1.4 Metal processes

1/10

There's no tags or description

Looks like no tags are added yet.

Name | Mastery | Learn | Test | Matching | Spaced |

|---|

No study sessions yet.

11 Terms

press forming

1. Sheet metal is clamped over a die of the product that will determine the final shape of the pressing

2. A hydraulic press pushes the die into the sheet metal. Cutting blades may be included to punch holes into the sheet and trim the excess from the edges

3. The hydraulic die is lowered and the pressed sheet component is removed

4. The sheet may be placed into further press forming machines for additional pressing, where the shape is complex

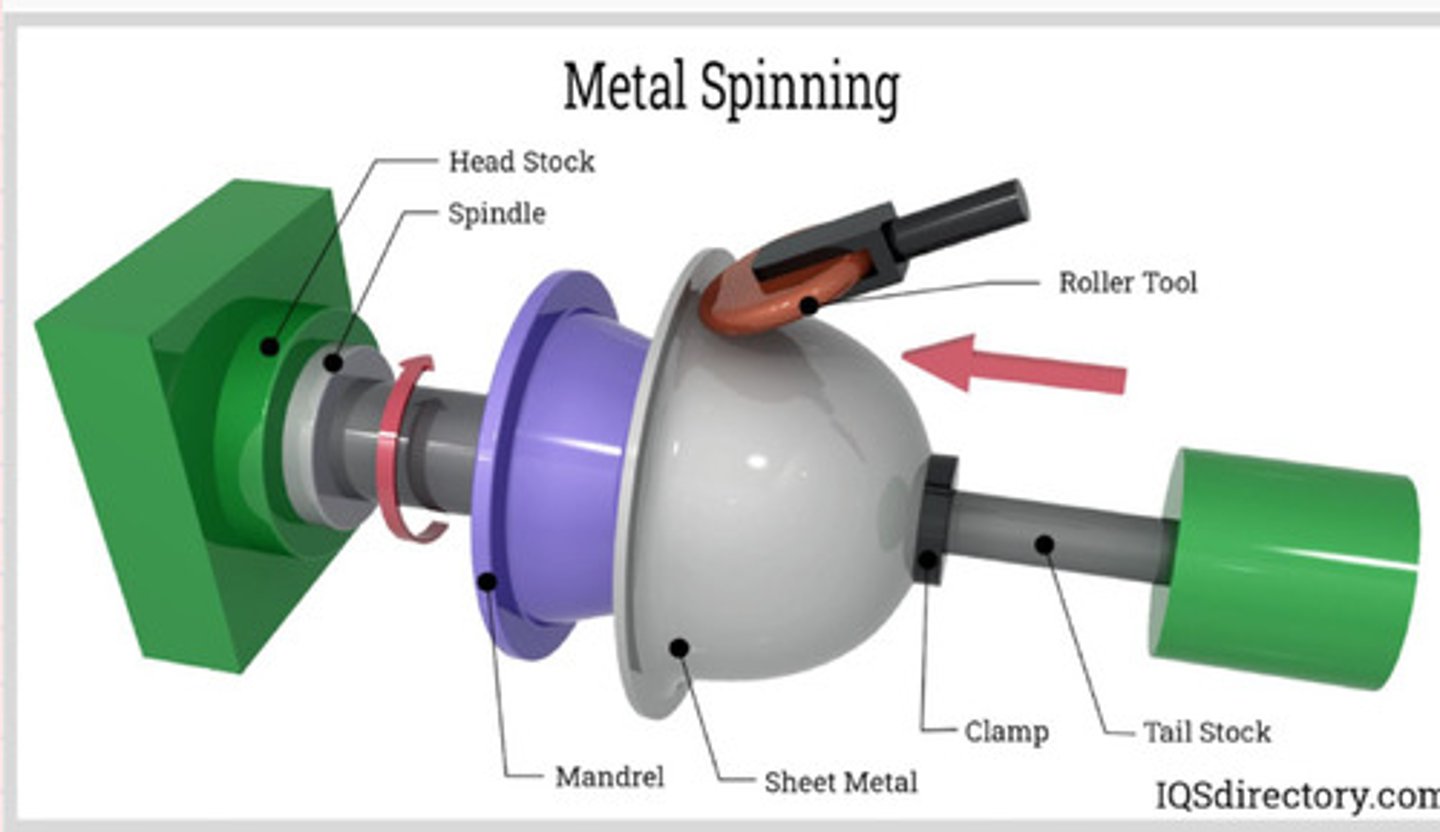

spinning

1. A former called a mandrel is put into a chuck.The sheet metal blank is held in place between the mandrel and the tail stock

2. The roller tool is moved into the blank and is rotated with the mandrel. This starts to stretch the metal over the mandrel

3. The roller tool is moved along the mandrel as pressure is maintained against the rotating blank

4. The roller toll is moved to the end of the mandrel,while still maintaining contact with the blank. This finishes the shape of the product

5. The finish product is removed from the mandrel

6. Excess material is trimmed off following the spirring process

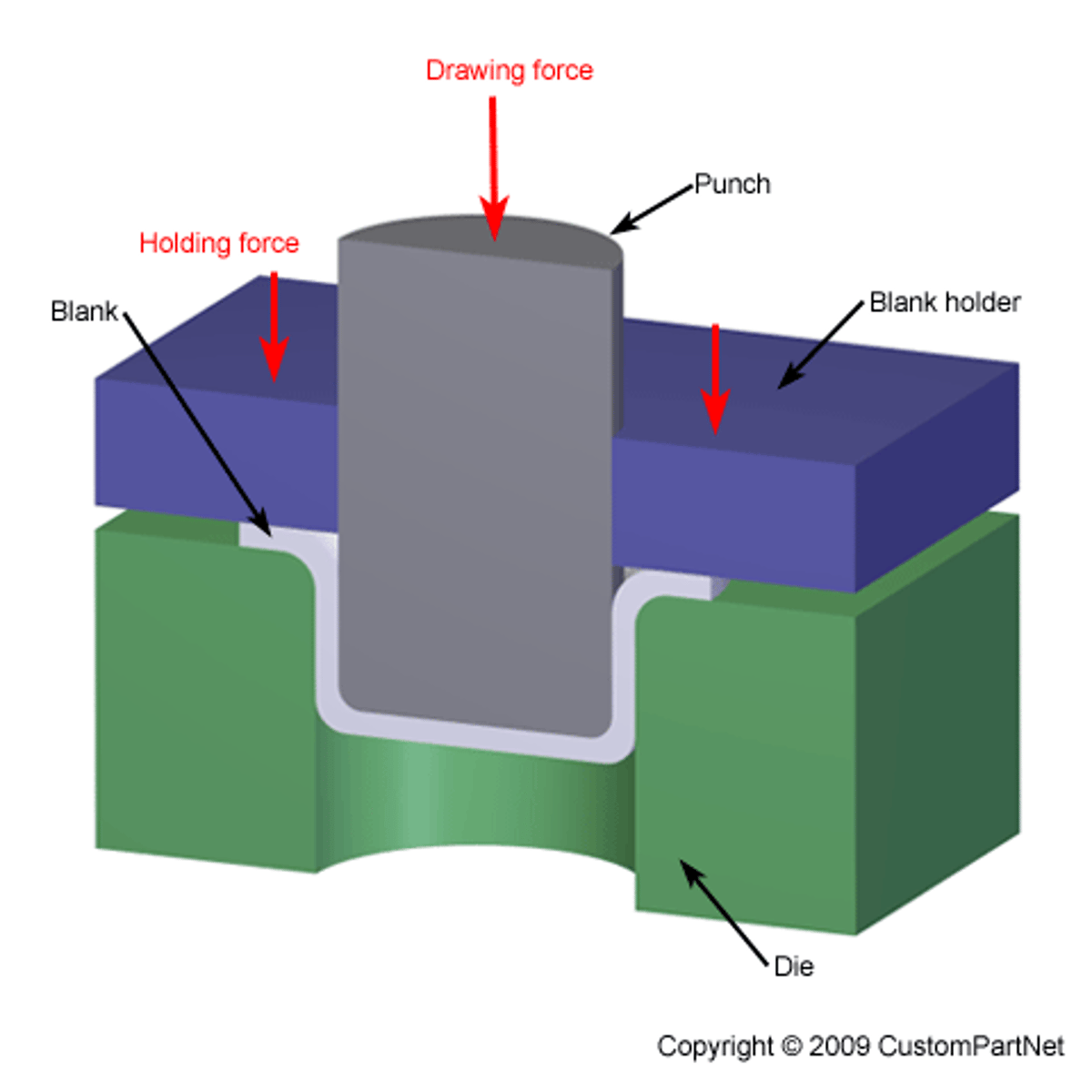

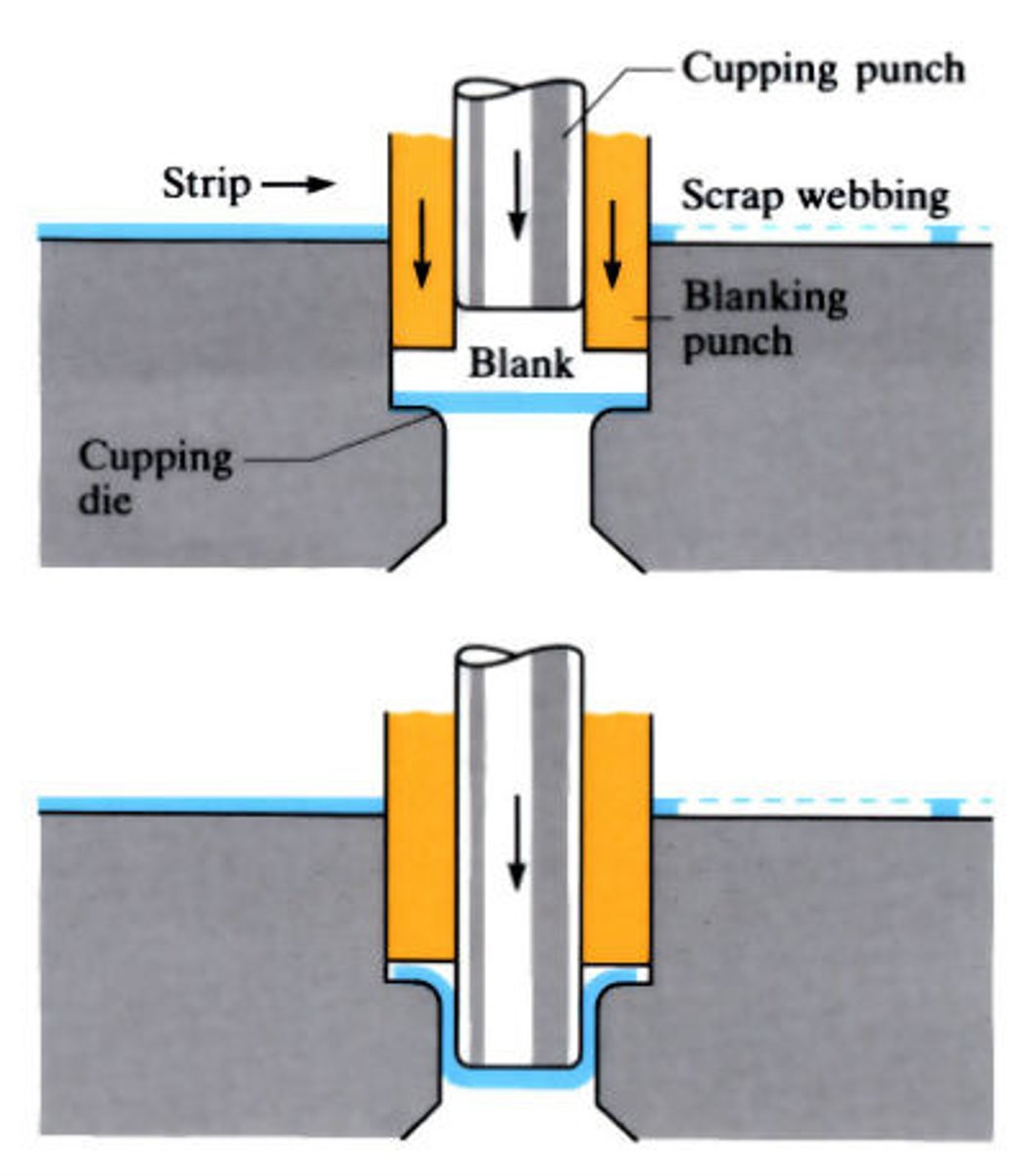

Cupping and deep drawing

1. The pressing blank is clamped over a deep drawing die using a pressure pad or clamping ring known as a retainer

2. A hydraulic press moves the deep drawing punch to be in contact with the blank. It then pushes the blank into the die cavity to make a cup shape

3. The cup is then pressed further down through the deep drawing die to make the desired tube shape

wrought iron forging

A metal forming process which uses an hammer and anvil to shape wright iron

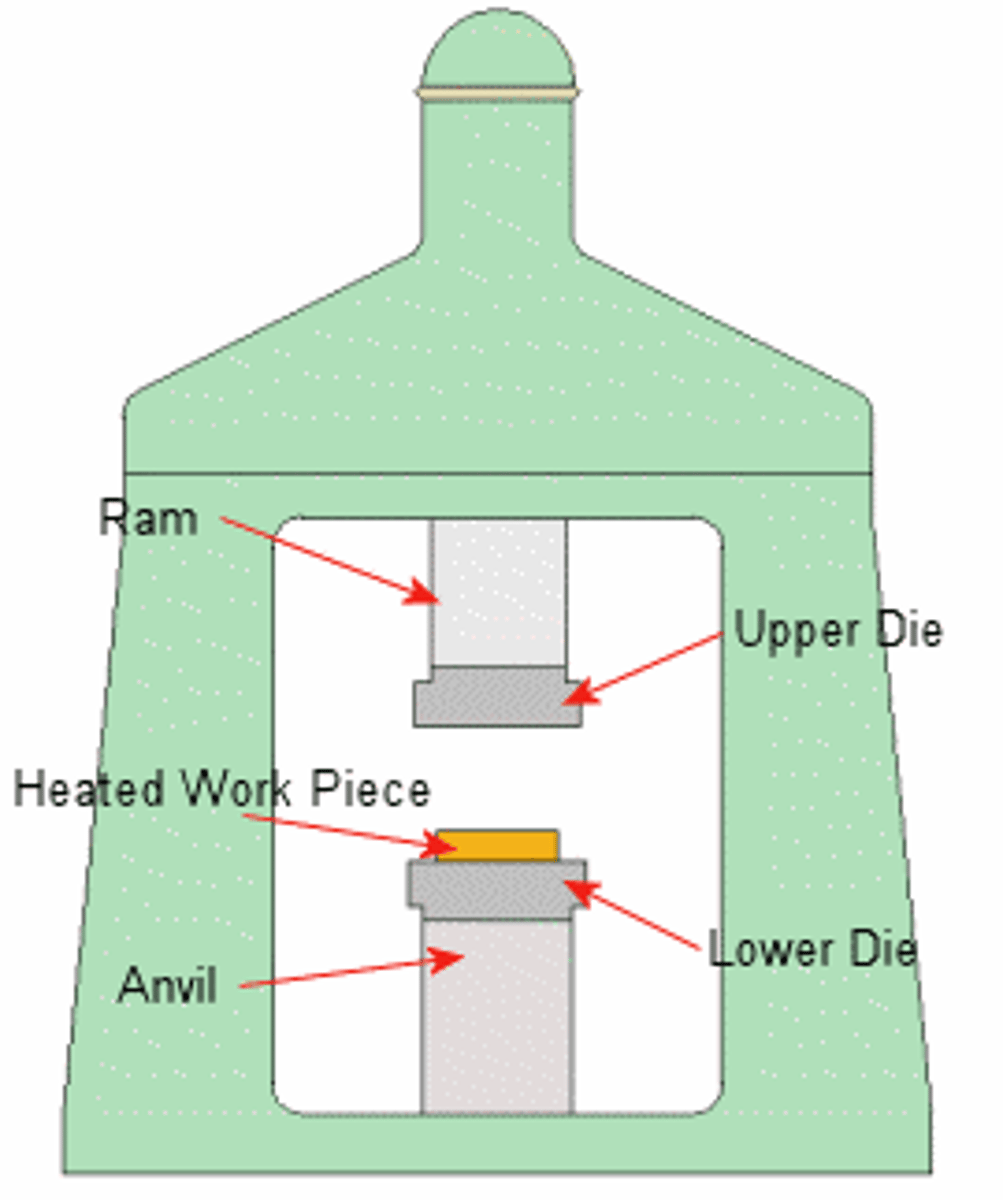

Drop forging

1. A die is made from cast tool steel ( which resembles a mould and this is secured to the top of an anvil

2. A ram is also equipped with a die that resembles a mould

3. The metal billet to be forged is heated to above recrystallisation temperature. This stops the product from a work hardening as it cools which would make it brittle

4 .Using tongs, the heated billet is placed by an operator into the anvil die, and the hydraulic ram is brought down with force. This makes the hot billet spread around the shape of the die

5. The ram is lifted and the completed product removed for cooling and finishing

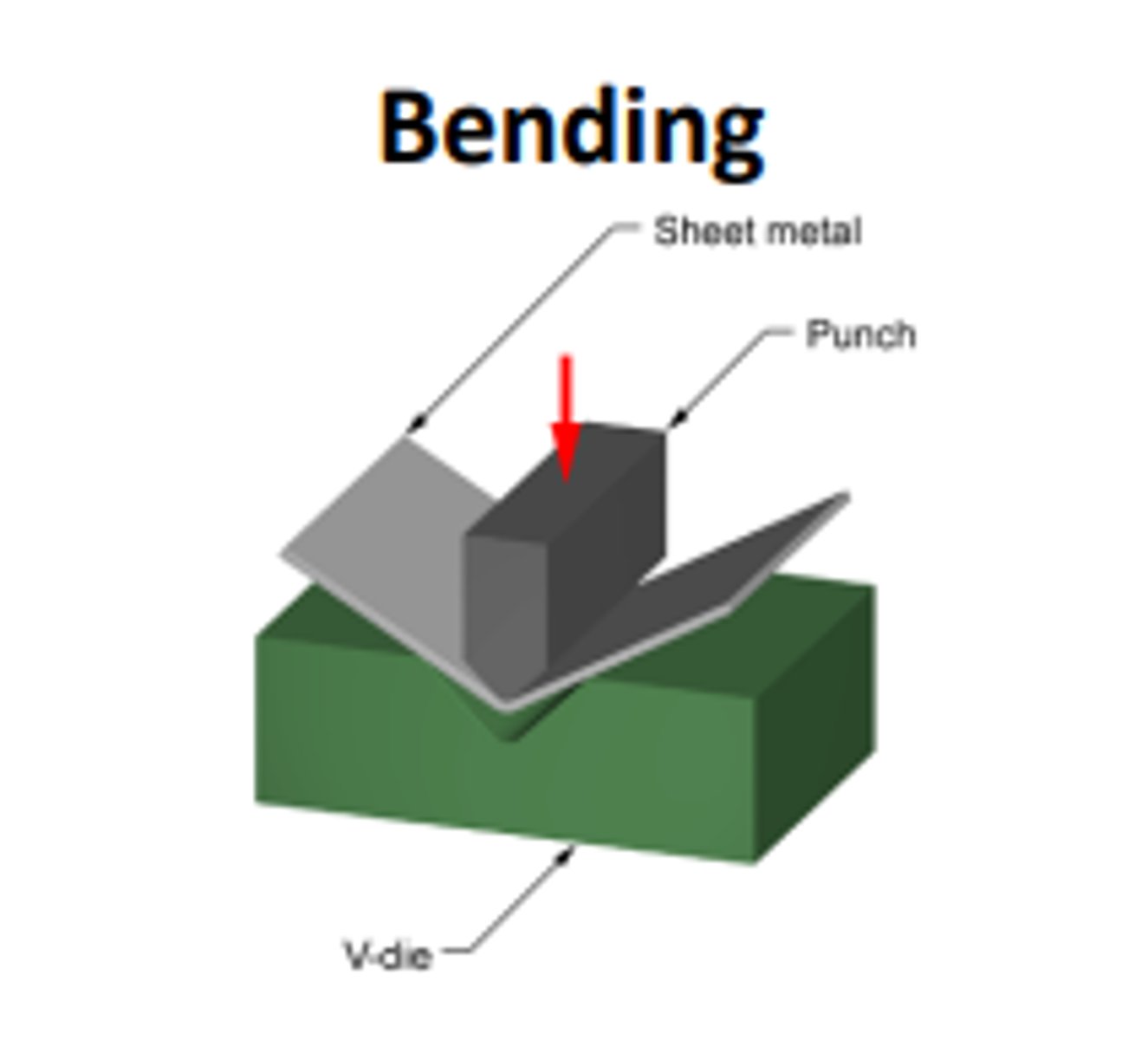

metal bending process

Bending sheet or plate metal industry is done using a machine called a press brake. The desired bends are achieved by clamping the stock metal and lowering the punch to create a shape.

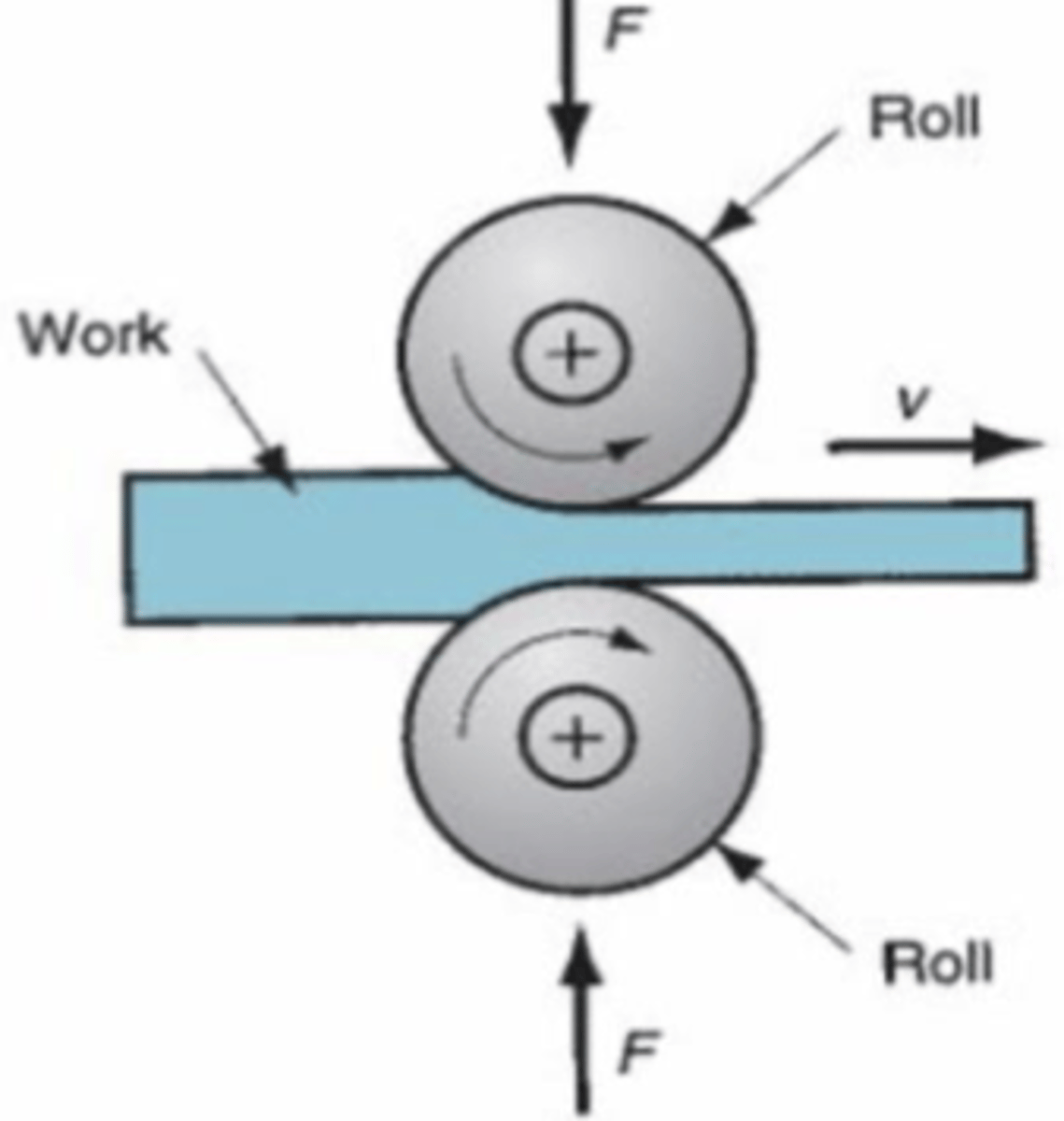

metal rolling

the process of reducing the thickness or changing the cross section of a long workpiece by compressive forces applied through a set of rolls

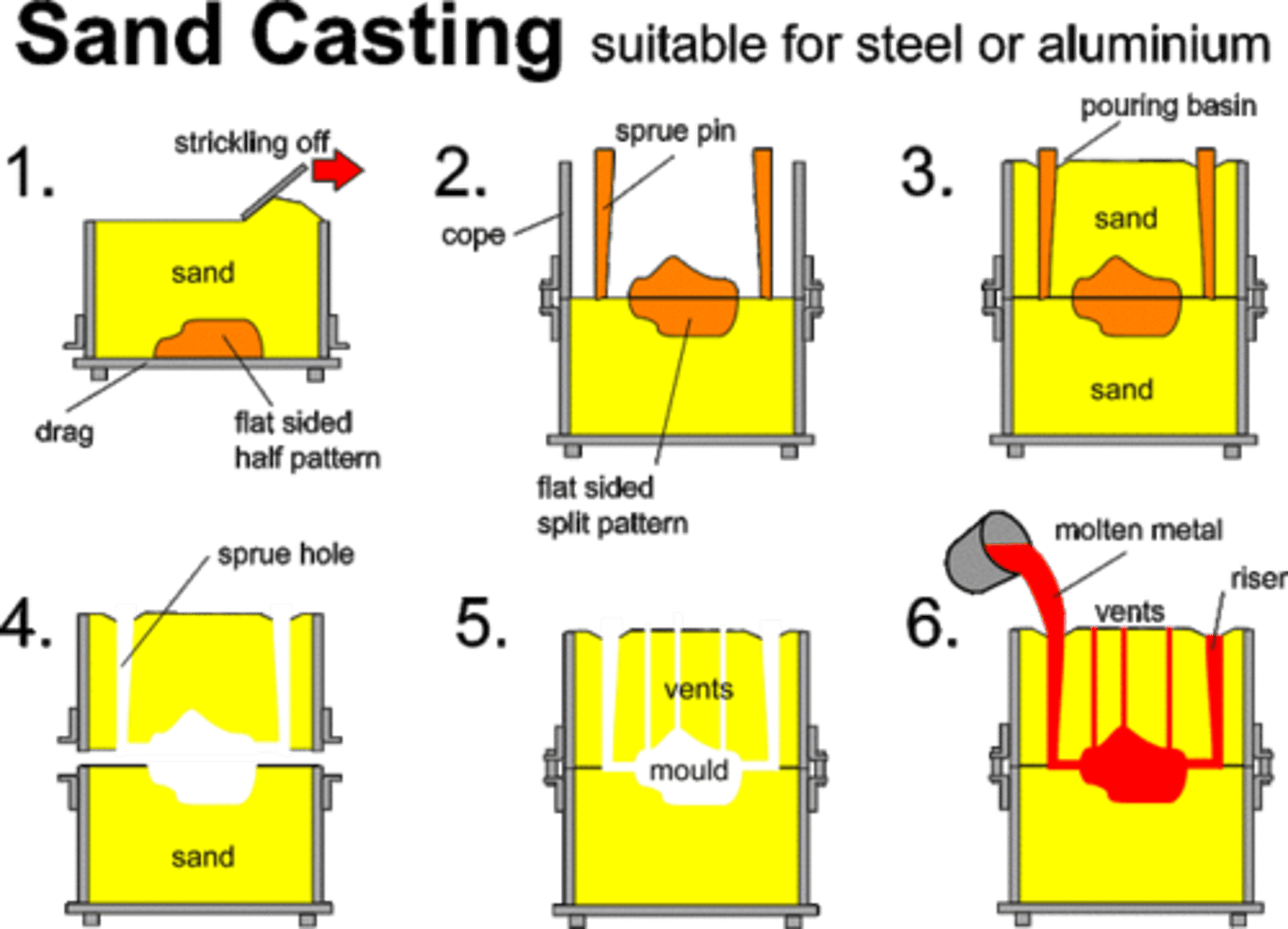

sand casting ( metal redistribution process )

1. Design and Pattern Creation

Design the object and create a pattern (usually from wood, plastic, or metal) that is slightly larger than the final size to account for shrinkage.

2. Prepare the Mold Box

Select a mold box (flask) slightly larger than the pattern. Coat the pattern with parting agent and ensure the pattern is positioned correctly to allow for easy mold separation.

3. Prepare the Sand and Compact the Mold

Mix sand with binder (like clay) and water, then compact the sand around the pattern in the mold box using a rammer to form a stable mold.

4. Remove the Pattern and Prepare for Pouring

Carefully remove the pattern, leaving a hollow cavity in the sand. Inspect the mold for defects and ensure the metal can flow into the mold properly.

5. Pour the Molten Metal

Heat the metal to a molten state and carefully pour it into the mold. Ensure safety precautions are followed when handling molten metal.

6. Break the Mold and Finish the Cast

Allow the metal to cool and solidify, then break open the mold. Clean up the casting by removing excess metal and finishing it with tools like files or a grinder.

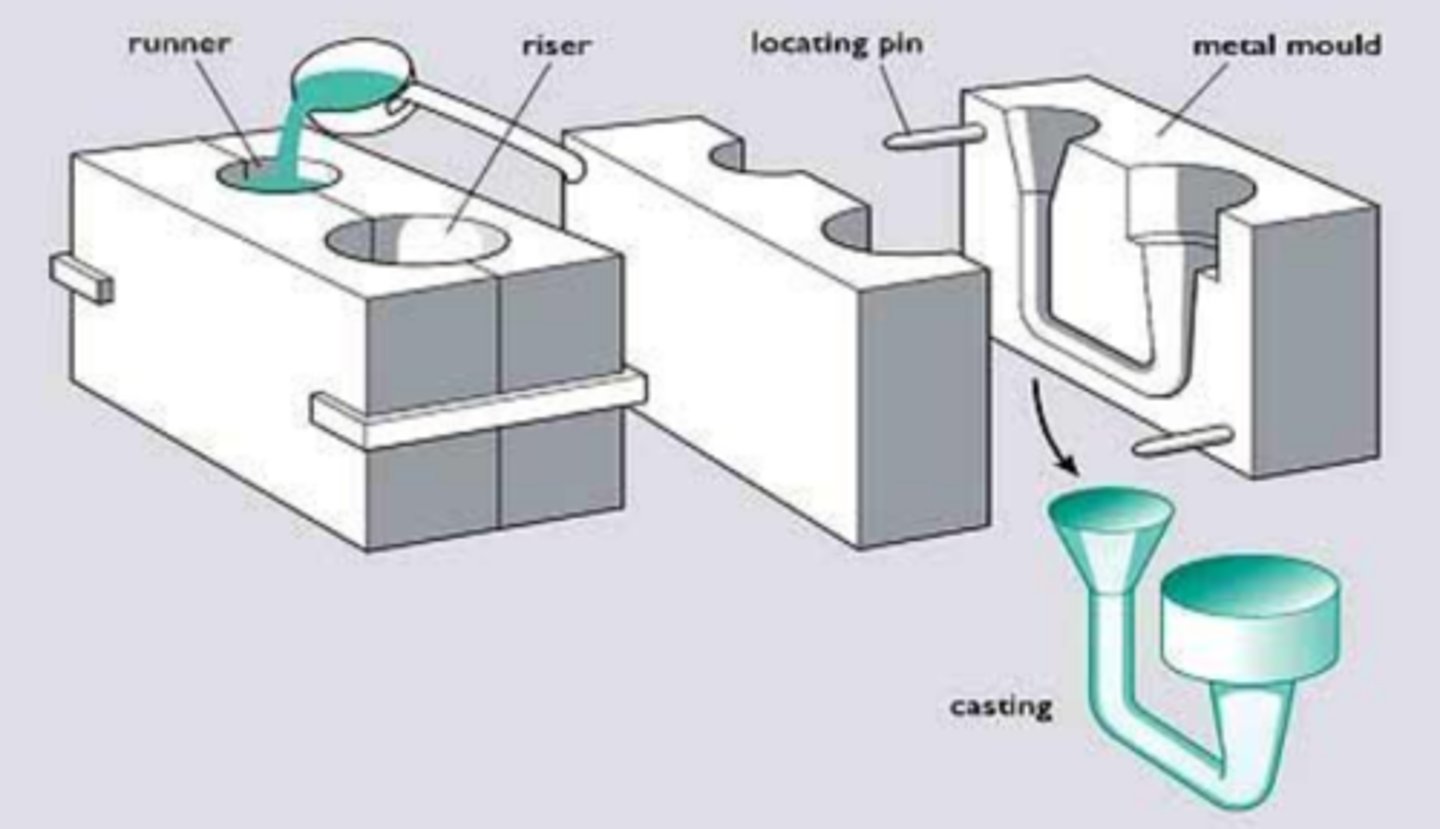

die casting

the process or product of forcing molten metal into a metallic mold under hydraulic pressure to give it a particular shape or form.

Investment casting

1. An exact replica or pattern of the product to be cast is made using wax. (This might be made using a master mould machined in steel or aluminium if the product is to be batch produced.) Where several items are to be cast, further wax patterns might be joined together in a 'tree', including a replica of the runner that will be used to pour the molten

metal in.

2. The wax pattern is dip coated with a refractory clay. It is then fired in a kiln to bake the clay hard. The wax is burned away, leaving a hollow clay mould.

3. Molten metal is poured into the clay mould.

4. Once the metal has filled the mould, it is allowed to cool.

5. The clay mould is then broken away, revealing the casting.

6. The runner and any connecting channels are machined off.

Low temperature pewter casting

1. A mould is made from MDF, plywood or high density modelling foam. If made from MDF or plywood, the mould might be laser cut or cut with a fret saw. The mould will include a spruce or runner which will be used to pour the pewter into

2. The mould is sandwiched between two piced of MDF and clamped together. The top of the mould will be level with the top of the side piece

3. The pewter is melted in a ladle and then ladled into the sprue

4. once the casting is cooled, it is removed from the mould

5. The spruce or riser is removed with a junior hacksaw

6. The casting is then filed, and cleaned up using abrasive wet and dry paper

7. The casting would then be polished