Environmental Engineering - Drink Water: Final Exam

1/66

Earn XP

Description and Tags

Final Exam concepts review

Name | Mastery | Learn | Test | Matching | Spaced |

|---|

No study sessions yet.

67 Terms

mass flux definition

rate of mass transfer

mass flux equation

m dot = J x A (flux density x area)

flux density definition

rate of mass transferred across a plane

flux density units

J = mass/time-area

3 mass transfer processes

advection, diffusion, dispersion

advection

“bulk flow” movement of a compound along with flowing air or water (J = C x v = concentration x velocity)

diffusion

net effect of random molecular movement caused by molecule’s thermal-kinetic energy. governed by Fick’s Law

diffusion equation

J = -D(dC/dx) = diffusion coefficient x concentration/position. Fick’s Law!

turbulent dispersion

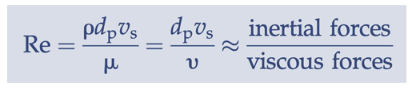

mass transfer through mixing of turbulent eddies. dependent on Reynold’s number

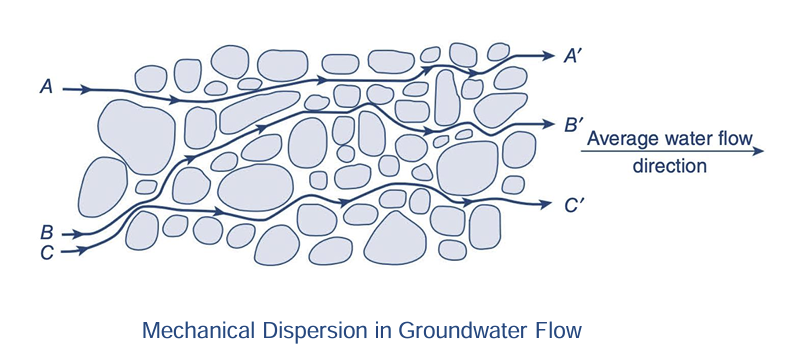

mechanical dispersion

variation in flow pathway and velocity of fluid particles with similar origin points

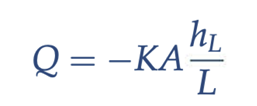

Darcy’s Law

rate of flow through a porous media

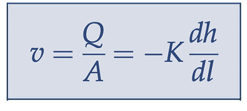

Darcy’s velocity

specific discharge

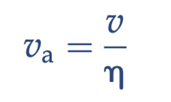

seepage velocity

seepage velocity

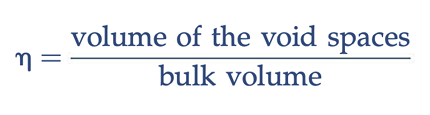

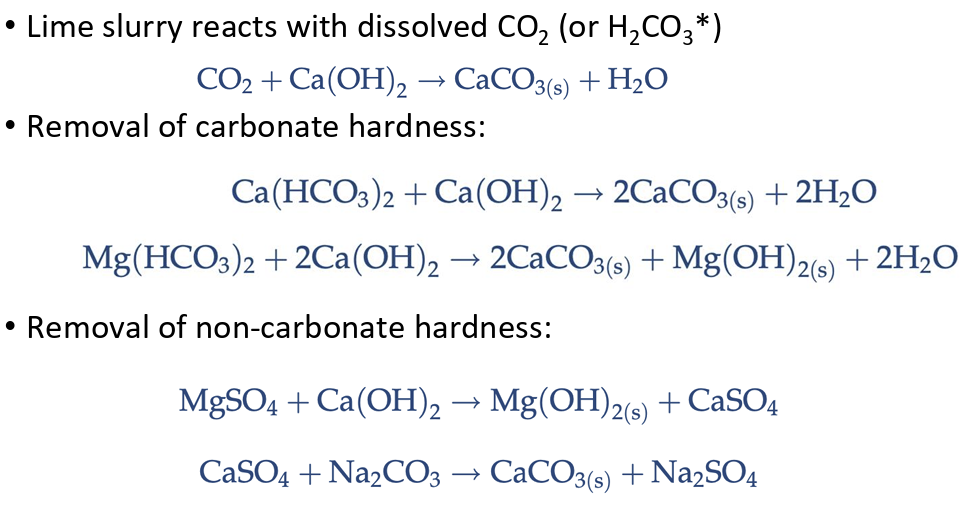

porosity (n) of an aquifer material

retardation coefficient

implies that a chemical that is undergoing sorption with the surrounding soil or aquifer material will travel at a slower rate than the average velocity (va) of the groundwater by a factor of Rf.

retardation coefficient equation

Kp - soil-water partition coefficient (L/kg)

n - porosity (unitless)

rohb - bulk density

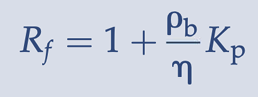

hardness in water

sum polyvalent metal cation (alkaline earth ions). given in mg/L as CaCO3

total hardness

TH = Ca2+ + Mg2+ = carbonate hardness + noncarbonate hardness

carbonate hardness (CH)

Ca2+ and Mg2+ associated with alkalinity anions (for example, HCO3- )

noncarbonate hardness (NCH)

Ca2+ and Mg2+ associated with nonalkalinity anions (for example, SO42- and Cl-).

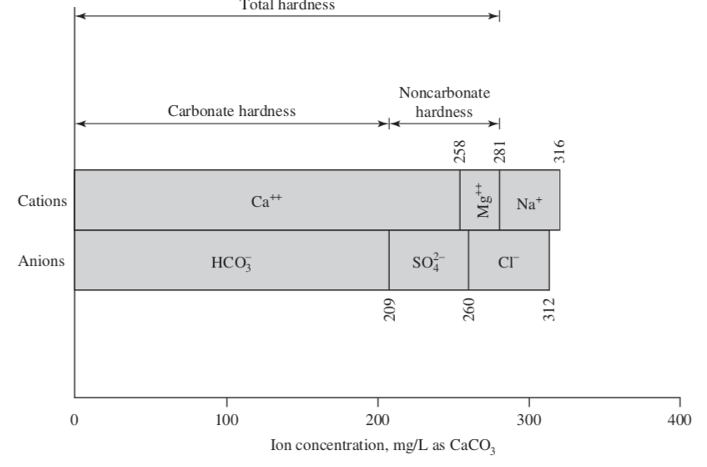

lime-soda ash softening

A water treatment process that removes hardness from water by adding lime (Ca(OH)2 and CaO) and soda ash (Na2CO3) to precipitate calcium and magnesium.

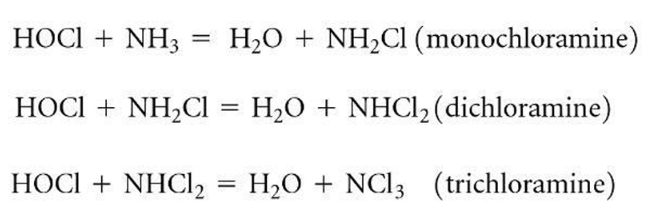

reactions for lime-soda ash softening

pH requirements for softening

removal of magnesium as Mg(OH)2 precipitate requires a pH value of at least 10.5. Therefore, extra lime (30–70 mg/L as CaCO3) in excess of the stoichiometric amount is added to raise the pH.

coagulation

water treatment process that involves adding chemical agents (coagulants) to destabilize suspended particles by enabling particles to come closer and stick together.

coagulant aid

substances that enhance the coagulation and flocculation process. insoluble particles like clay, diatomite, powdered activated carbon, fine sand.

flocculation

subsequent treatment step where gentle mixing encourages destabilized particles to aggregate into larger and heavier clusters (flocs), which can be more easily removed through settling or filtration.

particle stability

The tendency of suspended particles in a fluid (like water) to remain separated and resist aggregation or settling

repulsive electrical double layer (EDL) force

force between particles of the same charge. most particles in natural waters are negatively charged

van der Waals forces

attractive forces between particles

mechanism for C&F: Compression of the Electrical Double Layer (EDL)

Increasing ionic strength reduces repulsive forces by compressing the electrical double layer around negatively charged particles.

mechanism for C&F: Charge Neutralization

Negatively charged particles become destabilized and aggregate when their surface charges are neutralized by adsorbing positively charged ions or polymers.

mechanism for C&F: Adsorption and interparticle bridging

Nonionic polymers and long-chain low-surface-charge polymers form bridges between particles by adsorbing onto multiple particle surfaces, enhancing aggregation.

mechanism for C&F: Precipitation and Enmeshment

High doses of aluminum or iron salts form precipitates that physically trap particles, removing them through settling ("sweep floc")

types of coagulants

inorganic metallis coagulants

prehydrolyzed metal salts

organic polymers

natural plant-based materials

most commonly used coagulant

aluminum sulphate (Alum)

2 mechanism for particle aggregation

differential sedimentation and Brownian motion

granular (media) filtration

solid-liquid separation process for removal of colloidal and suspended particles

when is filtration used? what is the medium?

final particle removal process. sand or other media such as coal, activated carbon, or garnet.

slow sand filtration

A water treatment process using a bed of sand to remove suspended solids and pathogens through biological and physical processes.

requirements for slow sand filtration

low turbidity, regeneration (scraping of top sand layer)

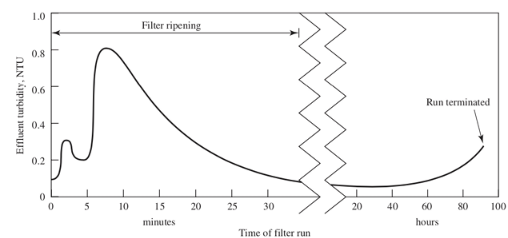

rapid filtration

high-rate filtration using filtration and backwashing stages

rapid filtration overview

sedimentation

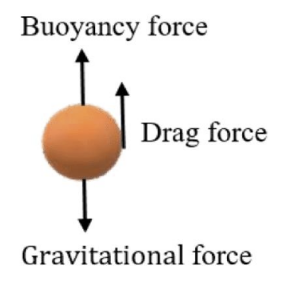

the process of settling out suspended particles from water through gravity (majority of particles removed this way). works for particles with a density greater than 1000 kg/m³ (density of water)

2 types of settling

discrete and flocculant

discrete particle settling

particles are discrete and do not interfere with one another

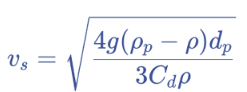

how to describe discrete settling velocity

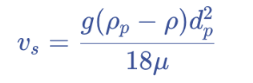

Stokes’ law or Newton’s law

Reynolds number

ratio of inertial forces to viscous forces (low = laminar flow, high = turbulent flow)

Stokes’ Law

applicable for spherical particles, Re < 1

drag coefficient for Stokes’

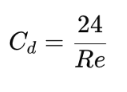

a dimensionless number to quantify resistance of a particle moving through a fluid

Newton’s Law

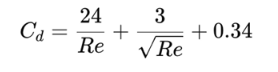

applicable for Re > 1 (transitional and turbulent flow)

drag coefficient for Newtons

primary disinfection

inactivation of microorganisms in water

secondary disinfection

residual maintenance. maintaining a disinfectant residual in treated-water distribution system

common disinfectants

free chlorine (primary and secondary)

monochloramine (secondary)

chlorine dioxide (primary and secondary)

ozone (primary)

UV light (primary)

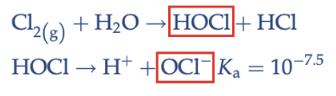

free chlorine

HOCl and OCL-

desired pH for free chlorine disinfection

pH = 7 because proportions of OCl decrease at lower pH and HOCl decreases at higher pH. HOCl is more effective so pH can be slightly lower than 7 if necessary

combined chlorines (chloramine)

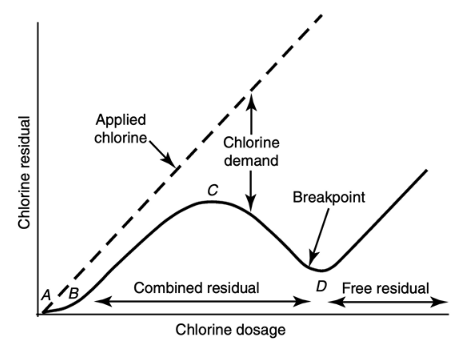

draw the chlorine dosage vs residual graph

chlorination breakpoint

when combined chloramines are mostly oxidized. beyond the breakpoint, all added residual is free available chlorine

disinfection kinetics

N: Concentration of viable organisms

N0: Initial concentration of organisms

t: Disinfectant contact time

k: Disinfection rate constant

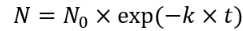

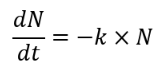

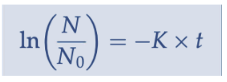

Chick’s law (derivative)

assumes the rate of disinfection reaction is pseudo first order with respect to the concentration of the pathogens being inactivated

Chick’s law (using a natural log)

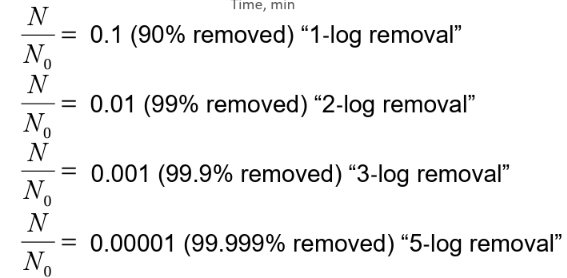

degrees of disinfection

disinfection dosage

(C x t product) inactivation of a microorganism is controlled by the concentration of the disinfectant and the time of contact

other disinfection factors

type of disinfectant

temperature

pH

viability of the microorganisms

turbidity

quantifying UV dose

I*t [mW/cm2 x s] (I is UV intensity)

chemical disinfectant most effective in inactivating microorganisms

C parvum