Effective capacity

the amount of output of a process under normal conditions

Utilization

how much of the available capacity is actually used

Demand smoothing

demand management either to increase or decrease demand in response to capacity constraints

Production smoothing

aims to reduce fluctuations in production to align with demand

What are some ways of managing capacity?

Add capacity during peak demand by using a seasonal workforce

Allow flexibility of the workforce to adjust to demand changes

Subcontracting some of the work to other firms

Leasing equipment to add or reduce capacity as needed

Influencing customer demand by varying the price of goods or services

Overbooking by accepting more reservations than available capacity

Why is service capacity more challenging to manage?

Time-dependent: cannot be inventoried, has to be available when needed

Location-dependent: involves the customer (patient), so should be near them

Subject to high demand volatility

Utilization is highly correlated with quality

Short-term capacity decisions

change labor capacity and schedules (eg overtime, extra shifts)

shift work for slack periods (eg paperwork at night or during slow times)

number of ER nurses during a festival weekend

Long-term capacity decisions

construction of a new facility

increasing number of beds in a hospital

closing a distribution facility

adding new machinery

Why do we have waiting lines?

High arrival rates at source points

Insufficient service capacity

Unpredictable or fluctuating arrival times

Queue configuration

Service complexity

Population of customers

What are the consequences of delays in healthcare?

Patient dissatisfaction

Increase in no-shows

Loss of revenue for providers due to no-show

Lower quality of care

Higher cost

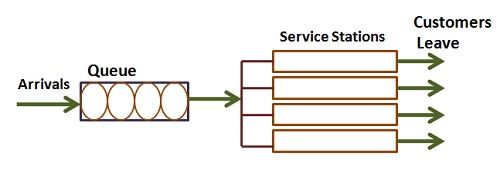

Queuing systems

consists of the waiting lines and available number of servers

Components:

source of population

service system

Queue

number of flow units waiting to be processed

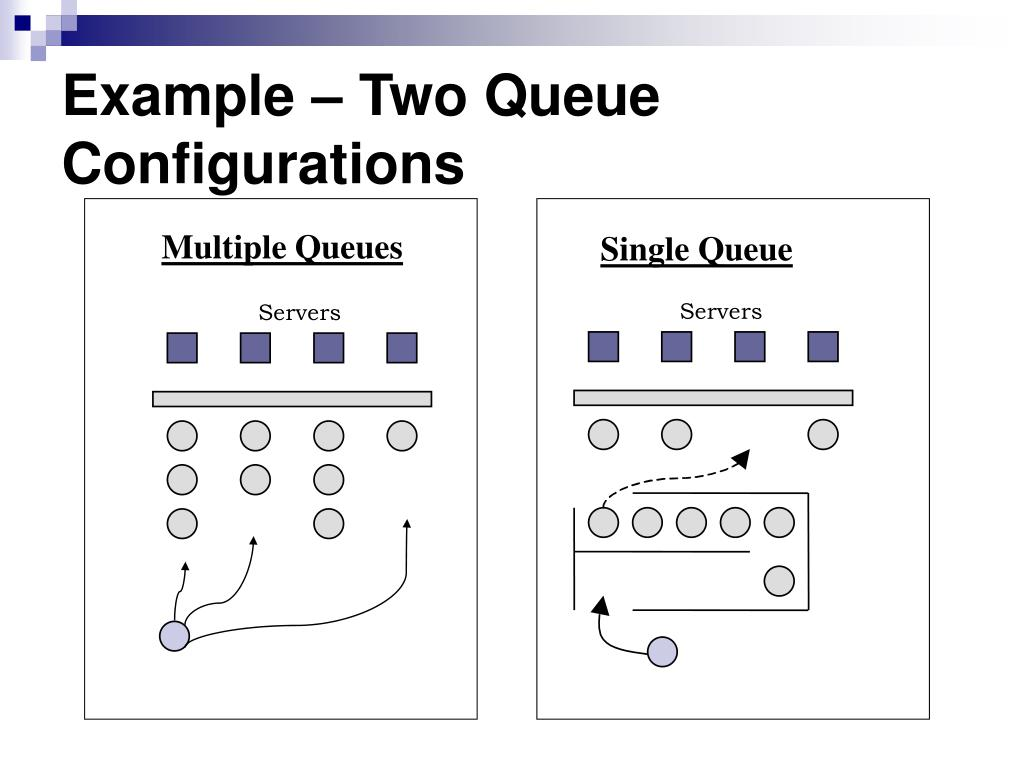

Queue configurations

One queue vs. multiple queues

One stage vs. multiple stages

How do you address the waiting line problem?

Understand key factors influencing customer satisfaction regarding waiting lines

Determine acceptable waiting time from customer’s perspective

Divert attention of the customer during the wait

Inform the customer of what to expect

Keep staff not serving customers out of sight

Train staff on customer service skills

Scheduling

the assignment of start and completion times to particular jobs, people, or equipment

Sequencing

refers to determining the order in which jobs or tasks are processed

Appointment

reservation of service time and capacity

What are some factors affecting scheduling?

Uncertainty in patient demand, staff availability, and availability of supplies needed

Not being able to hire adequate staff and staff members having different needs

Staff requirements vary

Need for flexible staffing

What are the major causes of delays and waits in making appointments?

Superficial examination of variations in capacity and demand

Provider centered systems misaligned with patient needs

Inefficient process design with disrupted flows

Shortage of clinical staff

Job scheduling

an approach to sequencing a series of jobs for processing in order to decrease tardiness, congestion, or some other criterion and improve overall efficiency

Patient appointment scheduling

decisions including determining the appointment time interval, length of each workday and time off duty, deciding how to handle overbooking for each day and developing customer satisfaction

Block scheduling

blocks of time are made available and multiple patients are scheduled within those timeframes

Modified block scheduling

A small number of patients are assigned to short time blocks

Individual scheduling

a single patient is scheduled at a particular time on a specific day according to providers availability

Open-access scheduling

patient appointment system that allows patients to block same day or near term appointments, rather than scheduling far in advance