power eng midterm (enumeration)☘️

1/57

There's no tags or description

Looks like no tags are added yet.

Name | Mastery | Learn | Test | Matching | Spaced |

|---|

No study sessions yet.

58 Terms

Laws of Thermodynamics

Zeroth Law (Thermal Equilibrium)

First Law (Conservation of Energy)

Second Law (Entropy)

Fourth Law (Onsager Reciprocal Relations)

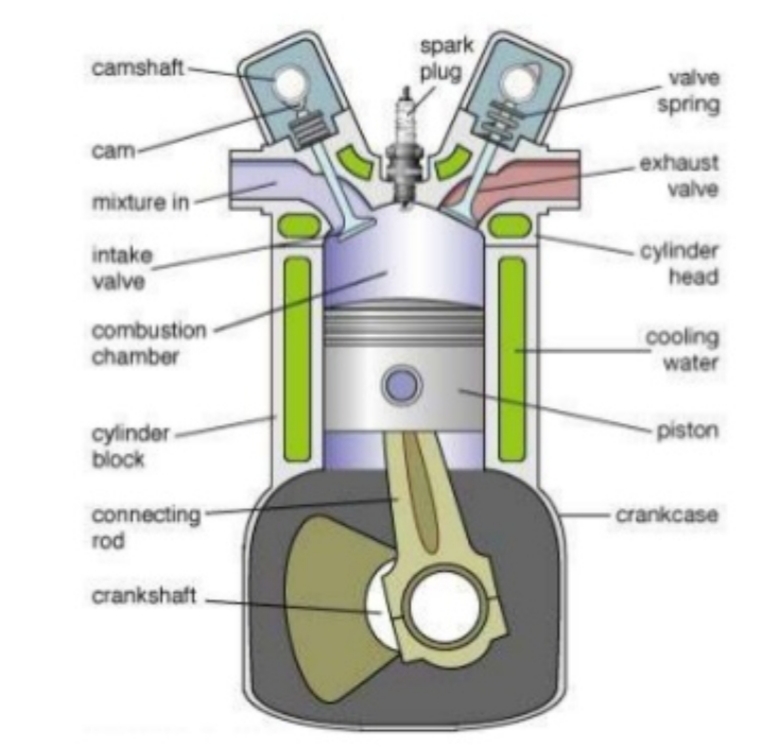

Sections/ Parts of an Internal Combustion Engine

Camshaft

Cam

Mixture in

Intake valve

Combustion chamber

Cylinder block

Connecting rod

Crankshaft

Spark plug

10. Valve Spring

11. Piston

13. Cooling water

14. Cylinder head

15. Crankcase

Working fluids can be:

Air

Hot water

Pressurized water or even liquid sodium

Heated in some kind of boiler by fossil fuel, wood - burning, nuclear, solar, etc.

Vehicles using Internal Combustion Engine

Automobiles

Trucks

Motorcycles

Boats

Wide variety of aircraft and locomotives

Steps Involved In A Two-Stroke Cycle

Intake and exhaust occur at bottom dead center

Compression Stroke : fuel-air mixture is compressed and ignited

Power stroke : piston is pushed down by the hot exhaust gases

Events In a Four-Stroke Cycle Engine

Air Intake

Compression

Combustion

Exhaust Emission

Steps Involved In a Four-Stroke Cycle Engine

Intake Stroke

Compression Stroke

Combustion Stroke

Exhaust Stroke

Five Stroke Cycle

Intake Stroke

Compression Stroke

Combustion Stroke

Exhaust Stroke

Refrigeration

Gas Turbine 3 Main Components

Turbine

Combustion Chamber

Compressor

Diesel Cycle Four Distinct Process

Process 1-2 = Isentropic Compression

Process 2-3 = Reversible Constant Pressure Heating

Process 3-4= Isentropic Expansion

Process 4-1 = Reversible Constant Volume Cooling

Engine Cycle

Two-stroke Cycle

Four-stroke Cycle

Five-stroke Cycle

Six-stroke Cycle

Diesel Cycle

Brayton Cycle

Internal Combustion Engine Cycle

Induction Stroke

Compression Stroke

Power Stroke

Exhaust Stroke

Each Stroke Begin and End Outside The:

0,180,360,540,720 (0) degree crank positions

Components Of An Internal Combustion Engine That Work Together To Ensure Its Proper Functioning

Valve opening and closing

Alternator

Fuel injector pump

Water pump, etc.

Auxiliary Systems and Mechanisms

Lubrication

Cooling

Fuel Supply

Filtration

Exhaust

Electrics, Etc.

Small Engine Use As A Stationary Power Source For:

Driving generators

Pumps

Threshers

Rice hull blowers, etc.

Types of Internal Combustion Engine

4-Stroke Cycle Water-Cooled Engine

4-Stroke Cycle Air-Cooled Engine

2- Stroke Cycle Water-Cooled Engine

2-Stroke Cycle Air-Cooled Engine

Water-Cooled Radiator Type

Hopper Type

Condenser Type

Water-Cooled Hopper Type

Heavy weight per power

Large tolerance to overloading

Large water requirement

Medium price

Medium troubles of maintenance

Water-Cooled Condenser Type

Medium weight per power

Small tolerance to overloading

Small water requirement

High price

Large troubles of maintenance

Air-Cooled Engine

Light weight per power

No water requirement

Low price

Little troubles of maintenance

4-stroke cycle engine

Heavy weight per power

Complicated complication of mechanism

Less fuel consumption per power

Expensive price

Troublesome maintenance and repair

Pure gasoline or pure light oil fuel

2-stroke cycle engine

Light weight per power

Simple complication of mechanisms

More fuel consumption per power

Cheap price

Simple maintenance and repair

Lubrication oil is mixed to fuel sometimes for fuel

Gasoline

Less durability

More trouble

More fuel consumption

Light weight per power

Cheap price

Easy starting

Normal lubrication oil

Fast revolution

Weak against moisture or water

Hazardous to fire

Regular accuracy of parts

Normal required cleanness of fuel

Troublesome maintenance

Diesel

More durability

Less trouble

Less fuel consumption

Heavy weight per power

Expensive price

Hard starting

High lubrication oil

Slow revolution

Strong against moisture or water

Nonhazardous to fire

High accuracy of parts

Strict required cleanness of fuel

Simple maintenance

Conclusions in advantages and disadvantages between a gasoline and diesel engine

•For continuous, long-hour operation, a diesel engine is preferable

•For carrying and frequent stop and start operation, a gasoline engine is better

•If exposed to moisture or rain, a diesel engine is better

•In using old engines, a gasoline engine can be easier to operate

Types of gasoline

Regular

Premium

Unleaded

Applications in selection of internal combustion engine

•For ambulance purposes, a gasoline engine is preferred since it is quick-starting

•If exposed to moisture/rain, a diesel engine is better

•For continuous stop and start operation, a gasoline engine is preferred

•For continuous or non-stop operation, a diesel engine is better

Typical Difference Between Gasoline and Diesel Engine

Spark Plug Vs Fuel Injector

Type of Fuel

Intake stroke

Compression Temperature

Fuel Line

Engine weight

Other names of dual combustion cycle

Limited pressure or mixed cycle

Trinkler Cycle

Seiliger Cycle or Sabathe Cycle

Other types of engines

Britalus Rotary Engine

Gas Turbine

Minto Wheel

Stirling Engine

Wankel Engine

Dual Cycle Operations

1-2: Adiabatic Compression

2-3: Constant Volume Heat Addition

3-4: Constant Pressure Heat Addition

4-5: Adiabatic Expansion

5-1: Constant Volume Heat Addition

Fuel used in a Gas Turbine

Gasoline

Kerosene

Oil

Major Components of a Gas Turbine

Turbine

Combustion Chamber

Compressor

Shaft

Types of Gas Turbine

Turbojet

Turboprop

Turbufan

Afterburning Turbojet

Advantages of gas turbines

Gas turbine engines have a great power-to-weight ration compared to reciprocating engines

Gas turbine engines are also smaller than their reciprocating counterparts of the same power

The gas turbine plant is simple in design and construction

The gas turbine is quite useful in the regions where due to scarcity it is not possible to supply water in abundance for raising steam

Disadvantages of gas turbine

They are expensive

Tend to use more fuel

General Cycle of Stirling Engine

Compressing cool gas

Heating the gas

Expanding the hot gas

Cooling the gas before repeating the cycle

Vehicles and devices in which the wankel rotary engine has been installed

Automobiles (including racing cars)

Aircraft

Go-karts

Personal water craft

Chain saws

Auxiliary Power units

Methods in Transmitting Power

Direct drive

Pulley and belt

Sprocket wheel and chain

Gears

Shaft and universal joint

Flexible shaft

Hydraulic System

Types of belt

Flat belt

V-shaped belt

Types of Belt Drive Connections

Open-belt drive

Cross- belt drive

Parts of an open-belt drive and cross-belt drive

Driver shaft

Driven shaft

Tight side

Slack side

Advantages of flat belts

Flexible, easy in construction, smooth operation

Efficient at hight speeds and protect against overload

Running and maintenance cost is low

Relatively long life and easy to work with

Disadvantages of Flat Belts

Not a positive drive

Not preferred in short - center distances

Loss of power due to slip

Advantages of V-belt drives

Compact

A positive drive

Smooth drive

Longer life, three to five years

Easy installation and removal

Quiet operation between belt and pulley

High-velocity ratio (maximum 10)

Two types of chain commonly used in power transmission on farm equipment

Hook-link chain

Roller chain

Four types of chain common in farm machines

Standard-pitch roller chain

Double-pitch roller chain

Malleable-cast iron, Detachable-link chain

Pressed-steel, Detachable-link chain

Types of Gears

Spur

Spur bevel

Spur bevel gear set

Spline shaft

Spiral bevel set used in tractors

Herringbone

Helical

Hypoid gear set

Worm and wom-wheel

Internal spur

Cluster

Types of Gears

Spur gear

Beveled gear

Helical gear

Worm gear

Pinion

Types of Spur gear

Internal Spur gear

External Spur gear

Helical gear may either be:

Spur & beveled gear

Pinion gear may either be:

Spur, bevel and helical gear

Parts id Power-Take Off Drive

Tractor power take-off drive

Universal joints

Shaft support

Sliding fit

Slip clutch

Flexible shaft assembly consist of:

Cable (spring, wire rope or cable)

Flexible Casing (sheath)

Shaft end fittings

Casing end fittings

Each Stroke in The Diesel Cycle Complete At

Top Dead Centre (TDC)

Bottom Dead Centre (BDC)