AS Product Design

1/50

There's no tags or description

Looks like no tags are added yet.

Name | Mastery | Learn | Test | Matching | Spaced |

|---|

No study sessions yet.

51 Terms

generation and development of ideas (4 points)

Understand Problem, Discuss with client, Come up with idea, Test,

User Centred Design

The user, or target market, should be consulted

regularly throughout the design process – they

are an important part of it!

Effective design specifications

Measurable Criteria, sorted into needs and wants

Methods of communicating Design Ideas (5 points)

Sketches, Card Modelling, 2D and 3D CAD models, CAM rapid prototyping, Formal Design Drawings

Benefits of CAD (7 points)

Increases productivity, more complex designs can be achieved, designs can be edited/reused easily, Designs can be easily understood, CAD files can easily be shared, no physical space required, Links to CAM seamlessly

Benefits of CAM (5 points)

Faster and more accurate, continually produces identical outcomes, creates complex outcomes, cost efficient, reduces labour costs

Disadvantages of CAD/CAM (6 points)

Expensive Setup cost, Requires servicing, parts are often expensive, training required, manual workers still needed, production becomes reliant on CAM, errors cam cause delays

Softwood

Comes from coniferous trees, evergreen, faster growth, softer and lighter and cheaper

Examples of Softwood

Pine, Cedar, Spruce

Hardwoods,

Deciduous Trees, shed leaves, grow slower, more expensive, harder, heavier

Examples of Hard wood

Oak, Beech, Mahogany

Thermosetting Polymers examples (4 points)

ER, MF, PR, ABS

Thermoforming Polymers examples (3 points)

acrylic, polystyrene, hips

Ferrous Metals

contain iron, magnetic, corrode

Non-ferrous metals

no iron, dont corrode, not magnetic

Examples of ferrous metals

Steel, Cast Iron, wought iron

Examples of non ferrous metals

copper, lead, aluminium

Alloy

A mixture of metals to improve properties or aesthetics

Examples of Alloys

Bronze, Stainless Steel, Brass

Composite material

A mixture of materials to enhance properties or aesthetics

When a material is light but strong, what do we say?

It has a high strength to weight ratio

Metal Finishes - Galvanising

Plating a metal with zinc, improves durability, corrosion resistance and exterior appearance

Metal Finishes - Heat Treatment

Hardening, increases durability

Metal Finishes - Anodising

Aluminium is anodised to provide corrosion resistance

Natural Timbers Finishes (4 points)

Stains, Varnishes, Paints, Pressure Treatment (used in outdoor fences)

Why do we apply finishes to Natural Timbers

Mainly decretive, but also protects against moisture. Pressure Treatment is used in outdoor fences

Finishes for Manufactured Boards

MDF, plywood, hardboard and chipboard are all absorbent and need to be sealed before a finish can be applied. Veneers often provide a finishing layer to manufactured boards and timbers.

Properties of natural timbers

durability, strength, hardness, toughness, and elasticity. Natural timbers are not good conductors of heat and electricity, and are therefore good insulators.

Properties of Manufactured Boards

Good insulators of heat and electricity, and do not warp as much as natural timbers. Manufactured boards are strong.

Properties of Metals

good conductors of heat and electricity, high density malleable and ductile, can be increased when a heat treatment finishing process is applied to some metals.

Modern Materials - Carbon Fibre

High strength to weight ratio, can be shaped into complex forms, smooth finish, can be sprayed and laqured

Modern Materials - Kevlar

fibre-based material which is commonly spun into sheets of fabric and used to produce protective clothing and jet engine linings

Nanomaterials

Nanomaterials are between 1 and 100 nanometres,

Smart materials

change in reaction to external stimuli

Thermochromic Pigments

Changes colour based on temperature

Photochromic pigments

Darken when light is applied

Shape memory alloys

can be set to a specific shape, and after it dents, it will return to the original shape

Hydrochromic Paint

Changes colour when it comes in contact with water

Phosphorescent materials

absorbs daylight and stores it, so it glows in the dark

Moulding

process involving shaping a liquid or malleable raw material using a frame, mould, former or cavity.

Extrusion

used to create objects with a fixed cross-sectional shape. A hot or cold material can be pushed through a die to create complex shapes that are consistent in length.

Laminating

technique of manufacturing materials in multiple layers

Milling

Using rotary cutters to remove material from a work piece

Casting

Process where liquid is poured into a mould and it cools to solidify

Forming

is where mechanical deformation changes the shape of a material. The shape of the material is permanently deformed without adding or removing any material.

Injection Moulding

Granular form pellets are fed into a hopper, and gravity is fed into a heater where they become molten. The molten plastic is injected into the mould cavity under pressure, until the cavity is filled. This is then cooled and ejected or removed from the mould

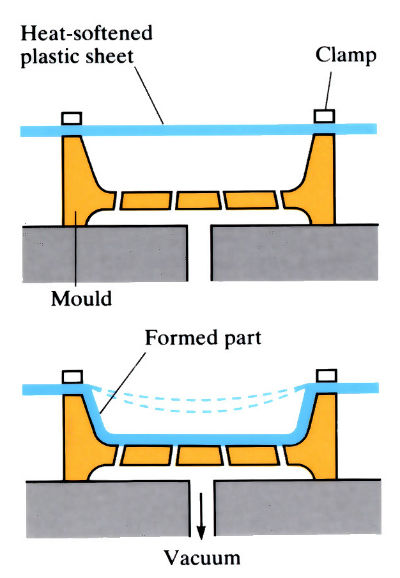

Vacuum Forming

A heater polymer tube is placed inside a cavity or mould and inflated to take the shape of the chamber, at the same time creating a hollow form with a thin wall.

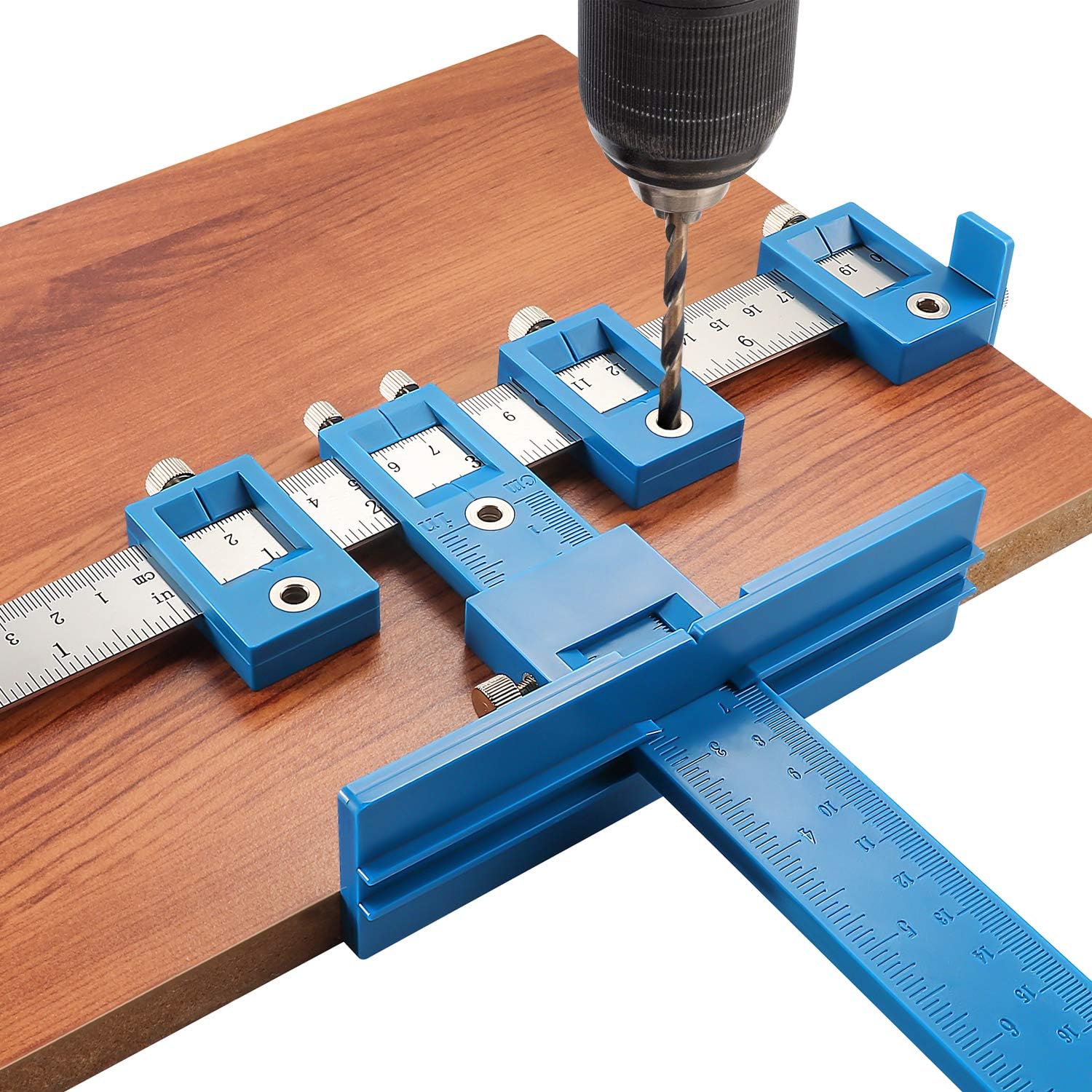

Jigs

A device used to guide a tool to a specific position on a workpiece

Fixture

Tool which holds the workpiece to a machine bed in a specific position

Stock Forms

materials machines into standard sizes or forms

5 Step risk assessment

IDERR - Identify, Decide, Evaluate, Record, Review