metal-ceramic and dental ceramics restorations

1/89

There's no tags or description

Looks like no tags are added yet.

Name | Mastery | Learn | Test | Matching | Spaced |

|---|

No study sessions yet.

90 Terms

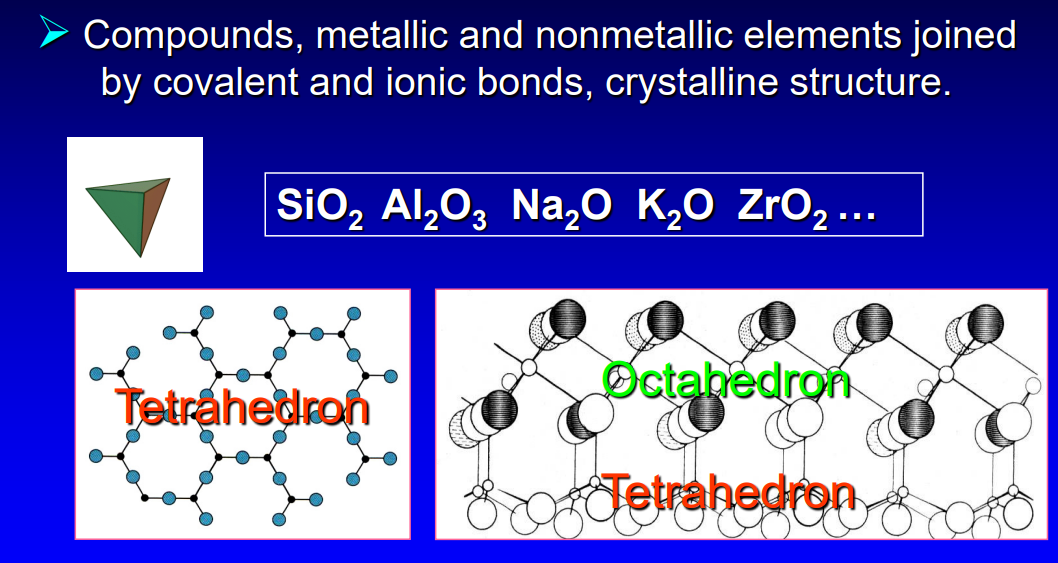

definition of ceramics

an inorganic compound w nonmetallic properties composed of metallic and nonmetallic elements

what are some examples of metallic and nonmetallic elements in ceramics

Al2O3 (alumina), SiO2 (silica), SiC (silicon carbide), TiN (titanium nitride)

ceramic components and how they are joined

compounds, metallic and nonmetallic elements are joined by covalent and ionic bonds → crystalline structure

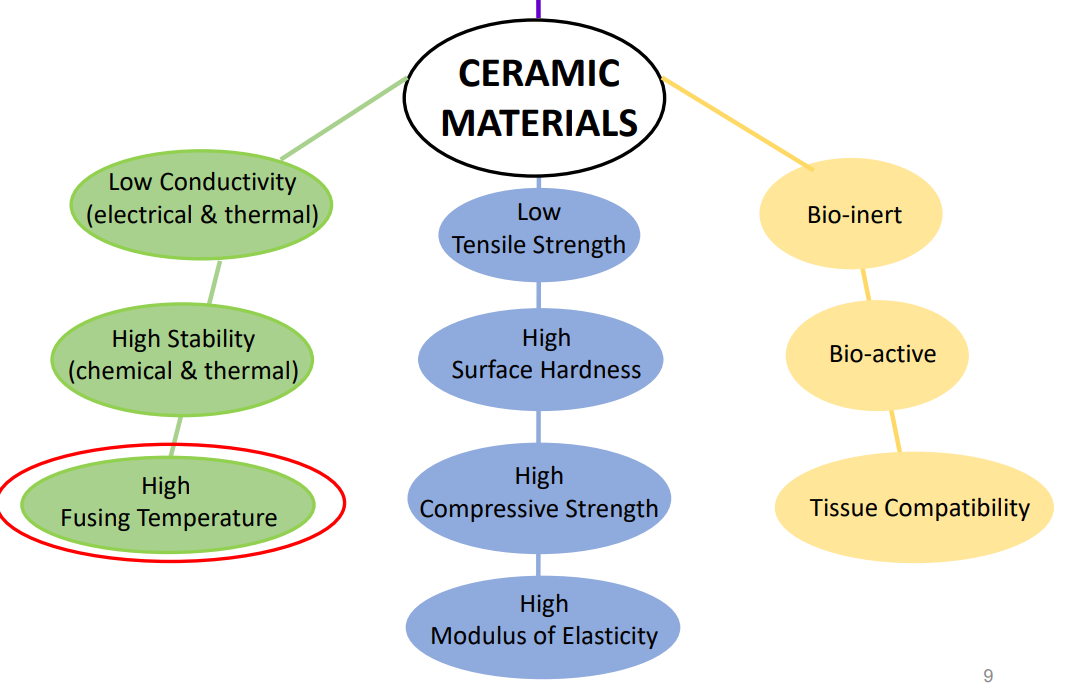

did ceramics have a higher or low conductivity, stability, and fusing temp

conductivity: low

stability: high

fusing temp: high

do metals and alloys have a higher or low conductivity, stability, and fusing temp

conductivity: high

stability: low

fusing temp: low

do ceramics or metals/alloys have a higher tensile strength

metal and alloys

true or false: ceramic materials have high surface hardness

true

true or false: ceramic materials have high compressive strength

true

true or false: ceramic materials have low modulus of elasticity

false

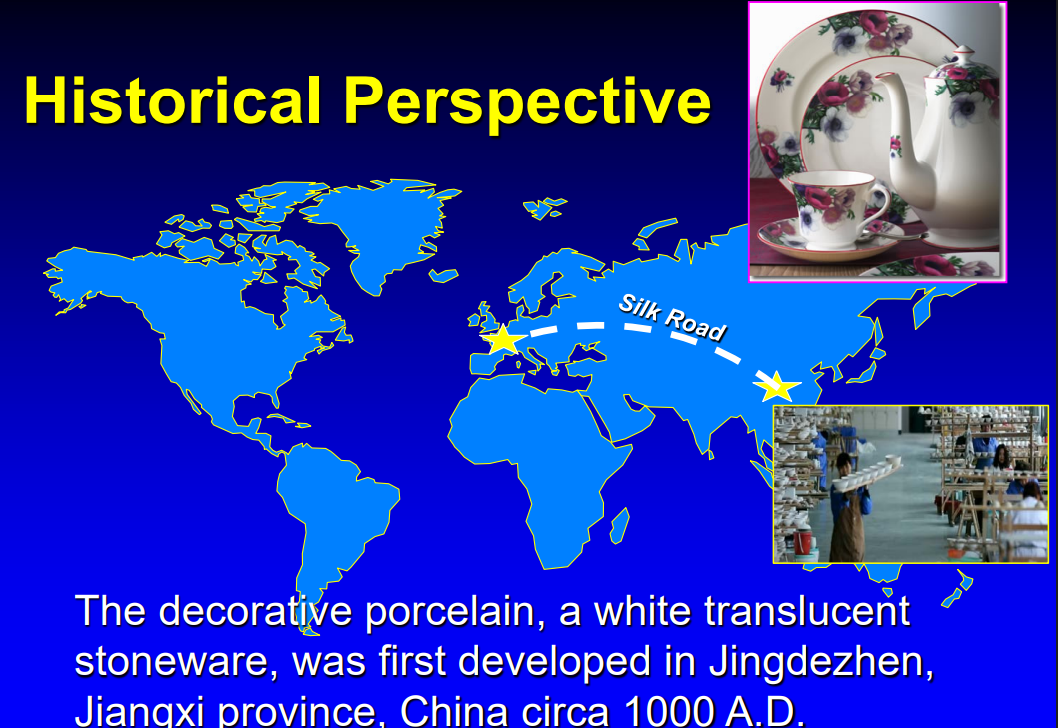

historical perspective of dental ceramics

dental porcelain definition

refers to specific compositional range of ceramic materials made by mixing kaolin, quartz, and feldspar, and fused at high temperature to form enamel like substance

decorative porcelain, a white translucent stoneware, was first developed in…

Jingdezhen, Jiangxi province, China circa 1000 A.D.

ceramic materials were the first material to be the subject of…

laboratory research (circo 1700 A.D.)

porcelain was the first material to be…

artificially made by man and used in dentistry in the late 1700s

De Chemant obtained French and English _________ for his formulation of dental porcelain in 1791

patents

who developed a practical formulation of porcelain denture teeth

Alexis Duchateau, a pharmacist, and Nicholas de Chemant, a dentist

Charles H Land, a detroit dentist, fused porcelain to a thin platinum foil in 1886, this developed into what in 1903

low-fusing porcelain and introduced porcelain jacket crown

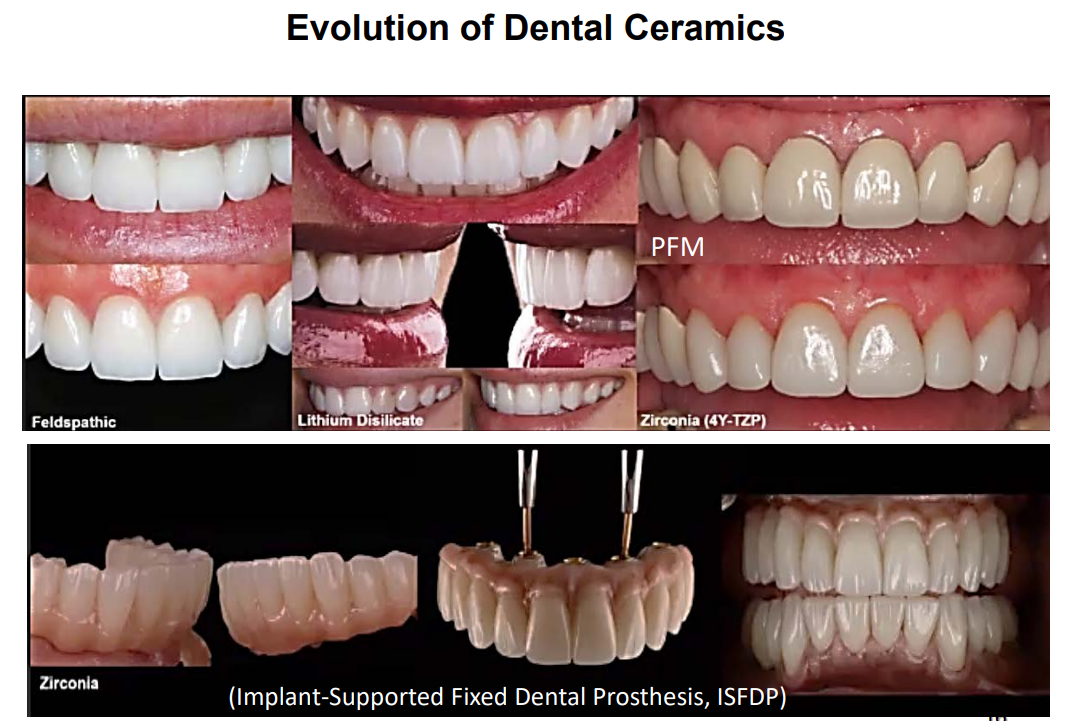

evolution of dental ceramics pic

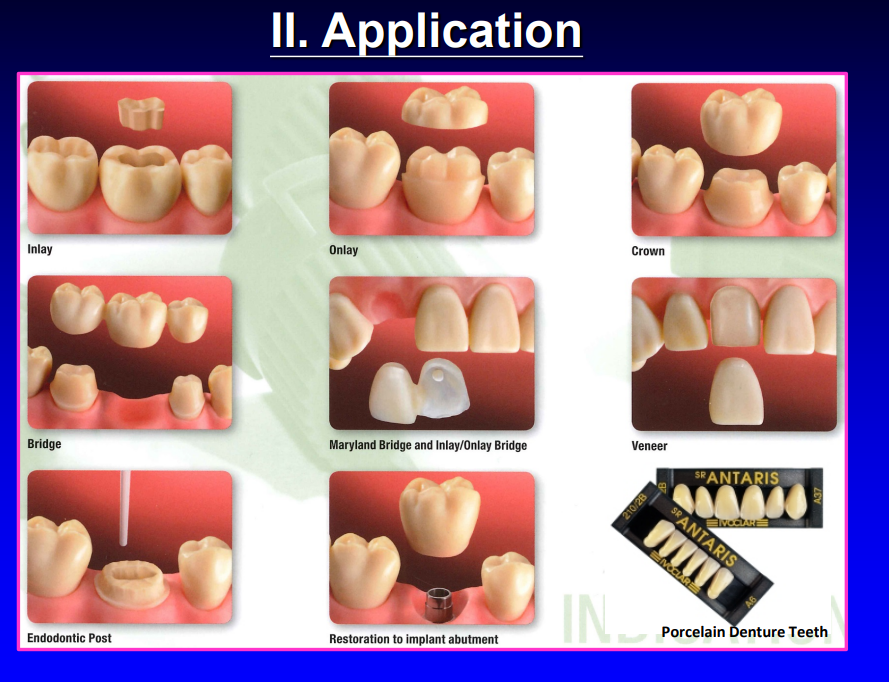

what are the 4 classifications for dental ceramics

fusing temp

application

fabrication technique

crystalline phase

do metal or ceramic have a higher melting temp, why

ceramic bc of the covalent bond

ultra low fusing temp

<850 C

low fusing temp

850-1100 C

medium fusing temp

1100-1300 C

high fusing temp

>/= 1300 C

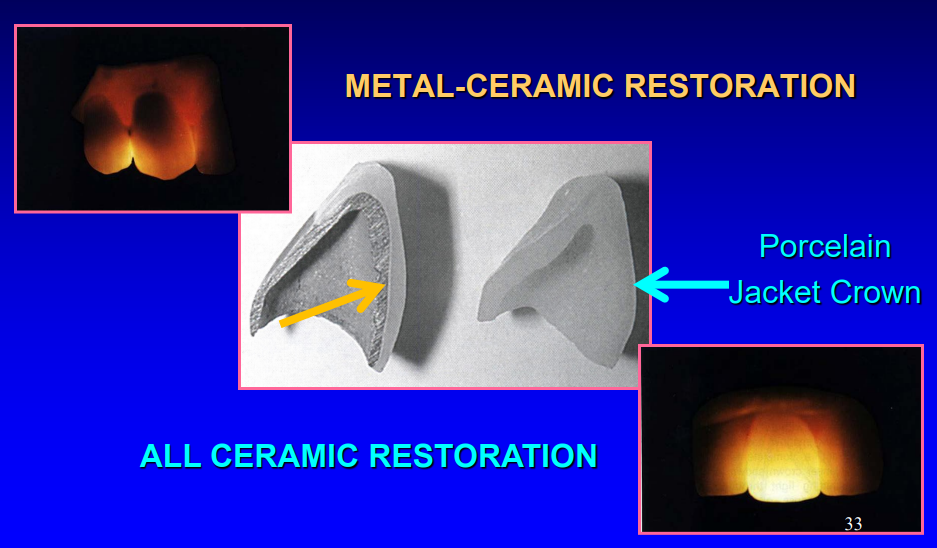

what is the difference between these two crowns

1 porcelain crown w an inner metal lining

2 all ceramic crown w no metal lining

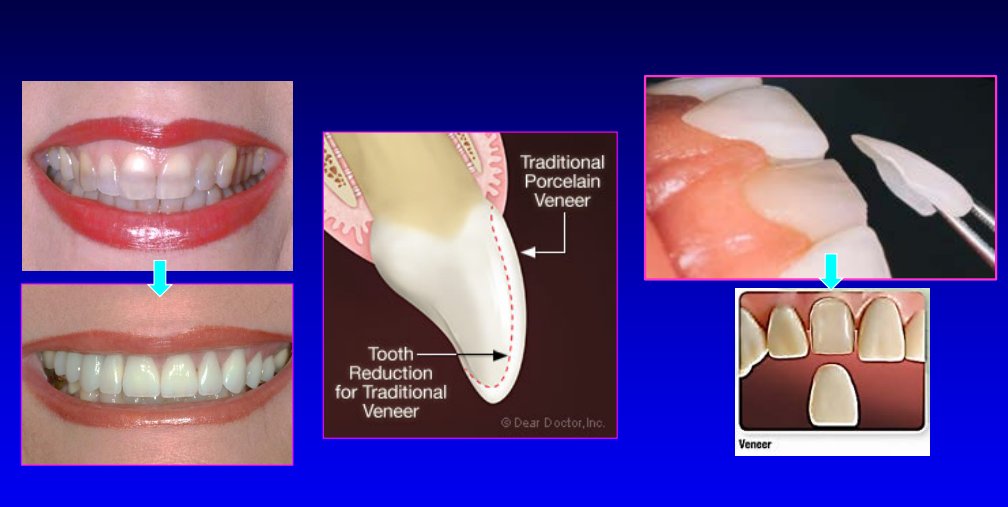

porcelain veneer application

different indirect restorative applications

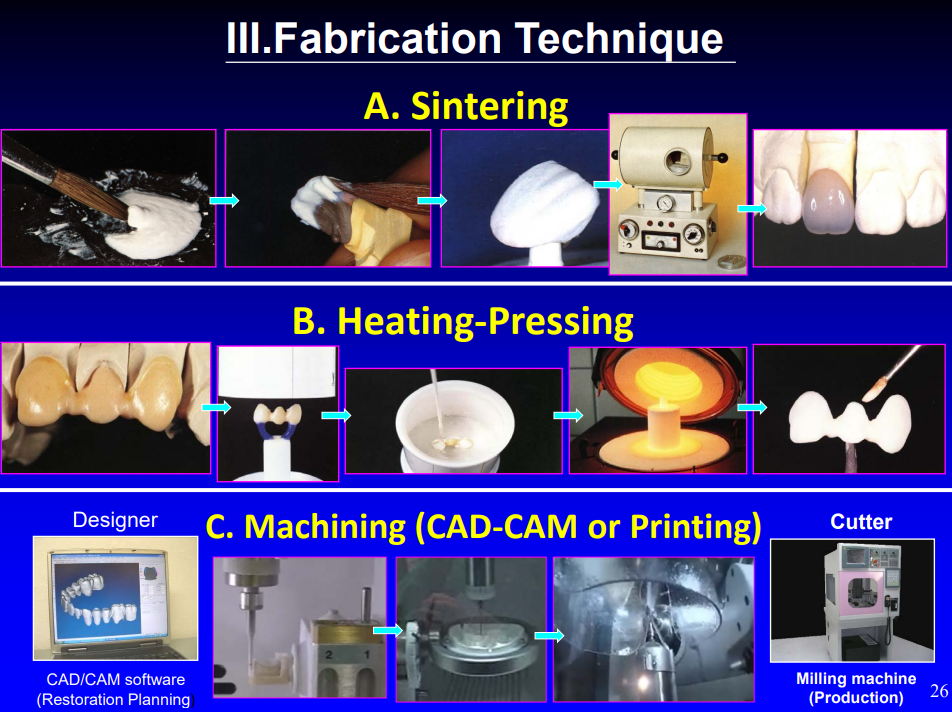

what are the three types of the fabrication technique

sintering

heat pressing

machining (CAD-CAM or printing)

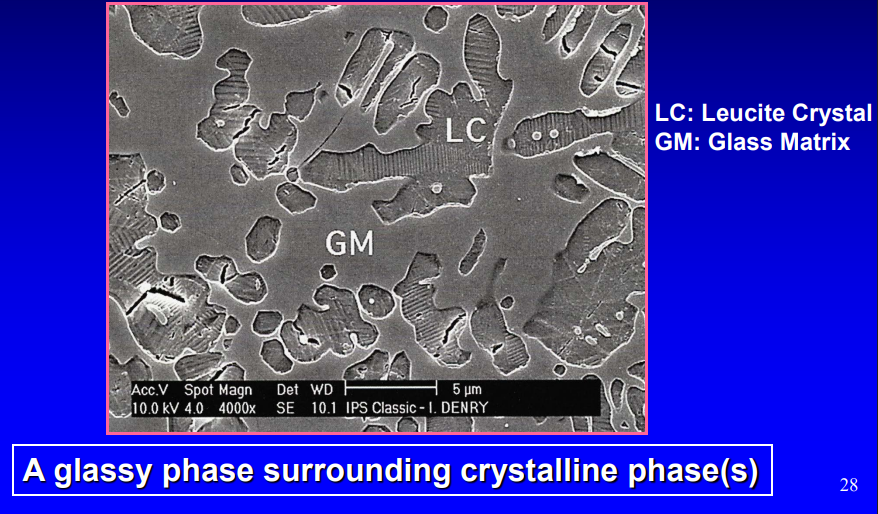

regardless of applications or fabrication technique, after firing, dental porcelains and ceramics are composed of at least what 2 phases

leucite crystal: ordered arrangement- strong

glass matrix- no structure

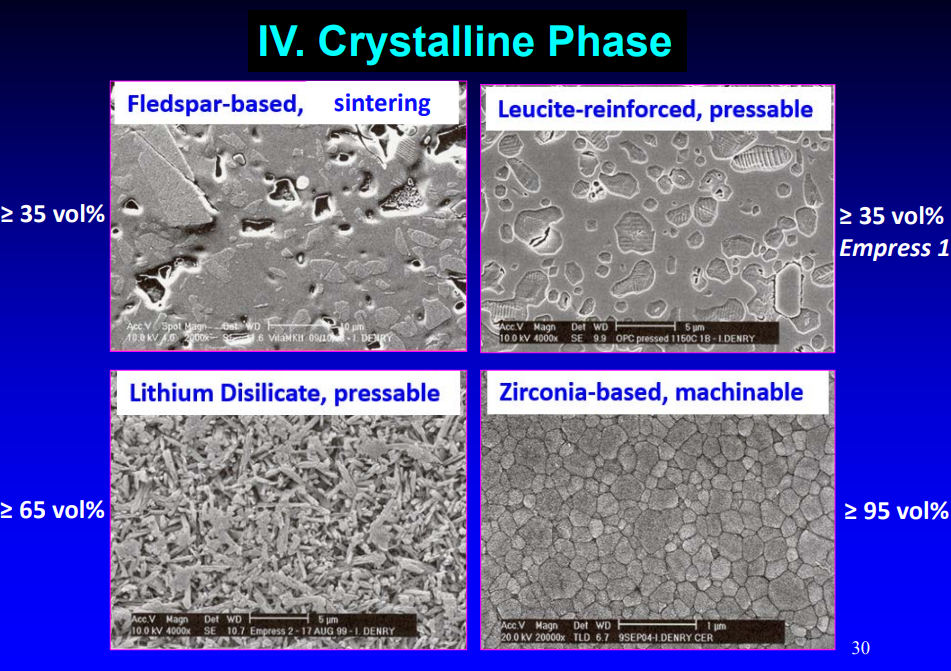

what are the four types of the crystalline phases

feldspar-based, sintering

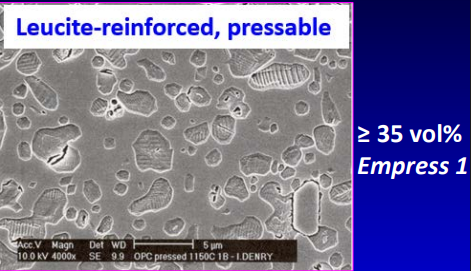

leucite-reinforced, pressable

lithium disilicate, pressable

zirconia-based, machinable

what is the crystalline percentage of feldspars

>/= 35 volume%

what is the crystalline percentage of leucite

>/= 35 volume% Empress 1

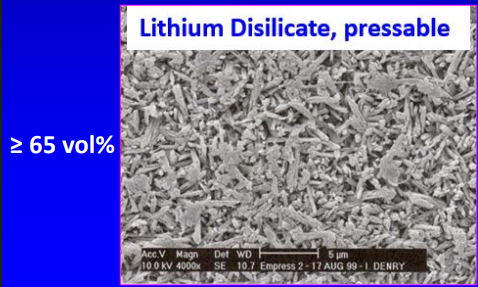

what is the crystalline percentage of lithium disilicate

>/= 65 volume%

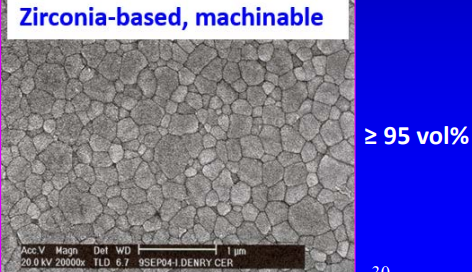

what is the crystalline percentage of zirconia

>/= 95 volume %

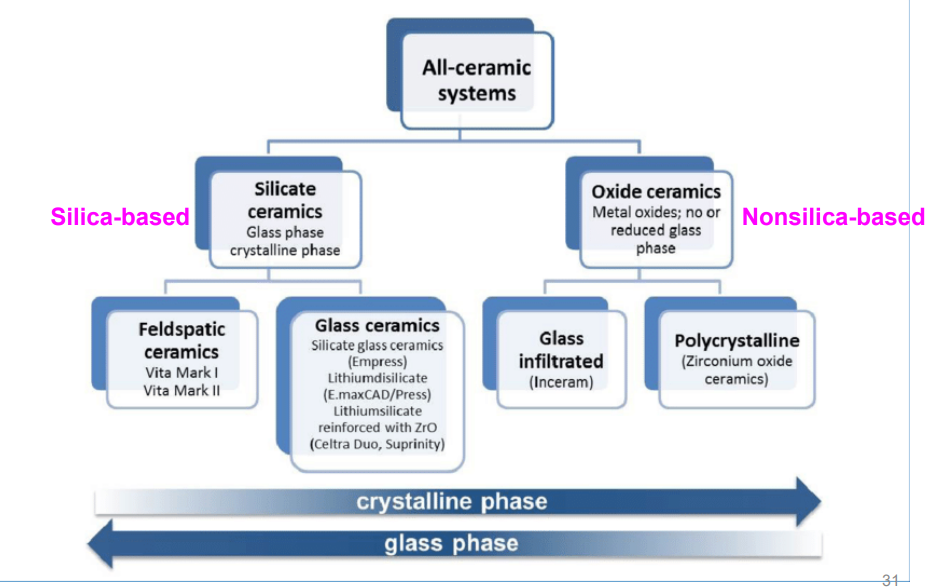

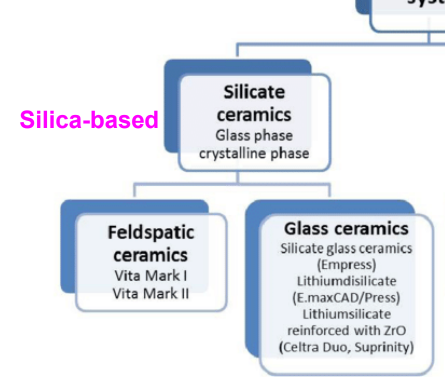

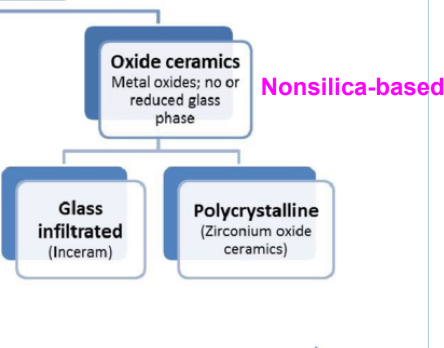

of the two types of all-ceramic systems, which is silica based and which is non-silica based

silicate ceramics- silica based

oxide ceramics- nonsilica-based

what are the types of ceramics that fall under silicate ceramics (2)

feldspatic ceramics

glass ceramics

what are the types of ceramics that fall under oxide ceramics- no or reduced glass phase

glass infiltrated

polycrystalline

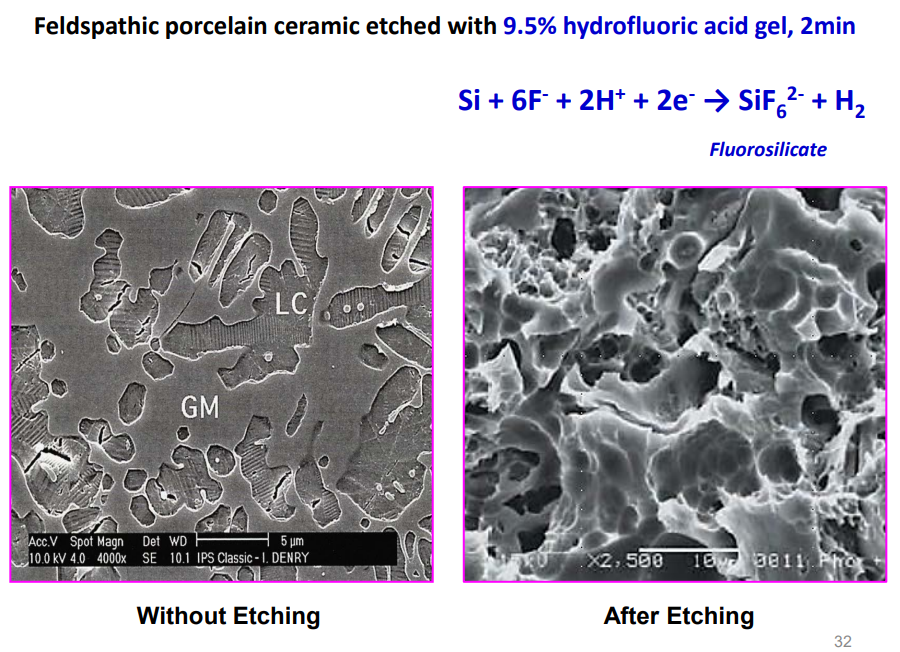

what do you etch Feldspathic porcelain ceramic with

9.5% hydrofluoric acid gel for at least 1 min

what are the two over-arching types of ceramic restorations

metal-ceramic restoration

all ceramic restoration

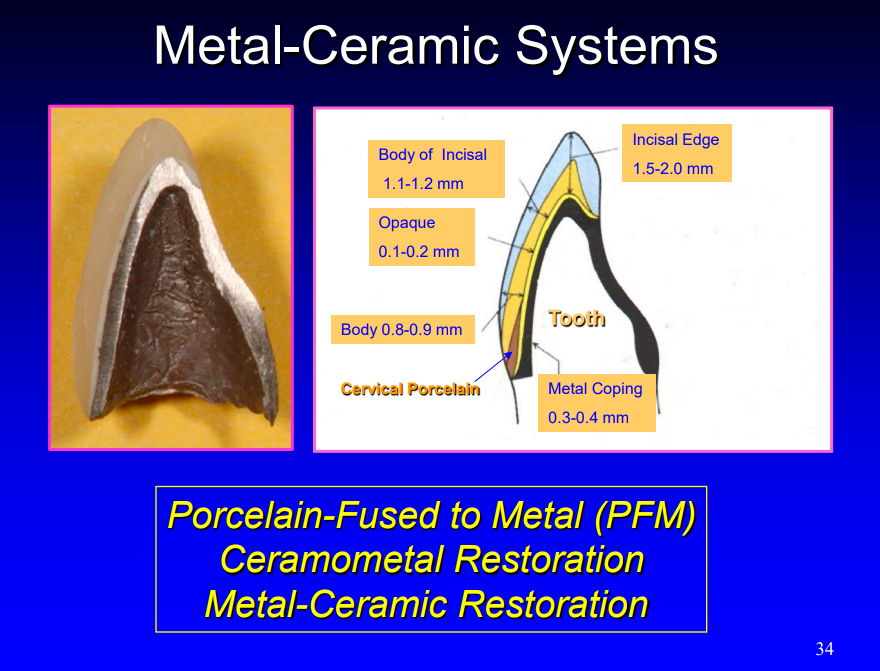

what are the three types of metal-ceramic restorations

porcelain-fused to metal (PFM)

ceramometal restoration

metal-ceramic restoration

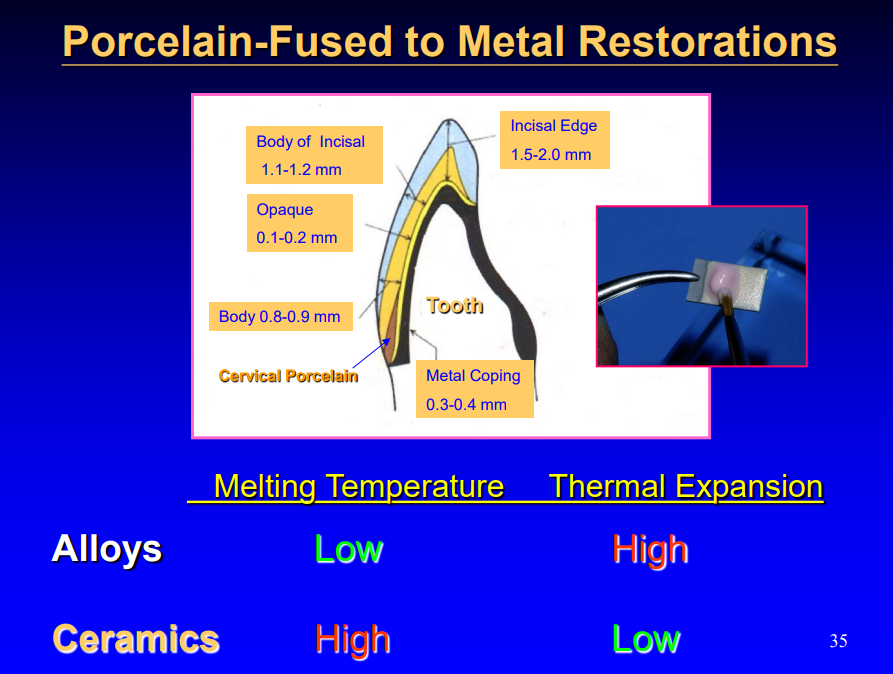

when referring to porcelain-fused to metal, what are the melting temperature and thermal expansion properties of the alloy and ceramic before bonding (high/low for each)

melting temp for alloy: low

melting temp for ceramic: high

thermal expansion for alloy: high

thermal expansion for ceramic: low

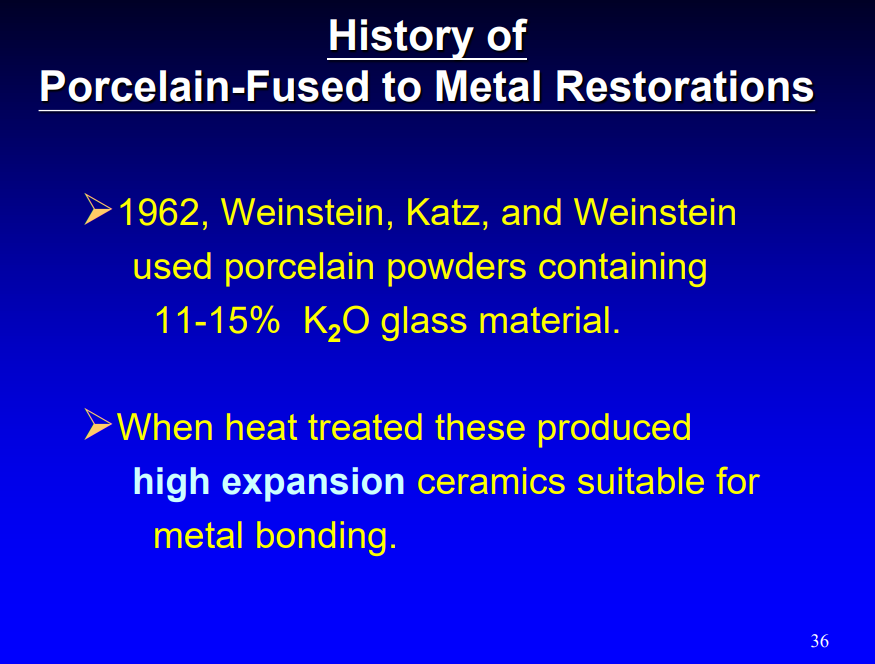

history of porcelain-fused to metal restorations

when heat treated, these produce high expansion ceramics suitable for metal bonding

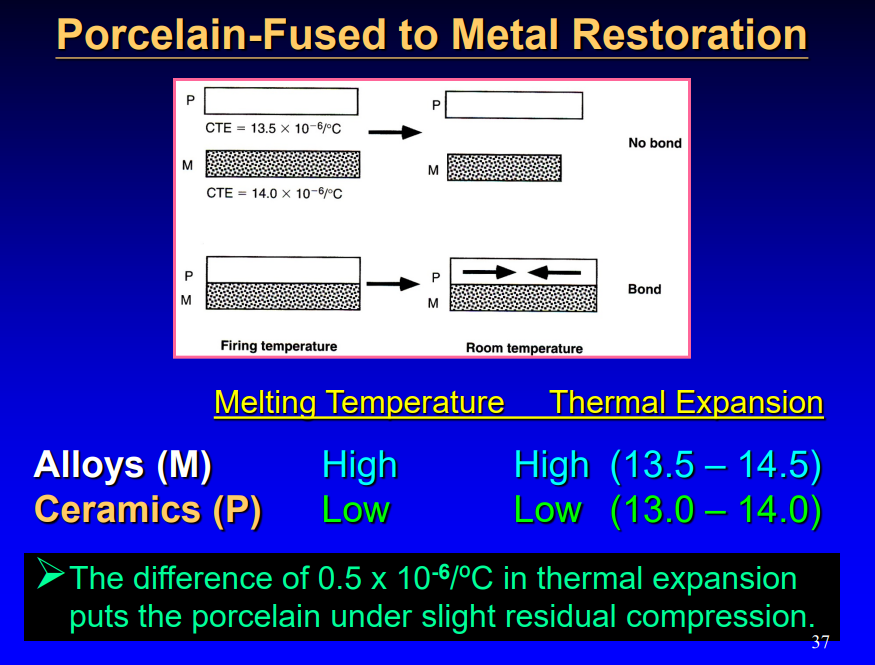

when referring to porcelain-fused to metal, what are the melting temperature and thermal expansion properties of the alloy and ceramic after bonding (high/low for each)

melting temp for alloy: high

melting temp for ceramic: low

thermal expansion for alloy: high

thermal expansion for ceramic: low

the properties of ceramics are customized for dental applications by precise…

control of the type and number of components (kaolin, quartz, feldspar) used in their production

dental porcelain fuses at a relative _________(high/low) temperature to form a hard substance much like enamel in appearance

relatively low temp

___________ is accomplished w various colored fusible materials

staining

what are the three triaxial porcelain compositions

quartz

kaolin (clay)

feldspar

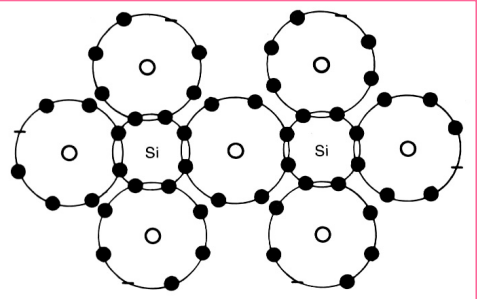

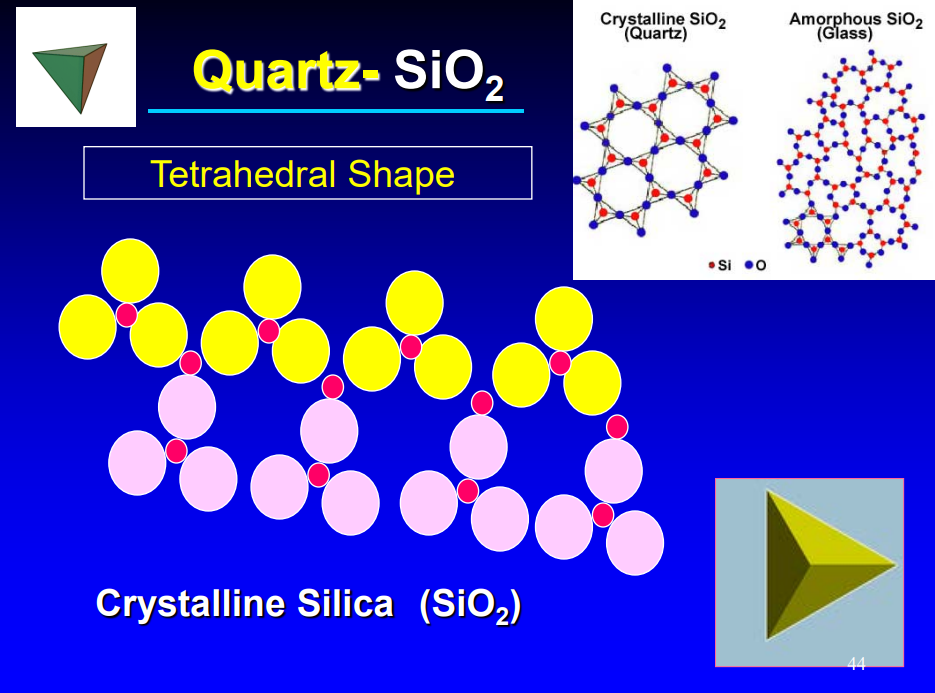

what is quartz

silica (SiO2)

what is kaolin (clay)

a hydrated aluminosilicate

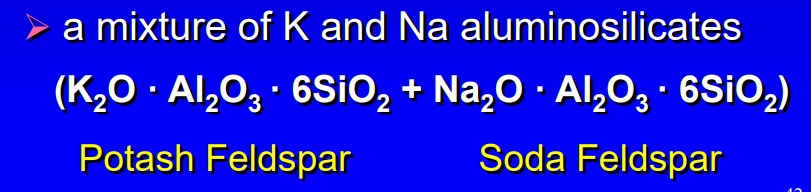

what is feldspar

a mixture of K and Na aluminosilicates

feldspar is a ______ (high/low) fusing component

low- 125-1170 C

what is the funx of quartz

binder

what is the funx of kaolin

opacifier and viscosity control

what is the funx of feldspar

strength and binder

what is the shape of quartz

tetrahedral shape

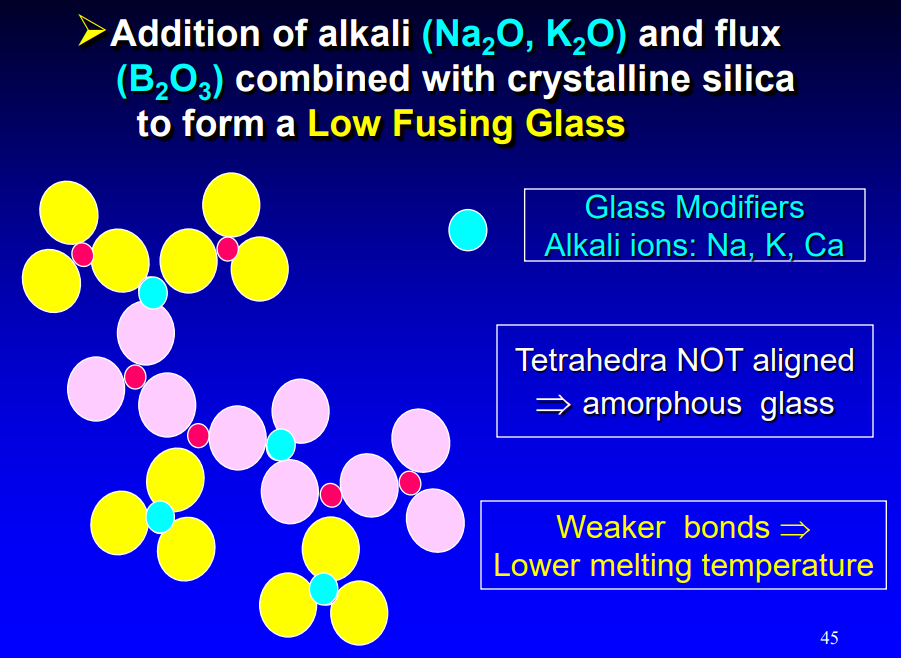

the addition of alkali (Na2O, K2O) and flux (B2O3) combined w crystalline silica forms a…

low fusing glass

what are glass modifiers

alkali ions: Na, K, Ca

if the tetrahedra is not aligned…

will be disorders → amorphous glass → weaker bonds → lower melting point

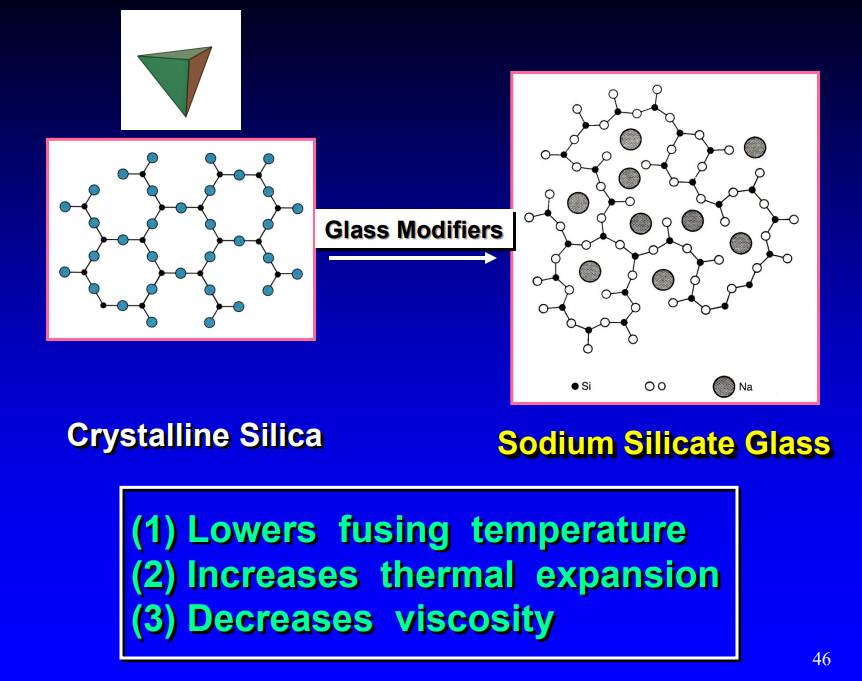

when adding glass modifiers to crystalline silica, you get…

sodium silicate glass

how do properties change when glass modifiers as added to crystalline silica to form sodium silicate glass

lowers fusing temp

inc thermal expansion

dec viscosity

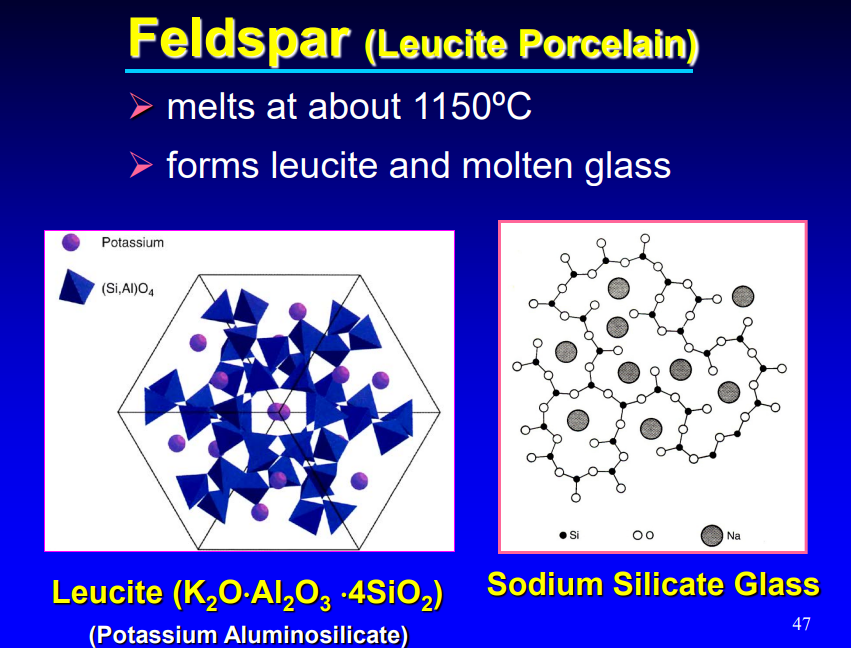

what does feldspar melt at

~1150 C

feldspar can form…

leucite and molten glass

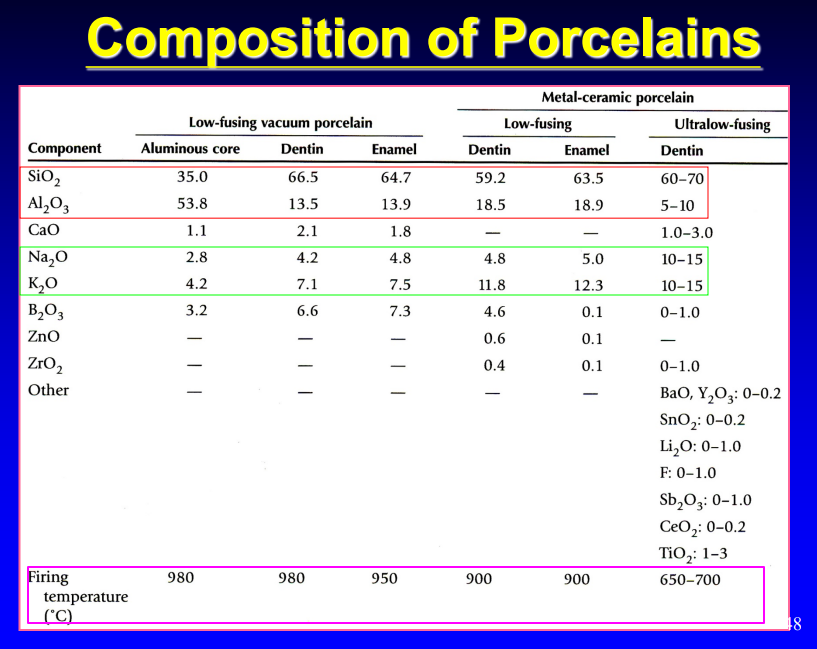

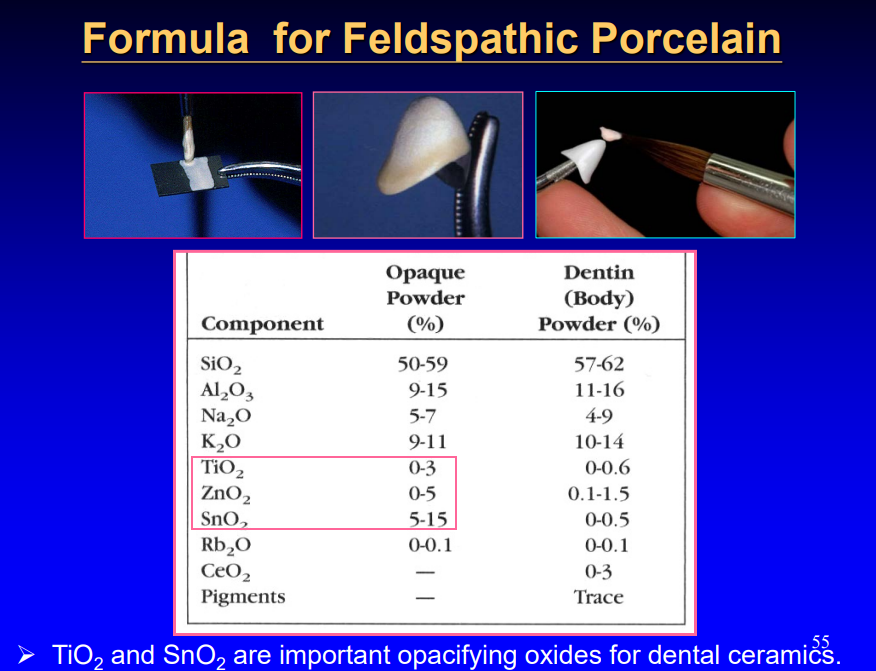

composition of porcelains

red box: major composition

green box: feldspathic material

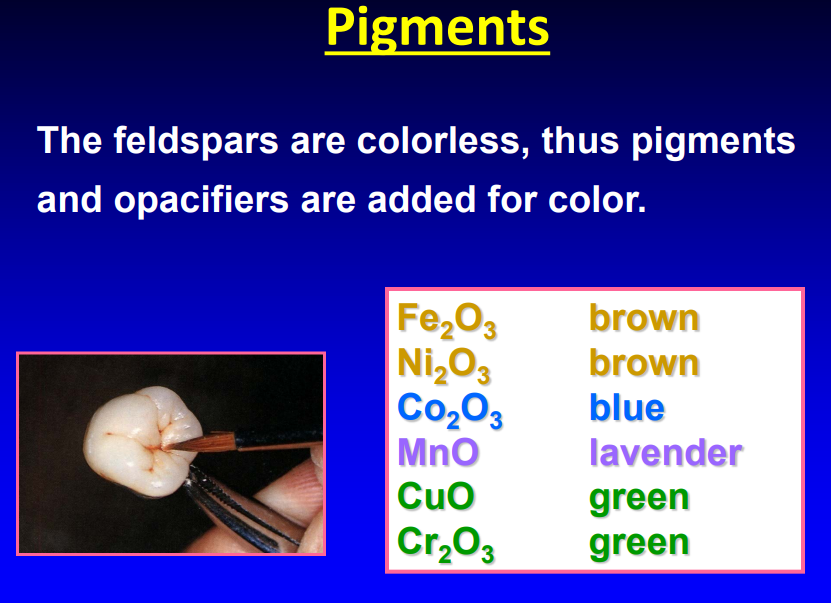

the feldspars are colorless, thus _______ and ________ are added for color

pigments and opacifiers

how are pigments made

grinding together metallic oxides w feldspar and glass

fusing the mixture in the furnace

regrinding to a fine powder

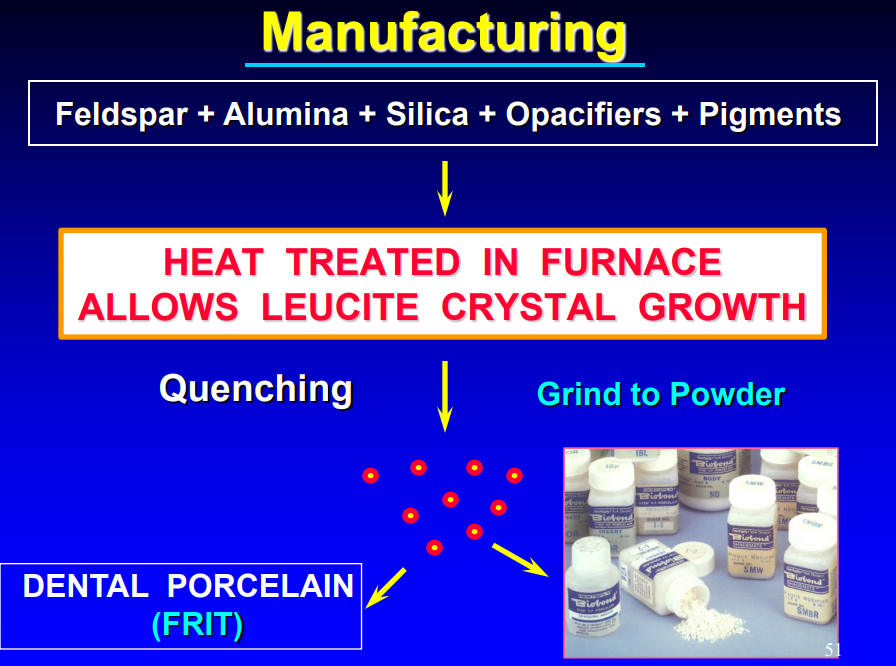

what is the manufacturing process (generally) to form dental porcelain (frit)

feldspar + alumina + silica + opacifiers + pigments

heat treated in furnace (allows leucite crystal growth)

quenching

grind pigments to powder

frit

what is the processing portion of dental porcelain

shade selection

porcelain powders are mixed w water to produce a plastic mass of material which can be molded and carved before firing

in the processing phase of metal-ceramic restoration, what do you apply w a brush

apply opaque w brush to oxidized alloy

apply body and enamel w brush to opaquing alloy

apply incisal or enamel over body porcelain

what are important opacifying oxides for dental ceramics

TiO2 and SnO2

when processing there is a 13% oversize to accomodate for what

shrinkage

in processing, the technician fuses the porcelain powder and simply…

remelts the drits w/o causing any significant inc in rxn between components

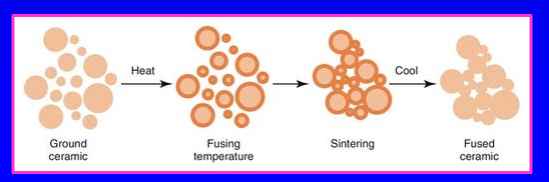

what is the fusion process known as

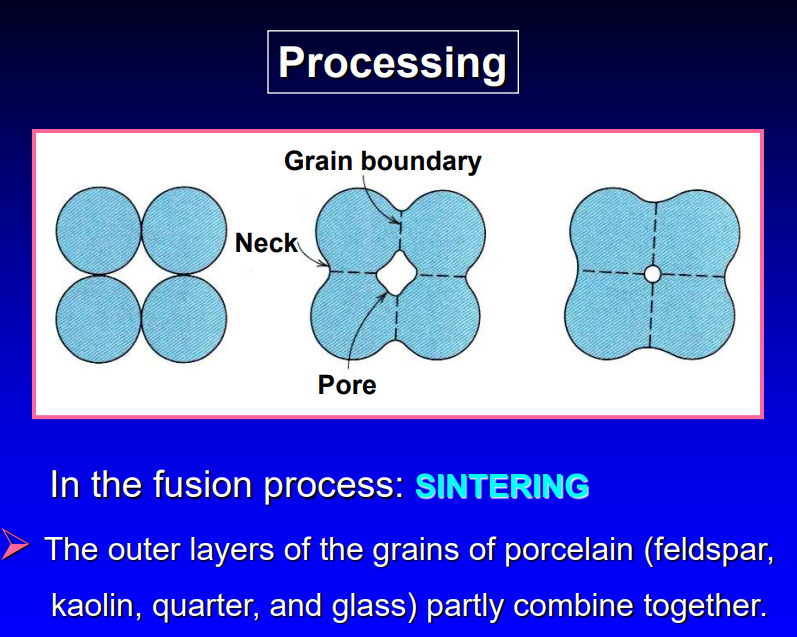

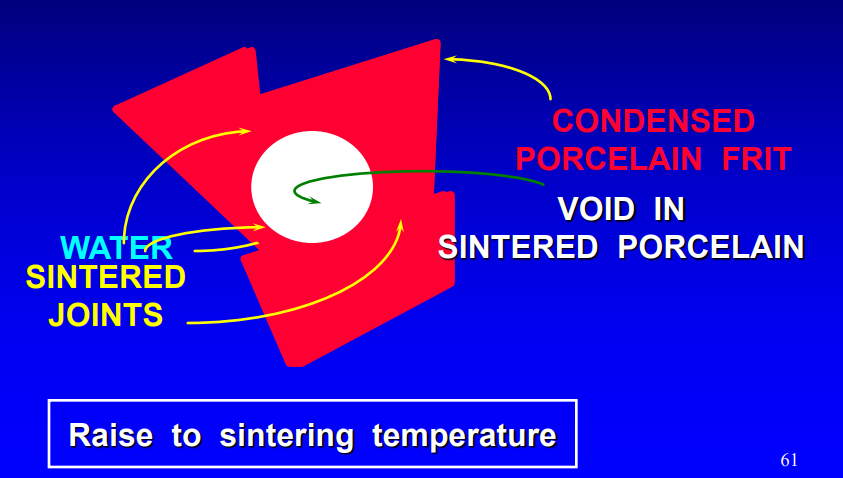

sintering

what is sintering

the outer layers of the grains of porcelain partly combine together; the process of heating closely -packed particles to achieve inter-particle bonding

sintering image

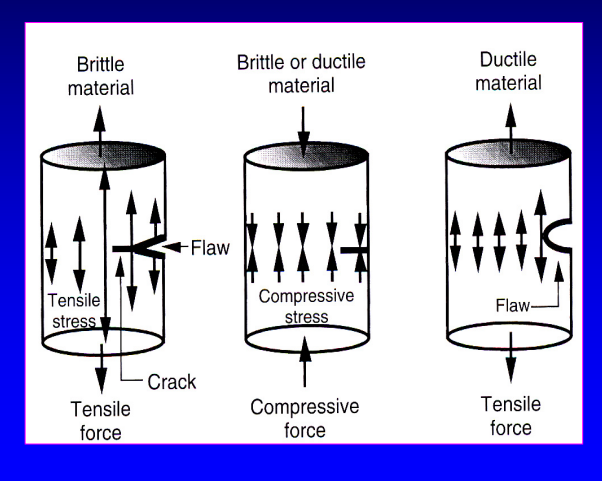

ceramic has a _________ (high/low) compressive strength and a _______ (high/low) tensile strength

high compressive and low tensile

what is glazing

a low-fusing, transparent glass that may be used as a glaze material; glaze give a crown an impervious, smooth surface and imparts greater translucency

requirements for a metal-ceramic system: the veneering porcelain must have a _____ fusing temp

low fusing temp

requirements for a metal-ceramic system: melting range of the alloy must be at least _____ higher than the firing range of the veneering porcelain

100 C

requirements for a mental-ceramic system: the alloy should have excellent _________

castability

requirements for a metal-ceramic system: the alloy substrate has adequate __________ and ______________

adequate stiffness and strength

requirements for a metal-ceramic system: the porcelain must wet the alloy surface readily during…

firing

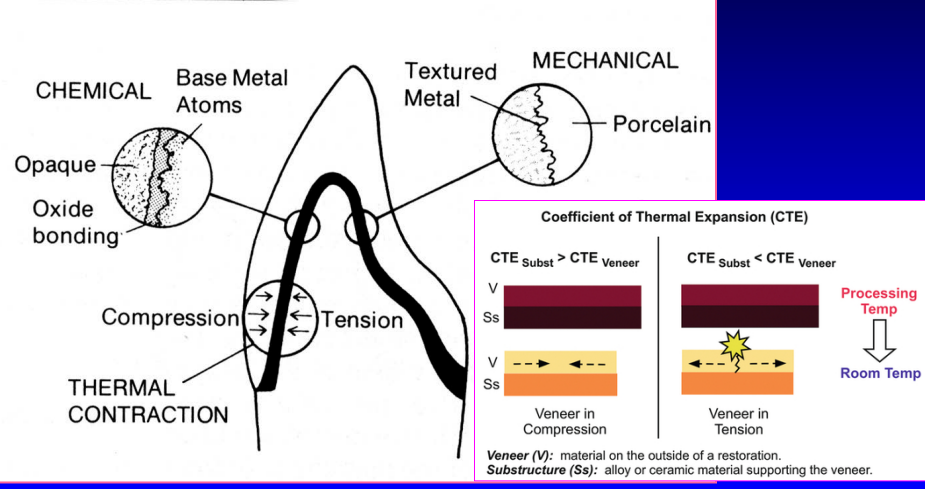

requirements for a metal-ceramic system: coefficients of thermal expansion of the metal is slightly ______ (higher/lower) than that of porcelain

slightly higher

requirements for a mental-ceramic system: a stronger bond between the __________ and __________ is essential

between veneering porcelain and metal substrate

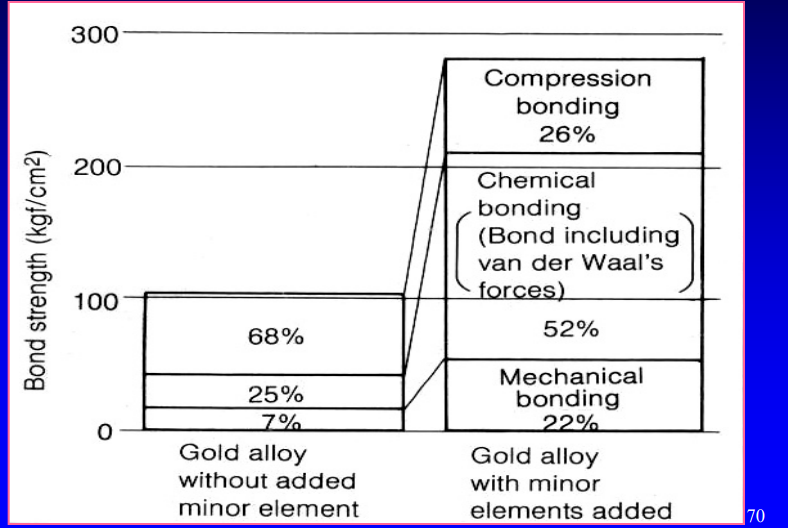

what are the three methods of bonding porcelain to metal

chemical

thermal contraction

mechanical

bond strength of gold alloy w. vs w/o minor element added

higher w added minor elements

in obtaining surface oxide, you introduce base metal elements into precious metal alloys to form…

thin oxide

in obtaining surface oxide, direct oxide production the constituents of the alloy such as…

base metal alloys

in obtaining surface oxide, surface coating of metals w oxidizable metals such as…

In and Sn

advantages of metal-ceramic restorations

adequate marginal integrity

predictable strength

disadvantages of metal-ceramic restorations

compromised esthetic results

potential biocompatibility problem w some base-metal alloys